Stevens Aero Model HeliumMG2 User manual

© 2008 Stevens AeroModel. Page 1 of 52

HeliumMG2

motorized glider / FPV platform

AA

BB

A

B

HS-65HB

DD

R10

R9

R11

R6

LE3

LE3

CC

C

C

CC

C

C

(He)MG2

Instruction Manual - Version 1.00b (02022010)

Span 77.75 in. / Length 44.5 in. / Area 645 Sq. In. / Weight 25 oz.

Made in the USA!

Of U.S. and Imported Parts

© 2008 Stevens AeroModel. Page 2 of 52

***Cautions***

1. Power system.

Overpowering this model with a heavier / more powerful system is not recommended.

Stevens AeroModel recommends a power system no greater than 300W, a maximum

pitch speed of 50 mph, and a maximum all up weight (AUW) of 36 oz.

Outrunner motors like the Hacker A30 transmit a great deal of stress to the motor

mount. DO NOT run your motor up until you have verified that your blade is accurately

balanced and in perfect track. Finally, disable your ESC’s prop braking function.

2. Throttle management.

Similar to full-scale and giant scale models this high performance model requires

careful throttle management. When tracking through a down-line it is mandatory to

govern the use of throttle, slowing the models descent, to avoid over speeding the

airframe.

WARRANTY

Stevens AeroModel guarantees this kit to be free from defects in both material and workmanship

at the date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Stevens AeroModel’s liability exceed the original cost of the

purchased kit. Further, Stevens AeroModel reserves the right to change or modify this warranty

without notice.

LIABILITY RELEASE

In that Stevens AeroModel has no control over the final assembly or material used for final

assembly, no liability shall be assumed nor accepted for any damage resulting from the use by

the user of the final user-assembled product. By the act of using the user–assembled product,

the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer

is advised to return this kit immediately in new and unused condition to the place of purchase.

THIS PRODUCT IS NOT INTENDED FOR CHILDREN 12 YEARS OF AGE OR YOUNGER

WARNING: This product may contain chemicals known to the State of California to cause cancer

and or birth defects or other reproductive harm.

© 2008 Stevens AeroModel. Page 3 of 52

REQUIRED TO COMPLETE KIT:

Kit Contents:

Laser Cut Wood (21 Sheets – See inventory on following pages)

Computer Drawn Plan Set

Illustrated Instruction Manual

Flat Stock and Push-Rods:

o4 - 1/4 in. x 24 in. Square Balsa Leading Edge

o1 - Pre-Bent Landing Gear (0.125 in.)

o2 - 48 in. length Flat Carbon Fiber Stock

o1 - DuBro Micro2 30in Pushrod System (DUB922)

o1 - Pair 2-1/4 in. foam wheels

Large Hardware Bag: (4x6 Bag):

o1 - Pair Delrin wing tip joiners

o1 - Package Rubber Bands #33

o1 - 4 in. length 1/16 in. aluminum tubing

o1 - 4 in. length 1/32 in. music wire

o3 - 3/16 in. x 3.75 in. Hardwood Dowels

Small Hardware (2x3 Bag):

o1 - 1 in. length 3/32 in. ID silicone fuel tubing

o2 - DuBro Micro2 Control Horns (1 pkg. / DUB919)

o2 - DuBro Mini EZ Connectors (1 pkg. / DUB845)

o2 - 1/8 in. star washers (wheel retainers)

o2 - 4-40 x 3/8 in. Nylon Machine Screw

o2 - 4-40 x 1-1/2 in. Nylon Machine Screw

o4 - 15/32 in. x 1/8 in. OD Aluminum Tubing (anti rotation pins)

o4 - 4-40 x 3/8 in. Machine Screw (motor mounting)

o4 - #2 x 1/4 in. Screw (A20-20L motor mounting)

o4 - assorted small black rubber bands

o8 - 4-40 Blind Nut

o10 - 3/16 in. Neo. Magnet

Recommended Finishing Items:

1. 2 Rolls of AeroFILM or AeroFILM Lite (Solarfilm, Solarfilm Solite, or Nelson Lite Film may be substituted).

Suggested Electronics:

1. 2 – High performance micro servos (Hitec HS-55 or HS-65)

2. 1 – Hitec HS-56 sub micro servo (for spoiler installation)

3. 1 – 6 in. servo extension (for spoiler installation)

4. 1 – Full range micro receiver (Castle Creations/Berg Micro Stamp 4 or 4L)

Power Systems:

1. Hacker A30-28S, E-Flite Park 480 1020kv, SA Sport 480 A2810-11

2. 9x5-10x5 APC-E Propeller. If you desire to utilize a folding propeller you will be required to reverse the motor

shaft of the Hacker and VSport motor - Out of the box the E-Flite motor is better prepared to accept a collet

style yoke and folding propeller assembly. We suggest using high quality Aeronaut Blades and an aluminum

yolk assembly. See www.stevensaero.com for suggested items for this model.

3. 11.1v 2100mAh LiPo (Rated for 15C discharge).

4. Castle Creations Thunderbird 36 or Phoenix 25 ESC – (Enable propeller braking)

Building Supplies Required:

1. Thin CA (super glue) and glue tips

2. Medium CA (super glue) and glue tips

3. Thread Locking Compound (Blue)

4. Hobby knife and blade(s) #11 and straight edge

5. Fine grit sand paper 250/400/600 and sanding block

6. Clear tape ¾” wide scotch or DuBro hinge tape.

7. Balsa wood filler

8. .047 in., 1/16 in., 1/8 in., and 3/16 in. drill bits.

© 2008 Stevens AeroModel. Page 4 of 52

Laser Cut Parts Inventory

Wing Parts

Balsa 1/16" A-HM

Balsa 1/16" AB-MH

Balsa 3/32" AB-MH

Balsa 1/16" ABC-MH

Balsa 1/16" AB-MH

Balsa 3/32" AB-MH

W6b

W6a

S2

S11

R7a

R8a

R9a

R10

R7

R8

R9

R6

W6

<- T5

<- T6

W6

R6

<- T6

<- T5

S11

S2

R6b

R10a

R7a R8a R9a

R6b

R10a

SW1

SW2

SW3

SW4

SW5

SW2

SW3

SW4

SW5

S9

S9

R1a

R1b

R3aR2a

R4b

R4a

R3b

R1a

R1b

R3a R2a

R4b

R4a

R3b

S1a

S1b

R2

R4

R3

R5

R2

R4

R3

R5

R2b

R2b

T4 ->

<- T4

S4

S6

S4

S6

F16

HEMG2 01/21

Fuselage Part

HEMG2 02/21

HEMG2 03/21

HEMG2 04/21

HEMG2 05/21

HEMG2 06/21

R10

R7

R8

R9

© 2008 Stevens AeroModel. Page 5 of 52

Wing Parts

Balsa 1/8" ABC-HM

Balsa 3/32" AB-MH

Balsa 3/32" AB-HM

Balsa 1/8" AB-MH

Balsa 1/8" ABC-HM

LE2

LE2

LE1

TE2

<- W5

R11

W7

W8

TE2

<- W5

R11

W7

W8

W8 W8

S5b

S3b

W4b

SP1

SP2

T2a

TE1a

TE1b

LE1

W4a

W3

W2

W6

W3

W3

W3

W6

W2

W2

W2

S5a

S3a

T3b

T2b

T3a

T1b

T1a

R1

DOWEL JIG01

W1b

R1

HEMG2 07/21

HEMG2 08/21

HEMG2 09/21

HEMG2 10/21

HEMG2 11/21

UNDERSIDE TRAILING EDGE BEVEL 45 DEG.

© 2008 Stevens AeroModel. Page 6 of 52

Fuselage Parts

Balsa 1/16" ABC-MH

Balsa 3/32" AB-MH

Balsa 3/32" AB-MH

Balsa 1/8" ABC-HM

Balsa 3/32" AB-MH

Balsa 3/32" AB-MH

F13

F13

C C

F15a

A

B

A

B

H1a

H1c

H2

F17

F15b

A

B

A

B

H1b

F10

F10

A

BFSb

F12a

F12c

A

BFSb

F12b

F14

C

C

C

C

C

C

C

C

F11b

F11a

H3

H3

HEMG2 12/21

HEMG2 13/21

HEMG2 14/21

HEMG2 15/21

HEMG2 16/21

HEMG2 17/21

© 2008 Stevens AeroModel. Page 7 of 52

Fuselage Parts

Ply 1/32"

Balsa 1/8" AB-HM

Ply 1/16"

LPly 1/8"

H4

F5 TOP F6 FORWARD/TOP F7 FORWARD/TOP F8 FORWARD/TOP F9 TOP

R6a

R5a

R5a

R6a

F1 TOP

F0 TOP

F3 TOP

F4 TOP

F2 TOP

D

D

D

G1

G1

G2

F19b

W1a

F19a

F19c

H1d

H3

F18

F18

LE3

S10

S10

S8

LE3

S8

SP3

SP3

W6c

SP4

HEMG2 18/21

HEMG2 19/21

HEMG2 20/21

HEMG2 21/21

© 2008 Stevens AeroModel. Page 8 of 52

General Assembly Instructions

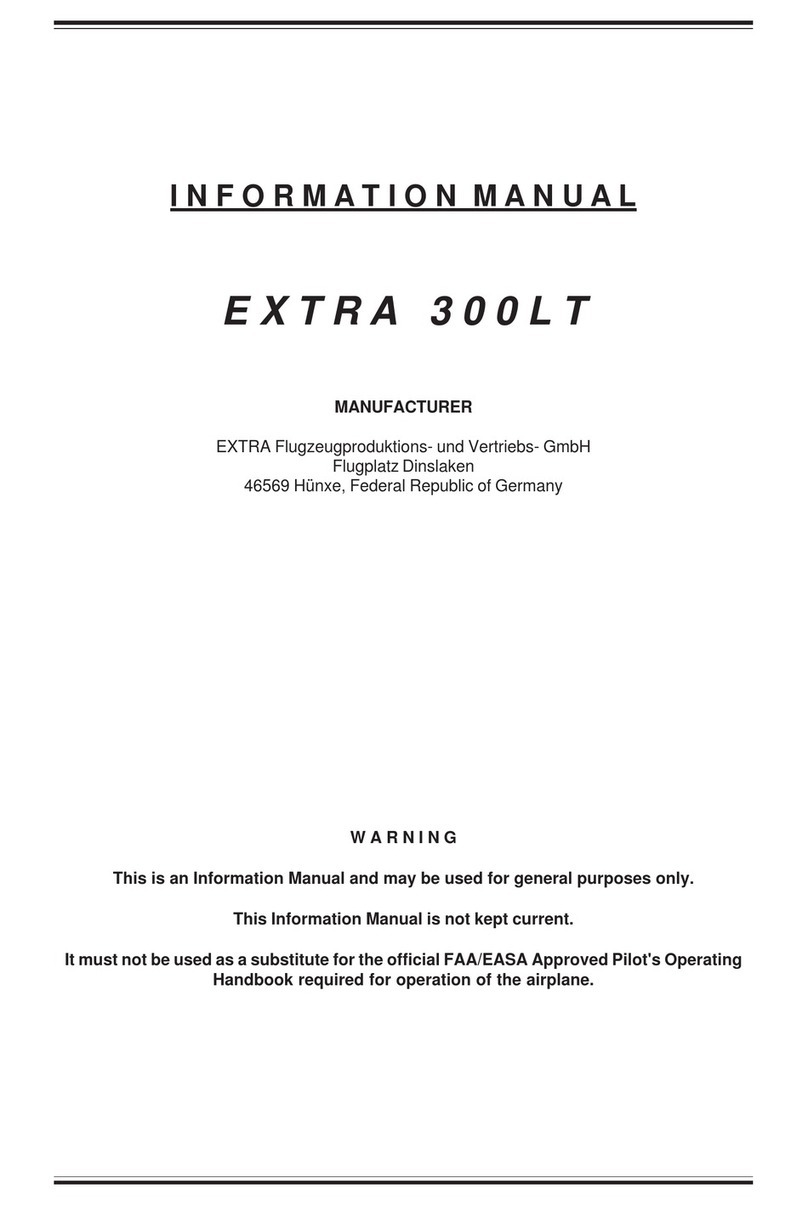

AA

BB

A

B

HS-65HB

DD

R10

R9

R11

R6

Thank you, for purchasing this Stevens Aeromodel HeliumMG2 – “2-Meter Motorized Glider / FPV Platform”. This kit

provides the builder and pilot a refreshing change of pace from heavy “ARF” style plywood box airframe construction, and

blends stick and tissue design methods of the past with state of the art CAD technology and precision interlocking laser

cut parts. The result is something you will find truly exceptional to build and fly. Please keep in mind that this kit is

intended for a novice-intermediate builder and novice-intermediate pilot as a 3 channel motor glider/trainer. If you do not

meet these criteria it is recommended to seek help from a more experienced builder / pilot.

Best Regards,

Bill Stevens

Stevens AeroModel “Laser Engineered”

P.O. Box 15347

Colorado Springs, CO 80935

Assembly Tips

READ THE INSTRUCTIONS and the plan sheet prior to starting any work!

Tape plans to work table. Protect plans from glue spills using the poly tubing your kit was bagged in.

Join all parts with Thin CA unless otherwise specified.

DO NOT REMOVE THE PARTS FROM THE BALSA SHEETS UNTIL REQUIRED!

DO NOT FORCE THE FIT. When in doubt, double check your parts. Removal of material should not be

required. If you feel that you have a poor connection, check first to see that the part is not upside down.

Reference each piece against the plan sheet.

Making solid glue joints: Hold parts together on top of plan sheet using moderate pressure to fit parts. Wick

Thin CA into joint. There is no need to pin parts to work table as all pieces interlock and self - jig.

© 2008 Stevens AeroModel. Page 9 of 52

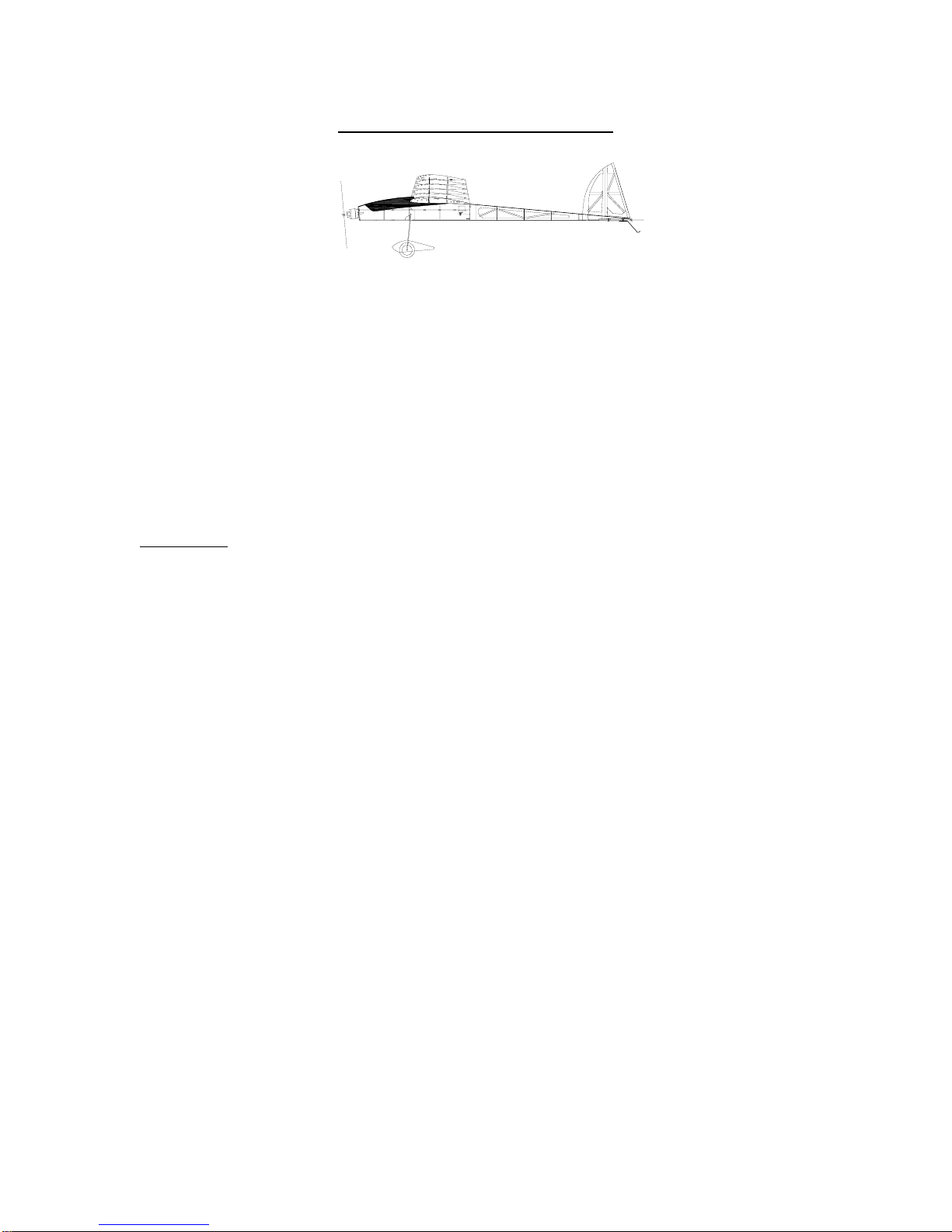

Tail Feathers

General Construction Notes: This kit features our proprietary Trus-Loc™ system as such typical “stick” type construction

has been replaced by precisely cut “stick” components that are keyed to fit in only one direction. The “knuckles” of the

truss are identified with an alpha-numeric use this to match adjoining truss components “A” to “A” and “B” to “B” etc. If a

part does not fit properly chances are very good that you have the wrong part or the part is in backwards. Under no

circumstances should you need to fill significant gaps or re shape the parts.

1. All of the parts to create the tail feathers are located on the 1/8 in. hard balsa sheets 17 and 18/21. Remove

parts from the sheet with a sharp #11 hobby blade. Assemble the parts on top of your plan set using the

drawings on the plan to reference part location and orientation. Frame up all tail feather components as

illustrated below.

CC

C

C

DD

CC

C

C

2. With the balsa tail feather framework complete refer to the plan sheet and install provided carbon fiber flat stock

where indicated using medium CA glue.

3. Round the leading edge of the stabilizers leaving then sand a 45 degree bevel to the leading edge of all control

surfaces (That’s Rudder and Elevator only) in preparation for tape hinges.

© 2008 Stevens AeroModel. Page 10 of 52

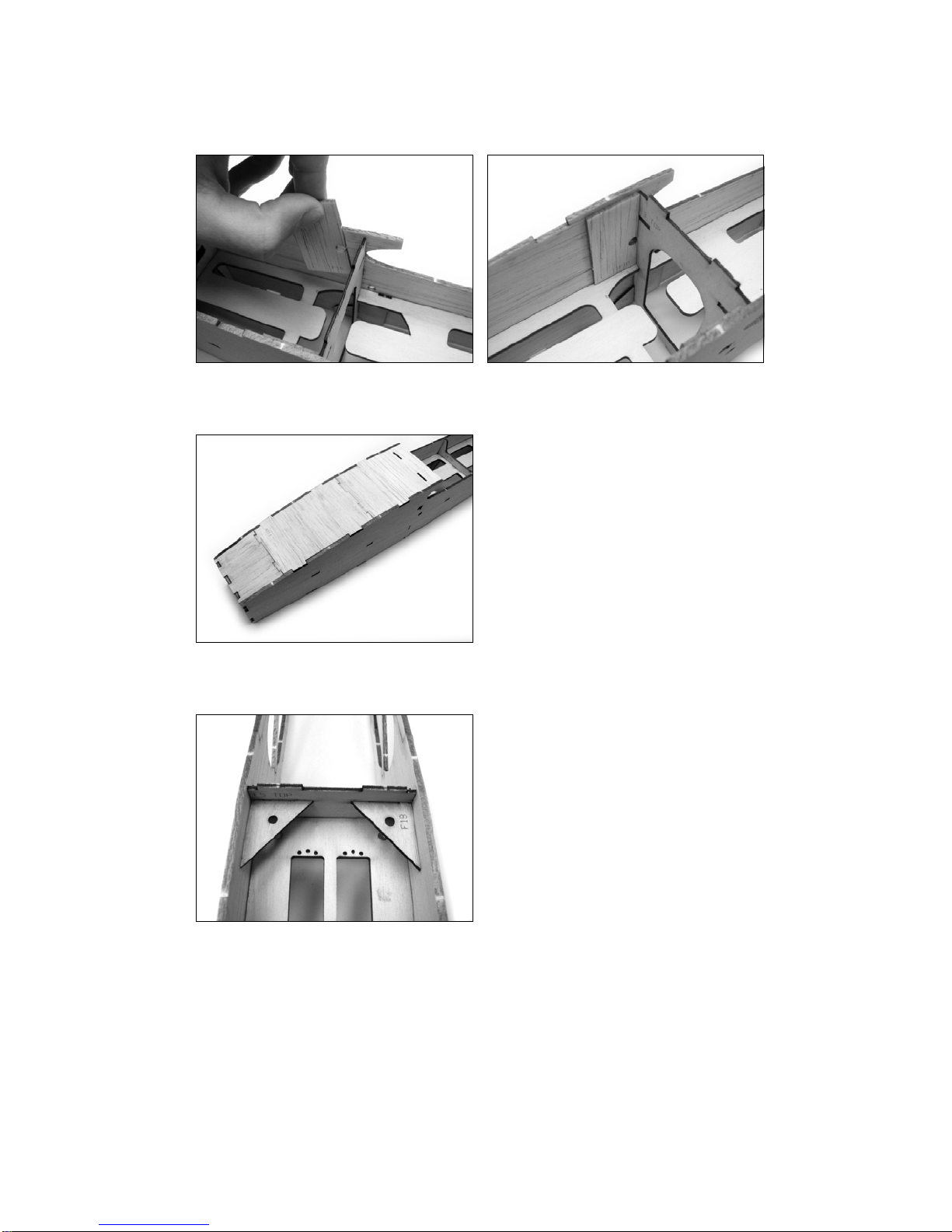

Fuselage

General Construction Notes: This fuselage utilizes an improved tab and notch construction method developed by Stevens

AeroModel. Each component precisely interlocks using unique tab and notch sizes to allow the parts to only fit in one

direction. Where parts orientation can be reversed or inverted parts are scribed with a reference such as “top” or “front”

for proper orientation. Throughout construction we suggest dry-fitting all components, and using minimal amounts of glue

at tab and notch locations only to hold parts together. By dry fitting the fuselage, each successive component will assist

with pulling the assembly square and straight.

1. Begin construction of the fuselage by completing the following sub assemblies: Build 3/32 in. balsa former F12

from parts F12a, F12b, and F12c (sheets 14 and 16/21). Build 1/16 in. balsa former F15 from parts F15a and

F15b (sheet 12/21). Build two each 3/32 in. balsa fuselage sides FS from parts FSa, FSb, and corresponding

truss parts (sheets 14, 15, and 16/21) when constructing fuselage sides use a straight edge to align part along

bottom edge, see illustration below the following diagram. Build 3/32 in. balsa former F11 from parts F11a and

F11b (sheet 13/21). Finally, build 3/32 in. balsa hatch component H1 from parts H1a, H1b, and H1c (sheet

13/21).

AA

BB

A

B

FSa

FSb

H1b

H1a

H1c

F12a

F12c

F12b

F15a

F15b

F11a

F11b

F12 F15

F11 H1

FS

2. Reference plan set for location of provided 4-40 blind nuts based on selected motor type then install to back

side of 1/8 in. lite plywood former F1 (sheet 21/21). The second photo in this series shows the F1 firewall with

blind nuts installed as viewed from the front. Secure blind nuts with gap filling medium CA glue. Set F1 aside.

© 2008 Stevens AeroModel. Page 11 of 52

3. The 1/8 in. lite plywood central crutch F0 (sheet 21/21) is clearly marked “TOP” locate this part and invert so

that you are looking at the underside of the part. Install two 4-40 blind nuts to holes just aft of servo pockets as

illustrated below. Secure blind nuts with medium CA glue. Do not allow glue to come into contact with internal

threads of blind nuts. The second photo below shows the F0 central crutch with blind nuts installed as viewed

from the topside.

4. Install the 1/16 in. ply former F3 (sheet 20/21) by inserting it through the lightening hole central to the F0 central

crutch then aligning the notches in F3 with the crutch sides and gently twisting it into location. See illustration

below. Make certain that the etching on F3 faces forward and to the top-side of the crutch assembly.

5. The 1/8 in. lite plywood parts F2 and F4 (sheet 21/21) are installed to the central crutch as illustrated below.

Make certain that the etching on these parts faces forward and to the top side of the central crutch.

© 2008 Stevens AeroModel. Page 12 of 52

6. Locate the 1/16 in. ply former F5 (sheet 20/21) and dry fit to the central crutch as illustrated below. Again, pay

attention to proper top side and forward orientation.

7. 1/16 in. ply part G1 (sheet 20/21) key to center crutch assembly as illustrated below. Tack glue G1 to the F3

former to assist with retaining this part.

8. Key the completed central crutch assembly to one of the FS 3/32 in. fuselage sides and bond with thin CA glue

at tab and notch locations. Next install the F1 firewall to the fuselage assembly observing proper top and front

orientation and bond to assembly using thin CA glue. Complete step by joining the second FS fuselage side to

the opposite side of the central crutch. With full access to central crutch, fuselage sides, and F1 firewall now is

the best time to build up a solid glue fillet (use medium gap filling CA) where F1 meets the crutch and fuselage

sides.

© 2008 Stevens AeroModel. Page 13 of 52

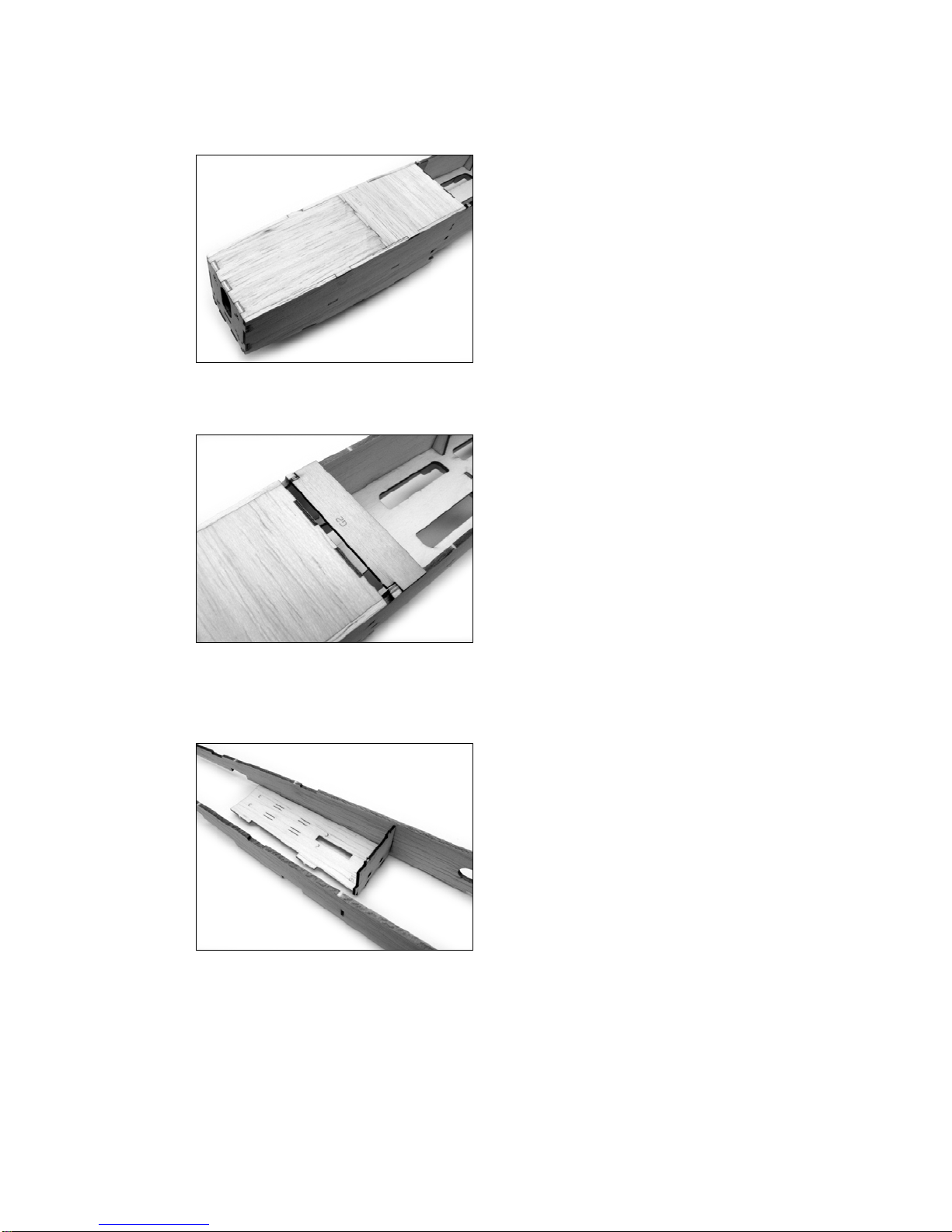

9. Install the 1/16 in. balsa forward cross-grain fuselage doubler F10 (sheet 12/21) as illustrated below. Match the

3/16 in. hole in F10 with that of the fuselage sides. Bond using medium CA glue.

10. Install 3/32 in. balsa part F12 (previously assembled in step 1) to top (curved) surface of fuselage assembly as

illustrated below. Retain by tack gluing with thin CA at tab and notch locations.

11. Install the 1/16 in. plywood F18 wing dowel guides/fuselage side braces (sheet 20/21) using the tab and notch

holes in F5 to align the parts. Retain with thin CA glue.

© 2008 Stevens AeroModel. Page 14 of 52

12. Install the 3/32 in. balsa former F11 (previously assembled in step 1)

13. Bond the 1/16 in. ply part G2 (sheet 20/21) into position directly aft of F15 as illustrated. Build up a solid glue

fillet between G2 and surrounding structure on inside of fuselage.

14. Locate the following parts: 1/16 in ply former F9 (20/21) and 1/16 in. balsa part F16 (sheet 2/21). Key F16 to

the back side of F9 using the notches in F9 to register the part. Now key the assembly to one of the fuselage

sides as illustrated below. Retain parts with thin CA glue. Do not glue the second fuselage side to the

assembly at this time.

© 2008 Stevens AeroModel. Page 15 of 52

15. Install two 4-40 blind nuts to one side of 1/8 in. balsa part F17 (sheet 17/22) then install F17 spanning aft end of

fuselage and former F16 as illustrated in the second photo below.

Finally pull the second fuselage side together with these assembled parts and tack bond with thin CA glue.

16. Install the 1/16 in. balsa part F14 (sheet 12/21) to the underside of the fuselage assembly. F14 extends from

F5 to laminate on top of F16. Tack glue this former to the fuselage at the tab and notch locations.

© 2008 Stevens AeroModel. Page 16 of 52

17. With the fuselage supported on your flat work table locate the 1/16 in ply parts F6, F7, and F8 (sheet 20/21).

These parts also have a top and forward designation etched on them. Pay careful attention to the part

orientation as you install and tack glue these to the fuselage assembly in their corresponding positions.

18. Install the 1/16 in. balsa aft cross grain doubler F13 (sheet 12/21) register part against the inside aft surface of

former F5 and F14 aligning the 3/16 in. hole in the doubler with the matching hole in the fuselage sides as

illustrated below. Bond part using medium CA glue.

19. Complete aft end of fuselage by installing 1/16 in. balsa part F15 (assembled in step 1) aligning tabs in former

with notches in fuselage. F15 spans former F5 to the tail of the fuselage assembly. Tack glue to retain part.

© 2008 Stevens AeroModel. Page 17 of 52

20. Final Glue Fuselage. Revisit all tack glued parts, hold the fuselage flat and square on your building board and

wick thin or medium CA glue along all part joints.

21. Complete the battery hatch catch assembly. Dry fit the 1/8 in. lite ply H3 (sheet 21/21) part as illustrated in the

first photo below. Now key the 1/16 in. balsa part H4 (sheet 20/21) to the fuselage on top of H3 and interlocking

with former F5 as illustrated in the second photo. Square both parts, as one unit, to the former and retain with

thin CA glue.

22. Locate the 3/32 in. balsa part H1 (assembled in step 1) on top of 3/32 in. balsa part H2 (sheet 13/21) matching.

Drive the tabs of the 3/32 in balsa part H3 (sheet 13/21) through stacked H1/H2 parts at notch locations. H3

properly locates H1 and H2. Bond hatch components together using medium CA glue.

Set the hatch assembly on top of your work table so that you are looking at the outside surface of the parts.

Bond the 1/32 in. ply part H1d to the exposed catch tab of the assembly as illustrated below.

© 2008 Stevens AeroModel. Page 18 of 52

23. Fill 3/16 in. diameter hole in battery hatch with a drop of medium CA glue then install one 3/16 in. diameter Neo.

Magnet to hole as illustrated below. Seat magnet only so that it is flush with the outside surface of the battery

hatch.

24. As magnets are polarized, attracting from one side and repelling when reversed, it is essential to identify the

proper polarity and install corresponding catch magnet without reversing it. Take a second Neo. Magnet and

allow it to “snap” itself to the previously installed catch magnet in the battery hatch. The magnet will

automatically flip to its attractive pole. Use a permanent marker to mark the outside surface of this magnet.

Remove the free magnet from the battery hatch and install within the fuselage catch assembly as illustrated with

the non-marked side exposed as illustrated below. Test the fit and function of your hatch. If satisfied that

you’ve correctly installed the second magnet to “attract” commit the part with CA glue.

25. Final Sand Fuselage. Using a sanding block or bar and fine grit sand paper lightly sand the fuselage and shape

as desired in preparation for covering with AeroFILM or AeroFILM Lite.

© 2008 Stevens AeroModel. Page 19 of 52

Landing Skid

1. From the DuBro RC pushrod kit (DUB922) cut a 4-1/2 in. length of the 0.045 in. diameter wire. Use the plan

set as a guide and bend this wire to the shape illustrated.

2. Locate the 1/16 in. ply part F19b (sheet 20/21) on top of 1/32 in. ply part F19a (sheet 19/21) matching the

corresponding edges and laser drilled holes in each part. Bond together using medium CA glue. Once glue

has cured test fit your bent tail skid wire to assembly and adjust fit if required. Bond tail skid wire within parts as

illustrated below using medium CA glue.

3. Bond the F19c 1/32 in. ply part (sheet 19/21) on top of F19b to capture wire tail skid. Allow glue to cure then

use the plan set once again as a reference an bend wire to final shape required by tail skid assembly. See

illustration below.

© 2008 Stevens AeroModel. Page 20 of 52

Pushrod Housing Installation

1. From the DuBro RC pushrod kit (DUB922) thread the plastic push rod housing through the fuselage assembly

as illustrated below. The pushrod housing passes through pre-cut holes in ply formers and exits fuselage

through one of the partially cut exits. Complete one side at a time using the plan set as a reference start

threading the housing from former F5 aft through fuselage. Housings will not cross so stick to the pre-drilled

holes in the formers on the same side as your start hole.

2. Once your housing has reached one of the pre-defined exit points through the balsa top or bottom of the

fuselage assembly remove the exit plug by completing the cuts in the top or bottom former to create an exit slot

as illustrated below.

3. With the exit point plug removed complete the pushrod installation by allowing the pushrod to extend

approximately 1/8 in. beyond the end of the exit point. Bond push rod housing at each capture point using CA

glue then trim excess housing to extend only 3/16 in. forward of former F5 as illustrated below.

Table of contents