2

English

USG

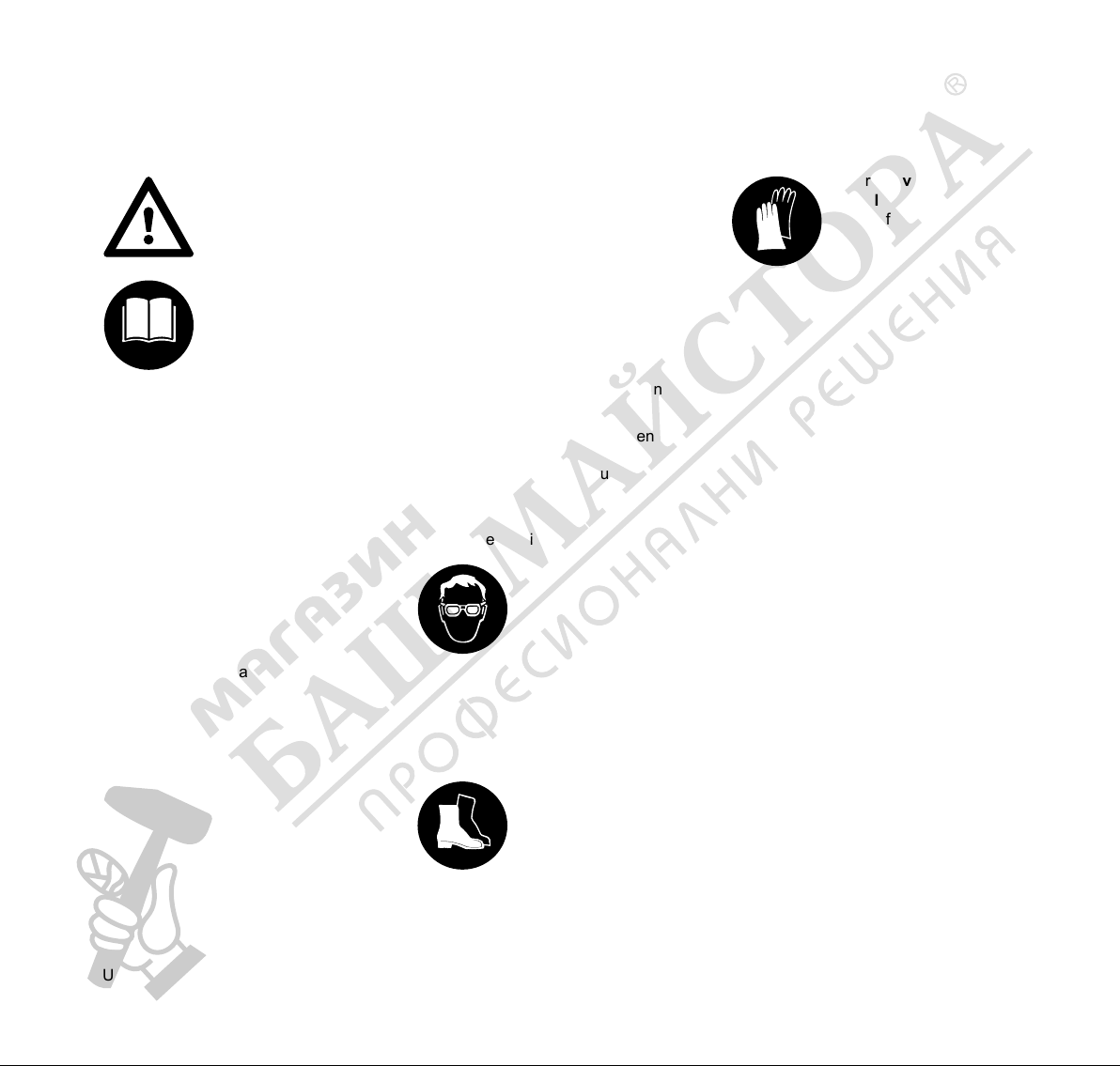

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

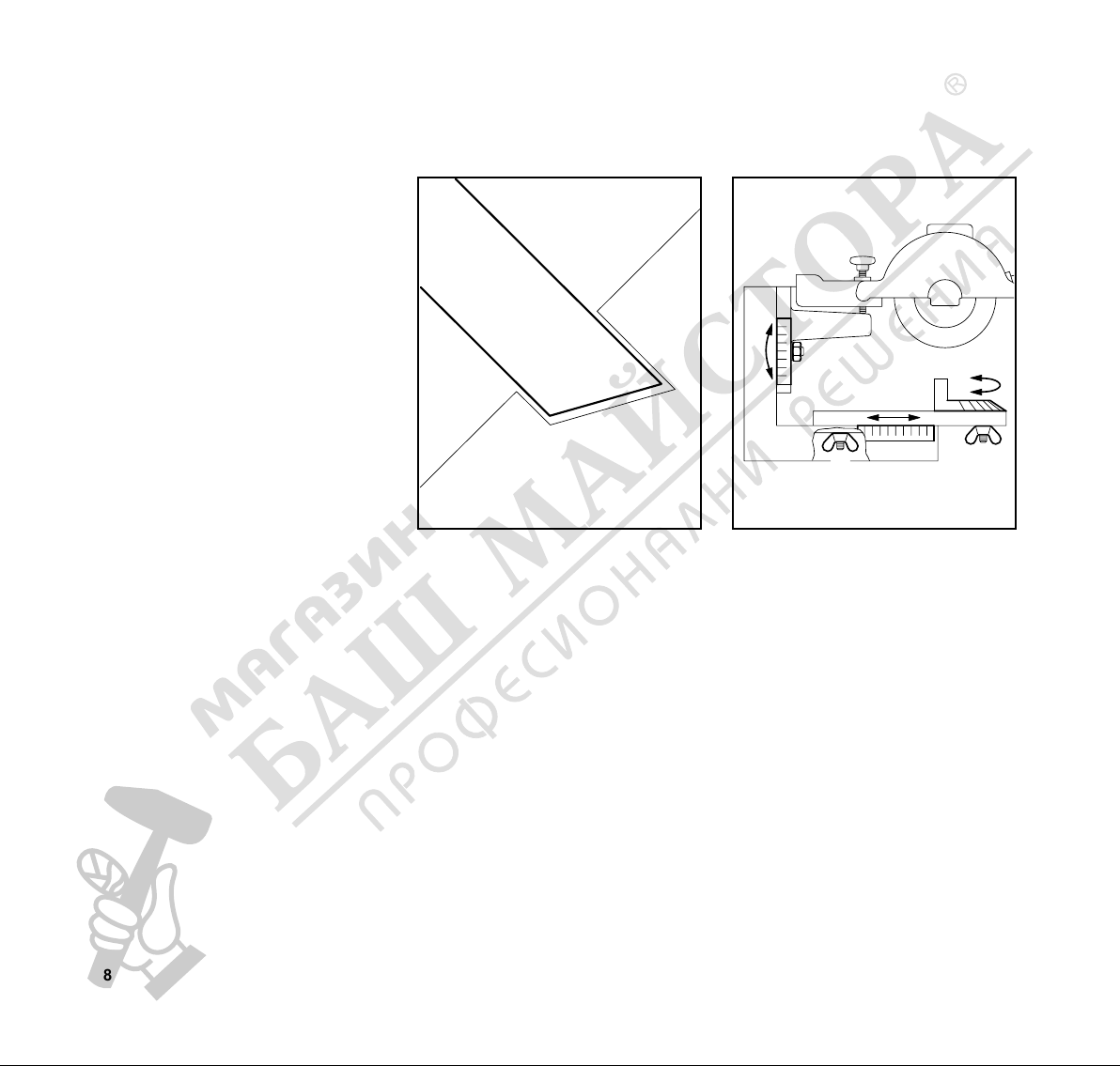

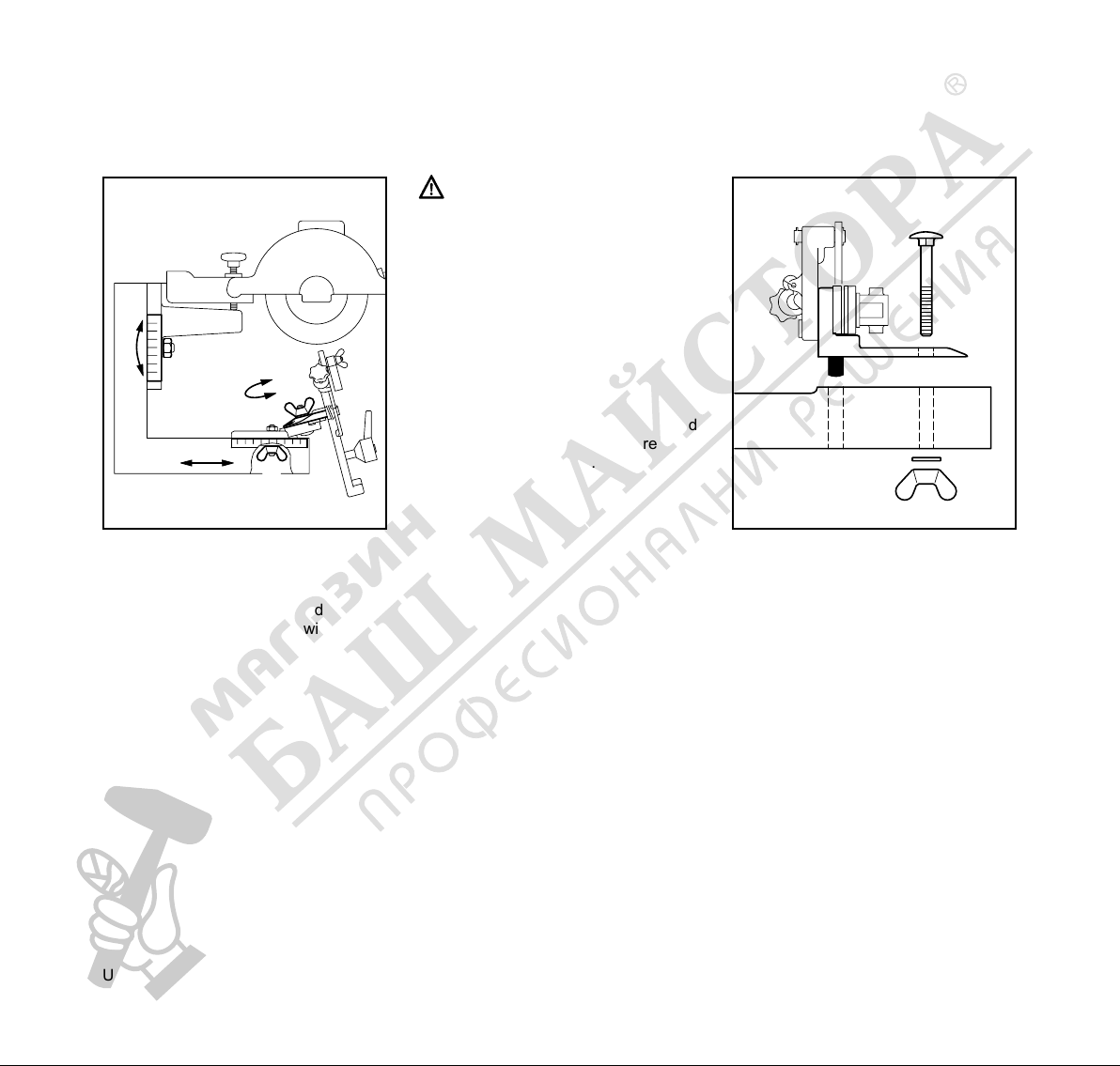

The operating and handling instructions

are supported by illustrations.

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

:Step or procedure without direct

reference to an illustration.

Description of step or procedure that

refers directly to the illustration and

contains item numbers that appear in

the illustration.

Example:

Loosen the screw (1)

Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or individual

components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s under-

standing of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual refers to

several models with different

features. Components that are not

installed in all models and related

applications are marked with an

asterisk (*). Such components may

be available as special accessories

from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore, we cannot be responsible for

changes, modifications or

improvements not covered in this

manual.

Guide to Using this Manual