environments. This may result in serious or

fatal injury to people and damage to property.

► Use the spark plugs described in the engine

instruction manual.

► Screw in the spark plug and tighten.

► Press firmly on the spark plug socket.

■ The tiller may be damaged if it is refueled with

petrol that is not suitable for the engine.

► Use fresh, good quality unleaded petrol.

► Observe the specifications in the engine

instruction manual.

4.8 Working

WARNING

■ The user may lose control of the tiller if they

do not start the engine correctly. This may

result in serious injury to the user.

►Start the engine as described in this instruc‐

tion manual.

■ In certain situations, the user may no longer

be able to concentrate on their work. The user

may lose control of the tiller, trip, fall and be

seriously injured.

►Work calmly and carefully.

► If the light and visibility conditions are poor:

do not use the tiller.

► Operate the tiller alone.

► Guide the hoes close to the ground.

► Watch out for obstacles.

► Do not tilt the tiller.

► If working on stony or hard ground: do not

work at full throttle.

► Work standing on the ground and maintain

balance.

► If signs of fatigue occur: take a break.

► If working on a slope: work across the

slope.

► Do not work on slopes with an inclination

greater than 15° (26.8%).

■ Exhaust gases are produced when the engine

is running. Breathing in exhaust gases may

result in poisoning.

►Do not breathe in exhaust gases.

► Use the tiller in a well ventilated place.

► If nausea, headaches, vision problems,

hearing problems or dizziness occur: stop

working and consult a doctor.

■If the user is wearing hearing protection and

the engine is running, their perception and

assessment of noise may be limited.

►Work calmly and carefully.

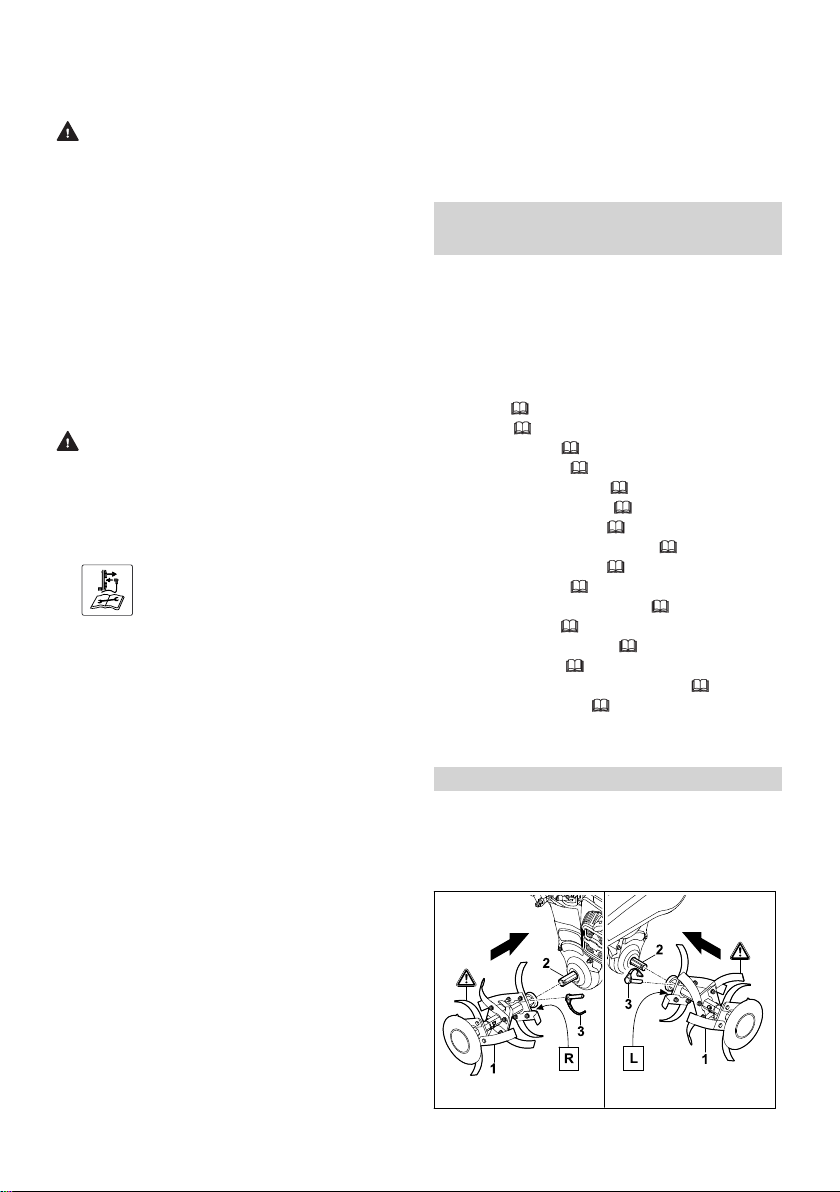

■ The turning hoes may cut the user. This may

result in serious injury to the user.

► Do not touch turning hoes.

■ The tiller may be damaged if the hoes are

blocked by an object and throttle is applied.

► Stop the engine. Only then remove the

object.

■ If the tiller changes or starts to behave differ‐

ently when working, it may not be in safe con‐

dition. This may result in serious injury to peo‐

ple and damage to property.

►Stop working and consult a STIHL special‐

ist dealer.

■ The tiller may cause vibrations when working.

► Wear gloves.

► Take breaks.

► If signs of a circulatory disturbance occur:

consult a doctor.

■ The hoes continue to turn for a short time

when the clutch lever is released. This may

result in serious injury to people.

►Wait until the hoes are no longer turning.

DANGER

■ If working near live wires, the hoes may come

into contact with the live wires and damage

them. This may result in serious or fatal injury

to the user.

►Do not work near live wires.

4.9 Transporting

WARNING

■The gearbox housing may become hot when

working. This may result in the user burning

themselves.

►Do not touch the hot gearbox housing.

■ The tiller may tip over or move during trans‐

port. This may result in injury to people and

damage to property.

►Stop the engine.

► Detach the spark plug socket.

► Secure the tiller with lashing straps, belts or

a net so it cannot tip over and move.

■ The muffler and engine may be hot after the

engine has been running. This may result in

the user burning themselves.

►Tilt and push the tiller towards the user.

■ The tiller is heavy. Attempting to carry the tiller

without assistance may result in injury to the

user.

►Wear gloves.

4 Safety Precautions English

0478-404-9902-B 7