StewMac G-STYLE GUITAR KIT User manual

Sheet #i-5202 Updated 10/18

Assembly Instructions

Welcome to guitar building! If you’re a first-time builder,

this kit is a great way to start. You’ll have fun and learn a lot.

This simple kit is an excellent entry into electric guitar

assembly. It can be built with basic tools. You’ll learn to cut

the peghead shape, attach the neck, and wire it up. After

you build it, we’ll show you how to set it up to play tip-top.

StewMac

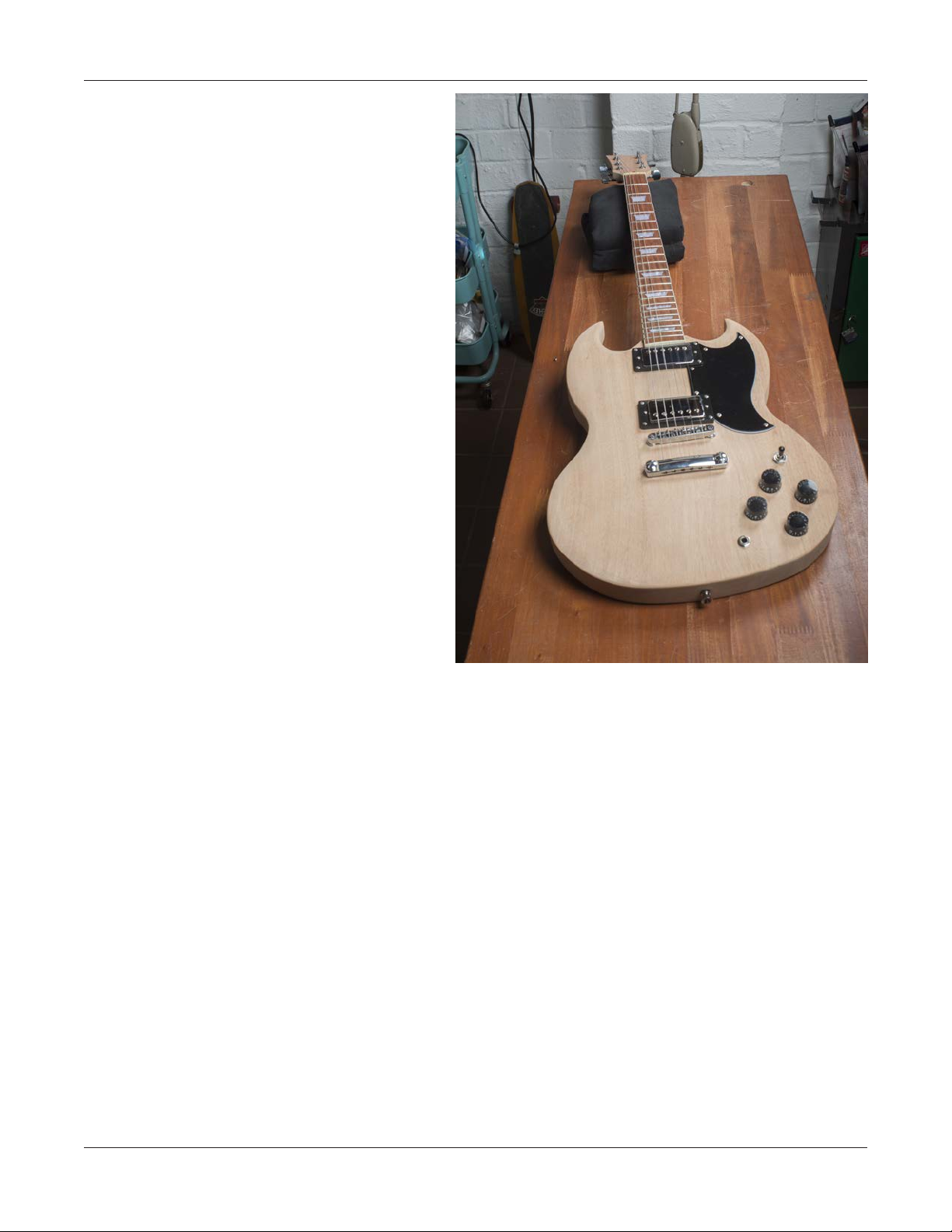

G-STYLE GUITAR KIT

stewmac.com

2

Tools and supplies ....................................

Parts list .............................................. 3

Create your peghead shape ........................... 4

Set the neck .......................................... 5

Fretwork ............................................. 7

Assemble your guitar ................................. 9

Wire the electronics ...................................11

Final setup ...........................................12

These are the tools and supplies we recommend for assem-

bling this kit. StewMac item numbers are included where

applicable.

Tools

Electric hand drill

Saw for peghead: band saw, jigsaw, or coping saw

Screwdrivers: Phillips, sizes #1 and #2 (#3000)

Flat blade, size 5.0mm (#3000)

Drill bits: 1/16" (#1710)

5/64" (#1712)

Nut slotting files: .013" width (#0823)

.020" width (#0828)

.035" width (#0832)

Fretting hammer (#4895)

Fret crowning file (#1602 or #4491)

Radius sanding block 12" (#0412)

Swivel handle clamp, total of 3 (#3704)

Straightedge (#3850)

6" Steel rule (#4905)

Nut driver, size 10mm (#5890, or wrench #3691)

Wire stripper, for fine gauge wire (#1606)

Adjustable wrench, 4" size (#1680)

Soldering iron (#0502 or #0515)

No-Chip Countersink (#1695)

Supplies

Wood glue (Titebond original, #0620)

Glue brush (#4167)

3M Scotch-Brite pad (#7445, light duty), or 0000 steel wool

Blue permanent marker

ColorTone Lemon Oil (#3864)

Guitar Finishing Step-By-Step Book (#5095)

Tools and supplies

Table of contents

stewmac.com 3

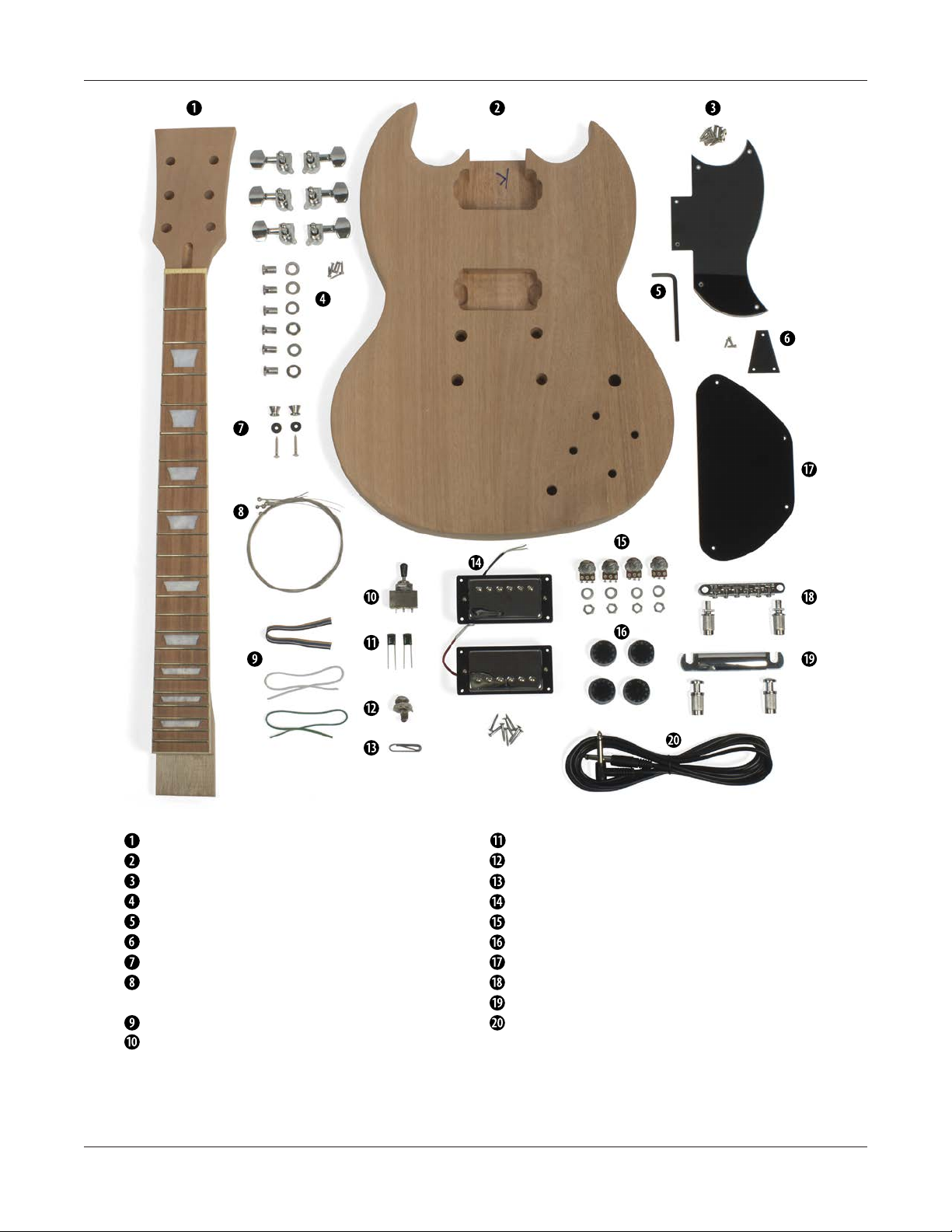

Parts list

Neck

Body

Pickguard with mounting screws

Tuners with bushings, washers, and screws (6)

4mm hex wrench for adjusting truss rod

Truss rod cover with mounting screws

Strap buttons with cushions and screws

Generic strings for preliminary set up

(also included higher quality strings for actual use)

Hookup wire 9.5" and 5.25" lengths

3-way toggle switch

Capacitors (2)

Output jack

Solder

Humbucking pickups (set of 2)

Control pots with mounting hardware (set of 4)

Control knobs (set of 4)

Control cavity cover with mounting screws

Bridge with posts and bushings

Tailpiece with posts and bushings

Output cord

stewmac.com

4

You can trace a favorite peghead or come up with a look all

of your own. You’ll be cutting your design from the blank

peghead on the kit’s neck.

Make a template

Sketch out your peghead design on a piece of cardboard

or heavy paper and cut it to shape with scissors. Using a

pencil, trace the shape onto the peghead. Use a light touch

that doesn’t dent or compress the wood which could make

sanding out any unwanted lines difficult. Don’t use ink,

because it leaves permanent stains that can even bleed up

through an opaque guitar finish.

Cut the shape

It’s important that your saw stays square to the face of the

peghead while you cut. If it tilts to an angle, you’ll get a

sloppy result that takes a lot of sanding to correct. Use a

bandsaw if you have one; a jigsaw is also good. A hand-held

coping saw can also be used, but it’s tough to hand-saw

smooth clean curves.

Never cut on the line

Always cut just outside the line, so you can sand to the line

afterward.

Smooth your saw cuts to create your peghead shape using

rasps, files and sandpaper. Don’t rush: rough patches will

disappear into a good final shape if you take your time.

When you’re happy with your peghead shape, sand the cut

edges smooth using 150-grit sandpaper followed by 220-

grit, then 320-grit.

Create your peghead shape

stewmac.com 5

Set the neck

This is a set-neck kit with a mortise and tenon joint, meaning

the heel of the neck (the tenon) is glued securely into the

neck cavity (the mortise).

Before gluing up the neck do a dry run first. Using two clamps

and a caul on the back of the body to prevent denting the

wood lightly clamp the neck into place. Note there will be

side to side movement of the neck.

There will be some gaps and chips around the joint; this is

normal for a production guitar. These will get filled when

you prep for finishing.

Take a 12" ruler or straightedge and line it up along the treble

edge of the neck, paying attention to where it falls in relation

to the treble side bridge stud hole. Then line it up with the

bass side of the neck and check it to the bass side stud hole.

stewmac.com

6

Set the neck

Loosen the clamps just slightly and adjust the position of

the neck until you have even space between the bridge

mounting holes. When achieved tighten the clamps securely.

Mark a line in the cavity and on the tenon to use as reference

when gluing up the neck.

Make note of your actual gluing surface and spread glue on

the bottom of the tenon. Repeat the same process as above

using your reference line to get you in the ballpark. When

properly aligned tighten up the two clamps on the tenon

and add a third over the fretboard end using a radius caul

to prevent damaging the frets.

Once the neck is seated remove any excess glue squeeze

out with a damp cloth. Watch for further squeeze out over

the next 15-30 minutes.

Let dry overnight.

stewmac.com 7

Fretwork

Run your fingers lightly along the edge of the fretboard

and feel for sharp fret ends. If the fret ends feel sharp where

they meet the edge of the neck, gently sand them back with

320-grit sandpaper using long strokes down the length of

the neck. Use care not to change the bevel of the frets in

the process.

Straighten the neck

Use the 4mm hex wrench to adjust the truss rod. With a

straightedge on the frets, adjust the truss rod until the

straightedge touches all of the fret tops without rocking.

Turn the truss rod nut counterclockwise (viewed from the

peghead end) to loosen the truss rod, allowing the neck to

bow upward. Turning it right tightens the rod, pulling the

neck back.

For more information, see our Trade Secrets article #33 “Don’t

be nervous about adjusting that truss rod!” at stewmac.com.

Seat the frets

The frets come installed, but they need a little work to

achieve the best playability. Use a fretting hammer to make

sure the frets are all seated properly. The more even your fret

tops are, the less leveling work there is to do later.

stewmac.com search: ts33

stewmac.com

8

Level the frets

Use adhesive backed sandpaper or double-stick tape to

attach 320-grit sandpaper to the 9.5" radius sanding block.

With this, level the frets using full length strokes down the

fretboard.

Leveling will leave flat tops on the frets. Use a fret crowning

file to restore their rounded shape.

Reapply blue marker to the fret tops. By filing the sides of the

frets, bring in the edges of the flats left over from leveling.

With a rounding motion, keep bringing in these edges until

all that remains of the top is a very thin line. Don’t remove

this line entirely; filing the fret tops would undo your leveling.

Polishing the frets

Using 400 grit, then 600 grit sandpaper wrapped around a

foam block, run up and down the entire length of the fret-

board. Polish the frets by going over each one with extra fine

Scotch-Brite or 0000 steel wool. Follow up by cleaning the

fretboard with ColorTone Lemon Oil or your favorite condi-

tioner. Use care not to get any excess oil on the bare wood.

Color the fret tops with a blue permanent marker to prepare

them for leveling. The blue ink will show your progress: the

frets are level when sanding has removed some of the blue

across all of the fret tops.

Fretwork

stewmac.com 9

Assemble your guitar

Assemble your guitar on a soft pad or cardboard to prevent

denting or scratching the instrument.

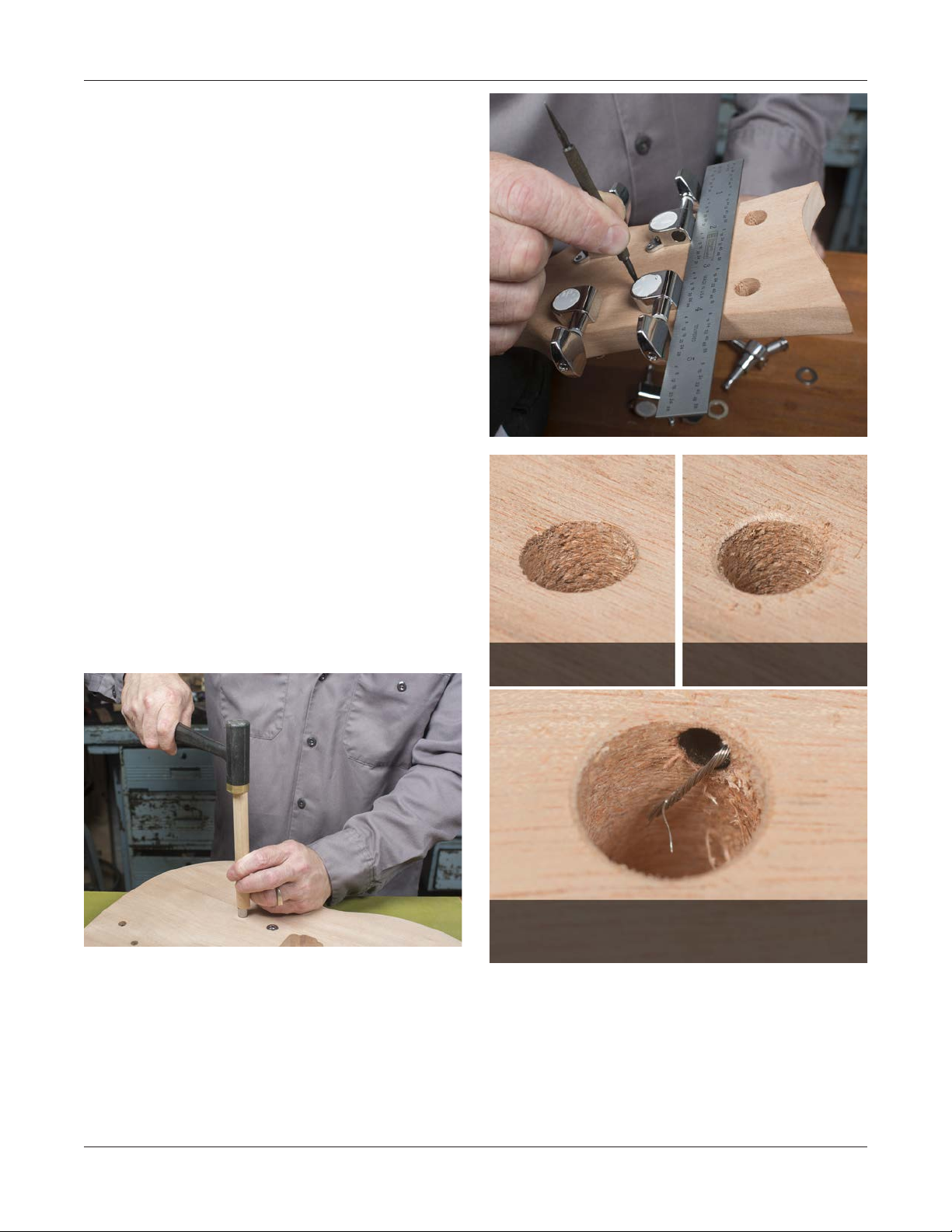

Install the tuners

Starting with the bottom set of pegholes, lay out the tuners

with a ruler to make sure they are in line with one another.

Mark out the mounting holes with a scribe or transfer punch.

Tuner mounting screws are very delicate. Use a 5/64" drill

bit to make pilot holes for the screws; if these holes are any

smaller you risk shearing off the screw heads. Lubricate the

screw threads by dragging them across soap or wax for

smooth installation.

With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver. On the tuner string post, add

a washer then the threaded bushing. Tighten with a 10mm

nut driver or wrench.

Install the body bushings

Install the tailpiece bushings. It’s a good idea to slightly

chamfer the holes for the bushings to prevent any chipping.

Cut the edge back just larger than the outside diameter of

the knurling.

Note that there is a ground wire access hole connecting the

treble side tailpiece post hole to the control cavity, this is for

the string ground. The 7" ground wire needs to be installed

before the bushing. Strip 1/2" off of both ends and run the

wire through the hole into the cavity leaving the stripped

end to come in contact with the bushing once installed.

Install the tailpiece bushings. Pressing them in with a drill

press is the preferred method but they can also be installed

with gentle hammer taps using a block of wood between

the bushing and hammer.

Install the bridge bushings in the same fashion.

Bushing hole

before chamfering

Bushing hole

with chamfer

Ground wire

in bushing hole

stewmac.com

10

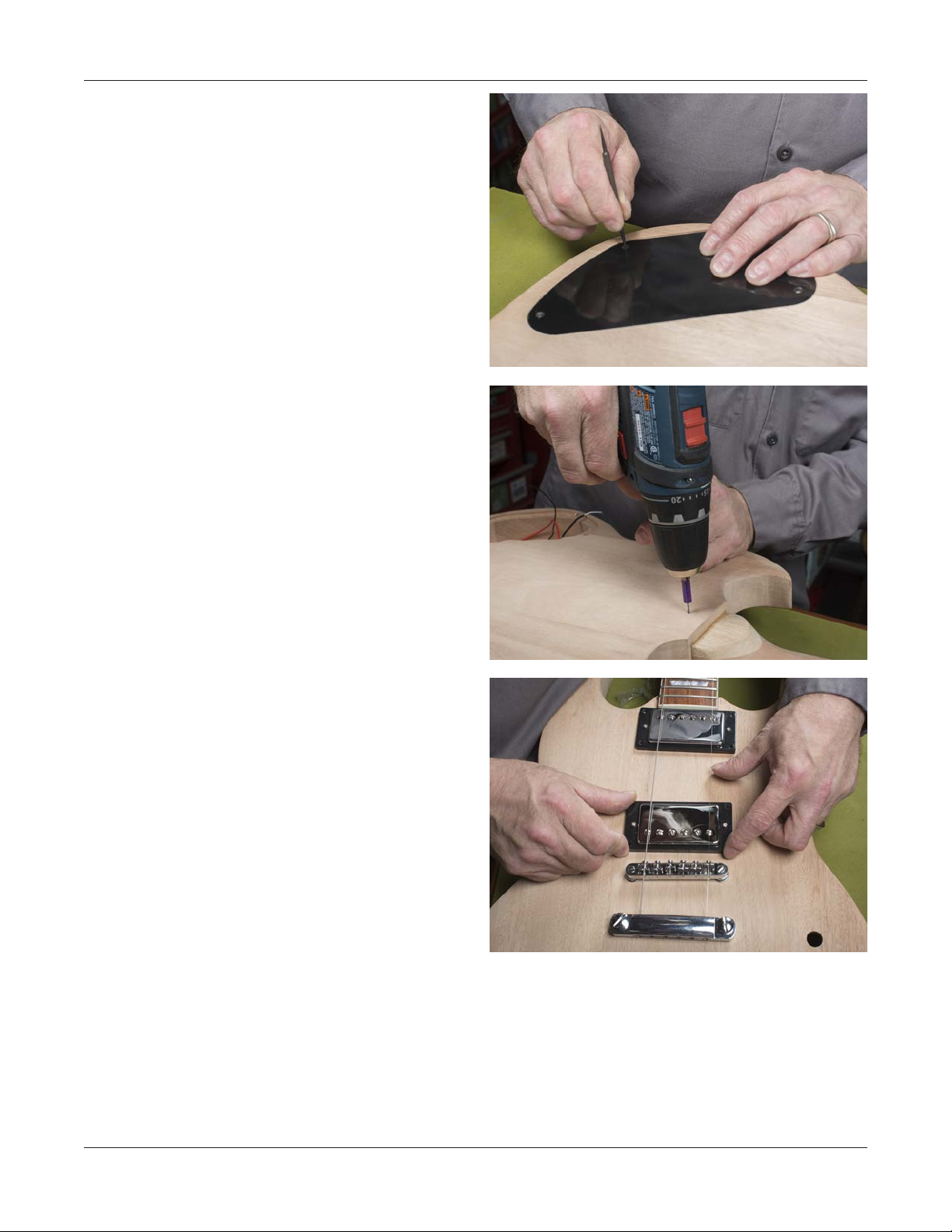

Drill for cover plates and pickguard

Use a sharp point, such as a scribe (#1672), to mark out the

mounting holes for the control cavity cover and truss rod

cover. Then, drill pilot holes for the screws using a 1/16" bit

stopping at 3/8" deep. Next, center the truss rod cover over

the truss rod cavity and mark it out. Using a 1/16" bit, drill

holes 3/16" deep.

Install the strap buttons

Mount the tail strap button. The top button screws into the

back of the body, just beyond the heel. Drill a 3/32" pilot

hole, 1/2" deep.

Install the pickups

Drop the bridge and neck pickups in place. The pickup with

the taller mounting ring is the bridge pickup, the pickup with

the short mounting ring is the neck pickup.

Install the tune-o-matic bridge and tailpiece. String up the

low and high E strings from the generic string set, to use as

reference.

Line up the neck pickup so it is square to the end of the

fretboard and the E strings are evenly above the polepieces.

Mark the locations of the holes.

Now carefully line up the bridge pickup to make sure it is

square to the neck pickup, temporarily positioning the pick-

guard in place will help with this step. After you've marked

the holes, remove the strings and pickups. Then drill the

holes with a 1/16" bit, 3/8" deep. Install the pickups. After the

pickups are mounted attach the pickguard with the same

bit and depth mentioned above.

Assemble your guitar

stewmac.com 11

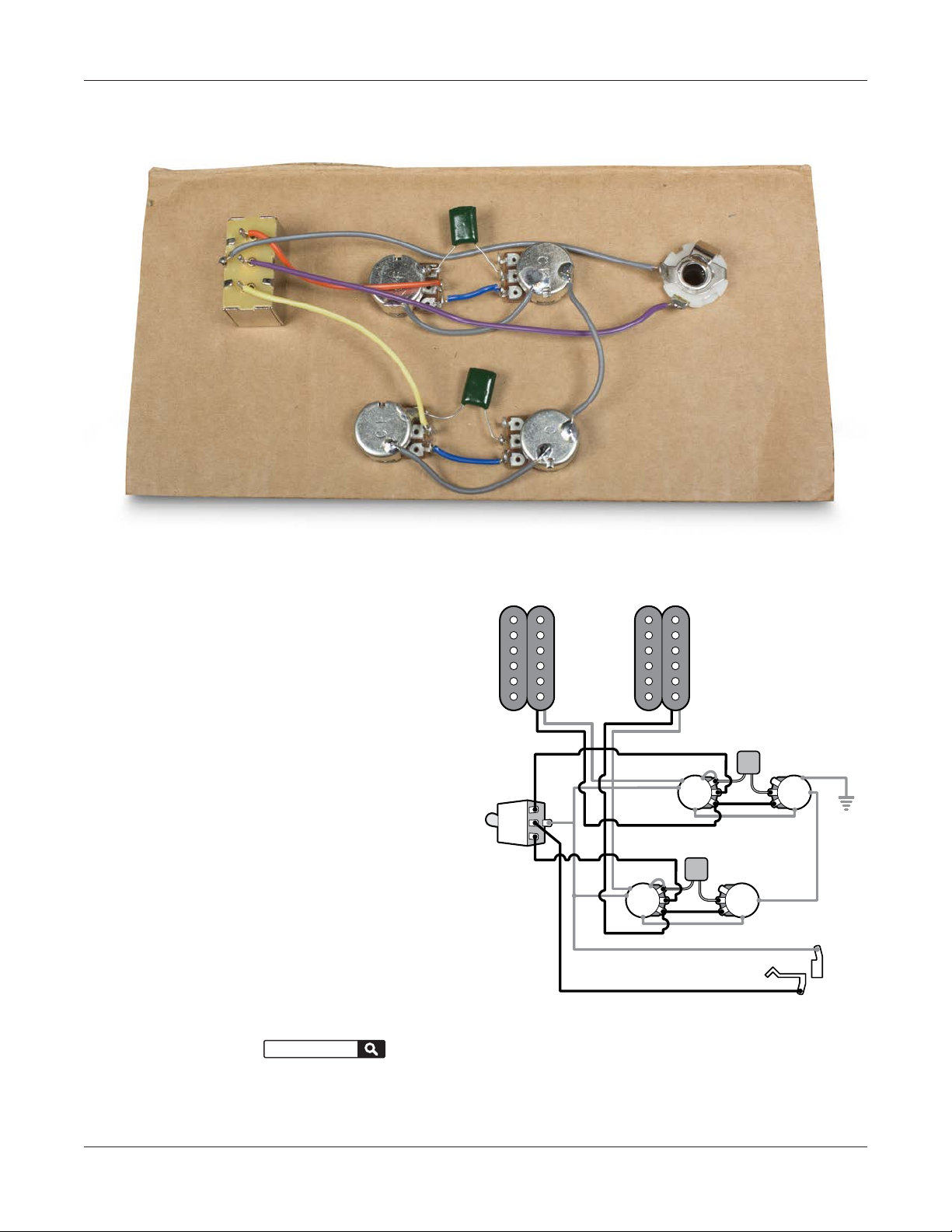

Wire the electronics

stewmac.com search: ts186

This kit comes with 9.5" and 5.25" lengths of hookup wire,

more than enough wire than you'll need but it gives you

plenty of extra in case something accidentally gets cut too

short. The longer lengths are for running the string ground

and output jack, the shorter for connecting the pots and

switch.

Make a cardboard template that matches the hole pattern

of the controls for proper parts spacing and easy soldering.

There are two different taper control pots included, 2 A500k

pots for volume and 2 B500K pots for the tone controls. Peel

the wires apart and cut to length giving yourself a little slack

between components. Strip about 1/8" of the insulation off

of the ends of each wire, twist each end tight then coat them

with a little solder; this is called “tinning”. Tinning the wire

ends as well as the lugs on the switch, pot, and jack will help

your solder joints flow together quicker and cleaner.

Solder up your circuit following the wiring diagram to the

right.

For help with soldering, see our Trade Secrets video #186

“How to get a good clean solder joint!” at stewmac.com.

Output

jack

Toggle

switch

Neck

Out

Bridge

Ground

Ground

to bridge

Neck

V

Neck

T

Bridge

V

Bridge

T

.022μF

.022μF

Neck Bridge

NV

BV BT

NT

stewmac.com

12

Final setup

Adjust the neck

Install the remaining generic strings.

Neck relief refers to adjusting a neck so that it has a very slight

upbow, rather than being perfectly straight. This relief allows

a little more room for string vibration, reducing the chance

of hitting the lower frets and causing fret buzz.

Depending on your playing style, and how perfectly level

your fret tops are, a neck should be anywhere from perfectly

straight to having 0.012" of relief. This measurement refers

to additional string height over the 12th fret, compared to

a perfectly straight neck.

A straight neck tends to play and sound better, but very few

guitars end up with no relief at all, and several thousandths

of an inch or more is perfectly normal.

You can use a straightedge or the low E string to get you in

the ballpark. Using your index finger, hold down the E string

at the first fret. With the other hand, hold down the string at

the 17th fret with your thumb and use your index finger to

check for relief. The smaller the gap between the bottom of

the string and the top of the frets, the straighter the neck.

Lower the nut slots

Once the neck is adjusted to the desired straightness, the

nut slots will need to be lowered for the best playability.

Measure the gap between the bottom of the string and the

top of the 1st fret.

A comfortable medium action over the first fret is .012" for

the plain strings (G,B,E), and .020" for the wound strings

(E,A,D).

Use feeler gauges to measure the gap or use guitar string

scraps whose gauges match the measurement you are shoot-

ing for. Using just a few file strokes at a time, stop filing when

the string sits on the top of your feeler gauge, whatever it

may be. Take your time and check your work frequently. It

is easy to go too far lowering the slots thus ruining the nut.

Turn the truss rod nut

counterclockwise to bring

the neck up, adding relief.

Measure string relief

at the 12th fret.

Turn clockwise to pull the

neck back, reducing relief.

Go slow: a little does a lot!

stewmac.com 13

Set the string height

Adjust the bridge action using the thumbwheels on bass and

treble sides. Measure the gaps between the bottom of the

low and high E strings and the top of the 12th fret.

Factory action for the high at the 12th fret is 1/16" for the

high E string, and 5/64" for the low E.

Adjust the pickup height

One at a time, hold the low and high E strings down at the

22nd fret.

Adjust the neck pickup to 1/16" between the bottoms of the

low and high E strings and the top of the pole pieces. Adjust

the bridge pickup to 3/32".

Set the intonation

The last step is intonating the guitar by adjusting the string

lengths at the bridge saddles. This will help ensure that the

guitar plays in tune all the way up the neck.

Remove the generic strings and install the higher quality set.

Tune the strings to pitch using a strobe or other accurate

tuner. Then, press the high E string lightly at the 12th fret

with just enough pressure on the fret to sound the note.

Check it with your tuner.

If the note reads flat, the saddle needs to be adjusted forward

towards the nut, shortening the length of the string. If the

note reads sharp, the saddle needs to be adjusted back away

from the nut, increasing the string length.

stewmac.com

14

You’re done!

Congratulations!

Your guitar is now ready for finishing. We hope this guitar

will be the first of many that you have fun assembling and

customizing. For detailed information about applying a

great looking finish check out our book Guitar Finishing

Step-By-Step.

Be sure to get a gig bag or case, so it doesn’t get banged

around!

21 N. Shafer St • Athens, Ohio 45701 • USA

USA & Canada call toll-free: 800-848-2273

9am-6pm weekdays Eastern time

stewmac.com

Table of contents

Other StewMac Musical Instrument manuals