StewMac UKULELE KIT User manual

Sheet #i-5371 Updated 11/18

Assembly

Instructions

StewMac

UKULELE KIT

PREMIUM SOLID-WOOD

stewmac.com

2

Tools and supplies..................................... 2

Parts list .............................................. 3

Installing the rosette .................................. 4

Brace the top and back ................................ 5

Make the body mold .................................. 7

Assemble the body ................................... 8

Prepare the neck ......................................15

Level the frets .........................................21

These are the tools and supplies we recommend for assem-

bling this kit. StewMac item numbers are included where

applicable.

Tool you will need (required)

Clamps (few are needed, but more are handy)

4-6 Small cam clamps (#3721)

2 Small sound hole clamps (#2010)

20 Mini clamps (2 packs of #3712)

Flat mill le or pillar le (#4175)

Razor knife (#4878)

Small chisel (#1619)

Fine-cut saw (#3617)

Side cutter or fret cutter (#0619)

Hammer for fret installation (#4895)

Micro-Mesh Soft Touch Pads (#3730)

Electric hand drill

1/4" and 1/16" drill bits (#4850, #1710)

Scissors

Straightedge to reach from string nut to bridge (#3850)

Good quality rule accurate to 1/64" (#4905)

18" Rule

Optional tools

Go-bar Deck (#4731)

Laminate Trimmer (#0488)

Flush Trim Bearing + Router Bit (#1298-B, #1298-000)

Fret Beveling File (#3760)

Tools and supplies

Table of contents

Sand the body and neck ..............................22

Locate the bridge .....................................23

Apply the stain (optional) .............................25

Attach the neck .......................................26

Apply the nish .......................................27

Glue the bridge .......................................28

Install the tuners ......................................28

Fit the nut and saddle .................................29

Supplies

Titebond Original Wood Glue (#0620)

or StewMac Fish Glue (#0702)

StewMac #20 Medium Super Glue (#0020)

Masking tape or low-tack protective tape (#1683)

Double-stick tape (#1689)

Scraps of wood for various clamping cauls and supports

Waxed paper

For body mold:

3/4" plywood, 19"x12"

Four 2-1/2" steel corner braces with mounting screws

Eight large screw eyes or screw hooks

Sandpaper (#5562 or #5096)

60-grit, 80-grit, 120-grit, 220-grit, 320-grit, 400-grit

Sanding blocks (scrap wood or #3701, #3699)

ColorTone Wipe-On Poly Finish (#3622)

ColorTone Liquid Stain (optional)

Steel wool, 0000-gauge

Fretboard oil or lemon oil (#3863 or #3864)

Paste wax, such as car wax

Cotton balls

Scraps of t-shirt material

stewmac.com 3

Welcome to instrument making!

Whether you’re a rst time builder or an experienced

luthier, this kit is a great way to have fun and learn a lot.

This solid-wood ukulele kit will produce a professional

quality instrument you will be proud of for decades

to come. The design and construction is similar to an

acoustic guitar, but faster and easier to build.

Parts list

This kit can be assembled with basic tools, but we've

also shown how to use more specialized lutherie tools

in the construction of this ukulele.

When you’re done, you’ll have an excellent sounding

ukulele, and you'll have the necessary skills to start

building guitars!

Kit contents

Top

Back

Sides

Fully shaped neck

Slotted ebony fretboard

Tuners with mounting hardware

Carved, drilled bridge

Shaped saddle

Rosette puring

Fretwire

Two back braces

Six top braces

Shaped bridge plate

Lining

Neck block

Tail block

Rubber binding bands

Full-size bracing plan

stewmac.com

4

Before we dive into bracing the top of your ukulele we need

to install the rosette. Your top has come with a pre-routed

channel that the rosette will t perfectly into.

To get started locate the cream and black puring pieces.

Neatly arrange them in the following conguration: cream /

black / cream / black / cream. As you can see it’s challenging

to align them all neatly, they have a tendency to slide around.

To help hold them It is helpful to use a tight piece of masking

tape on the end to help keep everything in place.

Once you have them arranged place them in the rosette

channel.

Using a razor blade or your fret cutters trim the ends of the

rosette. It’s not absolutely necessary that the puring pieces

make a perfect join. The upper ring of the rosette will be

hidden under the ngerboard extension.

Next remove half the rosette.

Flood the channel with glue (Titebond Original Wood Glue

works very well for this application).

Now take your nger and guide the purings back into the

glue lled channel. The glue acts as a lubricant and every-

thing should slide back in place very easily. (Don’t worry

about the mess, we will clean that up in a second.)

Now remove the purings from the unglued side and repeat

the process. Be sure you remove enough of the puring so

the entire rosette is glued into the channel.

Now we will clean up all the excess glue from the top of the

instrument and any that may have got through the sound-

hole on the inside of the top. (It’s a good idea to wipe up any

glue that may have got on your workbench as well.)

Now place a sheet of wax paper on your workbench under

the top, and one over top the wet glue on your rosette and

weight it down with something heavy to dry – a spare 10lb

plate does the job nicely, but a heavy book would work

equally well.

Let this dry for 2 hours.

After 2 hours, remove the weight and use a sanding block

with 120-grit adhesive sandpaper to sand the rosette ush

with the top. Be sure to sand in a wide area so you don’t

accidentally make the top thinner in this area.

Installing the rosette

stewmac.com 5

Apply the glue

For this application we recommend using Titebond Original

Wood Glue or StewMac Fish Glue.

Apply a thin bead of glue to the brace and use your pinky

nger to spread an even, thin, lm of glue across the entire

brace. Quickly wipe your hands with a dry cloth and seat the

brace in the proper location.

Start by placing a clamp (or Go-bar) in the center of the

brace. Parts tend to skate around during clamp up, so it is

always a good idea to ensure your brace hasn’t moved from

its intended location. If you are using clamps, lightly snug it

up once your brace is in place.

Now place a Go-bar or clamp at each end of the brace. (Again,

frequently check to ensure your brace hasn’t moved during

clamp up.)

If you’re using clamps, 3 will usually suce for a ukulele, but

if you like feel free to add a couple more for added assurance.

Snug them all up. It doesn’t take a lot of clamping pressure

so there is no need to over tighten your clamps.

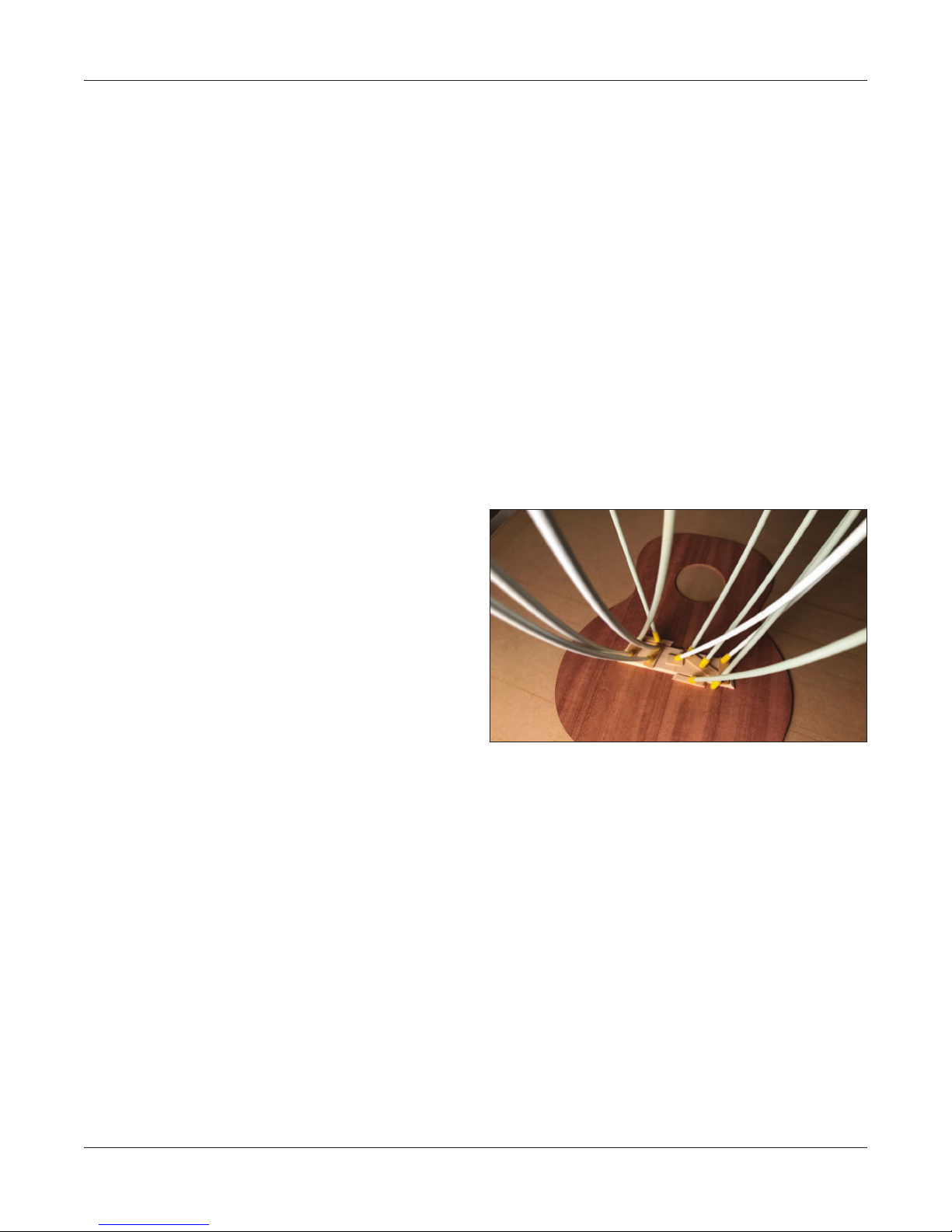

If you’re using Go-bars feel free to place 2 more bars on the

brace for added clamping pressure.

Wait 5 minutes and clean up the squeeze out. (Waiting a

few minutes gives the glue a bit of time to gel which makes

clean up easier.)

One extremely eective way to clean up squeeze out is

to use a scrap piece of spruce that has been sanded into a

crude “chisel” blade. The soft wood doesn’t dent your brace

or leave marks yet cleans up the glue quite nicely. Any re-

maining glue residue can be wiped away with a damp (NOT

wet) cloth rag.

Ensure your brace is seated tightly to the back across the

entire length.

Let it dry for 2 hours.

Begin by carefully cutting out the plan on or just outside

the solid black line that denotes the sides. This can be done

with scissors or a razor knife.

Transfer the brace plan to the wood

Mark a centerline precisely on your back plate along the

center seam.

Tape your plan carefully to your back plate taking care to

ensure the centerlines match perfectly at both ends.

Locate the back braces by using a pushpin, awl or scribe

to poke small holes into the wood at the brace ends. The

back braces are the two horizontal braces at the waist and

lower bout.

Connect these holes with a pencil and straightedge, which

will be your marks for where to glue the braces.

Save the plan drawing for use later throughout the build

process.

Gluing the back braces

Notice that the bottom of your back braces have a radius.

This adds structural integrity to your instrument as well as

improves the sound quality.

You can glue each brace separately, or use a Go-bar Deck

and a radius dish to clamp more than one brace at a time.

Do a dry run before gluing

It is always a good idea to test your clamping setup before

you apply glue. Decide where to place clamps and cauls on

your bench, and frequently check to see that the braces are

located in the proper location and held down tightly from

end to end.

You don’t want to gure this out while the glue is drying!

The important thing is that you’re comfortable with your

clamping plan, and have seen that it works before you’re

under the time pressure created by wet glue.

Brace the top and back

stewmac.com

6

We recommend starting with the bridge plate rst, followed

by the fan braces.

If you are using a Go-bar Deck you can probably glue all 3 of

the fan braces in place in one session, if you are using clamps

it may be better to take them one at a time.

Take your time. There is no rush.

Apply the glue

Let’s start with the bridge plate. Put a small dab of glue in

the center and use your pinky to spread an even, thin lm all

the way to the edge. Wipe up any excess glue on your hands

and glue that may have run over the edges of your plate.

Precisely locate the bridge plate and apply a clamp or Go-bar

to the center. After the clamp is applied carefully recheck

the position of the plate and apply additional clamps (or

Go-bars).

Ensure the bridge plate is seated tightly to the top all the

way around. After 5 minutes clean up the squeeze out. Wait

2 hours and remove the clamps.

Now it’s time glue in the fan braces. The center fan brace

has a notch for the bridge plate. Locate this brace directly

on the centerline. Apply glue and lightly clamp it in place.

The two outer fan braces should bump up to the right and

left side of the bridge plate. To get the best tone from your

instrument is important that the fan braces are all making

contact with the bridge plate.

Glue them all in place using the same method we have been

using and clean up any squeeze out.

Let them dry for 2 hours and then remove the clamps.

If you are using a Go-bar Deck feel free to go ahead and glue

up the other brace in the same manner now. If you’re using

clamps it’s best to wait and install the braces one at a time.

Bracing the top

We are going to begin by locating the position of the top

braces similar to the approach we used on the back.

Mark a centerline precisely on the center seam inside your

top. (While you had a choice of which side was the exterior

on the back of your ukulele, the top has been predetermined

since the rosette will be on the face of the instrument.)

Tape your plan carefully to the interior of your top plate

taking care to ensure the centerlines match perfectly at both

ends, and the soundhole aligns with the drawing.

Locate the upper and mid transverse braces with a pushpin,

awl or scribe. These are the long horizontal braces just above

and below the sound hole.

Note: The mid transverse brace resides in the same

location as one of your back braces, so don't let this

confuse you.

Connect these holes with a pencil and straightedge, and you

have the brace locations marked for gluing.

Now carefully mark the locations of the bridge plate and 3

vertical fan braces. Once this is done lightly draw the loca-

tions of all the braces for your top.

Remove the plan. We will be using it again shortly.

Gluing the top braces

As with the back braces you can glue each brace separately

with clamps, or use a Go-bar Deck and a radius dish to clamp

more than one brace at a time.

However, unlike your back braces which had a slight radius,

you’ll notice the top braces are at. This means that if you’re

using a Go-bar Deck you’ll want to make sure to remove the

radius dish and replace it with a at surface (or ip the radius

over and use its at back.)

Do a dry run before gluing

Getting the brace locations exactly right on the top is criti-

cally important to the structural integrity and tone of your

instrument. So like you did when gluing the back braces,

take a few minutes and do a dry run of your clamping setup

before you apply glue.

stewmac.com 7

in the photo (below). Screw these two braces to the plywood,

on the centerline. Position them so they are against the bold

line of the uke shape. These are clamp supports for gluing

the neck block and tail block to the sides.

These clamping blocks should be no taller than the sides

of the ukulele.

The other two corner braces support the sides at the uke’s

waist. To avoid metal scarring the mahogany sides, give

these brackets some padding. A piece of dowel wrapped

in masking tape works well.

Screw these braces to the plywood, positioning them against

the uke outline at the waist.

Now we’re ready to begin working on the body.Next glue in the lower transverse brace followed by the

upper transverse brace.

Let the braces dry for 2 hours before removing the clamps.

Make the body mold

Now we are going to turn our attention to the ukulele body,

and this begins with creating an outside mold.

This is a very simple xture: a piece of plywood (or MDF) and

four 2-1/2" corner braces (angle brackets). It holds the body

pieces in shape while you build.

Start with a high quality piece of 3/4" plywood (or MDF),

19"x12". Draw a centerline down the middle of the board.

Tape or spray mount the plan drawing to the plywood,

aligning it on the centerline. The bold black line on the plan

drawing is the nal shape of your uke.

Attach blocks of wood to two of the corner braces, as shown

Optional: showing the gluing setup with clamps.

stewmac.com

8

extension toward the back of

the instrument.

Carefully measure and mark

a centerline on both blocks.

The neck and tail blocks need

to be the same height as the

sides. If yours are taller than

the sides, trim them with a

saw or chisel. This is easier to

do now than later.

Glue the sides and blocks

You can glue the blocks in using the mold as support, or

out of the mold. Each method has pros and cons. Using the

mold provides rigidity, however, clamping up outside the

mold allows the visibility to ensure everything is aligned

perfectly during glue up.

For these instructions, we are going to glue up the tail block

outside the mold, and the neck block inside the mold.

Assemble the body

Place the bent sides into the body mold, with their ends

butted together at the center. Now you can see the body

of your ukulele taking shape!

If the sides are oversized and extend more than 1/8" past

the centerline when you insert them in the mold they will

need to be trimmed.

To do this, while holding the sides down rmly in the mold,

and ensuring they line up nicely with picture of the sides

axed to your work board, carefully mark the centerline

on your side near the headblock. Remove the side, mark a

square line and carefully cut this with a saw. (A little double

stick tape and a wood block provide a good fence to ensure

your cut is square and straight.)

Reinstall the side in the mold. Align the newly trimmed side

to the centerline at the neck block, hold the sides down to

the work board to ensure they line up with the prole on

your plan and mark the centerline at the tail block. Mark

and cut the side the same way you made the previous cut.

Repeat the process for the other side.

Now we are going to glue in the neck and end blocks.

Snap the sides into the mold so the neck and tail ends t

end-to-end perfectly. Align the seams to the centerlines

marked on your plan.

If the sides don’t precisely match the body shape on the

plan drawing, don’t worry. A little variation between ukes

is ne. As long as the side curves match each other nicely,

you’ll have a great looking instrument.

The corner braces will hold your sides nicely square to the

baseboard, so the body doesn’t “lean” in one direction. If

you like, use a square to double-check this.

The tail block is the smaller of the two blocks, and the neck

block has horizontal extensions on both ends.

When gluing in the neck block, place the “square” horizontal

extension toward the top of the ukulele and the “rounded”

stewmac.com 9

When you’re comfortable with your clamping setup, put

glue on the neck and tail blocks.

Put a little glue on the narrow edges of the sides that butt

together, too. If the neck and tail blocks quickly absorb the

glue, add more to make sure you have a slightly wet gluing

surface. You don’t want a glue-starved joint.

Clamp the blocks and sides, and let them dry for 1-2 hours.

Use warm water to clean up any glue squeeze out. Titebond

and Fish Glue cleans up nicely after 10 - 15 minutes. It is still

wet enough to remove, but rubbery enough to make clean

up less messy.

Install the linings

The exible wooden linings will be glued to the edges of the

sides, ush with the top and back. These strengthen the body

and provide a wider surface for gluing the top and back.

For rm gap-free pressure all along the linings, you’ll need at

least 12 Mini Clamps for Linings to glue one lining strip. Using

even more, closely spaced together, ensures that the linings

are pressed to the sides at every point along the curves.

The linings are oversized and will need to be trimmed before

glue up.

The easiest way to do this is to carefully install a piece of blue

painters tape ush with the top edge of the ukulele’s side.

Take your time to ensure the tape aligns perfectly with the

top edge of the side. Carefully trim the tape exactly where

it meets the neck block and the tail block. Before removing

the tape, place a visible mark at the apex of the waist.

Remove the tape and align the mark on the tape to the apex

of the waist on your pre-bent lining. Carefully align the tape

to the top edge of your lining.

At the end of the tape make a pencil line.

Technically, the pencil line at the ends of the tape should give

you a perfect t. However, due to small errors in alignment of

the tape when measuring the sides, and when tting them

to the linings if you cut to the pencil lines the linings will be

a smidge too short.

To account for this make a mark 1/16" past the trim line at

the ends of the tape, draw a square line and cut the lining

at these locations.

stewmac.com

10

Do a dry run of the clamp up before applying glue. Fit the

ends of the linings against the neck and tail blocks. Starting

at the neck block apply clamps closely working toward the

tail block.

Once all the clamps are in inspect the rim carefully to ensure

the linings are tight to the sides. If there are no gaps you’re

ready to glue!

Apply glue to the linings and clamp them. Wait 10 minutes

and clean up any squeeze out by gently scraping it away

with a razor blade. Any remaining glue marks can be gently

scrubbed o with a damp (not wet) cotton rag.

If you have enough clamps you can glue up both halves

of the rim at once. Allow them to dry for 1-2 hours before

removing the clamps, then turn the sides over in the body

mold and glue the linings to the other edge.

Sand the linings ush

The edges of the sides need to be smooth and uniform for

gluing the top and back. The easiest way to do this is with

adhesive sandpaper taped down to a at surface (such as

a piece of MDF).

Remove the rim from the mold and draw a pencil mark across

the face of the blocks and linings. Lightly rotate the rim on

the sandpaper until the lines disappear.

stewmac.com 11

Sand each brace with 80-grit, 120-grit, and 220-grit and try

to create an even, uniform, attractive looking brace.

Fit the back to the sides

The braces on the back are intentionally longer than the

width of the body. When you place the back on, these braces

will overhang the sides.

The next step is trimming braces to length, and creating

notches in the side linings so the back drops in place.

Place the back in position, aligning it on center. Use a weight

to hold it in place. Make small pencil marks on the sides to

show where the braces touch. Extend these marks over the

edge of the sides and linings.

Shaping the Braces

After the glue has dried at least 2 hours, and all the clamps

have been removed lightly shape the top and back braces.

Using a small block of wood with adhesive sandpaper at-

tached lightly round over the top of each brace.

(To keep your work clean and neat, and to protect the top

and back plates of your instrument it is helpful to put down

protective layers of tape. Simply take regular duct tape or

masking tape and stick it to your shirt a few times to remove

some of the stickiness and apply it right next to your brace.)

Once the top of your brace has been roughly shaped with

the sanding block use a piece of sandpaper between your

ngers to round over the top of the brace.

stewmac.com

12

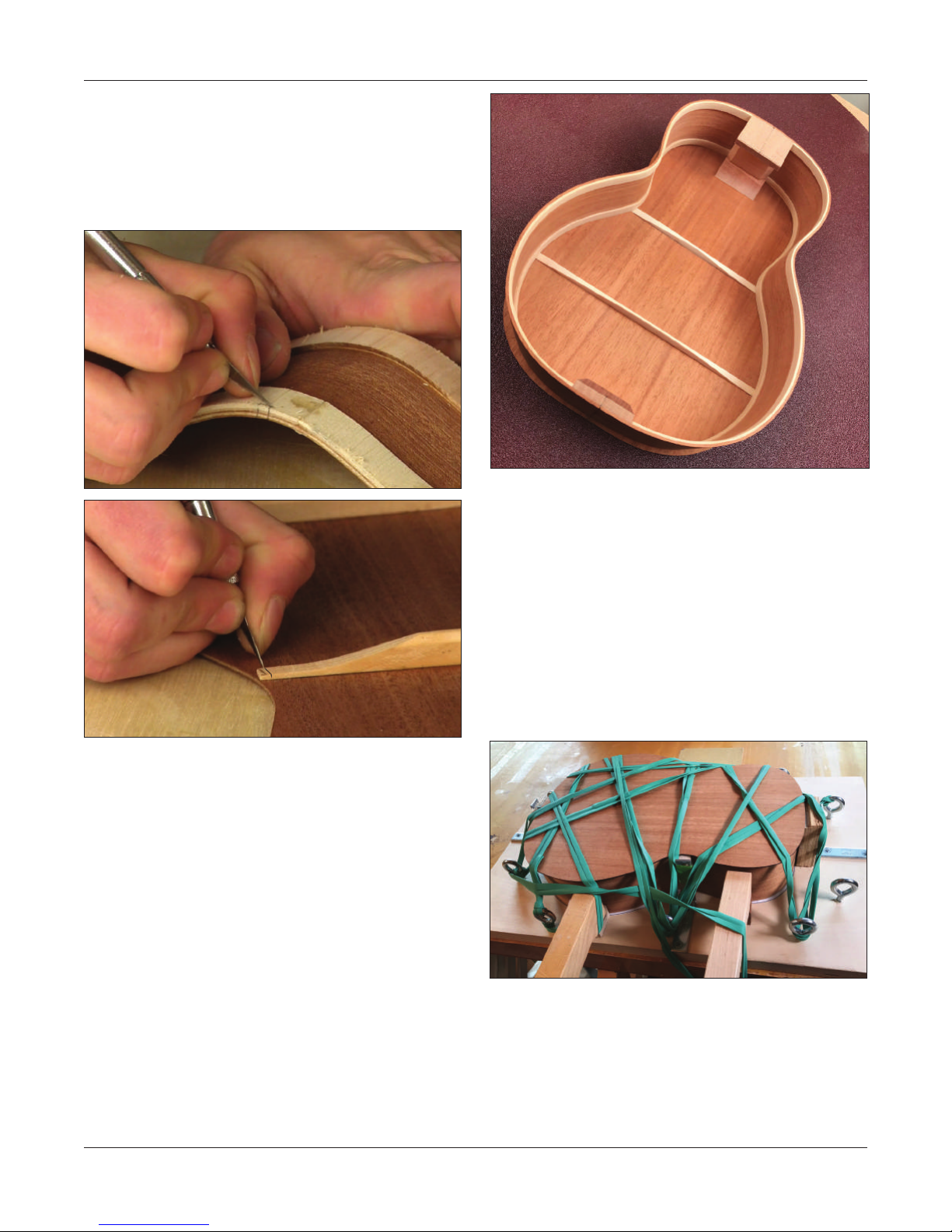

With a sharp razor knife, cut notches in the linings for the

braces. A small chisel is helpful for chipping out the notch.

Trim the ends of the braces so they t within the sides,

dropping into the notches. Scrape the trimmed brace ends

o the back. When you’re done, the back ts at onto the

sides, with the braces keyed into the notches.

The top and back are slightly oversize, with edges that hang

over the sides. This overhang will be removed after gluing.

Glue the back on the rim

To get good clamping pressure all around the back, the

body mold is now put to use again. By adding screw eyes

or hooks around the edges of the of the plywood, you can

ax the rubber clamping bands included with your kit. If

your clamping band is an unbroken loop, cut it to make it

one long strip.

Tie the end of the clamping band and stretch it tightly over

the body to the opposite corner. Continue strapping from

corner to corner until the back is clamped under a web of

rubber bands. Tie o the end to one of the screw eyes. Try

this as a dry run.

When you’re ready for glue, apply it to the edge of the side

and lining, and to the end of the neck and tail blocks. Put the

back in position and wrap with the rubber clamping band.

Let the glue dry for 2 hours, then remove the body from

the mold. Clean away any dripped glue, especially where it

can be seen through the soundhole of the assembled body.

stewmac.com 13

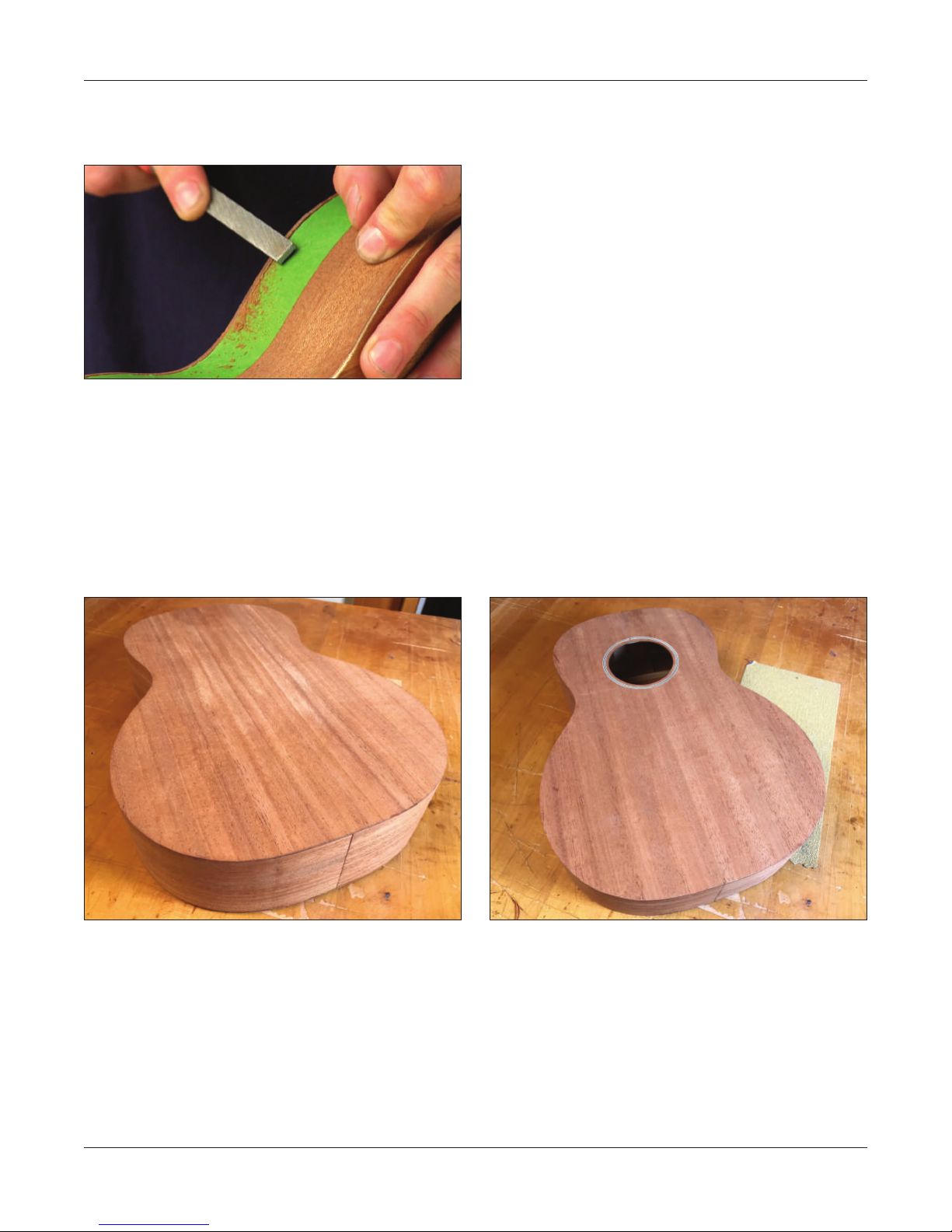

Trim the overhang

Before you glue the top on, you will need to trim the over-

hang on the back of your ukulele. This involves cutting the

overhang slightly proud of the sides, then sanding away

the remainder to make the edges smooth and ush with

the sides.

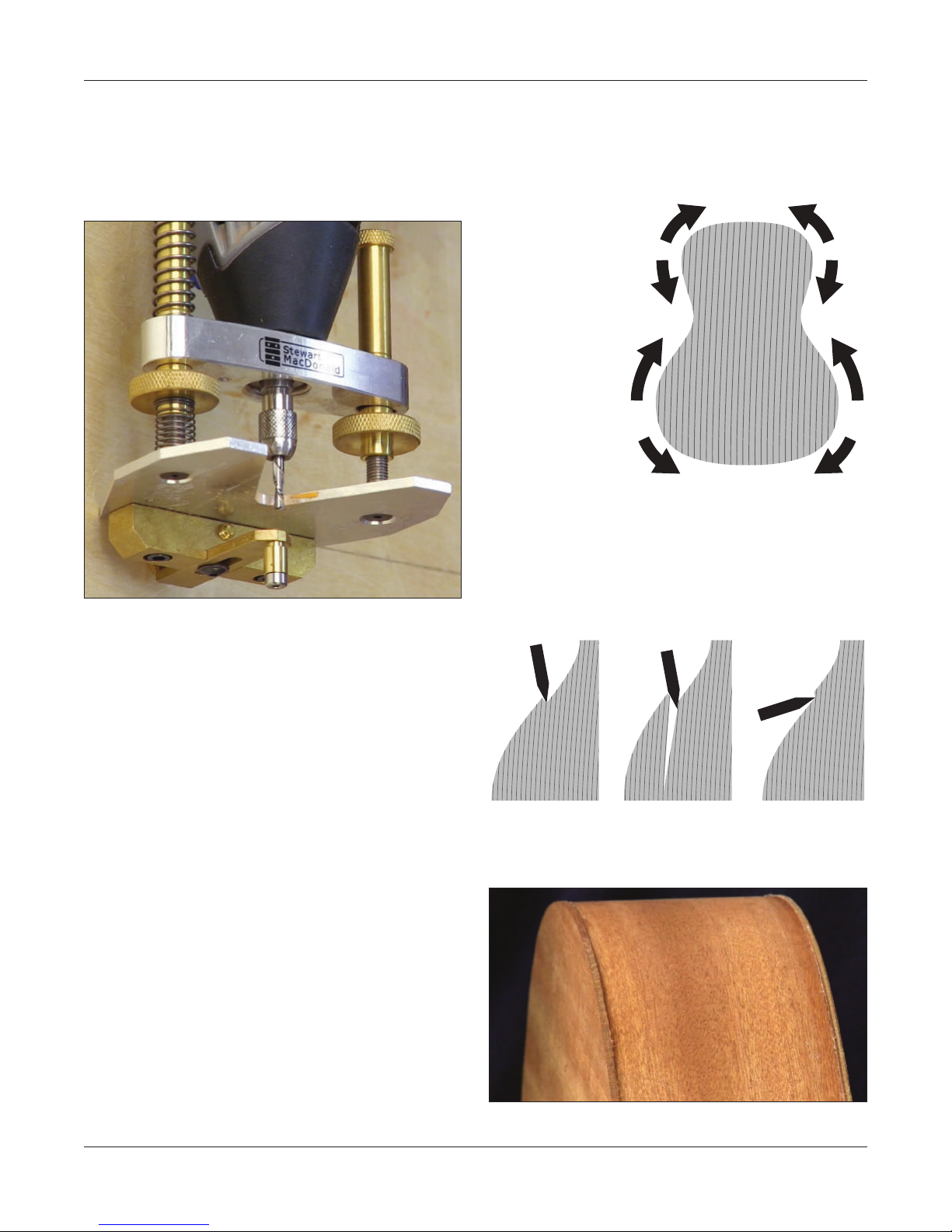

A Dremel rotary tool with StewMac’s Precision Router Base

and Edge Guide is ideal for trimming the overhang. Use a

down-cut router bit to make a clean cut. Rout away most

of the overhang, leaving it small enough to remove with

sandpaper.

You can also trim the overhang with a sharp razor knife and

a at le. Using the knife, carve away a small bit of wood

with each cut, reducing the overhang until it is close to the

sides. Follow with the le to bring it close enough to remove

with sandpaper.

Beware of tear out. Whether you use a router or a knife, you

must pay attention to the grain of the wood on the body

curves.

At the curves, a cutting tool working against the grain wants

to dig into the wood. This action makes it easy to tear out

a chunk of wood.

To avoid tear out, plan your cuts so that the router or knife

approaches each curve on its downward slope, rather than

climbing upward. The eight arrows on the illustration show

the direction to make each cut around the body.

After trimming, the remaining back and top overhang should

be very small. You’ll remove this with a le and sandpaper.

To avoid tearout,

make your cuts

on the downward

slope of the curve,

with the grain.

Don’t cut upward

against the grain.

Cutting tool

approaching

a curve from

this direction

invites tearout.

Tearout: accidentally breaking at the grain line

Tearout: the

wood breaks

at the grain.

Cutting from

the opposite

direction makes

tearout much

less likely.

stewmac.com

14

Don’t sand the sides at this point. That comes later. Just make

the top and back edges ush with the sides.

Sand until you have a smooth edge all around the uke.

Glue the top on the rim

Now we will t the top and glue it on.

Reinsert your body back in the mold with the freshly glued

on back facing down. Align the centerline with the marks

you placed on your end blocks.

Just like with the back braces, we will need to trim and t

the horizontal transverse braces. Perform the same steps

you did for the back braces - trim them to length, and create

notches in the linings so the top drops in place.

It’s very important during this step that the centerline of the

top remains on center with the rim. Take your time while

notching the braces and gluing up to make sure everything

is in the proper location.

Use the same clamping procedure to install the top. Wait

at least 2 hours and remove it from the mold and trim the

overhang like you did on the back.

Sand the top and back ush with the sides

A at le will remove the remaining bit of overhang, followed

by sandpaper to make a smooth, ush edge.

Put masking tape on the sides to protect them from le

marks. Carefully file away the overhang until it’s small

enough that you feel ready to switch to sandpaper. You

might not need the le at all: 120-grit sandpaper may be

all you need.

With a at sanding block, follow the outer curves of the body

to ush the edges with the sides. A curved sanding block or

a stout wooden dowel makes a good sanding block for the

inside curves at the waist.

stewmac.com 15

Prepare the neck

Install the side dots

The position markers on the side of the ngerboard are

made from a small plastic dowel, 1/16" in diameter. The dots

are centered between the same frets that have inlaid dots

on the board.

Use your scribe, awl or pushpin to mark holes for drilling.

Make sure all the holes are centered equally down the side

of the board. You might want to put two dots at the 12th fret

to indicate the octave; this is optional on a ukulele.

Using a drill with a 1/16" bit, start each hole by briey run-

ning the drill in reverse. This will create an indentation in the

wood to center the bit so it doesn’t wander when drilling.

Hold the drill square to the surface, and drill each hole about

1/8" deep.

Turn the end of the side dot dowel against a piece of sand-

paper to clean up the end so it will slide into the hole. Then

dip it in Titebond glue and insert it in the hole.

Wipe away any excess glue, then cut the dowel o at the

surface of the wood using fret cutters or side cutters. After

installing all the dots, use a le to level them ush with

the surface of the wood. The result is a line of small round

position markers.

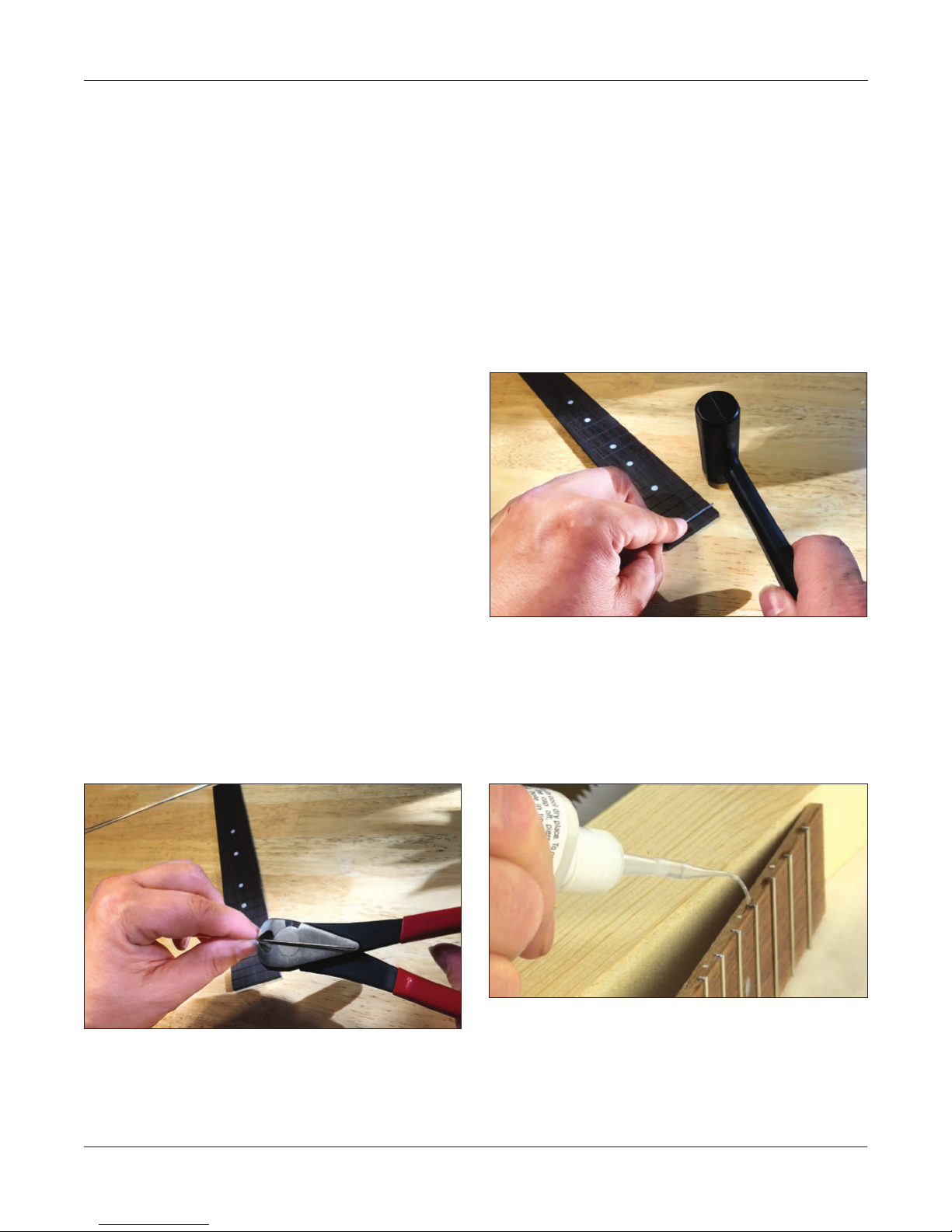

Preparing for fretting

Use a smooth flat work surface. You want a solid table

that won’t bounce or shake when you tap the frets with a

hammer.

Lay the end of the wire over the rst fret slot, so it protrudes

only very slightly over the edge of the board. Holding the

wire down with one hand, cut the fret at the other side of

the board. This creates a fret that’s cut to length for this slot,

with very little extra metal to le away from the ends later.

Use a fret cutter or side cutter to cut the fretwire.

Set the cut fret aside and move on to the next. Fasten a piece

of masking tape to your table, sticky side up, to keep your

cut frets in order while you work.

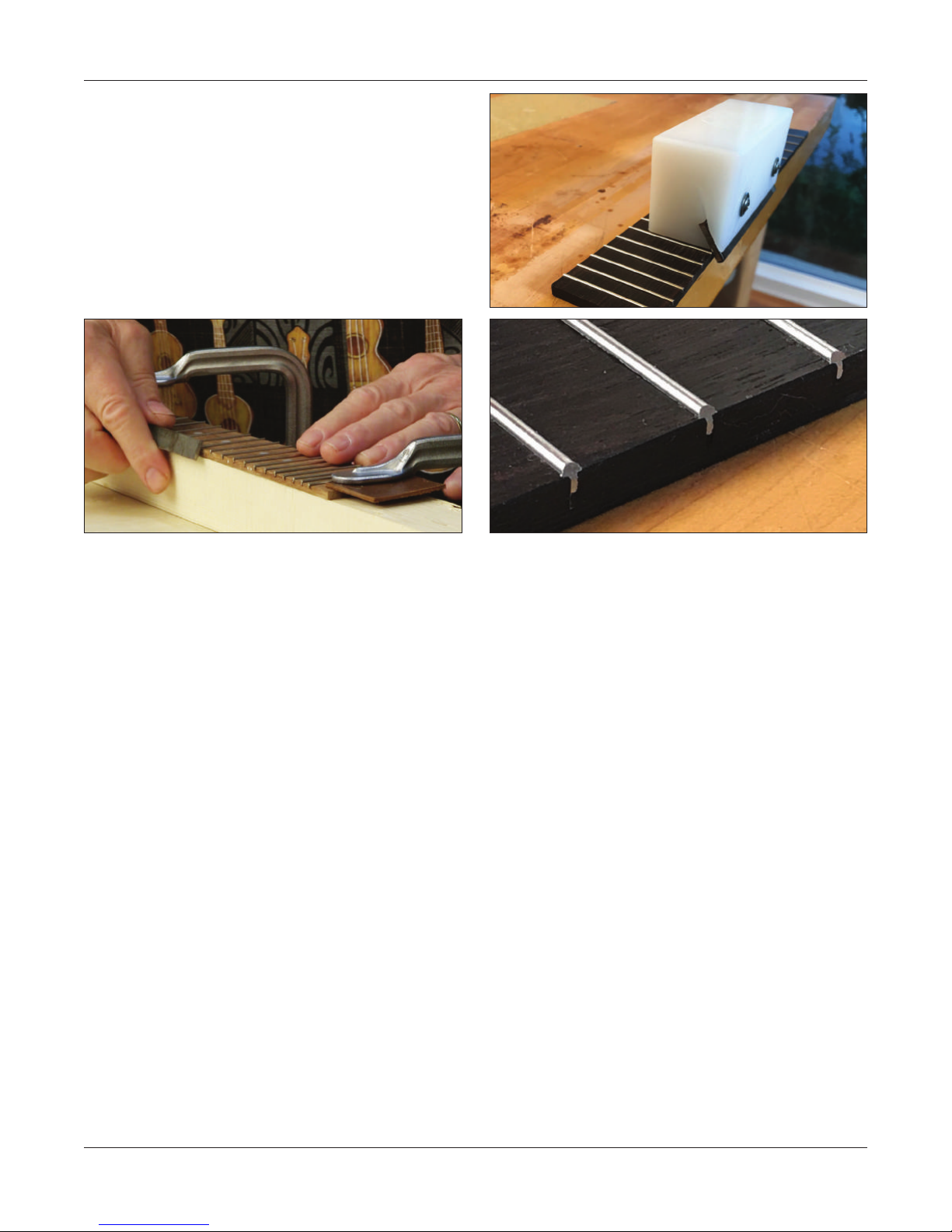

Install the frets

The top of the fret is called the crown. The strip that ts into

the fret slot is called the tang. Position the rst fret so the

tang sits on the fret slot. Hold the fret in position by pressing

it down at the center with one nger. With a hammer in your

other hand, tap the two ends of the fret into the slot.

When the ends are seated in the slot, you can remove your

nger and tap down the center of the fret. Do this for each

fret down the board.

Any hammer can be used, but a small one, like a fretting

hammer, works best. Don’t hit the fret or the board hard

enough to cause dents.

Glue the frets

Adding medium viscosity superglue under the frets, such as

StewMac #20, keeps the frets seated.

Turn the board on its side and run the glue under the fret

slots. A small whip tip on the glue bottle will help direct the

glue into the fret slot.

After adding glue to each slot, turn the board over and do

the same to the other side.

stewmac.com

16

File the fret ends

Clamp the fretted ngerboard onto a piece of wood with

one edge overhanging. This is a convenient way to le the

fret ends. Use cauls to prevent the clamps from damaging

the ngerboard.

Using long strokes with a at le, remove the ends of the

frets so they are ush with the ngerboard edge.

A two-handed grip is recommended: it takes rm pressure

to le down the fret ends—especially at rst, while their cut

ends are sharp and uneven.

When you’ve made the fret ends ush, tip your le and give

a slight bevel to the fret crowns. This makes the frets more

comfortable to play. When the fret ends on one side are

smooth, rotate the board and perform the same procedure

to the other side. (Optionally you can use a Fret Beveling

le – #3760 – to get a perfectly uniform bevel on both sides

of your ngerboard.)

stewmac.com 17

Pre-t the neck

Now is a good time to pre-t the neck. Let’s start by carefully

drawing a centerline down the face of the neck (where the

ngerboard will be placed), and extend this line through

the underside of the heel (the part of the neck that makes

contact with the body).

Carefully extend a pencil mark on the heel so you can re-

draw a centerline to the underside of the heel as necessary.

Gently set the neck in position so the centerline on the neck

closely aligns with the centerlines on the front and back of

the body. Lightly mark the shape of the heel on the body

of the instrument.

Now take a rule or straightedge and check to make sure the

sides are perfectly at along the lines you just drew. If they

aren’t at use a sanding block axed with 120-grit sand

paper and lightly sand the entire surface of the side (with

the grain) until the area where the neck meets the body is

dead at.

Now, ax 80-grit adhesive sandpaper to the body of the

instrument and trim o any overhang with an exacto knife

or razor blade.

Gently sand the underside of the neck prole on the body

taking care to keep the centerlines on the body and neck

aligned. (This isn’t as hard as it sounds.)

When the bottom of the neck is fully sanded and the cheeks

of your neck set ush against the sandpaper your neck has

been roughed in and this will allow it to quickly be ne-tuned

later just before gluing.

stewmac.com

18

Drill the neck joint

Now let’s drill the holes for the neck location.

The neck has two 1/4" diameter holes for the dowels that

support the neck joint. You need to drill matching holes in

the body to t these dowels.

Measure from the top of the neck to nd the center of the

two dowel holes. Use these measurements to mark and drill

matching holes on the body.

After measuring the locations the pins carefully mark them

with a pencil and make a deep indentation with a scribe, awl

or push pin. This will help keep the drill bit aligned when

you drill the hole.

Note: It is possible that the locating holes may not align

with the centerline on the body due to small dierences

in where the holes are drilled on the neck.

Drill the two holes using a 1/4" drill bit. To keep the drill from

skating around as you begin drilling the hole, start the drill

in reverse until it makes an indentation that will help keep

the drill positioned.

Drill them 3/8" deep. (Mark your drill bit with a piece of mask-

ing tape to keep from drilling the holes too deep.)

Attach the ngerboard

The nut should seat rmly between the pre-attached head-

plate and the ngerboard.

Measure the hole

locations on the

neck and duplicate

them on the body

stewmac.com 19

Insert the fret board position marker material in the hole you

just drilled and snip it o with 1/8"–3/32" protruding above

the ngerboard. (It’s not necessary to glue the material in if

it ts snugly in the hole.)

Now repeat the process between the 10th and 11th fret.

When this is completed carefully align centerlines you made

on the ngerboard with the centerlines drawn on the neck

and rmly squeeze the ngerboard onto the neck. (Remem-

ber to align it with the pencil mark you made for the nut. It’s

a good idea to cover the pencil line with nger board. This

will ensure the nut ts nice and snug.)

The plastic ngerboard marker material will easily embed

into the softer mahogany. These will serve as registration

pins to help hold the neck in place during glue up.

It’s important that the ngerboard seats tightly on the neck.

Align the nut against the headplate and trace a pencil along

the face of the neck to determine the ngerboard location.

Carefully measure and mark a centerline on each end of

the ngerboard, and draw a centerline down the back of

the ngerboard.

You should already have a centerline drawn on the face of

the neck. Carefully mark the underside of the heel with a

pencil at the centerline location. This will help you ensure

the ngerboard is perfectly aligned on the neck.

Registration pins

It’s very important that the ngerboard is perfectly aligned

on center to the neck. As you may have experienced parts

tend to skate around during glue up.

To help with this we can optionally add 2 locating pins in

the ngerboard that will hold the ngerboard securely in

place during glue up.

You should have excess side dot material left over from an

earlier step where we added side position markers to the

ngerboard.

Using a 1/16" drill bit carefully drill a hole 1/16" deep in the

reverse side of the ngerboard between the 1st and 2nd

fret. You want to drill this hole about half way between the

centerline and the edge of the ngerboard.

stewmac.com

20

If there is any glue squeeze out in the nut slot or under the

ngerboard near the heel wait 5 minutes and clean it up

as you did with the braces. (Don’t worry about squeeze

out along the edges of the ngerboard. We’ll clean that up

after it is dry.)

Allow the glue to dry overnight.

Smooth the ngerboard/neck transition

The glue joint between the ngerboard and neck needs to

be smoothed to get a comfortable transition between the

rounded neck and the at edge of the ngerboard.

Use a at le and sandpaper to slightly round the ngerboard

edge, blending it into the neck. At this stage, you’re shaping,

not nal sanding. Final sanding comes later, as you prepare

for nishing.

While ling along the length of the neck, this is a good time

to double-check the bevel of your fret ends. When playing

the uke, you’ll appreciate the feel of the rounded neck

blending smoothly into the ngerboard, with comfortably

beveled fret ends.

Trim the heel

If the heel of your neck extends past the sides of the ukulele

we will need to trim the neck so the heel transitions nicely

from the back of the instrument.

If the registration pins hold the neck up (even the slightest

amount) use a le to lightly remove some material from the

registration pins until the ngerboard sits dead at against

the neck.

Preparing the nut area

If there is any dried glue squeeze out from where the head-

plate was applied it is easiest to remove it now before the

ngerboard is glued on.

It is easiest to remove this with a very sharp chisel. Simply

lay the back of the chisel along the face of the ngerboard

and gently remove any dried glue.

Gluing the ngerboard on the neck

Brush glue onto the surface of the neck, and press the n-

gerboard in place.

Wrap the board tightly with rubber binding bands. Even with

the registration pins it is important to check to be sure the

board is centered on the neck.

Table of contents

Other StewMac Musical Instrument manuals