StewMac OFFSET TREM User manual

making guitars better

Sheet #i-6267 Updated 01/22

Assembly Instructions

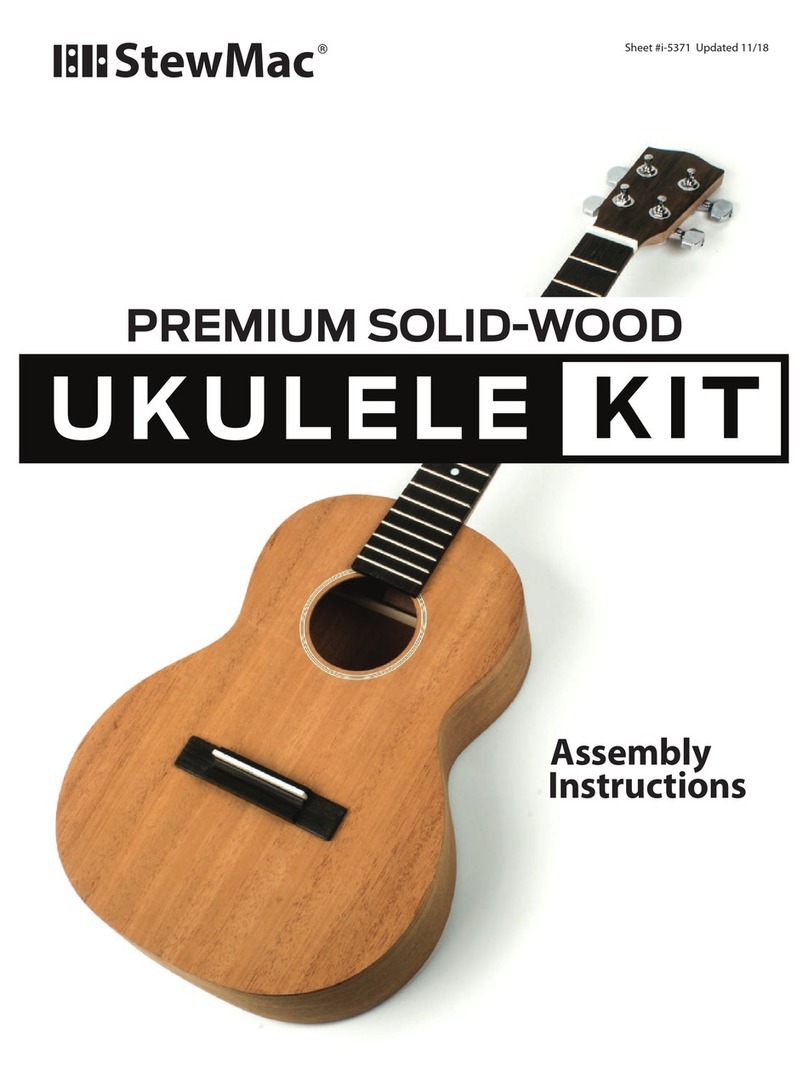

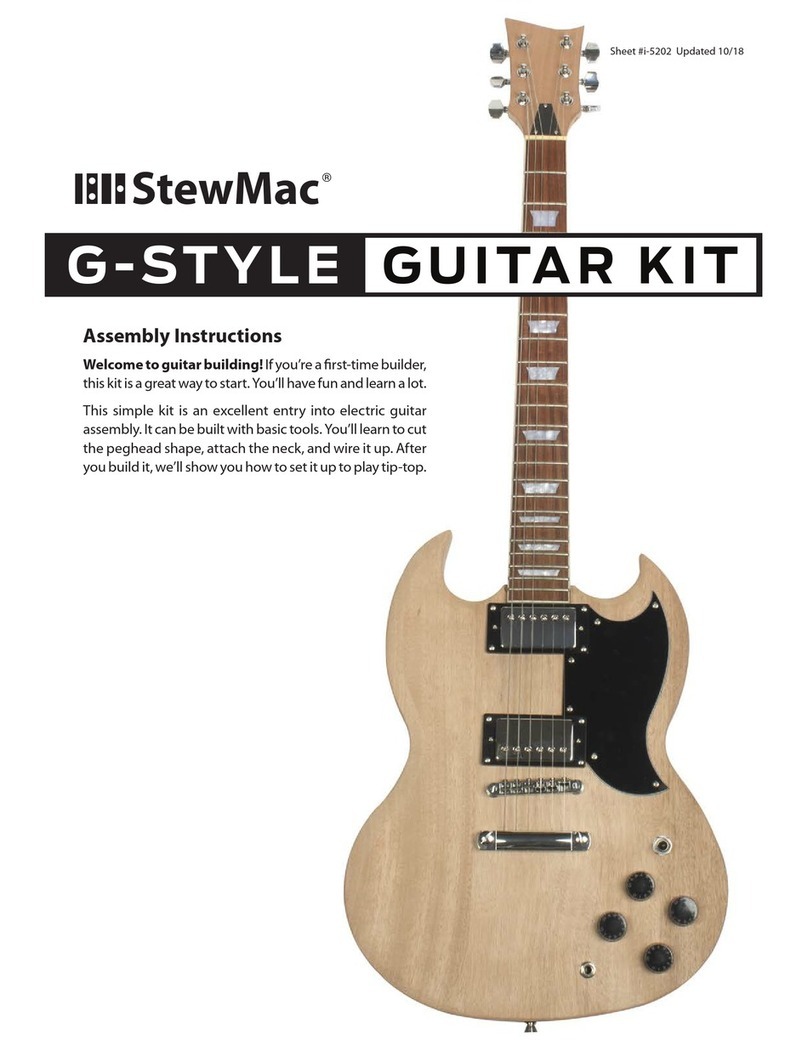

Welcome to guitar building! If you’re a first-time

builder, this kit is a great way to start. You’ll have fun

and learn a lot.

This simple kit is an excellent entry into electric guitar

building and can be made with basic tools. You’ll learn

to cut the peghead shape, attach the neck, and apply a

nish. After you build it, we’ll show you how to set it up

to play tip-top.

OFFSET TREM GUITAR KIT

stewmac.com

2

Tools and supplies..................................... 2

Getting started ....................................... 3

Parts list .............................................. 4

Create your peghead shape ........................... 5

Prep the neck ......................................... 6

Prep for nish ......................................... 8

Spray the nish ....................................... 9

Assemble your guitar .................................12

Final setup ............................................15

These are the tools and supplies we recommend for

assembling this kit. Stewmac item numbers are included

where applicable.

Tools

Electric hand drill

Foam sanding block (#3701 or 3699)

Fretting hammer (#4895)

Phillips screwdrivers, size #1 & #2 (#3000)

Center punch or awl (#3000)

Drill bits:

1/16" (#1710)

5/64" (#1712)

3/32" (#1714)

1/8" aircraft extension bit (#4840)

10mm nut driver (#5890) or wrench (#3691)

Nut-slotting les:

0.013" width (#0823)

0.020" width (#0828)

0.035" width (#0832)

Saw for peghead: bandsaw, jigsaw, or coping saw

14" radius sanding block (#0407)

Fret dressing le (#1602)

Ruler (#4905)

Straightedge (#3849)

Feeler gauges (#1811)

Soldering iron (#0502 or #0507)

Tremolo spring installer (#0579)

Supplies

Sandpaper: 150, 220, 320, 400 grits (#5562)

Light Duty 3M Scotch-Brite Pad (#7445)

or 0000 steel wool

Naphtha solvent (#0775)

Gloves

Blue permanent marker

Masking tape (#0692)

Double-stick tape (#2711)

Solder (#0505)

Finishing supplies

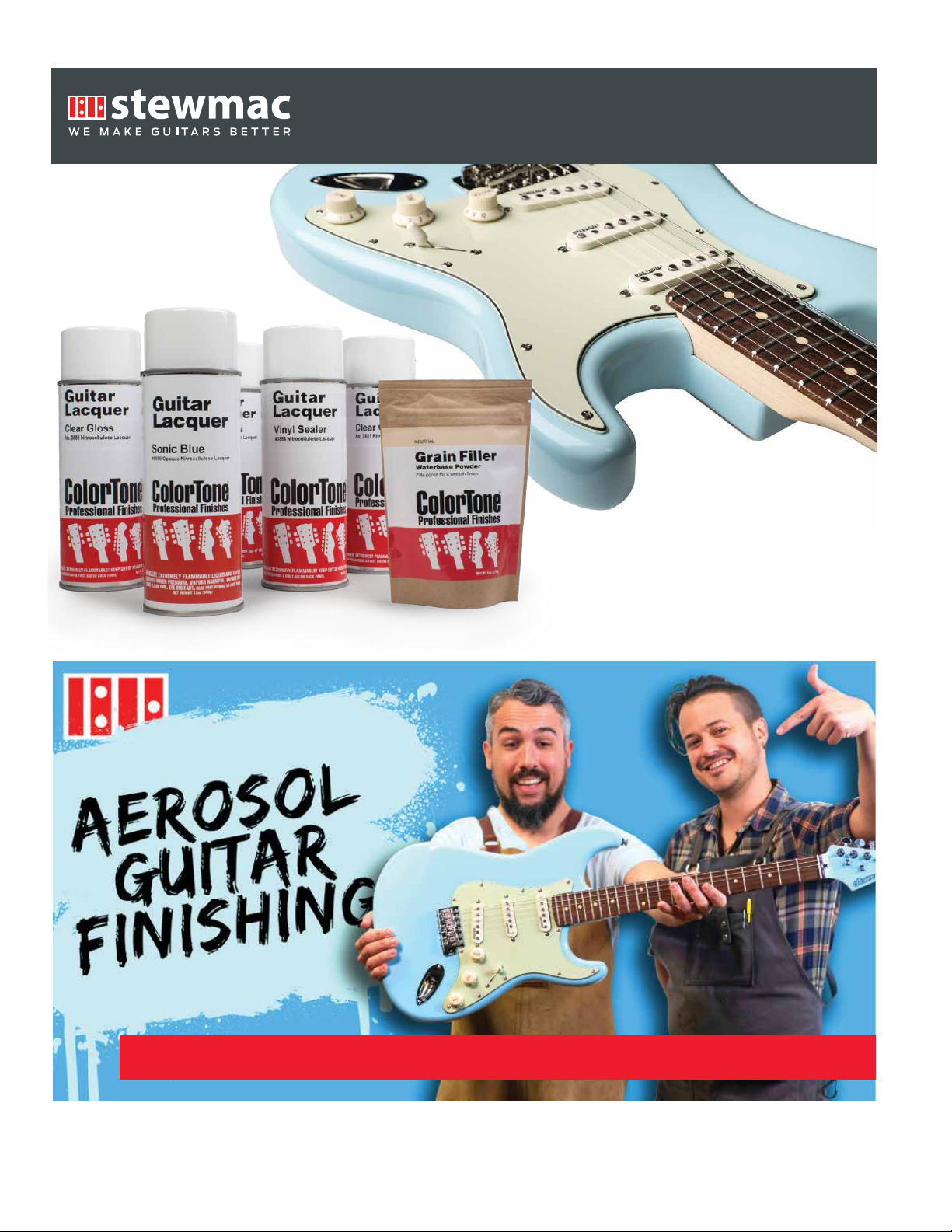

There are many nishes and application methods to choose

from. We use ColorTone Aerosol Guitar Lacquers because

they’re easy to use and you can get a beautiful nitrocellulose

nish without investing in spray equipment.

Here's a suggested list of the basic aerosol nishing

products you will need to nish your kit:

ColorTone Powdered Grain Filler, Neutral (#0269-N)

ColorTone Aerosol Guitar Lacquers:

1 can Sanding Sealer (#3883)

1 can Aged Clear (#5887)

1 can of the color coat of your choice (optional)

2-3 cans of Clear Satin (#3882)

Tools and supplies

Table of contents

stewmac.com 3

Getting started

While you’re probably excited to get started, you need to

take a little time to acclimate your kit. Wood can be extremely

sensitive to changes in humidity and temperature. The ideal

building environment is 70-80° Fahrenheit (21-26° Celsius),

with a controlled relative humidity of 45-50%. The woods in

your kit should be laid out and allowed to acclimate in your

shop for at least a few days before you start your build. Flip

the wood daily to neutralize excessive warping.

Depending upon your location and the season, you may

need to humidify or dehumidify your shop to maintain

the desired relative humidity. We advise you to purchase a

decent quality thermometer/hygrometer to monitor your

shop’s climate. Radical changes in humidity, especially

during season changes, can cause warping, splitting, and

other serious complications. If you’re unable to control the

relative humidity in your shop, we discourage building the

guitar during the transition from dry to wet seasons, or vice

versa.

You’re going to put a lot of love into this build, and paying

attention to the climate conditions while doing so is well

worth it.

Always use eye protection, and wear gloves while

working with glues and chemicals.

We wish you all the best on your build. If you get stuck or

have any questions along the way, contact us. We’re here

to help.

The oset-body guitar has been a staple of indie music since

its introduction in 1958. This oset kit breaks the mold by

adding P-90 pickups and a vintage-style six-screw tremolo

to those unmistakable curves. Tonally, it’s warm and thick,

with a tempered bite that shows up when you need it.

Countless famous names have reached for this body style to

craft their sound, including Elvis Costello, Nels Cline, Ric Oc-

asek, Robert Smith, Marcus Mumford, Jim Root, Thom Yorke,

Samantha Fish, Troy Van Leeuwen, and Chris Stapleton.

This kit makes creating your own oset-body guitar easier

than ever. You don't need production tools for shaping

the body, fretting the neck, or machining the neck joint.

The control pots and input jack are even pre-soldered! The

complicated steps are done, which allows you to focus on

the handwork of building.

The kit is made for the small shop builder with a modest tool

budget. With the exception of a few essential guitar-making

tools, you probably already own most of what you’ll need

to build this guitar.

Before you start

We strongly recommend you read all of this book before you

start building your kit. Understanding the later steps now

will be helpful to you as you start to build.

Also note that some photos in these instructions may

depict guitars with dierent woods or appointments, but the

building techniques shown are the same for your kit.

stewmac.com

4

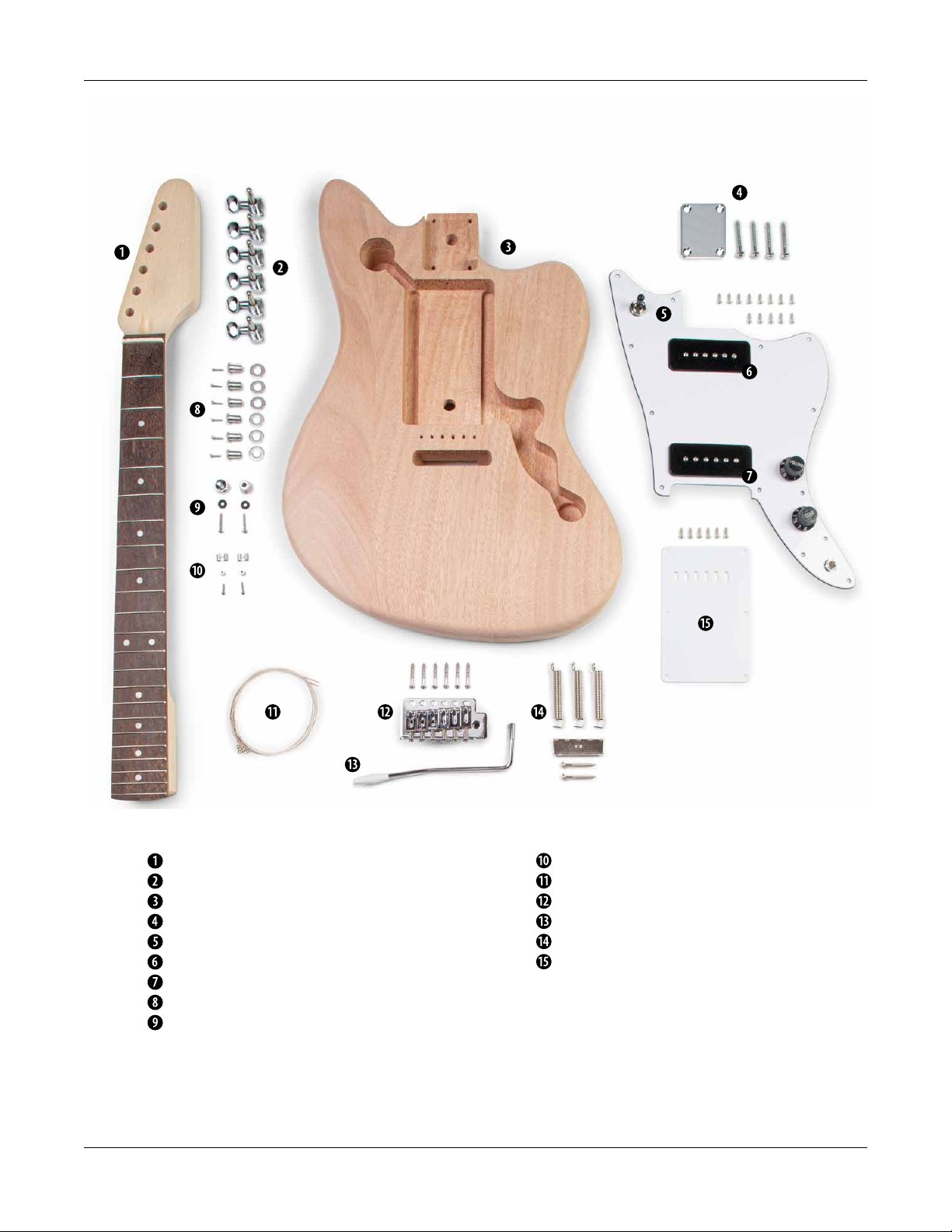

Parts List

Neck

Tuners

Body

Neck plate and attachment screws (4)

Pickguard with switch, pots, and mounting screws

Neck pickup

Bridge pickup

Tuner bushings, washers, and screws (set of 6)

Strap buttons with screws and protective washers (2)

String retainers with screws (2)

Strings

Bridge with mounting screws

Tremolo arm

Tremolo springs, claw, and screws (2)

Tremolo cavity cover plate and screws (6)

Parts and materials may vary.

stewmac.com 5

Some kits may ship partially assembled. If your kit arrived

with the neck and any hardware attached, remove it before

getting started.

You can leave the peghead shape as-is, trace a favorite

peghead, or come up with a look all your own. You’ll be

cutting your design from the blank peghead on the kit’s

neck.

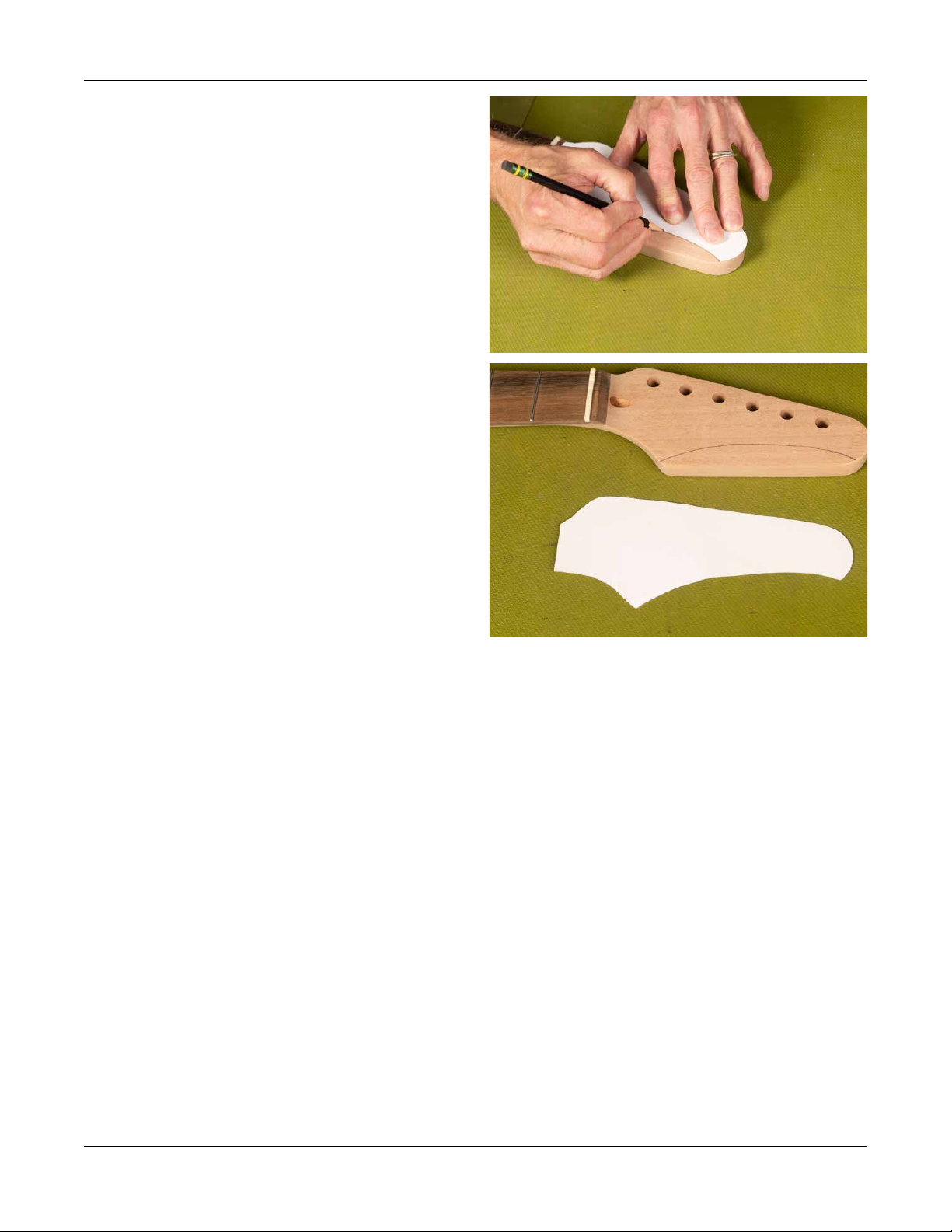

Make a paper template

Sketch out your peghead design on a piece of heavy paper

and cut it to shape with scissors. Using a pencil, trace the

shape onto the peghead. Use a light touch that doesn’t

dent or compress the wood which could make sanding

out any unwanted lines dicult. Don’t use ink, because it

leaves permanent stains that can bleed up even through

an opaque guitar nish.

Cut the peghead to shape

It’s important that your saw stays square to the face of the

peghead while you cut. If it tilts to an angle, you’ll get a

sloppy result that takes a lot of sanding to correct. Use a

bandsaw if you have one; a jigsaw is also good. A hand-held

coping saw can also be used, but it’s tough to hand-saw

smooth clean curves.

Never cut on the line

Always cut just outside the line, so you can sand to the line

afterward. Smooth your saw cuts to create your peghead

shape using rasps, les, and sandpaper. Don’t rush; rough

patches will disappear into a good nal shape if you take

your time.

When you’re happy with your peghead shape, sand it

smooth using 150-grit sandpaper followed by 220-grit,

then 320-grit.

Create the peghead shape

stewmac.com

6

Prep the neck

Note: If your kit has a maple fretboard, skip to the Prep

for Finish and Finishing sections on pages 8 and 9. After

nishing, return to this Prep the Neck section and proceed

as shown.

Straighten the neck

Use the 4mm hex wrench to adjust the truss rod. With a

straightedge on the frets, adjust the truss rod until the

straightedge touches all of the fret tops without rocking.

Turn the truss rod nut counterclockwise (viewed from the

peghead end) to loosen the truss rod, allowing the neck to

bow upward. Turning it right tightens the rod, pulling the

neck back.

For more information, see our Trade Secrets article “Don't

be nervous about adjusting that truss rod!” at stewmac.com.

Seat the frets

The frets come installed in the fretboard, but they’ll need

a little work to achieve the best playability. Use a fretting

hammer to make sure the frets are all seated properly. The

more even your frets are, the less leveling there is to do later.

After seating with the hammer, check for any high spots

across the frets—a short straightedge or a Fret Rocker work

well for this. Spanning three frets at a time, work down the

neck. If the tool rocks, you have a high fret. Knock down the

high frets you encounter with a le or Fret Kisser. Taking care

of these high spots now will prevent your leveling tool from

hanging up on them when sanding and will give you a more

even overall leveling job.

With the hammer handle running parallel to the frets, start at

one end of a fret and work your way across using light taps

that are square to the face of the hammer. Use care not to

edge of the hammer head as it can cause a bend in the fret,

making it dicult to seat properly.

The idea is to use light taps, just enough to seat the frets

ush to the fretboard. Hitting too hard can make a slight

kink in the fret that can cause the ends to spring and be

dicult to reseat. Using a heavy hand can also damage the

fretboard by driving the fret down into it. A drop of super

glue works well for keeping stubborn frets in place.

stewmac.com search: ts0033

Turn the truss rod nut

counterclockwise to bring

the neck up, adding relief.

Measure string relief

at the 12th fret.

Turn clockwise to pull the

neck back, reducing relief.

Go slow: a little does a lot!

stewmac.com 7

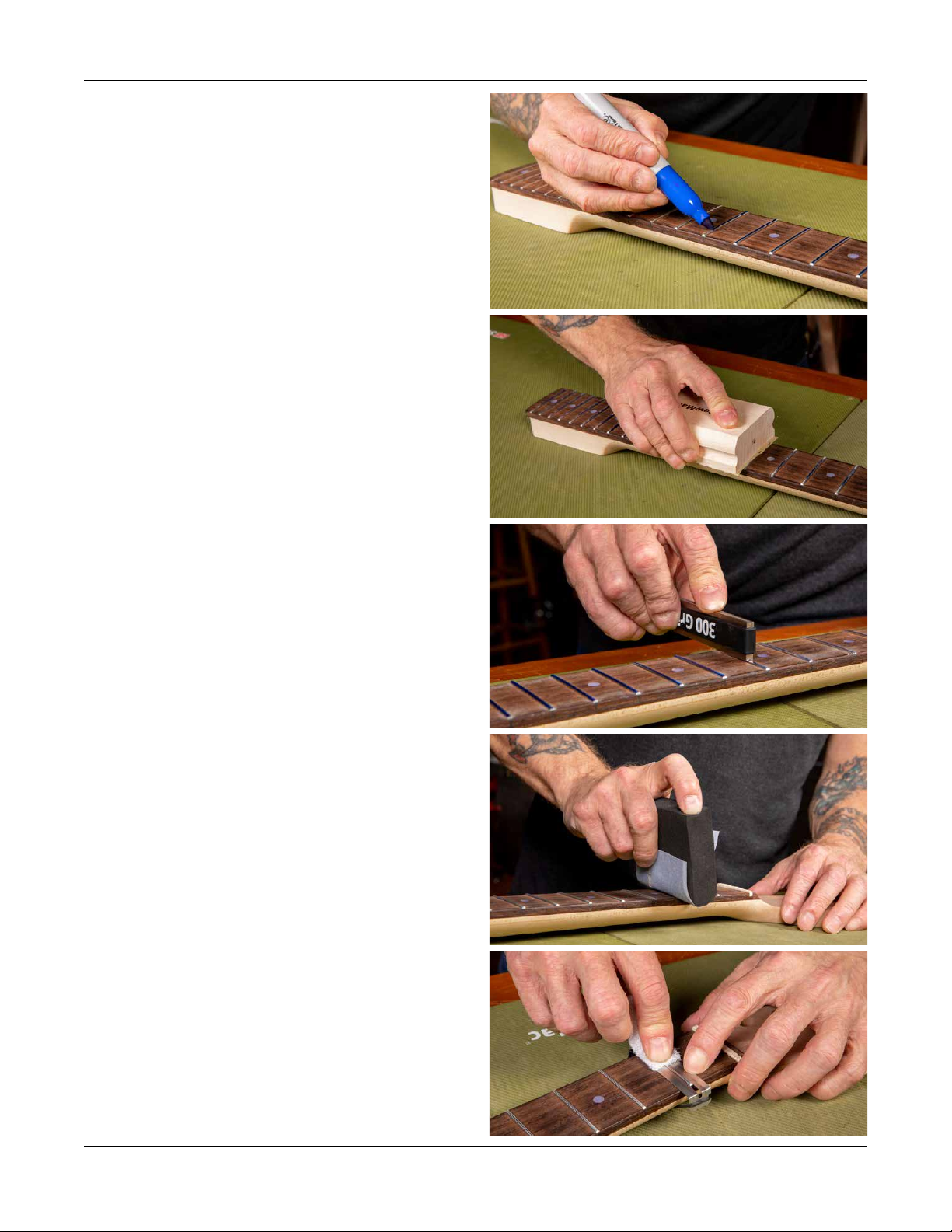

Level the frets

Color the fret tops with a blue permanent marker to

prepare them for leveling. The blue ink will show your

sanding progress.

Use double-stick tape to attach 320-grit sandpaper to the

14" radius sanding block. With this, level the frets by using

full-length strokes down the fretboard. Work slowly and

check every few strokes to monitor progress.

The frets are level when the blue ink is removed from the

fret tops. The idea is to remove as little material as possible

while still achieving a completely level fretboard.

Recrown the frets

Leveling will leave at tops on the frets. Using a fret crowning

le will restore the rounded look of the frets and improve

your guitar’s intonation.

Reapply blue marker to the fret tops. Using the crowning

le of your choice, work the le side to side to re-round the

top of the crown until the remaining atted top is a very

thin line. Don’t remove this line entirely; ling the fret tops

would undo your leveling job.

Sand the frets with 400-grit, then 600-grit sandpaper

wrapped around a foam block, running up and down the

entire length of the fretboard. Follow up with Light Duty

Scotch-Brite Pads or 0000 steel wool for a nal nish. This

will remove any of the remaining lacquer from the frets and

polish them to a smooth nish.

stewmac.com

8

Prep for nish

Preparing the neck and body for nish is just as important, if

not more important, than the nal spray. The key to a great

looking nish is patience and lots of it. Be thorough with

your sanding and follow the nishing schedule on page 9

for best results.

Inspect the body and neck for any dents, chips, or other

imperfections and repair them. Small dents can be steamed

out by placing a damp cloth over the dent and applying heat

with a soldering iron. To learn more, see our Trade Secrets

video #0317 “Fixing a guitar dent by steaming it out” at

stewmac.com.

Chips and knotholes will need to be lled. Remove the bridge

if you haven’t already and set it aside.

Fill the grain

If your kit has an open grained wood, such as mahogany or

ash, the grain will need to be lled before nishing in order

to achieve a at surface. As a general rule, if you can see the

pores of the wood with the naked eye, you should use grain

ller before nishing.

WesuggestusingourNeutralColorTonePowdered GrainFiller

following the instructions below. Three applications are

recommended to get a nice at surface to build nish coats

over. Tight grained woods such as alder and poplar do not

need to be lled.

ColorTone Powdered Grain Filler is supplied as a ne powder,

ready to mix with water (a 1:2 ratio of water to ller works

well). Mix thoroughly until you have a smooth consistency,

without any lumps.

Prepare surface by sanding to 220-grit. Remove all dust, oil,

and solvents from the surface.

Apply the ller liberally in the direction of the grain, then

against it. Allow to dry for 5 to 10 minutes depending on

thickness of the ller.

Use a grain ller spreader or plastic card to squeegee o any

excess. Wipe at a 45° angle to the grain.

When dry, wipe o remaining residue with a clean dry cloth.

Sand the surface with 320-grit sandpaper. Clean up with

warm water.

Sand the body and neck

Run your ngers lightly along the edges of the fretboard

and feel for sharp fret ends. If the frets feel sharp where they

meet the edge of the neck, gently sand them back with long

strokes down the length of the neck. Use care not to sand

the top of the frets and fretboard or change the bevel of the

frets in the process.

After a complete sanding, wipe down the body and neck

with a damp cloth to raise the grain to reveal bers that need

more sanding. Let the wood dry, then sand the raised grain

with 220- grit sandpaper. After sanding, raise the grain again

and sand a third time, using 320-grit sandpaper.

Slightly break and soften any sharp edges on the fretboard,

peghead, and body around the neck pocket. Softening hard

edges promotes even nish coverage. Later, when you’re

lightly sanding between coats of nish, these edges are less

likely to sand through to bare nish.

Wipe the neck with a damp cloth to raise the grain. After it’s

dry, sand it again with 320-grit.

Degrease with naphtha

When you’ve nished sanding, wipe the body and neck with

a naphtha-dampened rag to remove any oils or grease. From

this point on, wear clean gloves when handling so you won’t

contaminate the wood.

For rosewood or dark wood fretboards, tape o the string

nut and the fretboard face before spraying so it remains

free of nish.

stewmac.com search: ts0317

stewmac.com 9

Spray schedule with ColorTone Aerosol Lacquer

This nishing process can be completed in as little as three

days, followed by a week of curing. Remember that patience

is the key to a successful nish job. Don’t rush it! Spray the

lacquer using light passes to prevent runs.

Day 1

Body: Spray 1-3 coats of aerosol Sanding Sealer on the body,

waiting 1-2 hours between coats.

Neck: Spray 1-2 coats of Clear Satin lacquer, allowing 1 hour

between coats. Follow this with 1-2 coats of our Aged Clear

lacquer for a warm maple color. Wait 1 hour between coats.

Note: If your fretboard is maple, you will be spraying over

the entire neck, including the frets. Finish will be removed

from the frets during the leveling and dressing process after

it has cured. The nut will be taped o to keep it unnished.

Any excess overspray can be scraped away after nishing.

Allow the body and neck to dry overnight.

Day 2

Body: Spray 2-3 coats of color (optional), allowing 1 hour

between coats.

Body and neck: Spray 3-4 additional coats of Clear Satin, 1

hour apart.

Allow to dry overnight.

Day 3

Body and neck: Lightly sand the body and neck with 400-grit

paper to remove any nish spatter or dust.

Spray 3-4 additional coats of Clear Satin, 1-2 hours apart.

Allow the nish to cure for a week in a cool, dry room. Around

70° at 50% humidity is recommended.

After the nish has dried for 1 week, go over the entire

instrument lightly with Light Duty 3M Scotch-Brite Pads or

0000 steel wool for a nice satin appearance.

There are many nishes and application methods to choose

from. In creating these instructions, we’re using ColorTone

Aerosol Guitar Lacquers. These aerosols are a fast way to

build a quality nish.

Using a clear satin topcoat is recommended, because satin

doesn’t require much sanding or bung the way gloss does.

If you choose to spray a glossy nish, it will involve more steps.

For help with that or any kind of nish, see our book, Guitar

Finishing Step-By-Step (#5095).

Use scrap wood to make a spray handle. Mark and drill holes

in the handle that align with the holes in neck pocket of

the body. Use two bolts and nuts to temporarily attach the

handle to the body. Drill a hole in the other end of handle

and bend a thin metal rod into an S-shape to hang the body

and neck during spraying or while drying.

A brushed-on nish like tung oil, waterbase lacquer, or

shellac works great too. Any of these nishes will seal and

protect the wood from dirt and moisture.

The best advice for nishing: practice on scrap!

Test your nish of choice on scrap wood rst, so you can see

what you’ll get before applying it to your guitar.

Use warm lacquer, not cold. Professional nishers spray

heated lacquer because cold lacquer spatters, requiring extra

sanding. Warm up your aerosols before spraying by placing

the cans in a sink of warm tap water.

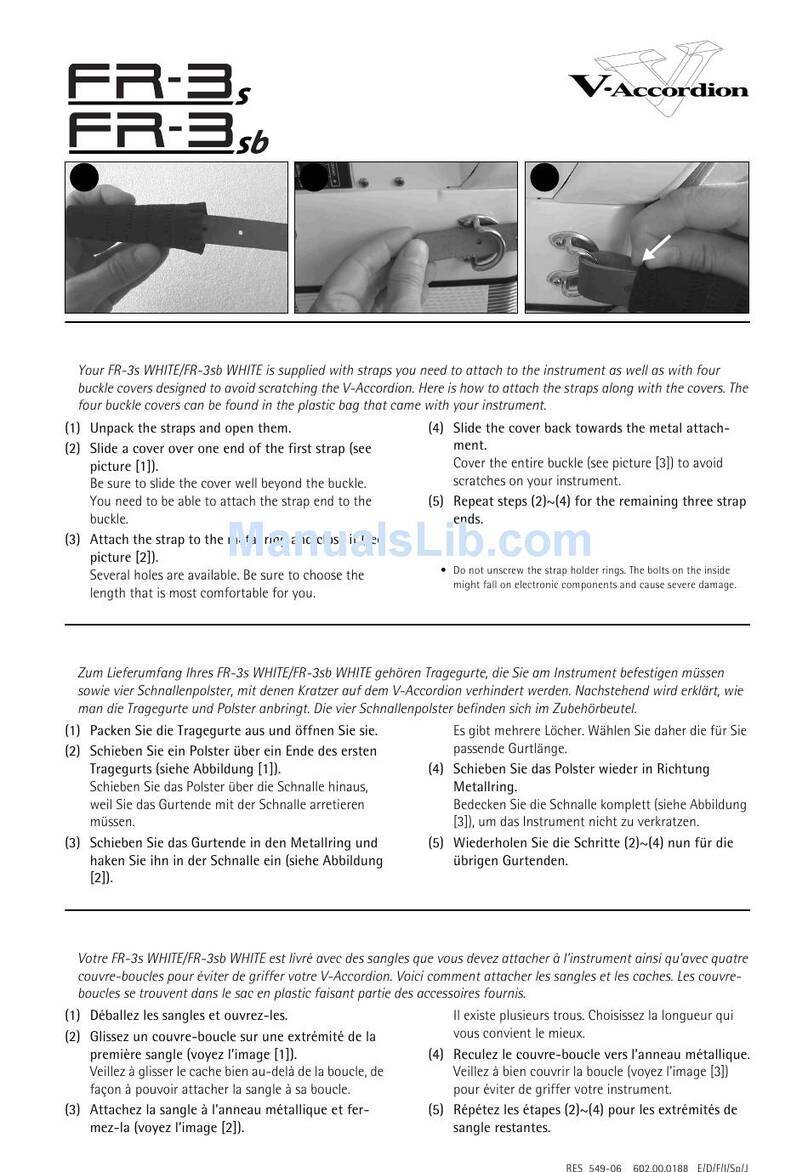

When spraying, keep the spray parallel to the surface of the

guitar for even coverage as shown below.

Spray the nish

The right way to spray: Move in a straight line, so the distance

from the work stays the same. This gives you even coverage.

Keep your

wrist exible

Sti wrist

The wrong way: Swinging in an arc moves the spray closer and

farther from the work. Center coverage is heavy, edges are light.

FRET KISSER

Locate and spot level high frets in an instant. What was a several hour job can be done in no time at all,

you only file exactly where it’s needed.

GAUGED NUT SLOTTING FILES

Precisely sized files for round-bottom string slots

on the nut and bridge saddles.

GUITAR TECH WRENCHES

Fit jacks, pots, switches, bridge studs…just about

every wrench you need for guitars and amps.

BY DAN ERLEWINE

From basic maintenance to advanced

repairs, this is the leading step-by-step

manual for every guitar owner.

RADIUS SANDING BLOCKS

For fingerboard prep and leveling frets too. Just

add sandpaper.

GUITAR BENCH PAD

Supple and dense non-slip surface for your guitar.

GUITAR TECH SCREWDRIVER SET

36-bit set specifically for guitar hardware, all in a

compact no-spill case.

TOOLS FOR A BETTER BUILD

MICRO-MESH FOAM SANDING BLOCK

Dense yet flexible, a great all around backer for

sanding, polishing, and fretwork, too.

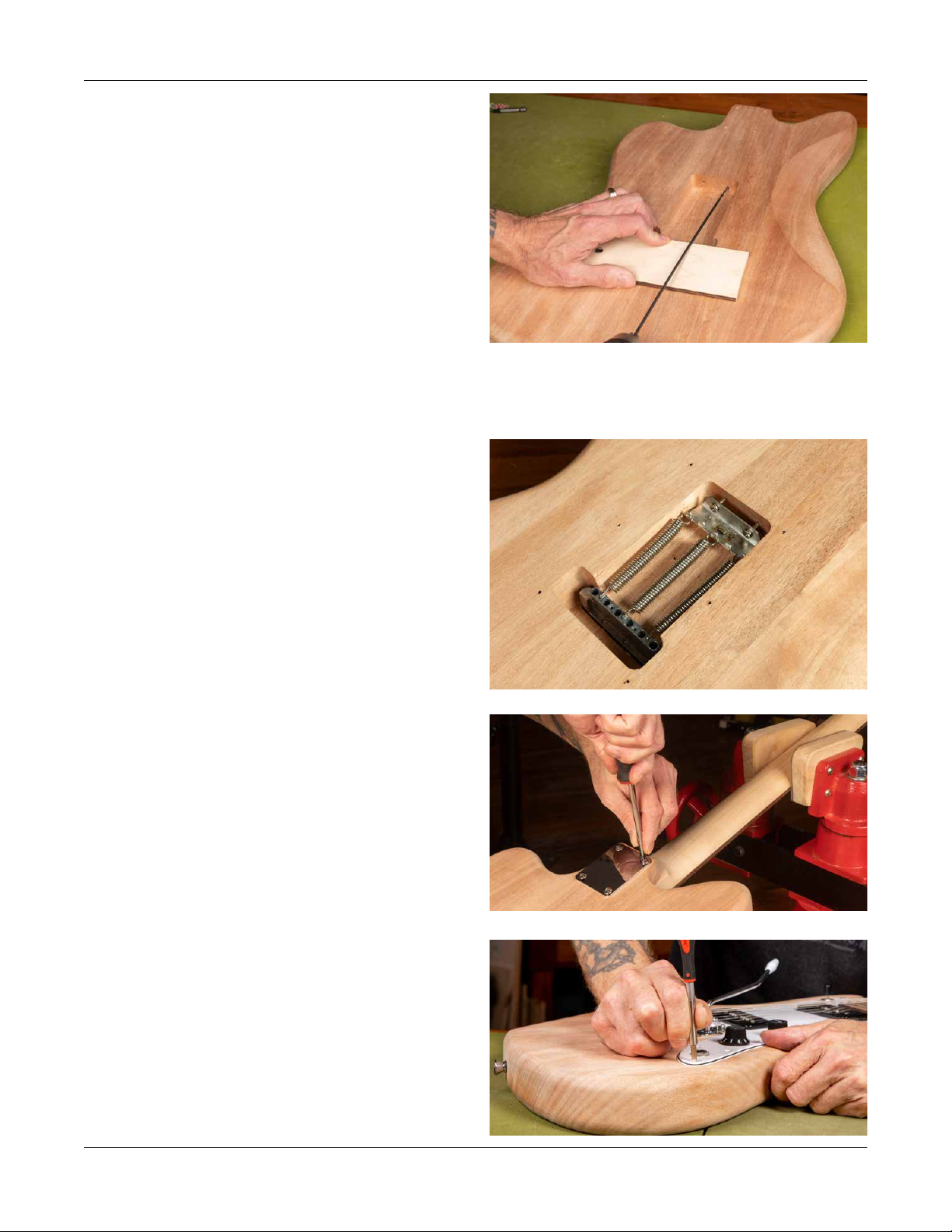

A FINISH YOU CAN DO AT HOME

FREE

FREE

STEP-BY-STEP COURSE

stewmac.com/aerosol-guitar-finishing

COLORTONE AEROSOL GUITAR LACQUER

Whether it’s a vintage sunburst you’re after, or a faded gold-

top, ColorTone’s line is filled with tints, solids, and metallics

that are formulated to the iconic guitar finishes we love.

You really can

get a pro quality

guitar finish

from a can!

Get a pro-quality finish (or refinish) on your next guitar! In this 3-part series we show you exactly what you need to do to get a professional-quality

guitar finish at home using aerosol lacquers. The results are pretty amazing!! This series covers every aspect, all using nitro aerosol finishes. It’s perfect

for anyone—no experience necessary! You really CAN get a pro-quality result (even on your first try) if you follow these steps.

stewmac.com

12

Assemble your guitar

Use a padded surface during assembly to protect the nish

from scratches and dents.

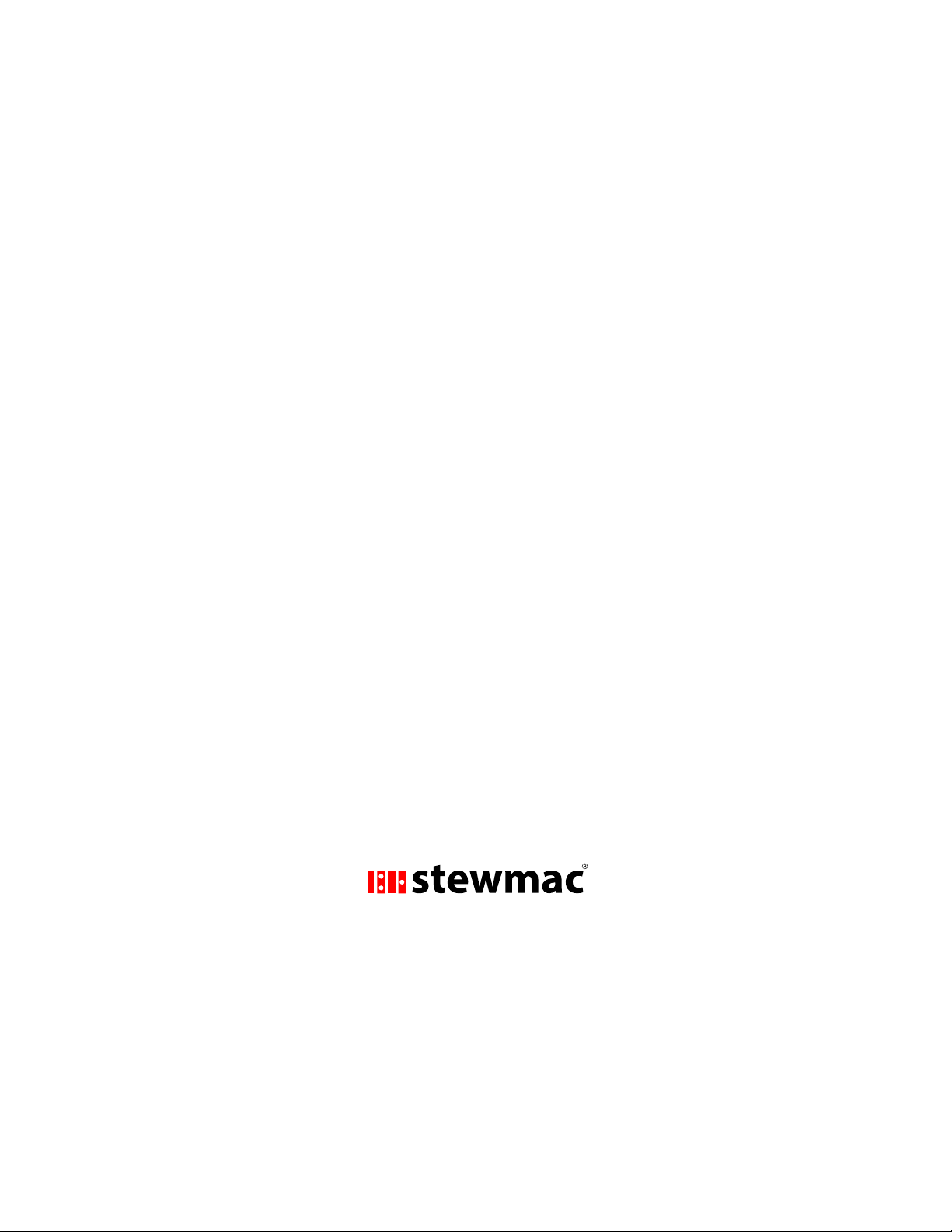

Install the tremolo spring claw

The spring claw must be attached to the body before the

bridge can be installed. Center the claw in the spring cavity

so it sits 1/16" below the surface of the body. Mark out the

mounting screw holes with a scribe or punch. Drill the screw

holes approximately 1-1/2" deep, with a 1/8" drill bit.

A long aircraft style bit works best for drilling these holes.

Place a shim of plastic or wood between the body and drill

bit to prevent damaging the nish.

For now, don’t tighten these screws against the cavity wall;

leave a gap of about 1/4". A small amount of thread lubricant

or bar soap on the ends of your screws will help them go

in more easily.

Install the bridge and tremolo springs

With a #2 Phillips screwdriver, install the bridge using the

six pivot screws. Don’t tighten them all the way down, just

enough so they sit just above the top of the baseplate, al-

lowing the plate to sit at on the body.

Connect the tremolo springs between the tremolo block

and the claw.

Attach the neck

The neck's fretboard extension overlaps the pickguard, so

the pickguard needs to be held in place—but not screwed

down—while the neck is installed.

Hold the pickguard in place temporarily with a rubber band

around the waist of the body (no screwing yet!).

Pilot holes in the neck and body are pre-drilled. Align the

neck plate to the back, and the neck in the pocket. Use a #2

Phillips screwdriver to insert the neck attachment screws.

Mark out the pickguard

Lay out the pickguard using the neck and bridge for refer-

ence. Once positioned, mark out the mounting screw holes

with a scribe or punch. Drill pilot holes for the screws using

a 1/16" drill bit.

stewmac.com 13

Install the pickups

Temporarily attach the pickguard to the body with a few

screws and place one of the pickups upside down into the

routs on the pickguard. The neck pickup has the letter “N”

stamped on the bottom. The bridge pickup is stamped “B”.

Run one of the mounting screws through the holes in the

pickup using light pressure to mark out the proper location

in the body. Note: you may need to press through the inner

wax coating to get the screws through the pickup.

Remove the pickguard and pickups. Drill pilot holes 1/4"

deep using a 1/16" drill bit.

Mount the pickups to the body. The springs packaged with

the screws are meant to go between the pickups and the

bottom of the pickup routs.

Wire the pickups

If the switch has lead wires attached, detach and discard

them. You'll connect the pickup leads directly to the switch

instead.

Trim the neck pickup lead to 7" long. (The neck pickup has

the letter "N" stamped on the bottom.)

Twist the strands of the braided shield together; this is the

pickup's ground lead. Heat this braid with your soldering iron

and melt a little solder into it. This is called "tinning" the lead.

Strip 1/8" of insulation from the white (hot) and tin it also.

Solder this hot lead to the switch's neck position lug—the

lug that's closer to the neck when the pickguard is installed.

Solder the braided ground wire to the side of the switch

body as shown.

Trim the bridge pickup lead to 9" long. (The bridge pickup

is stamped "B".) Tin the ground and hot leads as you did for

the neck pickup. Solder the hot lead to the switch's bridge

position lug, and solder the braided ground to the body of

the switch.

Feed the ground wire through the hole leading into the

spring cavity and install the pickguard.

For tips on soldering, see our Trade Secrets video #0186 “How

to get a good clean solder joint!” at stewmac.com.

stewmac.com search: ts0186

Neck

Lug

Bridge

Lug

stewmac.com

14

Install the strap buttons

Mark the locations of your strap buttons. At the tail of the

guitar, position the button in line with the center of the neck

and bridge. The other button is typically located on the tip

of the upper horn.

Drill 1/2" deep holes with a 3/32" bit, and install the strap

buttons with their protective washers.

Install the tuners

Lay out the tuners, using a ruler to make sure they’re in line

with one another and square to the edge of the peghead.

Mark out your mounting holes with a scribe or punch.

Tuner mounting screws are very delicate and will break o

if forced into the wood. Use a 5/64" drill bit to make pilot

holes for the screws; if these holes are any smaller you risk

shearing o the screw heads. Hold a screw up to the drill bit

and wrap tape around the bit to mark your depth. Lubricate

the screw threads by dragging them across soap or wax for

smooth installation.

With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver. On the tuner string post, add

a washer then the threaded bushing. Tighten with a 10mm

nut driver or wrench.

Install the string retainers

Install the included generic strings or your own preferred

brand of strings and mark the locations for the string

retainers on the peghead. These retainers maintain the

proper string angle over the nut for the D, G, B, and E strings.

Install the D/G string retainer between the E and A string

posts (approximately 2" from the nut).

Install the B/E string retainer between the A and D string

posts (approximately 3" from the nut).

Tune the guitar to pitch, and adjust the neck using the

included 4mm hex wrench.

Solder the string ground

The remaining black lead wire is for the string ground. Feed

this wire through the hole from the pickup cavity to the

spring cavity. Solder this ground wire to the spring claw.

Make sure to heat the claw well enough to get a good, solid

solder joint.

stewmac.com 15

Final setup

Turn the truss rod nut

counterclockwise to bring

the neck up, adding relief.

Measure string relief

at the 12th fret.

Turn clockwise to pull the

neck back, reducing relief.

Go slow: a little does a lot!

Set the action at the nut

Lower your string nut slots for better playability, using

gauged nut les. Measure string height over the 1st fret,

between the bottom of the string and the top of the fret.

A comfortable medium action is:

Unwound strings (G, B, E): 0.012" at the 1st fret

Wound strings (E, A, D): 0.020" at the 1st fret

Use feeler gauges to measure the gap. If you don’t have feeler

gauges, you can use a guitar string that closely matches the

size of the gap you are shooting for. Stop when the string

sits on your feeler gauge. Go slow and check your work fre-

quently—it’s easy to go too far in this step and ruin the nut.

Straight neck or a little relief?

Neck relief refers to adjusting a neck so that it has a very slight

upbow, rather than being perfectly straight. This relief allows

a little more room for string vibration, reducing the chance

of hitting the lower frets and causing fret buzz.

Depending on your playing style, and how perfectly level

your fret tops are, a neck should be anywhere from perfectly

straight to having 0.012" of relief. This measurement refers

to additional string height over the 12th fret, compared to

a perfectly straight neck.

A straight neck tends to play and sound better, but very few

guitars end up with no relief at all, and several thousandths

of an inch or more is perfectly normal.

stewmac.com

16

Installing spring cover plate

Mark out screw locations for the spring cover plate and drill

pilot holes 1/2" deep using a 1/16" drill bit.

Install spring cover plate using the six provided screws.

Hand tighten.

Set the action at the bridge

Adjust the action at the bridge by raising or lowering the

string saddles. Measure string height over the 12th fret,

between the bottom of the string and the top of the fret.

A good starting point is:

High (unwound) E string: 1/16" at the 12th fret

Low (wound) E string: 5/64" at the 12th fret

You can always go lower or higher depending on your play-

ing style. After setting the two E strings, dial in the remaining

strings to match the curve of the fretboard’s 14" radius using

the cut-out gauge included on page 17.

Adjust the pickup height

You can adjust the height of the poles on the pickups for the

best response by turning the two mounting screws.

Holding down the low E and high E strings at the 22nd

fret, adjust the bass side of the pickups to 5/64" from the

top of the pickup pole to the bottom of the low E string.

Adjust the treble side to 1/16". Feel free to experiment with

other heights, but the measurements here serve as a good

starting point.

Bridge set up

The vintage-style bridge can be set up a couple of dierent

ways.

A “oating” set-up allows for both raising and lowering the

pitch of the strings with the tremolo bar. To achieve a oating

set-up, tune the guitar to pitch and evenly adjust the tremolo

spring claw so the back of the bridge sits 1/16" - 3/32" o of

the body. Tightening the screws will bring the back end of

the bridge closer to the body, loosening them results in the

back end of the bridge raising up o of the body slightly,

allowing it to oat.

The bridge can also be set up to only lower the pitch. With

the guitar tuned up, adjust the springs so the back of the

bridge just starts to lift when you pull a hard bend on the

low E string. This is a good starting point; you can further

adjust the spring tension to suit your playing.

To immobilize the tremolo unit completely, simply tighten

the spring claw all of the way down.

stewmac.com 17

Set the intonation

The nal step is intonating the guitar by adjusting the string

lengths at the bridge saddles so the guitar plays in tune all

the way up the neck.

Using a high-precision tuner, rst tune the strings to pitch.

Then, press the high E string lightly at the 12th fret using just

enough pressure to sound the note. Check it with your tuner.

If the note reads at, the saddle needs to be adjusted forward

toward the nut, shortening the length of the string.

If the note reads sharp, the saddle needs to be adjusted back

away from the nut, increasing the string length.

Screw the tremolo arm into the bridge.

You’re done!

Congratulations! Your guitar is ready to play.

We hope this guitar will be the rst of many that you enjoy

building. Visit Stewmac.com to view our full lineup of electric

and acoustic guitar kits.

Cut-out radius gauge

Carefully cut out this radius gauge to check your saddle

heights as shown on page 16. We’ve included two, so you

have a backup.

14" RADIUS

14" RADIUS

WHAT’S NEXT?

YOU CAN’T STOP NOW

PERFECT YOUR SETUP

STRING ACTION GAUGE

PRECISION STRAIGHTEDGE

UNDERSTRING RADIUS GAUGE

Every great playing

guitar begins here.

Buy these tools once

and they’ll last you a

lifetime.

Basic Setup Kit

stewmac.com

BUILD YOUR SIGNAL CHAIN

BUILD SOMETHING NEW

Pickups Pedal Kits Amp Kits

Electric Guitar Kits

Our promise to you is simple and uncomplicated:

If any of our products ever break, wear out, or fail to exceed

your every expectation simply return it for a replacement.

That’s quality you can trust. For life.

Looking for your next weekend project? “The kit is superb and produces one of the best sounding

amps I have ever heard. Tommy at StewMac was looking out for me and replaced my parts that I ruined at no

charge. Superb documentation, fantastic experience, and a LOT of fun to assemble. I’m thrilled!”—HB from Michigan

Speaker Cabinet KitAcoustic Guitar Kits

335-Style • Offset • LP-Style

S-Style • T-Style • Modern • Vintage

Dreadnought • OM • Triple-O

Pre-war • Jumbo-45 • Limited Edition

For 10 or 12-inch Speaker

Solid Mahogany

What will you build next?

21 N. Shafer St • Athens, Ohio 45701 • USA

USA & Canada call toll-free: 800-848-2273

9am-6pm weekdays Eastern time

How can we help?

stewmac.com/contactus

making guitars better

Table of contents

Other StewMac Musical Instrument manuals