HT-KM

English

6

Note when reaching the end of a cut that

the power tool is no longer supported by

the guide bar in the cut. The user must

bear the weight of the machine – risk of

loss of control!

Always pull the power tool out of the cut

with the saw chain running.

Use the power tool for limbing and

pruning only, not for felling – Risk of

accidents!

Keep the saw chain away from any

foreign objects: Stones, nails, etc. may

be ejected and damage the saw chain.

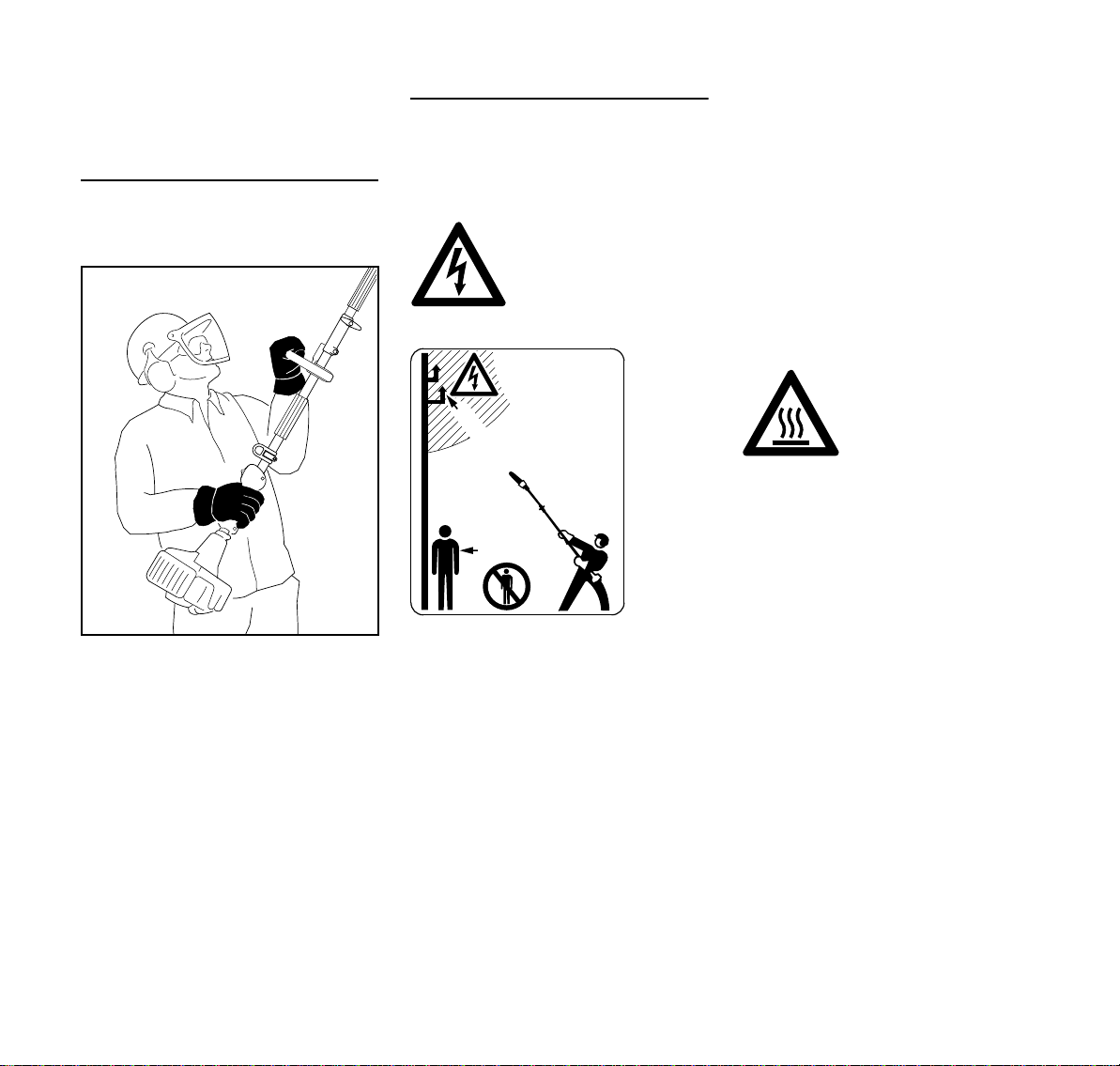

If a rotating saw chain hits a stone or

another hard object, sparks may be

generated which may ignite easily

flammable materials under certain

conditions. Also dried-out plants and

brushwood are combustible, above all in

hot and dry weather. If there is a risk of

fire, do not use your pole pruner near

easily flammable materials, dry plants or

scrub. It is mandatory that you ask the

responsible forestry office about the

current fire hazard.

Maintenance and Repairs

Service the machine regularly. Do not

attempt any maintenance or repair work

not described in the KombiTool and

KombiEngine instruction manuals. Have

all other work performed by a servicing

dealer.

STIHL recommends that you have

servicing and repair work carried out

exclusively by an authorized STIHL

servicing dealer. STIHL dealers are

regularly given the opportunity to attend

training courses and are supplied with

the necessary technical information.

Only use high-quality replacement parts

in order to avoid the risk of accidents

and damage to the machine. If you have

any questions in this respect, consult a

servicing dealer.

STIHL recommends the use of genuine

STIHL replacement parts. They are

specifically designed to match your

model and meet your performance

requirements.

To reduce the risk of injury,always shut

off the enginebefore carrying out any

maintenance or repairs or cleaning the

machine. – Exception: Carburetor and

idle speed adjustments.

Stopping the engine

–before checking chain tension.

–before retensioning the chain.

–before replacing the chain.

–before rectifying problems.

Observe sharpening instructions – keep

the chain and guide bar in good

condition at all times for safe and correct

handling of the saw. The chain must be

properly sharpened, tensioned and well

lubricated.

Always change the chain, guide bar and

sprocket in good time.

Store chain lubricant in properly

labelled, safety-type canisters only.

Preparation

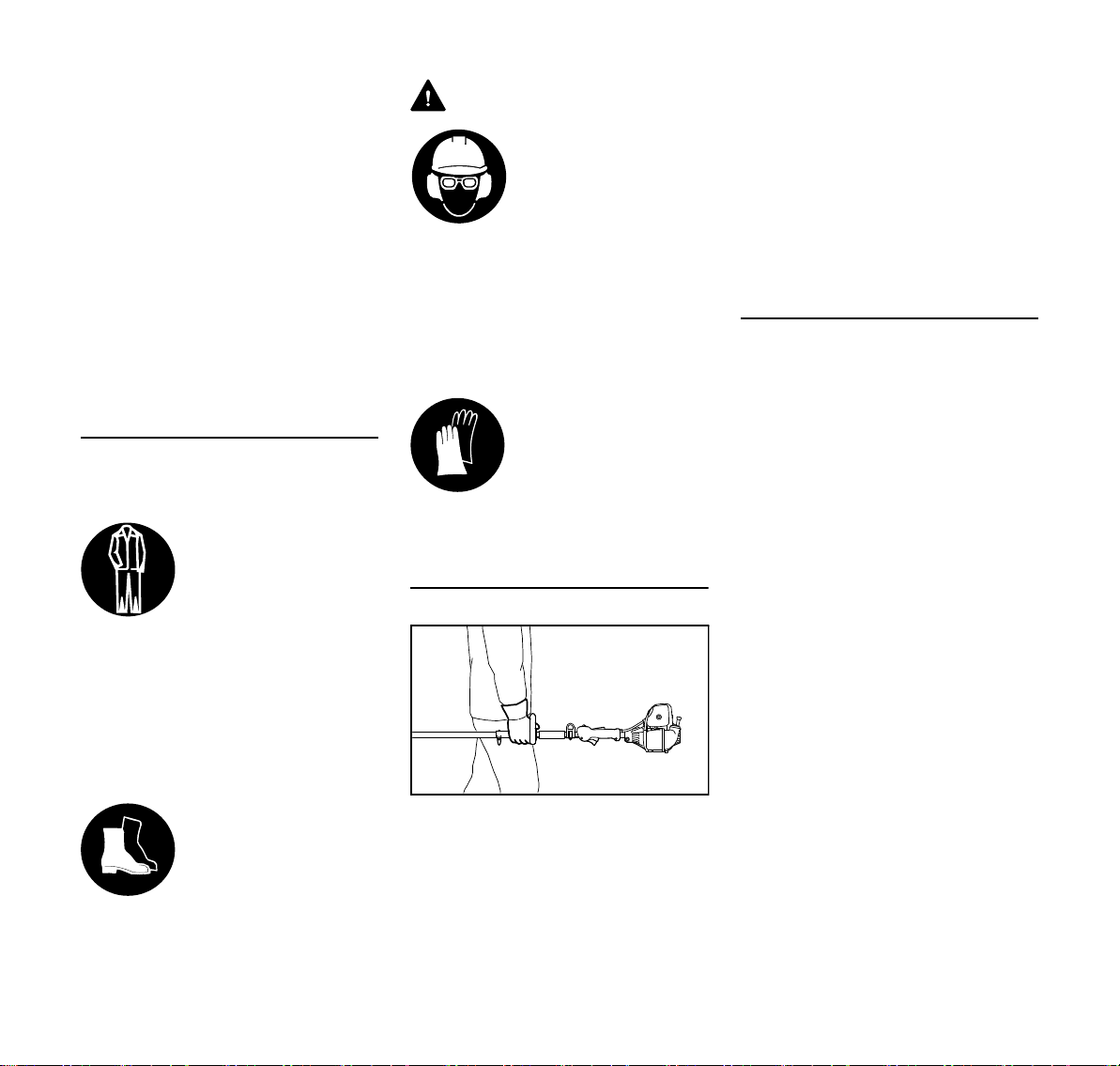

NWear suitable protective clothing,

observe safety precautions.

NStarting the engine

NFitting the harness

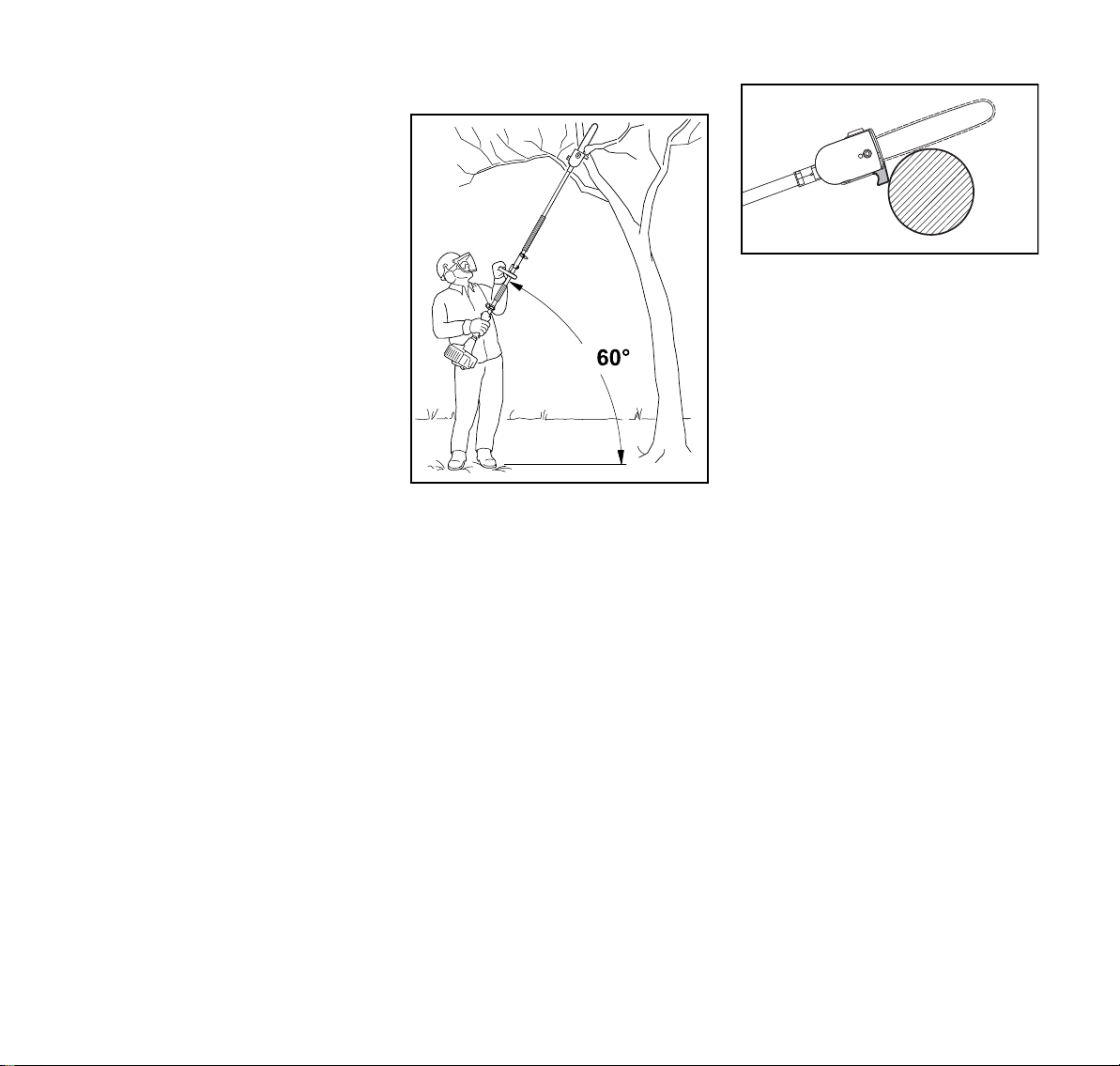

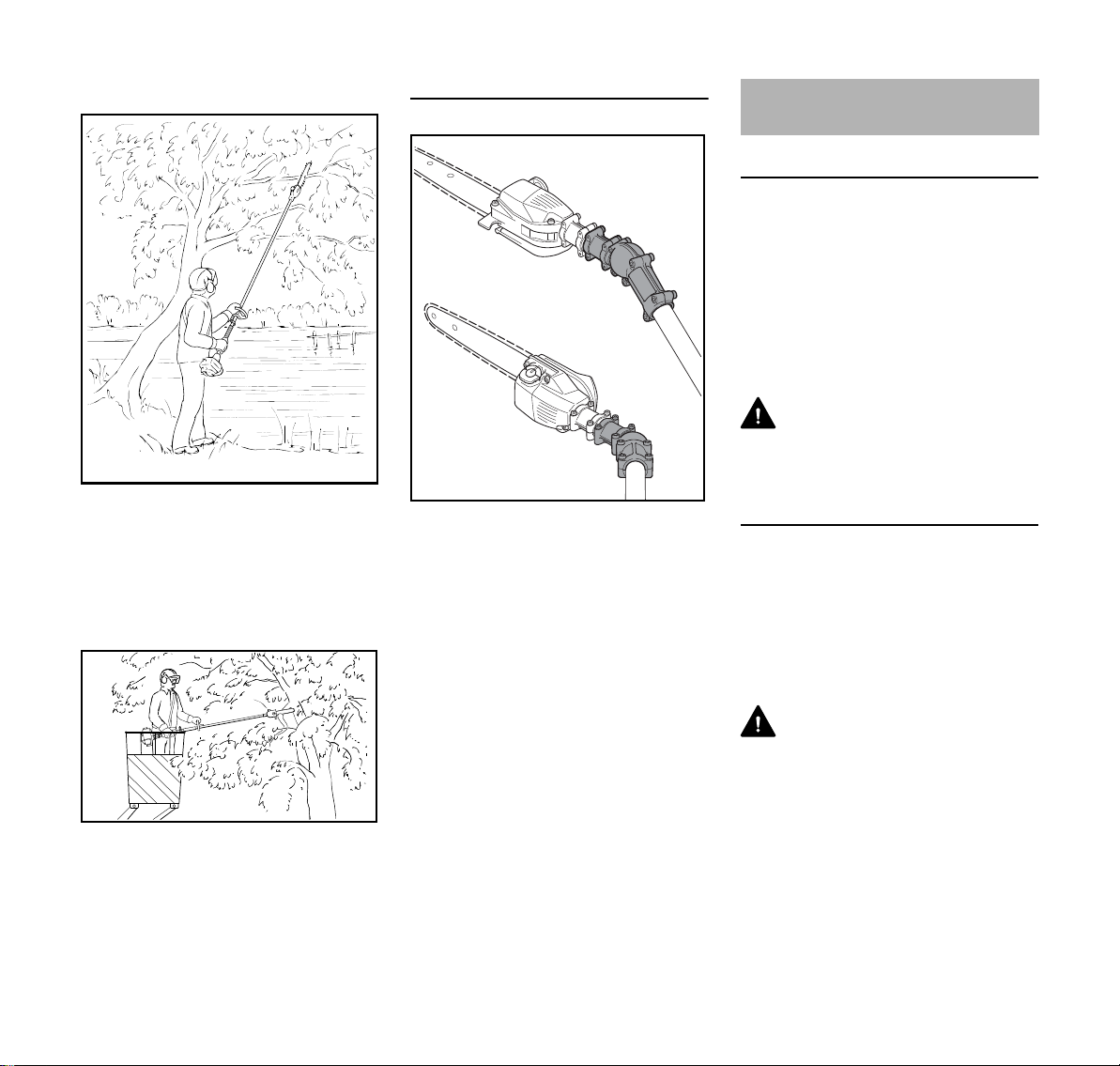

Cutting sequence

To allow branches to free fall, always cut

the lower branches first. Prune heavy

branches (large diameter) in several

controllable pieces.

WARNING

Never stand directly underneath the

branch you are cutting – be wary of

falling branches. Note that a branch may

spring back at you after it hits the ground

– risk of injury

Disposal

Do not throw cuttings into the garbage

can – they can be composted.

Working techniques

Hold the control handle with your right

hand, and the loop handle with your left

hand. Your left arm should be extended

to the most comfortable position.

Using the Unit