Watch out for obstacles: tree stumps, roots – risk

of tripping or stumbling!

Check the work site – rocks, metal objects etc.

may be caught up and ejected – risk of injury! -

and may damage the rotor blades.

To avoid the risk of electrocution,

never use your power tool in areas

where electrical lines are laid on the

surface or buried just below the sur‐

face.Striking and damaging such

lines with the attachment could cause

serious or even fatal injury.

Make sure you always have a firm and secure

footing.

Operate your power tool at normal walking pace

only.

Take particular care when working close to fen‐

ces, walls, stones, roots, trees and areas of

dense growth. The rotor blades may snag – risk

of injury!

Be extremely cautious when pulling the power

tool towards you because of the risk of injury

from contact with the rotating blades.

Be particularly alert and cautious when wearing

ear protection because your ability to hear warn‐

ings (shouts, alarms, etc.) is impaired.

Take breaks when you start getting tired or feel‐

ing fatigue – risk of accidents!

Work calmly and carefully – in daylight conditions

and only when visibility is good. Proceed with

caution, do not put others in danger.

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting". Make sure the safety devices

are working properly. Never use a power tool

that is no longer safe to operate. In case of

doubt, contact a dealer.

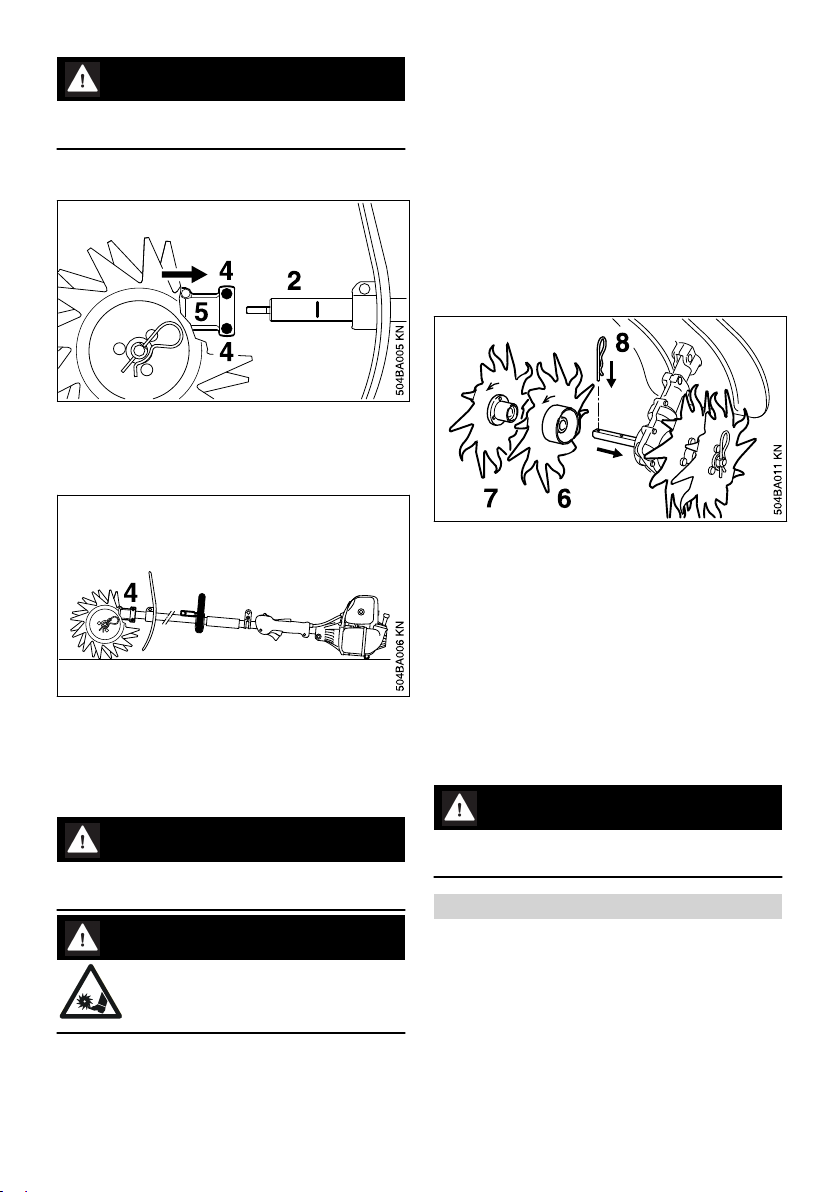

Do not touch the rotor blades while the engine is

running. If the rotor blades become jammed by

an object, switch off the engine immediately

before attempting to remove the object – there is

otherwise a risk of injury!

Opening the throttle while the rotor blades are

blocked increases the load and reduces engine

speed. The clutch then slips continuously and

this causes overheating and damage to impor‐

tant components (e.g. clutch, polymer housing

components) – and this can increase the risk of

injury from the rotor blades running while the

engine is idling.

Check the rotor blades at regular short intervals

during operation or immediately if there is a

noticeable change in operating behavior:

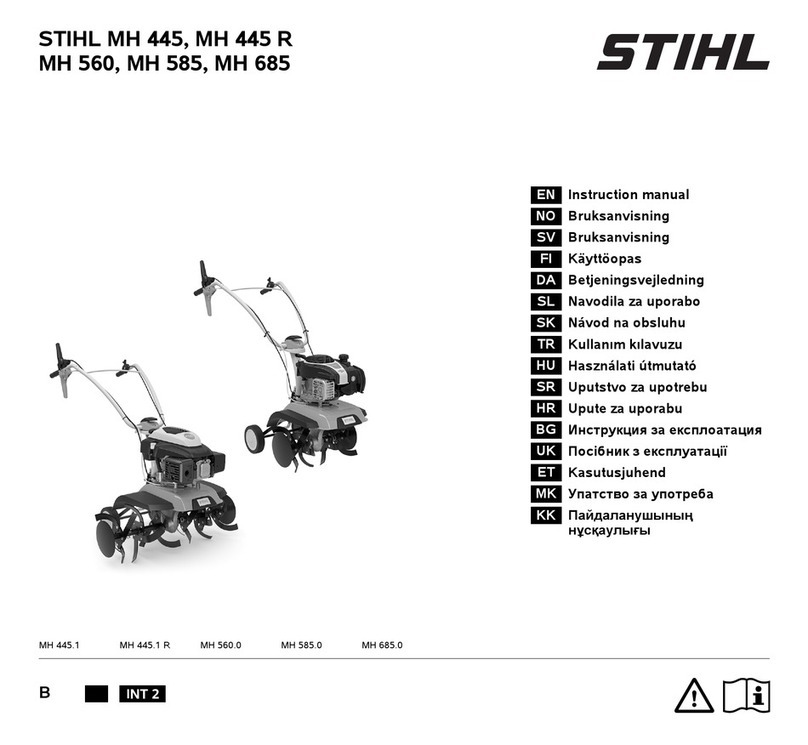

–Shut off the engine, hold the machine

securely.

–Check condition and secure fitting; watch out

for cracks

–Replace damaged rotor blades immediately,

even if they have only superficial cracks.

Clean the rotor blades and deflector at regular

intervals during operation.

–Shut off the engine

–Use gloves

–Remove grass, weeds, clumps of soil, etc.

Switch off the engine before changing the rotor

blades – Risk of injury!

Do not continue using or attempt to repair dam‐

aged or cracked rotor blades by welding or

straightening – risk of deformation (out of bal‐

ance).

Particles or pieces may come off and hit the

operator or a bystander at a high speed – risk of

most severe injuries!

3.6 After Finishing Work

After finishing work or before leaving the power

tool unattended: Shut off the engine.

After finishing work, regularly clean dust, dirt, soil

and plant residue off the attachment – wear

gloves to reduce the risk of injury!

Do not use any grease solvents when cleaning.

After thoroughly cleaning, coat metal surface of

attachments with a corrosion inhibitor.

3.7 Maintenance and Repairs

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the instruction manuals of the basic power tool

and attachment. Have all other work performed

by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

Only use high-quality replacement parts in order

to avoid the risk of accidents and damage to the

3 Safety Precautions and Working Techniques English

0458-504-0121-B 5