Contents

1 KombiSystem..............................................2

2 Guide to Using this Manual.........................2

3 Safety Precautions and Working Techni‐

ques............................................................ 2

4 Using the Unit............................................. 6

5 Approved KombiEngines............................ 7

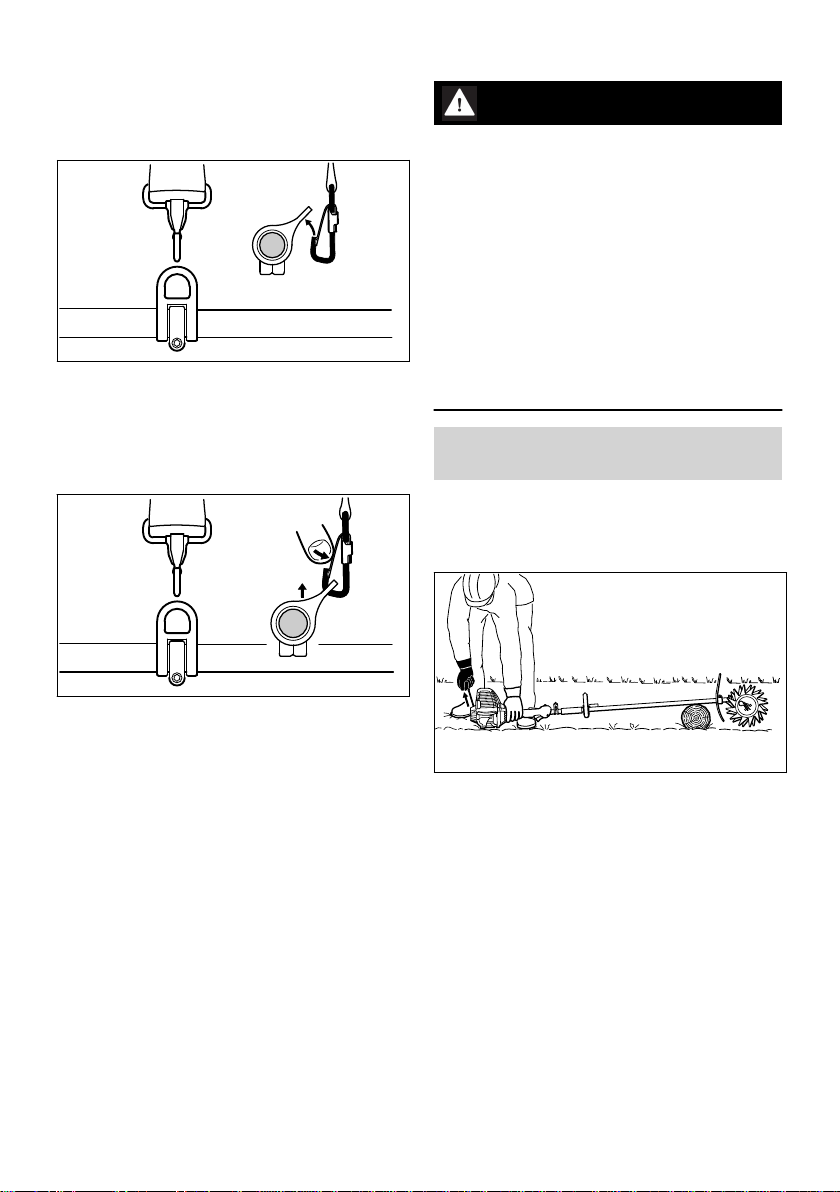

6 Assembling the Unit.................................... 7

7 Mounting the KombiTool............................. 9

8 Fitting the Harness......................................9

9 Starting / Stopping the Engine.................. 10

10 Storing the Machine.................................. 11

11 Maintenance and Care..............................11

12 Minimize Wear and Avoid Damage...........11

13 Main Parts.................................................12

14 Specifications............................................12

15 Maintenance and Repairs......................... 13

16 Disposal.................................................... 13

17 EC Declaration of Conformity................... 13

18 UKCA Declaration of Conformity.............. 14

1 KombiSystem

In the STIHL KombiSystem a number of different

KombiEngines and KombiTools can be com‐

bined to produce a power tool. In this instruction

manual the functional unit formed by the Kom‐

biEngine and KombiTool is referred to as the

power tool.

Therefore, the separate instruction manuals for

the KombiEngine and KombiTool should be used

together for the power tool.

Always read and and make sure you understand

both instruction manuals before using your

power tool for the first time and keep them in a

safe place for future reference.

2 Guide to Using this Manual

2.1 Pictograms

All the pictograms attached to the machine are

shown and explained in this manual.

2.2 Symbols in text

WARNING

Warning where there is a risk of an accident or

personal injury or serious damage to property.

NOTICE

Caution where there is a risk of damaging the

machine or its individual components.

2.3 Engineering improvements

STIHL's philosophy is to continually improve all

of its products. For this reason we may modify

the design, engineering and appearance of our

products periodically.

Therefore, some changes, modifications and

improvements may not be covered in this man‐

ual.

3 Safety Precautions and

Working Techniques

Special safety precautions must be

observed when working with the culti‐

vator because its pointed and sharp-

edged rotor blades rotate at high

speed.

Always read and and make sure you

understand both user manuals (Kom‐

biEngine and KombiTool) before

using your power tool for the first time

and keep them in a safe place for

future reference. Non-compliance

with the user manuals may cause

serious or even fatal injury.

Lend or rent your machine only to persons who

are familiar with this model and its operation – do

not lend or rent your machine without the Kom‐

biEngine and KombiTool user manuals.

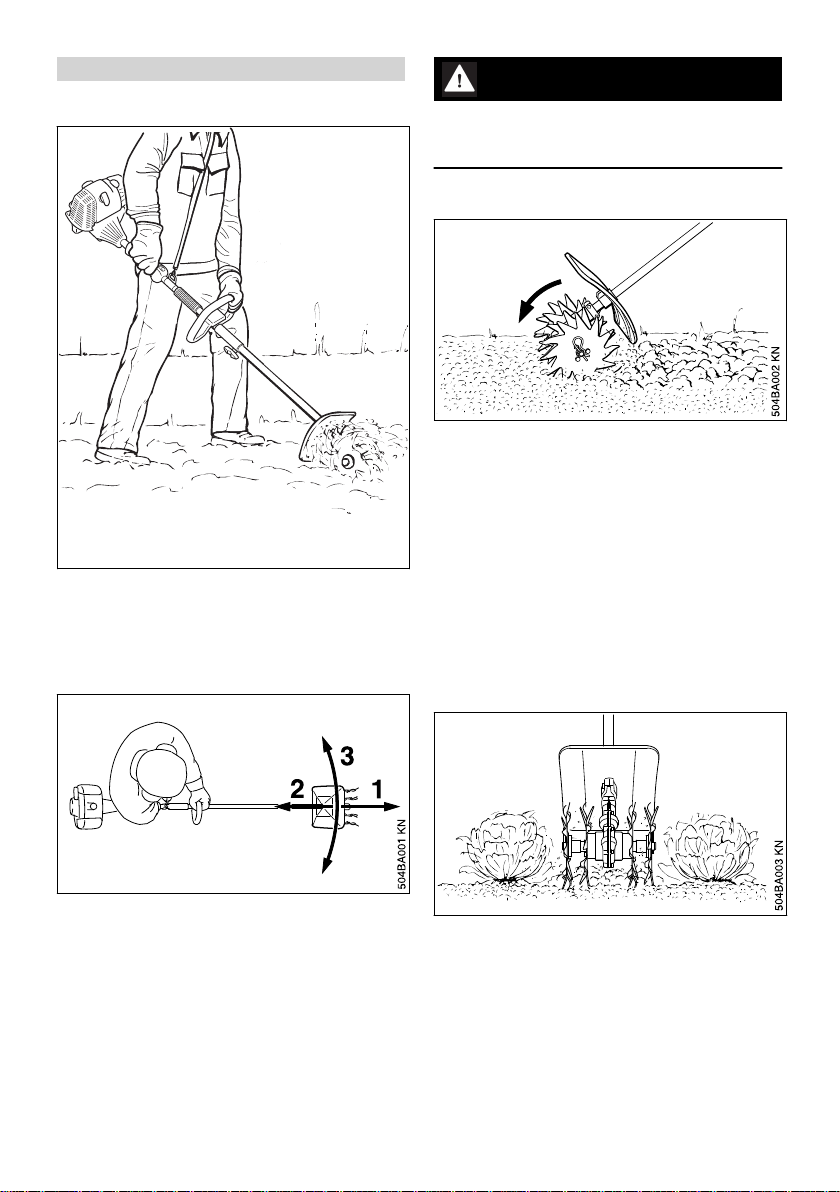

Use the cultivator only for tilling previously culti‐

vated, packed or loose soil, furrowing and work‐

ing in mulches.

The machine must not be used for any other pur‐

poses – risk of accident!

Only mount rotor blades and accessories that

are explicitly approved for this power tool by

STIHL or are technically identical. If you have

any questions in this respect, consult your

dealer.

Use only high-quality parts and accessories. Oth‐

erwise, there is a risk of accidents and damage

to the machine.

English

2 0458-478-0121-D

© ANDREAS STIHL AG & Co. KG 2022

0458-478-0121-D. VA0.G22.

Printed on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

Original Instruction Manual

0000000666_022_GB