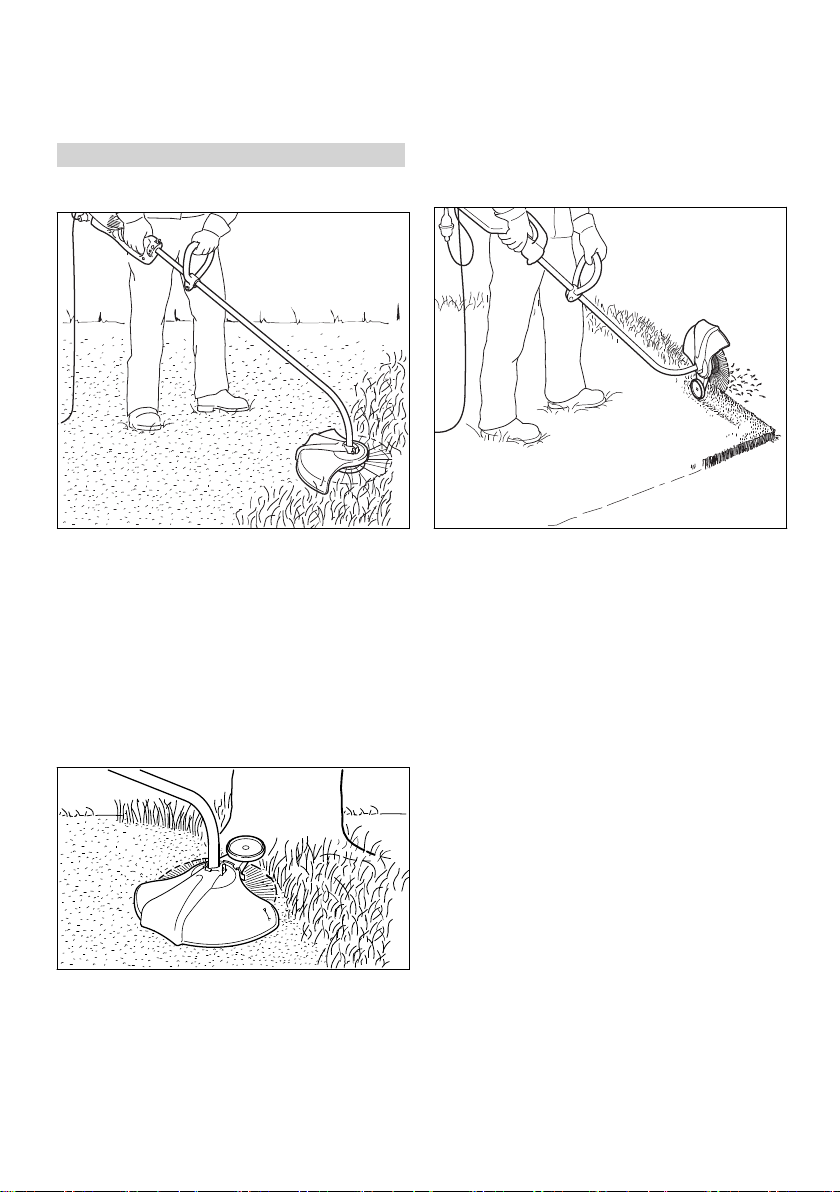

–Clean grass and plant residue off the cutting

attachment mounting at regular intervals –

remove any build up of material from the cut‐

ting attachment and deflector.

Always switch off the power tool and unplug it

from the power supply before replacing the cut‐

ting attachment This avoids the risk of injury from

the motor starting unintentionally.

Do not continue using or attempt to repair dam‐

aged or cracked cutting attachments by welding,

straightening or modifying the shape (out of bal‐

ance).

This may cause parts of the cutting attachment

to come off and hit the operator or bystanders at

high speed and result in serious or fatal injuries.

Use only the deflector with properly mounted line

limiting blade to ensure the mowing lines are

automatically trimmed to the approved length.

To reduce the risk of injury, avoid contact with

the blade.

To reduce the risk of injury, always switch off the

power tool and unplug it from the power supply

before manually adjusting the nylon line.

Using the unit with over-long nylon cutting lines

reduces the engine's operating speed. This

results in overheating and damage to the motor.

To reduce the risk of injury, never use wire in

place of the nylon cutting line.

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting Work". Make sure the safety

devices are working properly. Do not continue

operating your power tool if it is damaged. In

case of doubt, consult your servicing dealer.

Before leaving the power tool unattended: Switch

it off and disconnect the plug from the power

supply.

2.9 Vibrations

Prolonged use of the power tool may result in

vibration-induced circulation problems in the

hands (whitefinger disease).

No general recommendation can be given for the

length of usage because it depends on several

factors.

The period of usage is prolonged by:

–Hand protection (wearing warm gloves)

–Work breaks

The period of usage is shortened by:

–Any personal tendency to suffer from poor cir‐

culation (symptoms: frequently cold fingers,

tingling sensations).

–Low outside temperatures.

–The force with which the handles are held (a

tight grip restricts circulation).

Continual and regular users should monitor

closely the condition of their hands and fingers. If

any of the above symptoms appear (e.g. tingling

sensation in fingers), seek medical advice.

2.10 Maintenance and Repairs

Always switch off the machine and disconnect

the plug from the power supply before carrying

out any maintenance work to reduce the risk of

injury from the motor starting unintentionally.

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the instruction manual. Have all other work per‐

formed by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

Only use high-quality replacement parts in order

to avoid the risk of accidents and damage to the

machine. If you have any questions in this

respect, consult a servicing dealer.

STIHL recommends the use of genuine STIHL

replacement parts. They are specifically

designed to match your machine model and

meet your performance requirements.

Never attempt to modify your power tool in any

way since this will increase the risk of personal

injury.

Regularly check that the insulation of the power

cord and plug is in good condition and shows no

sign of ageing (brittleness).

Electrical components, e.g. power cord, may only

be repaired or replaced by a qualified electrician.

Clean plastic components with a cloth. Do not

use aggressive detergents. They may damage

the plastic.

Do not spray the machine with water.

Check tightness of mounting screws on safety

devices and the cutting attachment and retighten

if necessary.

English 2 Safety Precautions and Working Techniques

6 0458-282-0121-C