Stiles Ironwood FX 550 User manual

Ironwood FX 550

User Manual

general information.

features.

operation. spindle height adjustment.

tool adjustments. noise reduction.

maintenance. troubleshooting.

periodic maintenance. safety.

delivery and installation. inspection.

receiving the machine. assembly.

fences and fence assembly. safety guard assembly.

technical specifications. safety considerations.

Ironwood FX 550 | User Manual2

1.0 General Information ............................................................... . 3

1.1 Thank You!

1.2 Before Contacting Stiles

1.3 Features

1.4 Intended Use

1.5 Technical Specifications

1.6 Safety Considerations

2.0 Facility Preparation ................................................................. 6

2.1 Floor

2.2 Work Space

2.3 Power

3.0 Delivery and Installation ............................................................. 7

3.1 Receiving Your Machine

3.2 Unpack the Machine

3.3 Inspection

3.4 Move Machine to Final Position

3.5 Remove Machine from Pallet

3.6 Level

3.7 Pre-Operation Cleaning

4.0 Assembly ....................................................................... 10

4.1 Fence Assembly and Fences

4.2 Spindle

4.3 Cutter Head/Tooling

4.4 Top Dust Cover

4.5 Safety Guard Assembly

4.6 Miter Gauge Assembly and Clamp

5.0 Connect to Power ............................................................... . 14

6.0 Safety.................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.0 Start the Machine… ........................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Control Panel

7.2 On/Off

7.3 Reverse Spindle Rotation

8.0 Operation… .............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . 17

8.1 Speed Change and Belt Adjustment

8.2 Spindle Height Adjustment

8.3 Using Fence(s)

8.4 Adjusting Fence Extensions

8.5 Positioning and Using Collars

8.6 Tenoning

8.7 Tool Adjustments

8.8 Noise Reduction

9.0 Maintenance...................................................... . . . . . . . . . . . . . . . 21

9.1 Lubrication

9.2 Inspection

9.3 Periodic Maintenance

10.0 Troubleshooting ........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . 22

10.1 Electrical Diagram

Table of Contents

PLEASE REVIEW AND OBSERVE ALL SAFETY

INFORMATION / DIRECTIVES BEFORE INSTALLING,

OPERATING, OR PERFORMING MAINTENANCE ON

THIS MACHINERY.

Ironwood FX 550 | User Manual 3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood FX 550 Shaper. At

Stiles Machinery, our goal is to ensure that you are fully satisfied with

your purchase. This manual is provided so that you may properly

assemble, operate, and maintain your FX 550. Should you need

help, our team of dedicated service personnel are available to

answer your questions and provide any resource recommendations

you may need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system is also listed on the

metallic plate.

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/fx550

Machine Model

____________________________________________

Machine Ser ial Number

_____________________________________

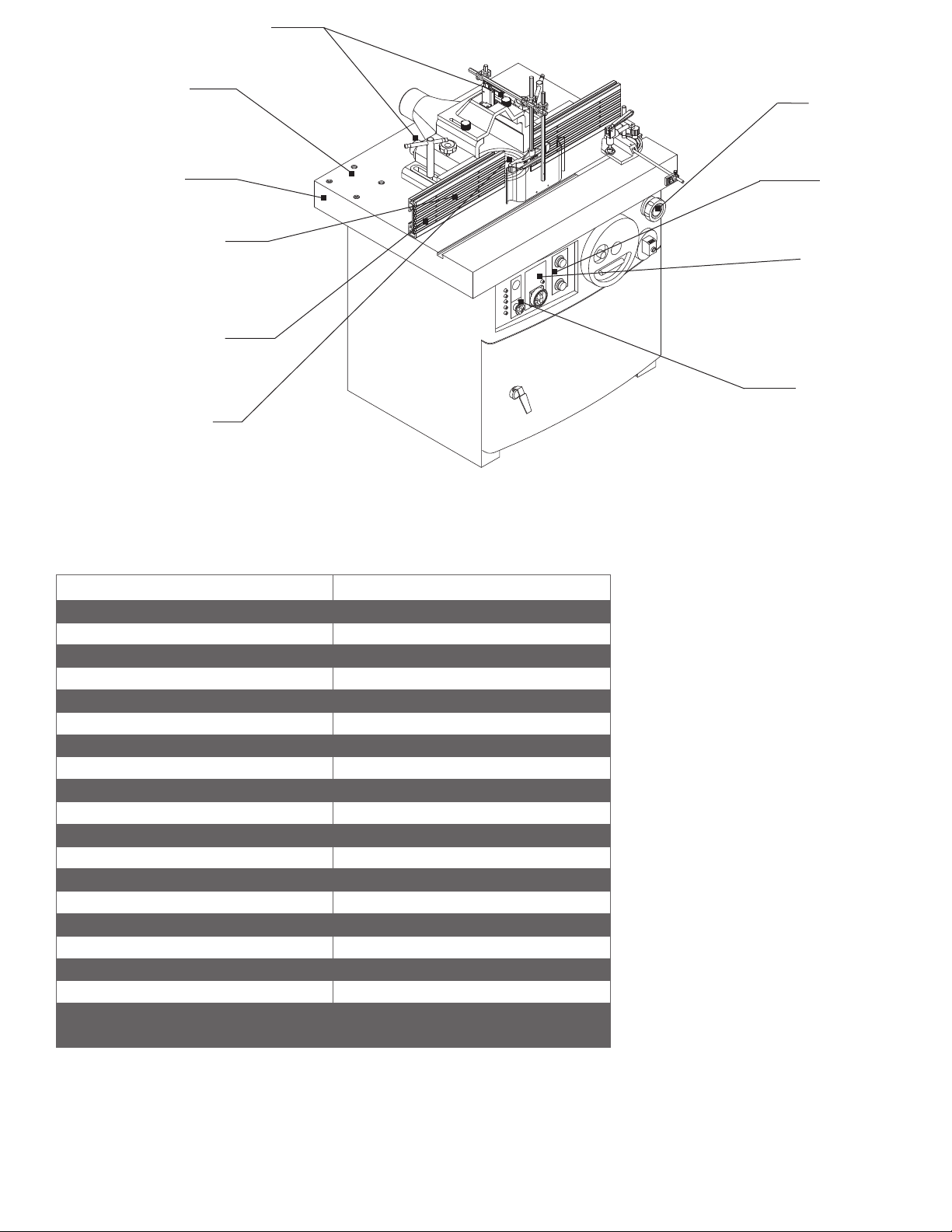

1.3 Features

• Cast iron, ground and polished table is designed for heavy

cutting operations.

• Generous table size supports large workpieces

• 11⁄4" interchangeable spindle has over 6 1⁄4" (160mm) of spindle

capacity under the nut. Other spindle diameters are also

available. Contact Stiles Machinery for more information.

• Cast iron fence assembly provides independent fine adjustments

for infeed and outfeed fence positioning.

• Directional indicator light for forward and reverse spindle

rotation control ensure safe operation in clockwise and

counterclockwise applications.

• Digital readouts for spindle height position and infeed and

outfeed fence positions ensure precision.

• All control functions are located on the convenient and

easy-to-use control panel.

• Electric mechanical spindle brake and spindle lock with safety

limit switches enhance safety.

• Adjustable aluminum fingers on the fence protect the operator

from the cutter and add support for the workpiece.

1.4 Intended Use

The Ironwood FX 550 shaper is designed for shaping and tenoning

wood and wood material. Use your FX 550 to create outside profiles

on workpieces such as raised panel doors, furniture components,

trim, and custom moldings.

Performance and dependability are optimized when the machine is

operated with care and maintained properly. When used according

to the instructions in this manual, you can expect years of trouble-

free operation.

The FX 550 shaper features a vertical spindle that protrudes from the

table. The spindle turns at between 3,000-10,000 rpm. A cutter is

mounted on the spindle. The workpiece is guided along the fence,

passing over the cutter. The position of the cutter and the fence can

be finely adjusted, allowing you to create a wide array of casings,

moldings, trim, and more.

An optional sliding table or extension table should be used to

support longer workpieces.

Power feeders are recommended to ensure consistent finish quality

and improve operator safety.

All Ironwood shapers feature heavy-duty motors up to 10 hp and

spindles driven by 5- or 6-speed balanced v-belt pulley systems for

speeds ranging from 3,000 to 10,000 rpm (see section 4.2).

Ironwood FX 550 | User Manual4

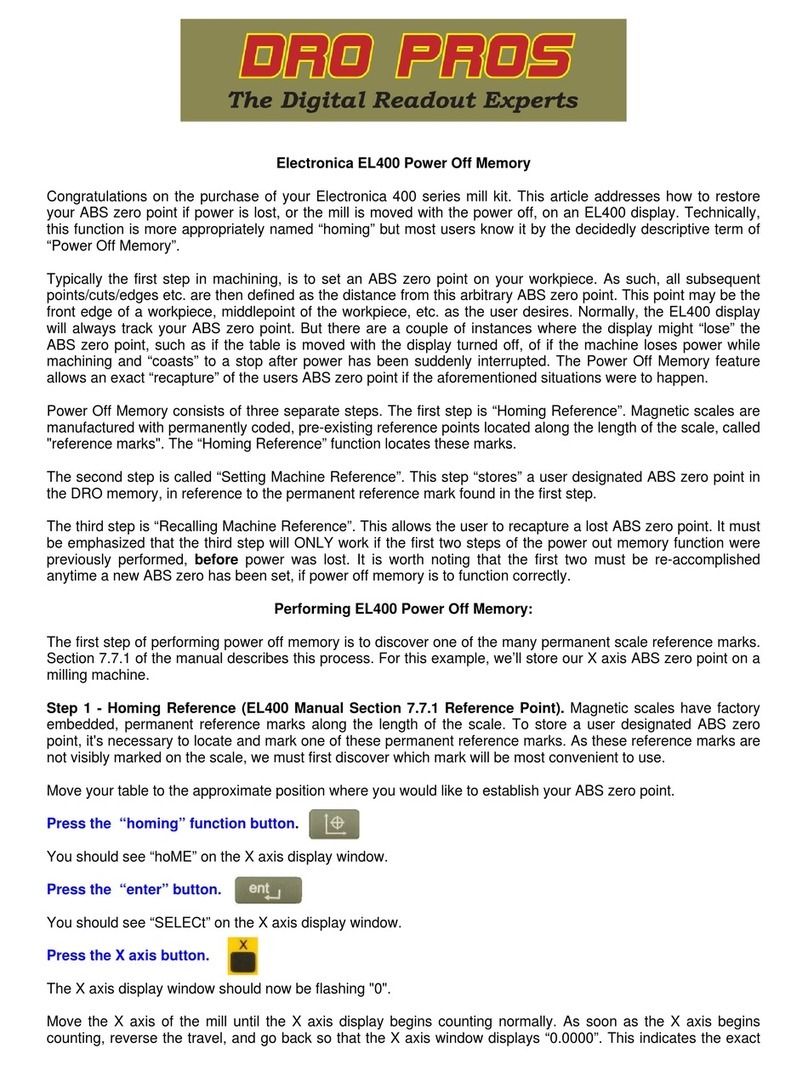

Large, cast i ron,

ground and polished

table is rugged and stable,

with maximum rigidity for

heavy cutting operations

Generous table

for larger workpieces

Aluminum fence

assembly provides

for infeed and outfeed

independent fine adjustments

fence positioning

on the fence protect the

Adjustable fingers

operator from the cutter

and add support for the

workpiece.

11⁄4" interchangeable

spindle has over 6 " of spindle

capacity under the nut; other tooling

diameters a re also available

1.5 Technical Specifications

Description Ironwood FX 550

Working Table 27-9/16”x 35-7/16”(700x900mm)

Table Height 35-7/16”(900mm)

Spindle Capacity (under the nut) 6" (152mm)

Vertical Spindle Stroke

Spindle Speed 5 Speeds (3000, 4000, 6000, 8000, 10000 RPM)

Spindle Height Adjustment Handwheel

Spindle Position Display Mechanical Digital Readout

Spindle Size

Spindle Rotation Forward/Reverse

Max. Tool Diameter (Below Table)

Max. Tool Diameter (Above Table)

Fence Assembly Manual

Dust Port Diameter

Dust Extraction Requirements 1000 cfm @ 4,500 feet/min.

Motor 5.5 HP

Motor Power 230v (3 phase), 460v (3 phase)

Amperage 14.0 (230v) / 7.0 (460v)

Machine Weight 924 lbs. (420 kg.)

Shipping Dimensions (L x W x H) 42-15/16" x 34" x 42-1/8"

(1090mm x 864mm x 1070mm)

size provides support

Spindle locks with

safety limit switches

enhance safety

Convenient and

easy-to-use control panel

handles all control functions

Directional indicator

light for forward tnad reverse

spindle rotation control ensures

safe operation in clockwise and

counterclockwise applications

Emergency stop for

stopping motor with

the spindle brake in

10 seconds

7-1/16”(180mm)

1-1/4” x 6” (31.75mm x 152.5mm)

7-1/16” (180mm)

8-7/8” (225mm)

2 @ 4”

Ajustable Knobs both sides for

infeed and outfeed fence positions

help ensure precision

Ironwood FX 550 | User Manual 5

1.6 Safety Considerations

For your safety, read these instructions thoroughly before you install

and operate this machine. Always have these instructions available

at the machine for reference.

Observe all codes and regulations that apply to the installation and

operation of this machine.

Keep visitors at a safe distance from the workspace.

Keep children away from this and all machines. Childproof your

work area!

Familiarize yourself with the safety notices used in this manual.

CAUTION

If cautions are ignored, personal injury and/or machine damage

may result.

WARNING

If warnings are ignored, serious injury or death may result.

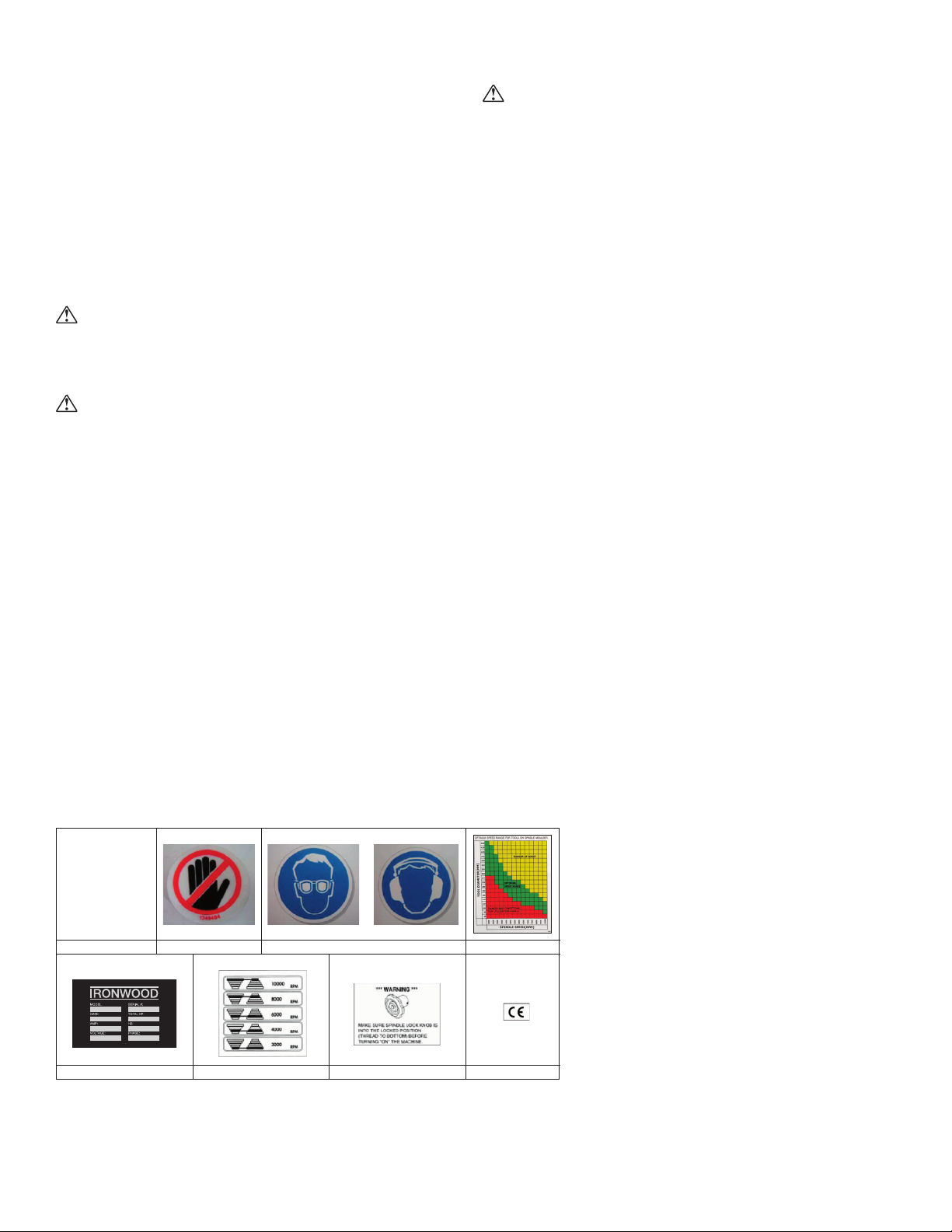

Warning Labels

This machine has warning labels attached to ensure safe operation.

These warning labels are very important and should be kept clean

and never be removed. If warning labels become damaged or lost,

contact Stiles Machinery immediately for replacements.

Label 1 Safety rules and features

Label 2 Do not touch turning spindle or cutters

Label 3 Always wear eye and ear protection

Label 4 Optimum speed range

Label 5 Hazardous voltage

Label 6 Belt placement/speed diagram (inside access door)

Label 7 Spindle lock

Label 8 CE marking regulations

Never use the FX 550 for purposes other than its intended use. Do

not modify or remove any guards or other safety features. Improper

use or modifications may affect your warranty or result in serious

injury or death.

Training

This machine is intended for use by authorized, well-trained

operators only.

Do not operate this machine until you have a complete working

knowledge of this shaper and have been properly trained for its

safe operation, correct adjustment and use. All operators should

thoroughly read and understand this manual and the workings of

this machine prior to operation.

It is essential that all operators be aware of the following:

• The dangers associated with the operation of this machine.

• The use of personal protective equipment for ear and

eye protection.

• The proper positioning of the operator and operator hands

relative to the cutters.

• The principles of machine operation, proper use and adjustment

of the fence, jigs, safety guards templates, extension tables and

end stops.

• The correct selection of tools and the associated spindle speeds

for each operation.

• The safe handling of the workpiece when cutting.

• The safe stacking of the workpiece before and after cutting.

• Connection of the optional power feed unit.

MAIN MOTOR

CAN ST AR T AND

OPERA TE THIS

MACHINE ONLY

IF THE DOOR IS

COMPLETELY

CLOSED AND

SECURED.

LABEL NO. 1 LABEL NO. 2 LABEL NO. 3 LABEL NO. 4

LABEL NO. 5 LABEL NO. 6 LABEL NO. 7 LABEL NO. 8

WARNING

Ironwood FX 550 | User Manual6

2.0 Facility Preparation

Prior to uncrating your machine confirm that your location can

accommodate the Ironwood FX 550. Follow these guidelines:

2.1 Floor

• The floor must be flat and level.

• Although no special foundations are required, a concrete floor

is recommended.

• All floors must have a load-bearing strength suitable for the

machine weight of approximately 814 lbs.

• If anchoring the machine to the floor, purchase high quality

anchor bolts appropriate to the floor construction and material.

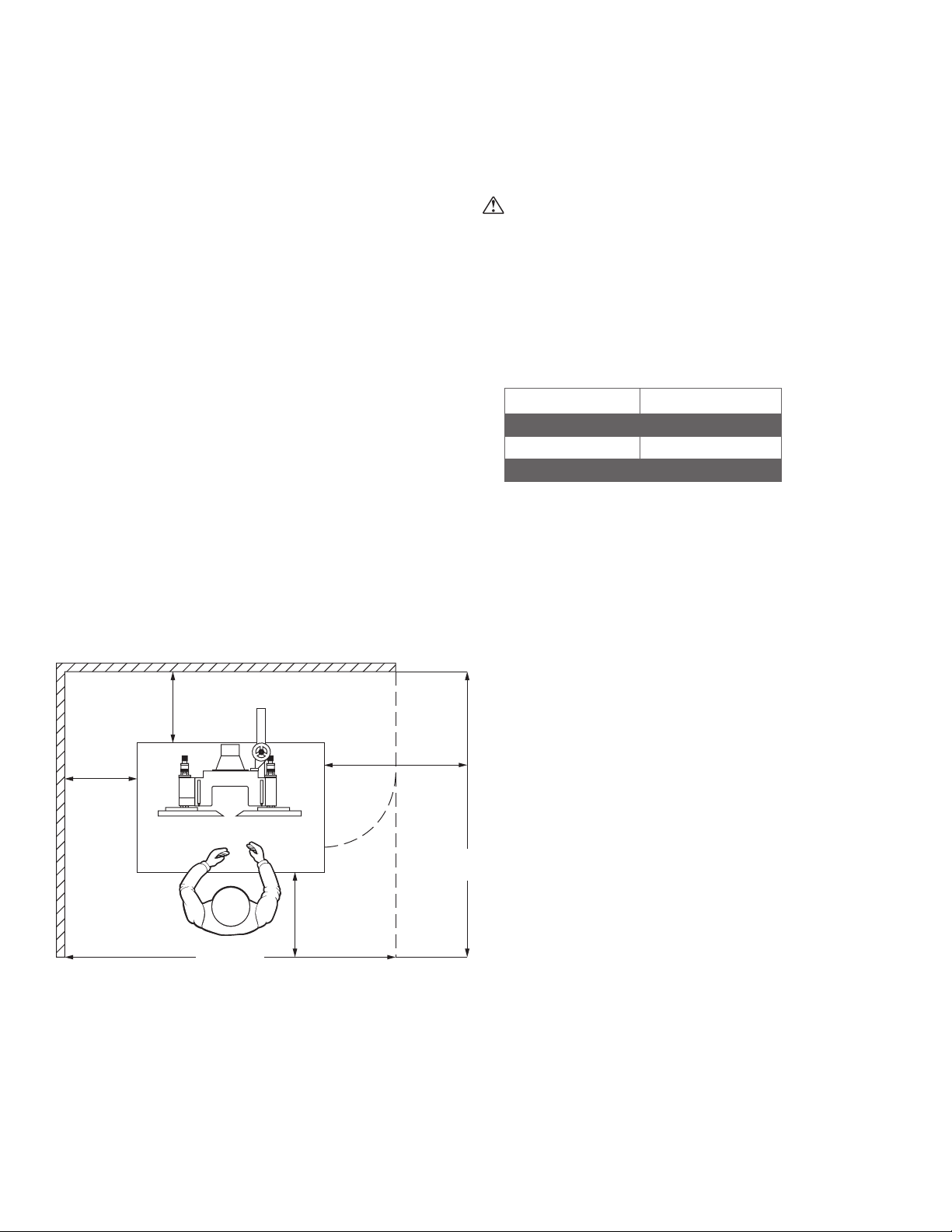

2.2 Work Space

• Provide adequate work space surrounding the machine.

• Provide proper non-glare, overhead lighting.

• Place the machine so that any potential kickback area is not in

line with aisles, doorways, or other work and traffic areas.

• Provide adequate dust extraction system. The dust extraction

system should have a flow rate of 4,500 feet/min. at 1,000 cfm.

• Avoid exposure to any environment where vibration is present.

Standard machine clearance requirements*

1'-6"*

(500mm)

1'-6"

(500mm)

1'-6"*

(500mm)

2'-0"

(600mm)

6'-6"

(2000mm)

7'-6"

(2300mm)

*Actual clearance requirements may very depending on length of

material to be processed.

2.3 Power

WARNING

A licensed electrician must connect the FX 550 to the building

power source.

• Do not using extension cords.

• Be sure that the electrical current of the power source is of the

same characteristics as the electrical system supplied with your

machine. If other machine voltage capabilities are required,

contact Stiles Machinery.

FX 550

Motor 5.5 HP

Motor Power 230v / 460v (3 phase)

Amperage 15.6 (230v) / 7.6 (460v)

• Ensure the machine is protected with an external over-current

protective device per your local electrical codes.

• Electrical equipment operating conditions:

• Air temperatures between +41ºF (+5ºC) and +113ºF (+45ºC).

• Relative humidity not to exceed 50% at a maximum temperature

of +113ºF (+45ºC).

• Electrical equipment is designed and protected to withstand the

effects of transportation and storage temperatures within a range

of -13ºF (-25ºC) to +131ºF (+55ºC), and for short periods of time

not exceeding 24 hours at up to +158ºF (+70ºC).

• Ensure connection to factory ground system is wired correctly

(IAW local electrical codes and NEC) and not connected to any

electro magnetic interference source such as welders.

Ironwood FX 550 | User Manual 7

3.0 Delivery and Installation

3.1 Receiving Your Machine

You will be contacted to arrange delivery. Your machine will be

delivered by truck to your location. If there is no loading dock, be

sure that you have informed the carrier in advance so that they

deliver using a truck with a lift gate to lower the machine to

ground level.

Before accepting the machine and signing the bill of lading from

carrier, please inspect crating and machine condition, note potential

damage on the bill of lading, take pictures of potential damage, and

contact Stiles Machinery immediately.

The machine will arrive fully crated and secured to a pallet. Use a

hand truck or fork lift to move the machine on its pallet as close to

its final position as possible.

If you do not intend to install the Ironwood Shaper immediately after

delivery, store it in a protected, cool, and dry location.

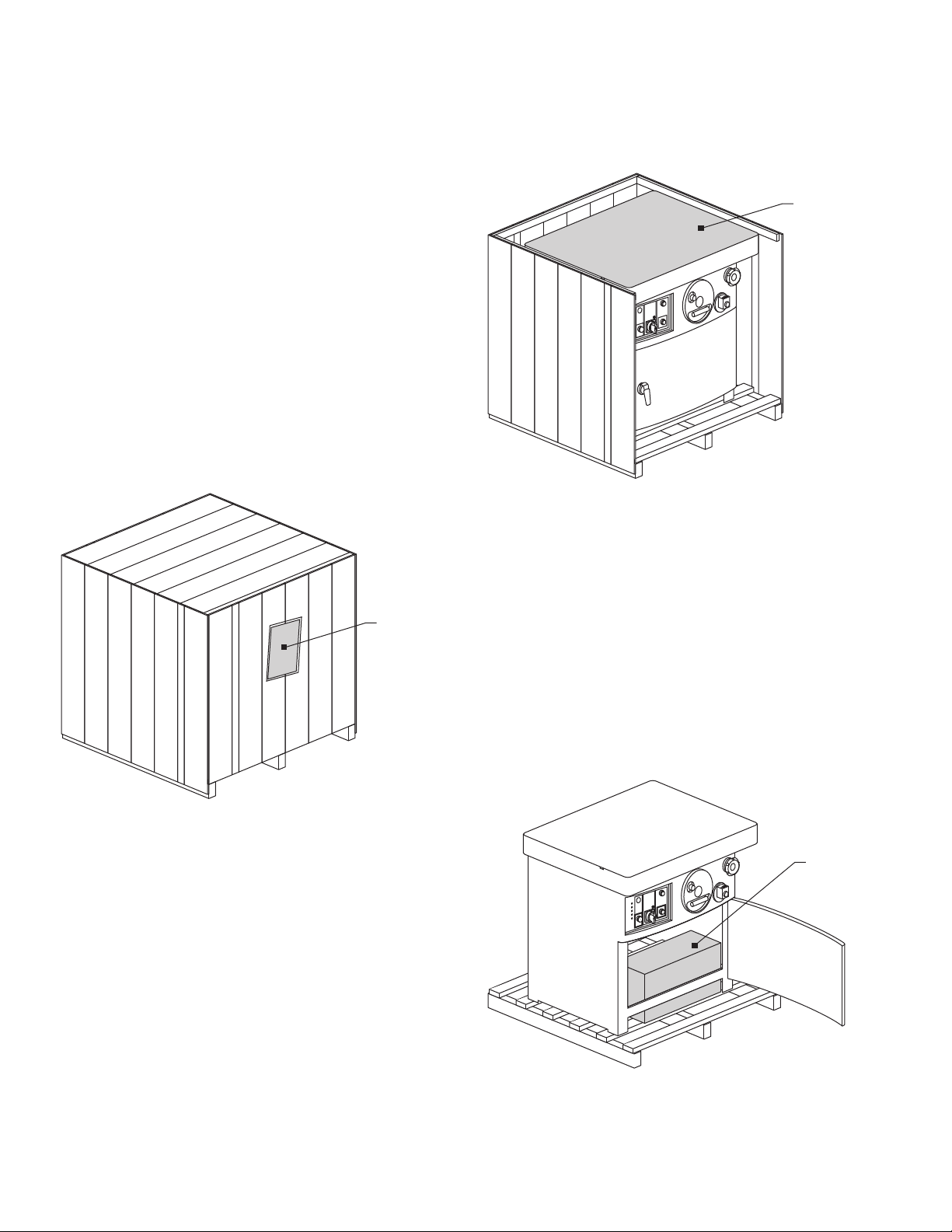

The machine

arrives fully

crated. Remove

and save the

paperwork

attached to

the outside.

3.2 Unpack the Machine

TOOLS REQUIRED:

• Hammer

• Crowbar

Unpack as follows:

Do not remove the machine from the pallet.

1. Remove and save all paperwork attached to the outside of

the crate.

2. Remove the crating, starting with the top, then remove the four

sides. Use caution to avoid personal injury and prevent damage

to the machine’s finish.

3. Remove the protective plastic from the machine, starting at

the bottom.

Remove the

crating, starting

with the top,

then remove

the four sides.

Do not remove the protective paper that covers the

tabletop surface.

4. Remove the plastic sleeve from the front access door handle.

The door is locked when the handle is in the vertical position.

Turn the handle to the right to unlock and open the

access door.

5. Remove the hardware, accessories, and a tool kit that are

shipped inside the machine. If additional accessories are

ordered, such as a power feeder, they are delivered on

a separately.

6. Close and lock the front access door.

Remove the

parts stored

inside the

machine.

Ironwood FX 550 | User Manual8

3.3 Inspection

Save all containers and packing materials until you are satisfied

that your machine has arrived in good condition. If you discover the

machine is damaged after you’ve signed for delivery, immediately

call Stiles Customer Service.

When you are completely satisfied with the condition of your

equipment, you should inventory its parts.

Open and check the contents of all containers to ensure all tools,

hardware, and accessories are included. The tool kit should contain

the following items:

1. 6-piece open end wrench set

2. T-wrench for fence with adjustable supporting bar

3. Spanner wrench for spindle retaining nut

4. 11⁄4" spindle nut wrench

5. 11⁄4" x 6" (152mm) spindle set with safety nut

6. 7-piece Allen wrench set

7. Grease gun

8. Cabinet handle key for locking/unlocking cabinet access door

9. Handwheel

10. Paint (2-color set)

3.4 Move Machine to Final Position

Be sure the site is properly prepared. Refer to section 2.0 for details.

Be sure the front access door is closed and locked

before transporting.

TOOLS REQUIRED:

• Hand truck or fork lift

Use a hand truck or fork-lift to move the machine on its pallet to

its final location. If using a fork lift, make sure fork travel is clear of

any obstacles.

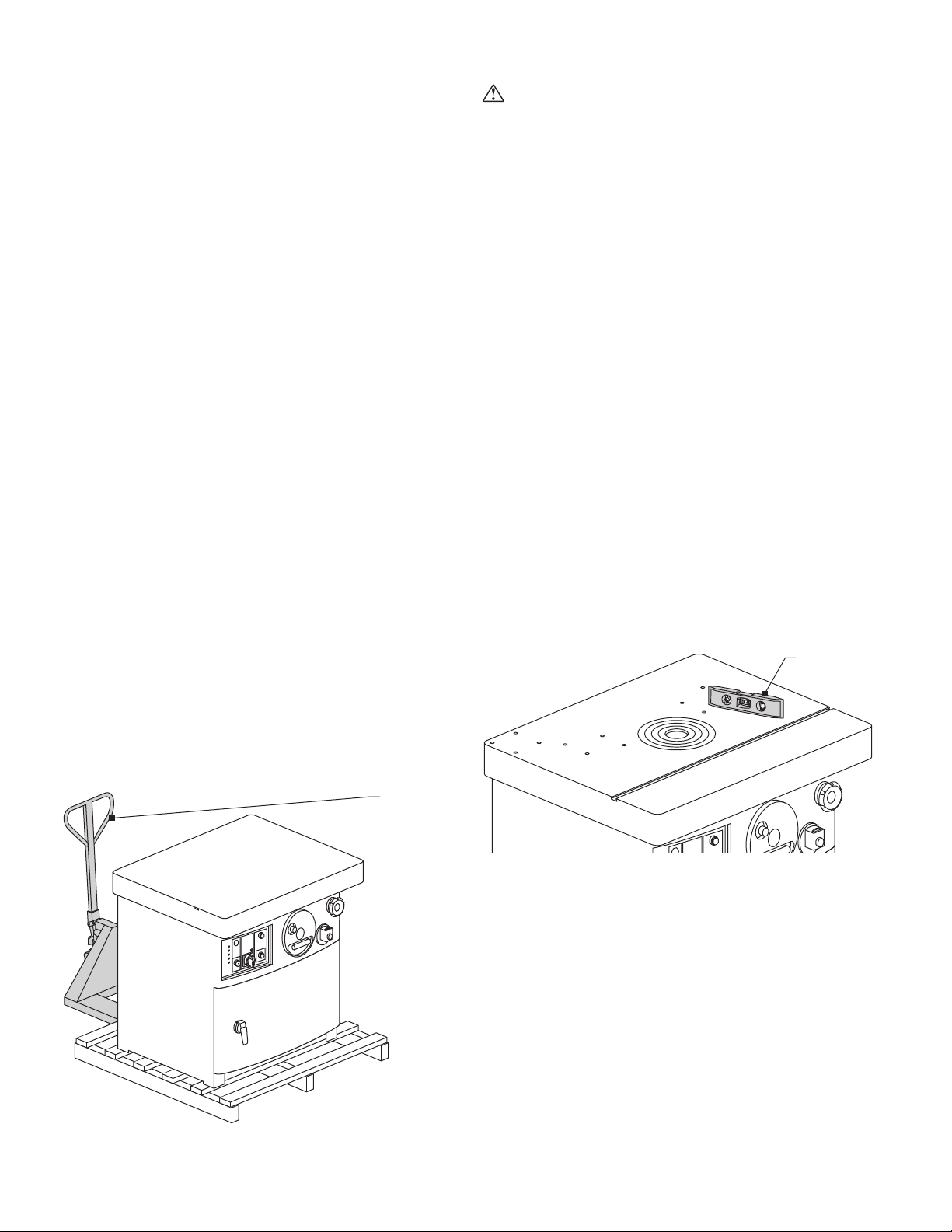

Use a hand

truck or fork

lift to move

the machine.

3.5 Remove Machine from Pallet

CAUTION

The FX 550 weighs 814 lbs. For this procedure, we

recommend using four people.

TOOLS REQUIRED:

• Adjustable wrench

• Access door key

Carefully remove the machine from the pallet.

1. Remove the two bolts that secure the fence assembly.

2. Remove the fence assembly.

3. From inside the cabinet, remove the four 1/2” (13mm) bolts that

secure the machine to the pallet at the interior corners.

4. Lift the machine from the pallet by one of 2 methods:

a. Team lift

b. Slide machine onto forks of fork lift

5. Carefully slide the machine into final position.

3.6 Level

TOOLS REQUIRED:

• Bubble Level

• Adjustable wrench

Use a bubble level along the length and width of the tabletop surface

to check for level. Use an adjustable wrench to adjust leveling bolts

to level machine.

Be sure to level

the machine.

Ironwood FX 550 | User Manual 9

3.7 Pre-Operation Cleaning

WARNING

Use proper cleaning agents and methods described below. Do not

use gasoline or other petroleum-based solvents. Risk of fire

or explosion.

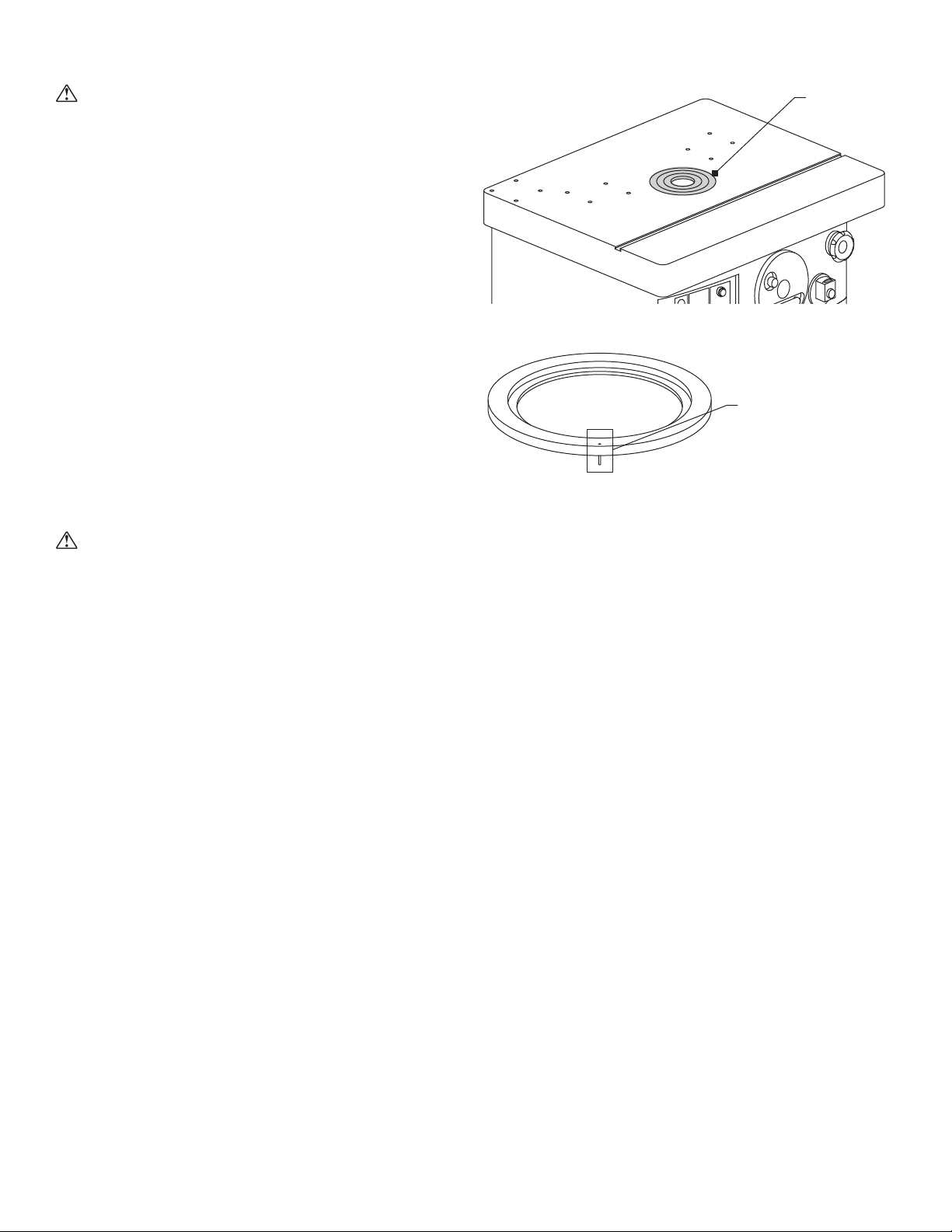

Machine Tabletop Surface

Remove and discard the protective paper from the top of the

machine. Use a soft cloth and nonflammable degreasing agent, such

as Simple Green or other citrus-based cleaners to carefully clean off

all grease. Do not use abrasive pads.

Table Rings

Spindles are fitted with up to three table rings for a wide variety of

tooling configurations. Table rings may be inserted or removed

individually. Remove and clean the rings, starting with the

innermost ring.

Be aware that the rings fit tightly. To remove a ring, place fingers

inside ring and position on opposite sides. Gently rock the ring

back and forth to release the pin. Remove all rings and clean with

degreasing agent.

CAUTION

Threads on the spindle and spindle shaft are very sharp. Use care

when cleaning to prevent injury.

With all rings removed, thoroughly clean the taper of the spindle and

the internal taper of the spindle shaft.

To replace the rings, start with the outer ring. Align the locator pin

on the bottom of the ring with the insert on the outer rim. Repeat for

each ring.

Table rings are

supplied with

the machine.

Outer ring with

locator pin.

Ironwood FX 550 | User Manual10

4.0 Assembly

To be assembled:

• Fence Assembly and Fences

• Spindle

• Cutter Head/Tooling

• Top Dust Cover

• Safety Guard Assembly

• Mitre Gauge Assembly and Clamp

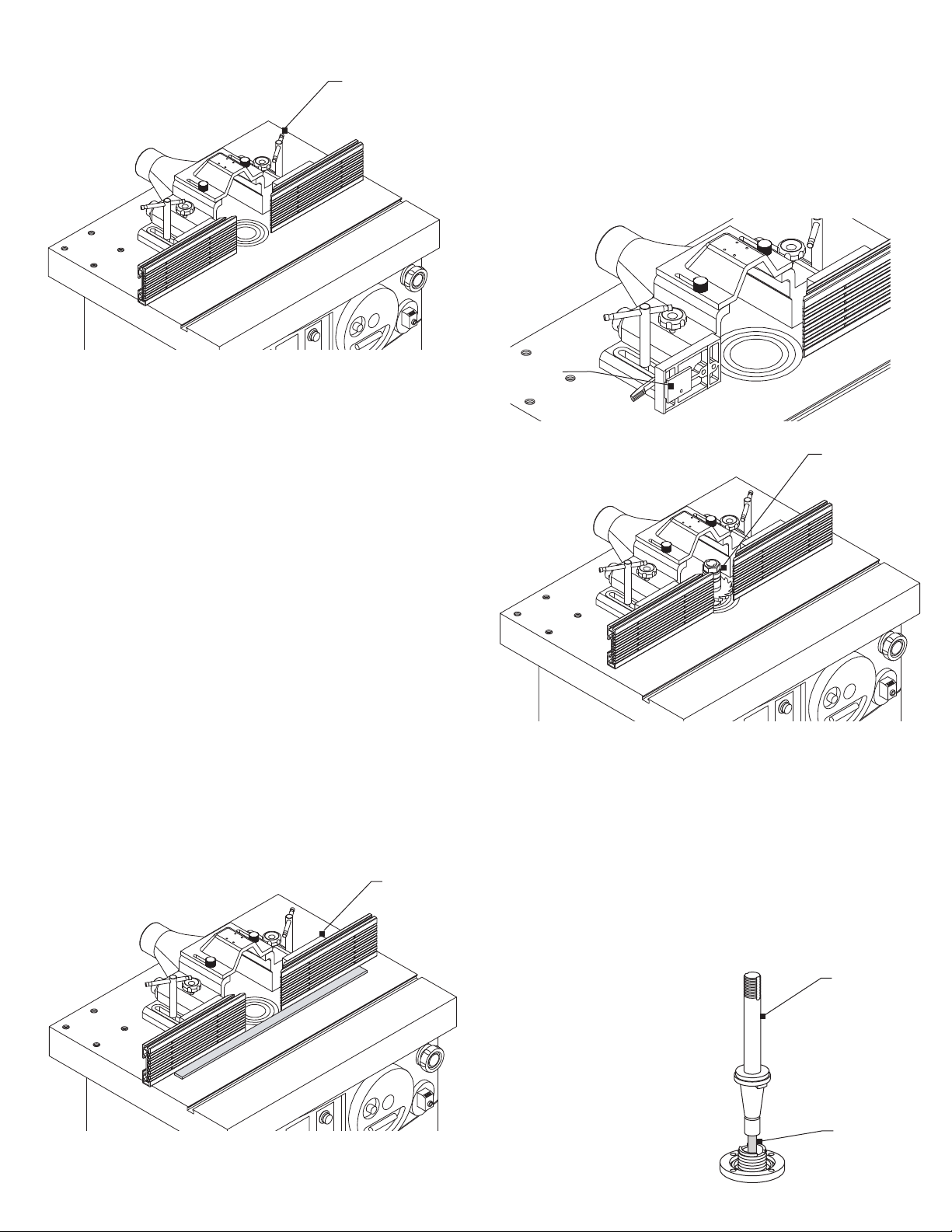

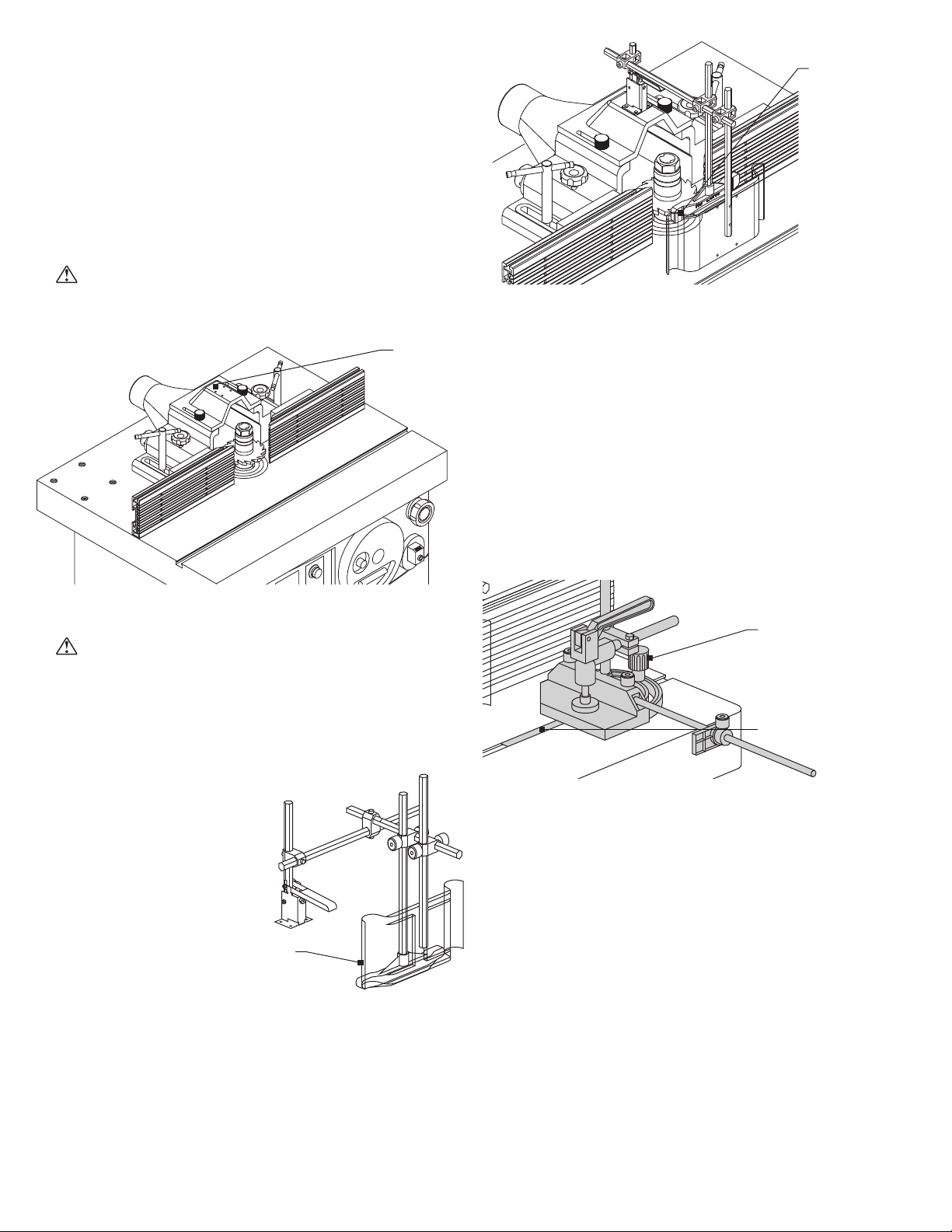

4.1 Fence Assembly and Fences

CAUTION

For this procedure, we recommend using two people.

PARTS REQUIRED:

• Fence assembly

TOOLS REQUIRED:

• Allen wrench set

• Adjustable wrench

The fence should always be used for straight work cutting to guide

the workpiece.

The fence has two halves: An infeed fence and an outfeed fence.

Both must be installed to the fence assembly. The infeed fence is on

the right as you face the machine; the outfeed fence is on the left.

The cast iron fence assembly is adjustable, and the slotted

aluminum fences can be adjusted to maximize safety and allow

precision shaping for every cutter used on the machine. Independent

fine adjustments and digital readouts are included to precisely

position infeed and outfeed fences. Quick fence changeovers

provide the flexibility needed to create quality profiles in a short time.

Fence assembly

(front and back views).

1. Locate the bracket at the rear of the table. Remove the screws

from the horizontal arm of the bracket and set them aside.

2. Place the fence assembly body on the rear of the table as

shown, aligning the forward set of pilot holes with the

bracket holes.

3. Reattach the screws to secure the fence to the bracket. Do not

fully tighten.

4. Fasten locking bars to the front of each fence block half using

the locking lever and washer. Locking levers are spring-loaded

and can be repositioned by pulling out the handle or by using

an Allen wrench.

5. With the locking levers loosened, slide the infeed fence half and

outfeed fence halves onto the locking bars. Be sure the beveled

end of each fence faces the center of the table. Tighten each

fence using its locking lever and washer.

Fences attach

to the fence

block

6. Locate the two fence locking handles and washers. Attach

the handles in the slots. Position the fence so that the locking

handles align with the forward two sets of holes located on the

machine table. Tighten the locking handles.

7. To reposition the complete fence assembly on the table, loosen

the two locking handles, move the fence assembly to the

desired position, and tighten the two locking handles.

Infeed

fence

Outfeed

fence

Ironwood TS 750 | User Manual

Ironwood FX 550 | User Manual 11

Be sure the fences

are be aligned

Locking handles

Moving fence assembly

The fence assembly is moved in an out to roughly align fence and

move into the desired position.

To move the fence assembly, loosen locking handles located on top

of the fence assembly until the fence assembly is in the desired

position. Tighten the locking handles to secure.

Moving infeed and outfeed fences

Each fence half (infeed and outfeed fence) can be moved

independently, in or out, depending upon the type of shaping

operation to be performed.

To move fence(s) in or out, loosen one of the locking knobs and turn

one of the adjusting knobs until the desired setting is obtained on

the digital readout. Tighten the locking knob.

Aligning infeed and outfeed fences

1. Place a solid steel ruler along the infeed and outfeed fences,

adjust the fences so they are parallel to one another.

Fences are

adjustable

2. Adjustment of the fences depends upon the configuration of

your machine. If adjusting screws are present on your model,

adjusting screws will be used for alignment. To adjust fences

for parallelism, either adjust adjustment screws or place shims

between the round rods and fence block until both fences are

parallel to one another. Fences are aligned at the factory but

may move during shipping. Check parallelism before continuing

with procedure.

Adjustment point

is shown behind

the plate

Adjust the fence

gap in relation to

the cutter.

4.2 Spindle

PARTS REQUIRED:

• Spindle

• Drawbar

TOOLS REQUIRED:

• Spanner wrench

• Adjustable wrench

1. Remove table rings for easy access to main shaft.

2. To access the locking collar, use the handwheel on the front of

the machine, raise the main shaft all the way to the top.

3. Thread the short-threaded end

of the draw bar into the threaded

hole in the bottom of the spindle.

This is the end without the 2 nuts

and bevel washer.

4. Remove the two lock nuts and

bevel washer from the other end

of the draw bar.

5. Carefully insert the draw bar and

spindle down through the shaft.

Spindle

Draw bar

threaded

into spindle

Make sure

the lip on the

spindle is

engaged with

the notch.

Ironwood FX 550 | User Manual12

Make sure the lip on the spindle is engaged with the notch on

lock nuts and bevel washer on the bottom of the draw bar as

shown in picture. Ensure the bevel washer is put on the draw

bar before the 2 lock nuts. Tightening the drawbar will center

the spindle.

6. Engage the spindle lock. The spindle lock is provided to assist

when changing the spindle or installing and removing cutters.

Two lock nuts and a bevel

washer attach to the

bottom end of the draw bar.

• To lock the spindle, turn the knob counterclockwise and

push into the locked position.

• To unlock the spindle

so it rotates freely,

pull out the knob

and turn clockwise.

The knob will latch

into the unlocked

position.

The manual lock has a

limit switch to prevent the

motor from starting when

engaged.

7. Securely tighten the two lock nuts

with wrench.

8. Thread the spindle safety nut onto the

threads.

9. Tighten the spindle safety nut, using

the spanner wrench supplied with

machine.

4.3 Cutter Head/Tooling

PARTS REQUIRED:

• Spacers

• Tool/cutter head (Not supplied. To

source or for more information, contact Stiles Machinery.)

TOOLS REQUIRED:

• Spindle nut wrench

Install the cutter head or other tooling on the spindle.

Spindle

lock knob

Tighten

the spindle

safety nut.

WARNING

The cutter is extremely sharp. Use caution when handling or working

with the cutter.

1. Place the cutter head and spacers onto the spindle. Place the

tool as close to the bottom of the spindle as possible.

2. Attach the keyed washer on the spindle, making sure the

washer engages the grooves on the spindle.

WARNING

Always place the keyed washer on the spindle before threading on

the nut. The keyed washer prevents the nut from loosening when the

spindle turns in a counterclockwise direction.

3. Be sure that the top retaining nut and top spacer are in

firm contact.

CAUTION

There must be no gap between the bottom of the retaining nut

and the top of the uppermost spacer. Any gap that exists during

operation could result in significant damage to the spindle.

4. Attach and tighten the nut with all threads engaged using the

provided spindle nut wrench.

5. Disengage the spindle lock as explained in 4.2 Step 6.

CAUTION

The cutter should be positioned on the spindle so that the cut is

performed from underneath the surface of the workpiece.

WARNING

After installing or replacing cutters and before operating the

machine, carefully check to ensure that the direction of the cutter

and keyed washer is correct, and that the spindle rings are directly

underneath the spindle nut and securely tightened.

Retaining

ring nut

Spacer

Cutter

Spindle

safety nut

Tooling

attaches to

the spindle.

Secure

tooling to

the spindle.

Ironwood FX 550 | User Manual 13

4.4 Top Dust Cover

PARTS REQUIRED:

• Dust cover assembly

TOOLS REQUIRED:

• Allen wrench

Assemble the top dust cover to the top of fence body using the

two locking knobs and washers included in your attachment

hardware pack.

WARNING

Do not operate the machine without the dust cover attached.

The top

dust cover

attaches

to the

fence body.

4.5 Safety Guard Assembly

WARNING

Always use the safety guard assembly and hold-down when

operating the FX 550. Select and adjust the safety guard to the

tooling currently being used.

PARTS REQUIRED:

• Safety guard assembly

TOOLS REQUIRED:

• Allen wrenches

1. Attach the guard base to

the fence assembly body at

the pilot hole locations using

screws provided.

2. Attach a bracket to the

vertical bar in the base,

with the bracket facing

the operator. Loosely

attach the bar using an

Allen wrench and set screw.

3. Loosely install a horizontal bar on the bracket. Loosely attach

a bracket at the other end, with the bracket facing up. Loosely

install the other horizontal bar so it extends toward the operator,

beyond the fence. Attach two brackets with hand screws at the

other end of the horizontal bar.

4. Attach the orange hold-down to the end of the inner vertical bar.

5. Attach the clear plastic safety guard to the outer vertical bar

using set screws.

Always use

the safety

guard assembly.

The safety guard

is installed on the

fence assembly.

6. Once the safety guard assembly is configured as shown, tighten

all set screws.

The safety guard hold-down assembly can be angled up out of the

way using the adjustment lever.

4.6 Miter Gauge Assembly and Clamp

Use a miter gauge to make small or angled cuts.

PARTS REQUIRED:

• Miter gauge assembly

TOOLS REQUIRED:

• None

Mitre gauge

assembly.

Mitre gauge

bar.

1. Angle the hold-down and safety guard up out of the way.

2. Locate the miter gauge bar and insert the bearing of the bar

into the T-slot of the machine table.

3. Place the miter gauge on the bar, with the stud of the bar

protruding up through the opening in the miter gauge body.

4. Fasten in place using washer and locking knob.

Stop Bar

1. Insert the stop bar into the hole on the side of miter gauge

body, and lock into place with locking knobs.

2. Assemble the stop to the stop bar as shown in image above,

and tighten the locking knob.

Clamp

A clamp is supplied with your miter gauge to securely hold

workpieces. The clamp can be moved up or down as required.

Ironwood FX 550 | User Manual14

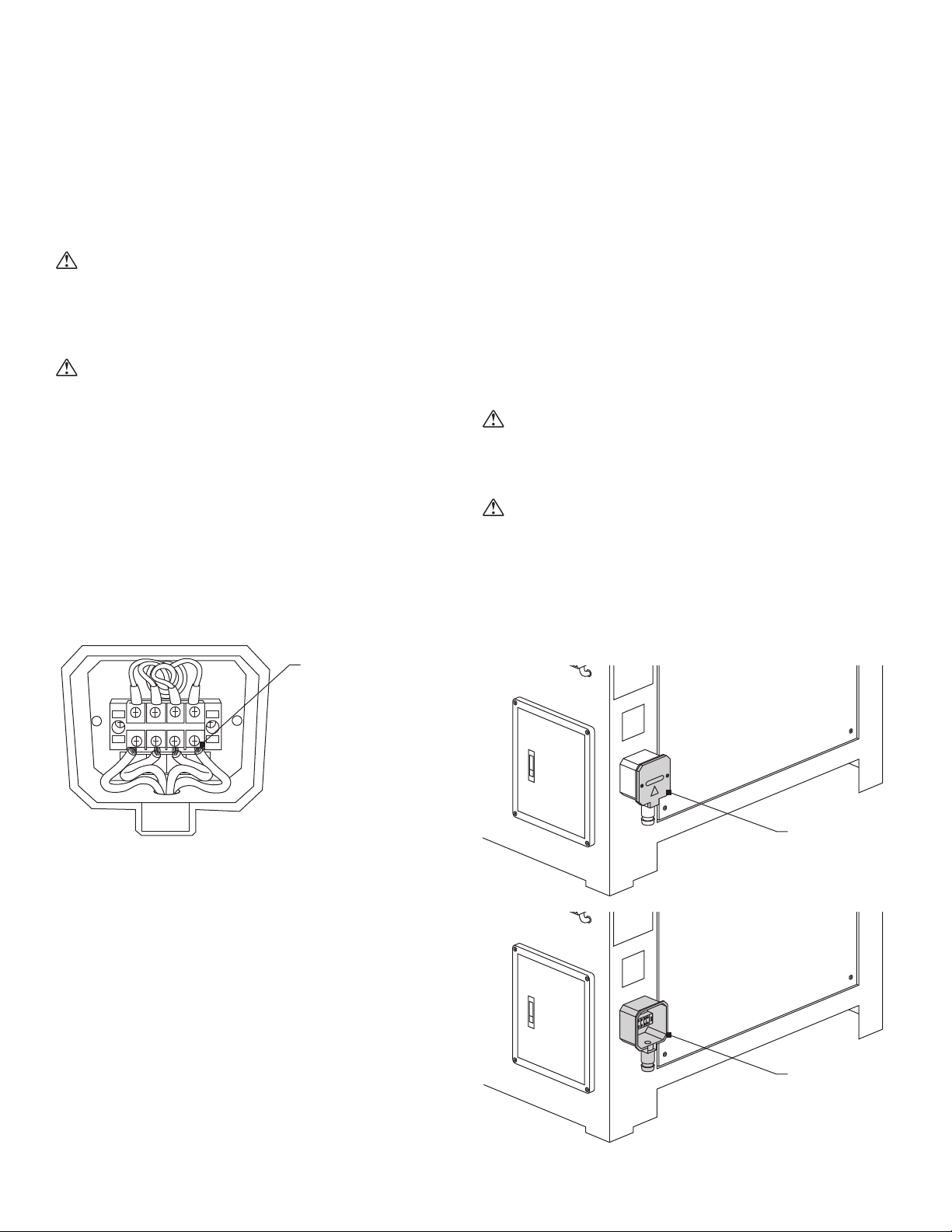

5.0 Connect to Power

• Voltage – Steady state voltage +/- 10% of nominal voltage

@230v +/- 10% of voltage @460v .

• Machine needs steady voltage at all times.

WARNING

Before connecting power to the machine, make sure all screws and

fasteners are tightened, all mechanical functions work freely and the

cutter turns freely without touching the table rings.

WARNING

All connections to electrical power should be completed by a

licensed electrician.

Before connecting to a power source, confirm that the electrical

current of the power source is the same as the electrical system

supplied with your machine. Ensure the machine is protected

with an external over current protective device per your local

regulating authorities.

Machine must be properly grounded to prevent electric shock.

Never connect the yellow/green wire to a live terminal.

Once connected to power source, terminals are electrified even

while the power switch is off.

L3

234

L2L1 PE

PE

L1

L2

1

L3

Proper wiring inside

the terminal strip box

To connect source power to the machine:

1. Remove two screws and remove terminal box cover.

2. Remove clear plastic insulator that covers the terminals.

3. Insert source power cables through opening of terminal box.

4. Connect the three power cables to terminals L1, L2 and L3,

and the yellow/green ground wire to ground terminal.

5. Replace the clear plastic insulator and the power box cover.

6. When wiring is complete, tape all terminal box joints to keep out

dust and debris.

WARNING

Always shut off power at source before removing terminal box cover.

Failure to comply with this action may result in electric shock.

CAUTION

We have covered some basic electrical requirements for the safe

installation of your machine. These requirements may not cover

all installation requirements. You must confirm that your particular

electrical configuration complies with all local codes. Ensure

compliance by checking with your local municipality and a

licensed electrician.

Remove terminal

box cover.

Remove the clear

plastic insulator that

covers the terminals.

Connect power and

grounding wires.

Ironwood FX 550 | User Manual 15

6.0 Safety

WARNING

Like all power equipment, there is danger associated with the

Ironwood FX 550. Use caution and follow all safety instructions.

Take every precaution to protect yourself, others around you, and

the machine itself from improper use. Safety is a combination of

common sense, training, and being alert at all times while operating

your machine. If instructions, warnings, and cautions, are not

followed, serious personal injury or death may occur.

EYE PROTECTION: Always wear approved safety glasses, or a

face shield when operating this machine. Only use eye protection

that meets or exceeds the standards of the American National

Standards Institute (ANSI).

EAR PROTECTION: Always wear ear protection during

machine operation.

DRESS CODE: Do not wear loose clothing, neckties, jewelry, or

gloves that can get caught in moving parts. Confine long hair and

keep sleeves above the elbow.

ELECTRICAL GROUNDING: Your machine must be electrically

grounded. If a cord and plug are used, make certain the machine is

properly grounded. Follow the grounding procedure indicated by the

National Electric Code and local regulating authorities.

GUARDS: Make certain that machine guards are in place and in

good working order. If a guard must be removed for any operation,

replace it immediately following completion of that operation.

TOOLING AND ACCESSORIES: Use only recommended tooling

and accessories. Improper tooling and accessories may cause

damage to your machine or personal injury. Always run at the

correct speed and feed rate. Never force a tool or accessory to

perform a job for which it was not designed. Maintain your tools

and accessories. Knives should be sharpened and cleaned for

safe, optimal performance. Follow instructions for lubricating and

changing tooling and accessories.

POWER: On machines equipped with a manual starter, make sure

that the starter is in an “OFF” position before connecting power to

machine or electrical maintenance.

Make certain the machine is either unplugged or electrically

disconnected and locked out when performing all other

maintenance, cleaning, or machine adjustments. Never leave the

machine running unattended. Always turn the power off and stay by

the machine until the cutterhead comes to a complete stop.

HOUSEKEEPING: Before turning machine on, remove all extra

items on or around the machine. Keep the work area clean and free

of scrap material, sawdust and other debris to minimize the danger

of slipping. Use compressed air or a brush to remove chips or

debris. NEVER use your hands.

Ironwood FX 550 | User Manual16

7.0 Start the Machine

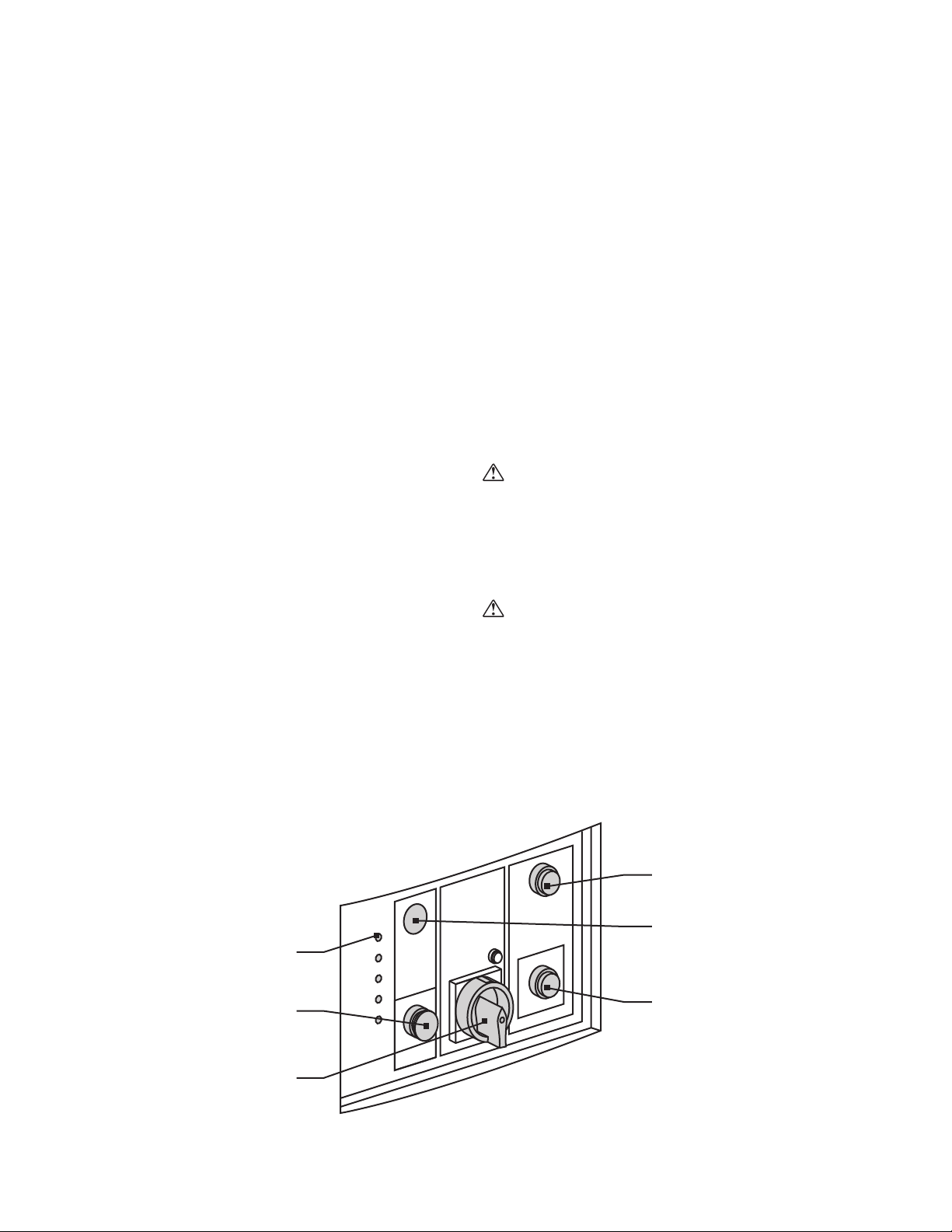

7.1 Control Panel

The control panel on the front of the machine handles all control

functions. It has the following features:

A. Speed indicator

B. Emergency stop

C. Forward/Reverse/Off switch

D. Spindle Reverse light

E. Control Power on Switch

F. Control Power off Switch

7.2 On/Off

Use the following procedure to start or stop the machine:

1. Make certain that the spindle lock is disengaged and that the

front access door is in the closed position.

2. Check rotation of spindle motor by turning motor on and off

very quickly. Observe direction of rotation. If spindle rotation is

backwards, do the following:

a. Turn power off to the machine.

b. Turn off main power supply / disconnect the machine.

c. Open terminal box, remove plastic covers and test with as

multimeter to ensure there is no power at the machine.

d. Swap leads L1 and L2 to change phase rotation.

e. Reassemble terminal and plastic covers.

f. Turn on main power supply / connect the machine

g. Turn power on to the machine.

h. Repeat steps to check direction.

3. Rotate the Forward/Reverse/Off switch to either the forward or

reverse rotation depending on tooling.

4. Push the Control Power On switch to start the machine.

5. To stop the machine, push either the Control Power Off button

(preferred method), or turn the Forward/Reverse/Off switch to

the middle.

In an emergency press the Emergency Stop button.

a. When servicing the machine, press the power off button

and turn the main on/off switch to 0, then place a sign

on machine and install padlock on the main on/off switch

before servicing it.

The electrical cabinet door must be closed except while servicing or

troubleshooting.

WARNING

When opening the electrical door, make certain that the main power

switch is shut OFF. Failure to comply with this action may result in

electric shock.

7.3 Reverse Spindle Rotation

CAUTION

Never attempt to reverse the rotation of the spindle while the motor

or spindle is in motion. Control power will drop out when the switch

is turned to the middle/off position.

To reverse the rotation of the spindle, shut off the motor then rotate

the forward/reverse/off switch after the spindle has come to a

complete stop.

E

D

F

C

B

A

Ironwood FX 550 | User Manual 17

8.0 Operation

WARNING

Do not attempt to operate machine if you are not completely familiar

with its operation. Obtain immediate advice from a supervisor,

instructor, or other qualified personnel.

Use of this machine requires that you give your work your undivided

attention, and careless acts or not paying close attention to work

being performed may result in serious injury to yourself and/or

others. Never operate this or any machine under the influence of

drugs, alcohol, or any medication that may impair judgement.

SPINDLE: Make sure the direction of the spindle’s rotation is

correct. Start the machine to ensure it rotates in the correct

direction. The rotation direction should correlate with the spindle

rotation indicator light. The light is on only if the direction is in

reverse. If the direction is incorrect, check the power phase

sequence and have it corrected by a licensed electrician and see

section 6.3.

Dust created by manufacturing activities may be harmful to

your health.

Your risks from exposure may vary. Always work in a well-ventilated

area and wear safety approved, protective dust masks specifically

designed to filter out microscopic particles. Utilize wood dust

collection systems appropriate to your machine type.

d1:

spindle

diameter

d2:

tool cutting

diameter

b:

length of cut

d1

l

1

b

d2

l1:

maximum

useable length

of spindle

10000

RPM

8000

RPM

6000

RPM

4000

RPM

3000

RPM

Spindle dia. Tool length

30 mm 140

AVOID KICKBACK: It is very important that each workpiece be

carefully inspected for stock condition and grain orientation before

running through the machine. “Pull-out” and the danger of kicked

back material can occur when the workpiece has knots, holes, or

foreign materials such as nails. It can also occur when the material is

fed against the grain on the shaper. The grain must run in the same

direction you are cutting.

Use of a power feeder greatly reduces the risk of kickback.

CAUTION

During certain applications, it may be necessary to shape against

the grain. This application requires that the operator use a shallow

depth of cut and a slower feed rate.

0

0

1

2

3

4

5

b = 140

b = 120

b = 100

6

7

8

9

10

11

12

50 100 150 200 250 300 350 d2(mm)

d1= 30 mm l1= 140 mm

1000 (min-1)

nmax

b = 10

b = 20

b = 30

b = 50

b = 80

10

11

12

1000

Ironwood FX 550 | User Manual18

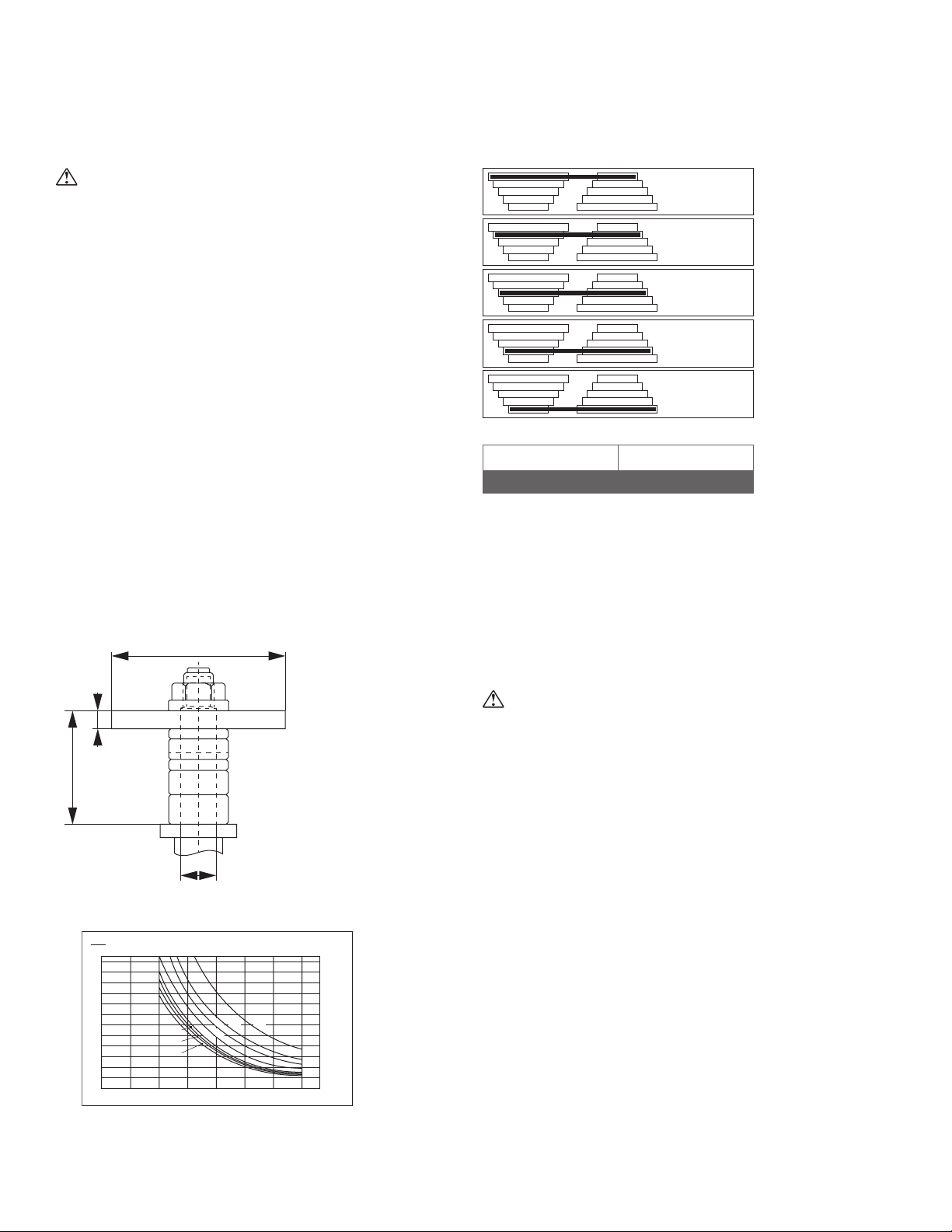

8.1 Speed Change and Belt Adjustment

Confirm that the selected spindle speed matches the suggested

spindle speed provided by the tooling manufacturer.

Before operation, check that all tools are sharp, are the correct tool

for the work to be performed, properly maintained and adjusted

according to the tool manufacturer’s instructions.

There is a relationship between tool diameter, cutting length, and

maximum rotation speed.

The maximum safe spindle speed depends on:

• Spindle diameter

• Usable length of spindle

• Length of cut

• Tool cutting diameter

• Tool specifications per the spindle manufacturer

The following charts can be used as a reference guide for the

maximum spindle speed for various tool cutting diameters given the

values of d, l, and b. Always refer back to the ratings provided by the

tool manufacturer.

Reminder: Always place the tool as close to the bottom of the

spindle as possible.

The FX 550 machines are supplied with a 5-step motor pulley and a

5-step spindle pulley that provides spindle standard speeds of 3000,

4000, 6000, 8000 and 10,000 RPM.

A chart (Label 6) is located on the inside of the access door for

easy reference of the belt position on the pulleys for the five

speeds available.

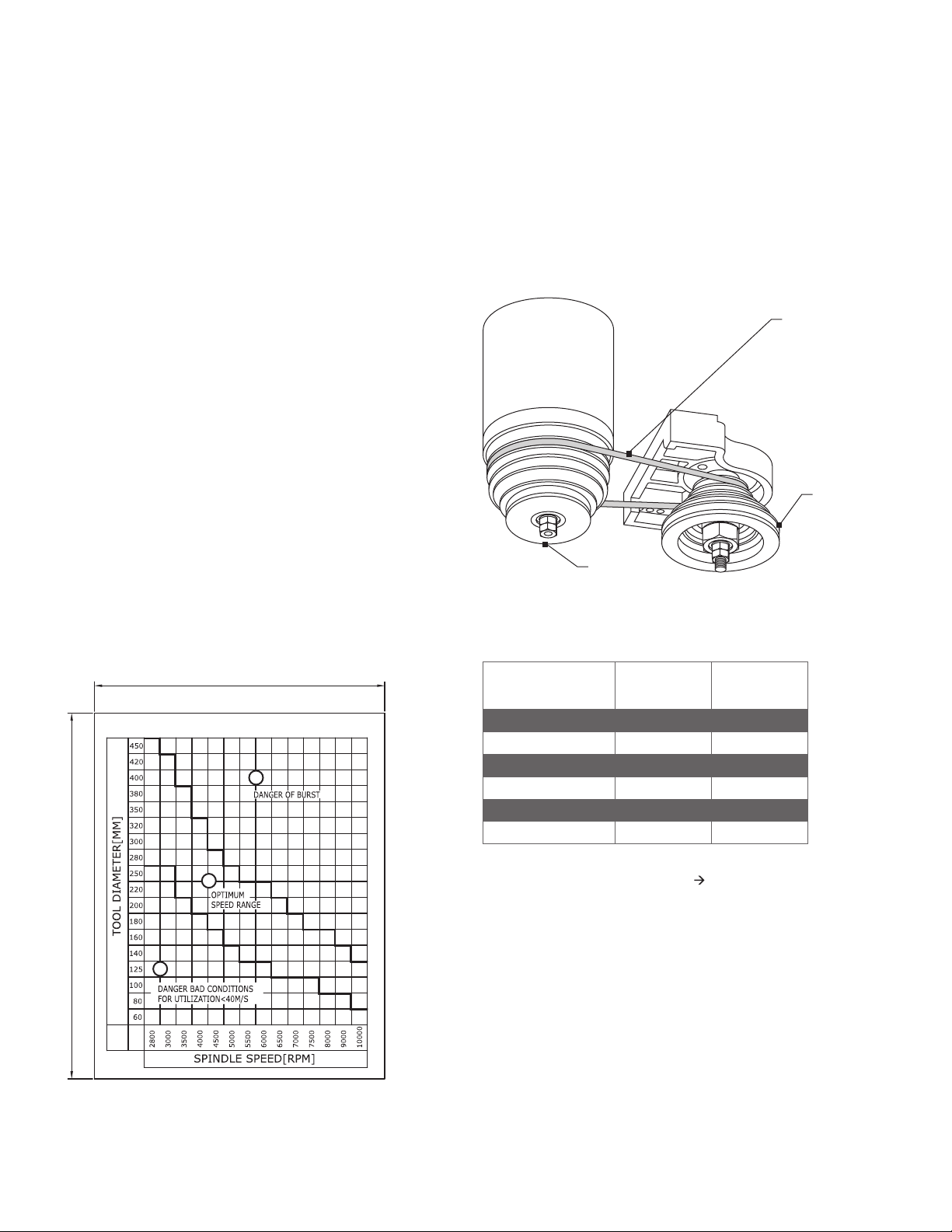

OPTIMUM SPEEDRANGE FORTOOLS ON SPINDLE MOULDER

95

120

1. Hazard: bad machining conditions

2. Bursting hazard

3. Recommended spindle tool speed

1

2

3

Confirm the machine’s speed settings before operating. Make

certain that the cutter meets or exceeds speed rating of tool.

The diagram is an example of choosing a speed in relation to the

diameter of the tool, and the most appropriate peripheral speed for

the type of material that is being worked on. Always refer back to the

ratings provided by the tool manufacturer.

Cutting speed should always be sufficient to prevent kickback risk,

but never fast enough to cause tool damage.

The cutting speed range m/sec (lower and upper) is selected

according to the tool diameter (mm) D (left vertical axis), and the tool

spindle speed N min-¹ (bottom horizontal axis).

The belt attaches

to the motor

pulley and

spindle pulley.

Spindle

pulley

Motor

pulley

Guide values for cutting speed

Material Cutter HS

(m s-1)

Cutter HW

(m s-1)

Softwood 50-80 60-90

Hardwood 40-60 50-80

Chipboard — 60-80

Coreboard — 60-80

Hard fibreboard — 40-60

Plastic-coated board — 40-60

Example:

Cutter: 160 mm diameter, vc= 76m s-1 n = 9000 min-1

Cutter speed formula:

v = (D x π x N) / (60 x 1000)

D: Tool diameter (mm)

N: Tool spindle speed (rpm)

Ironwood FX 550 | User Manual 19

WARNING

Always operate a tool at the speed range set by the manufacturer.

Failure to do so may result in serious injury or machine damage.

To change the speed and adjust to proper belt tension:

1. Disconnect the machine from its power source.

2. Open the access door. NOTE: A limit switch is provided which

prevents the machine from being turned on when the access

door is open.

3. The belt can be moved to the desired steps of the motor pulley

and spindle pulley. To loosen belt tension, move the belt tension

lever to the right. At the same time, rotate the knob to slide the

speed bar up or down so that the belt will be positioned in the

cut-out in speed bar.

4. After the belt is positioned as desired, move the tension lever to

the left to apply tension to the belt.

5. Close and latch the access door.

Note: After a short time, the belt may stretch. Check tension by

pressing the center of the belt with a force of 6.6 lbs (3 kg.) Tension

is correct when 3⁄16" (5mm) of defection is observed. Turn the two

nuts to adjust best belt tension.

Never place the V-belt under excessive strain, as this can overload

the motor and damage the bearings, spindle or belt.

8.2 Spindle Height Adjustment

Adjust spindle height to achieve the desired cut. The spindle height

can be precisely measured using the digital readout feature.

1. Loosen handwheel lock and spindle locking lever.

2. To raise the spindle, turn handwheel counterclockwise and to

lower the spindle, turn handwheel clockwise.

3. Note: One complete turn of the handwheel moves the spindle

up or down by 1mm or 2.5 mm indicated on the machine frame

(sticker).

4. Tighten handwheel lock and spindle locking lever when desired

spindle height is obtained.

8.3 Using Fence(s)

WARNING

Keep guards in place and in working order. Always use the fence

assembly when work permits.

Using the fence is the safest and most accurate method of shaping,

and should always be used when work permits. The majority of

straight work can be performed using the fence.

For normal work, where a portion of the original edge of the stock is

not touched by the cutter, both the infeed and outfeed fences are in

a straight line.

When the shaping operation removes the entire edge of the

workpiece, e.g. in jointing or making a full bull nose, the shaped

edge will not be supported by the outfeed fence edge when both

fences are in line. In this case, the workpiece should be advanced

to the position shown and stopped. The outfeed fence should then

be moved forward to make contact with the workpiece. The outfeed

fence will then be in line with the cutting circle, and the operation

can continue.

Cutting Circle

Cutter

Outfeed Fence Infeed Fence

No Support Workpiece

Feed

For some shaping

operations, the

outfeed fence should

be moved forward to

support the workpiece.

Cutting Circle

Cutter

Outfeed Fence Infeed Fence

Workpiece

Feed

For normal work,

the infeed and

outfeed fences are

in a straight line.

Note: All Ironwood shapers accommodate Stiles power feeders.

Power ports are included on the rear of the machines. For more

information review operators instructions included with the power

feeder or contact Stiles machinery.

8.4 Adjusting Fence Extensions

WARNING

To eliminate gaps between the edges of the fence and cutter, both

fences should be adjusted as close to the cutter spindle tooling

as possible.

For added safety, the fence extensions can be adjusted to the

height of the cutterhead so that you expose only the amount of tool

required to make a safe cut is exposed.

Using an Allen wrench, loosen the aluminum fence extensions, slide

them horizontally into desired position, and tighten.

Ironwood FX 550 | User Manual20

8.5 Positioning and Using Collars

When shaping with collars, the collar must have sufficient bearing

surface. Also, the workpiece must be fairly heavy relative to the cut

being made.

The collars may be used above, below, or between the cutters.

Under no circumstances should you shape a short or light work

piece against the collars.

When the collar is used below the cutter, the progress of the cut can

be seen throughout the operation. However, any accidental lifting of

the workpiece will gouge the product and ruin the workpiece.

When the collar is used above the cutter, the cut cannot be seen,

but this method offers an advantage: the cut is not affected by light

variations in the thickness of the workpiece. Also, accidental lifting

of the workpiece will not gouge the work piece; simply repeat the

operation to correct the mistake.

Using the collar between two cutters has advantages and

disadvantages of the first two procedures, and is frequently used

where both edges of the work are to be molded.

Note: Place the cutter as low as possible on the spindle to reduce

spindle deflection and ensure the best possible finish. Also, make

sure that the contacting surfaces of the cutter are smooth, clean,

and without dents.

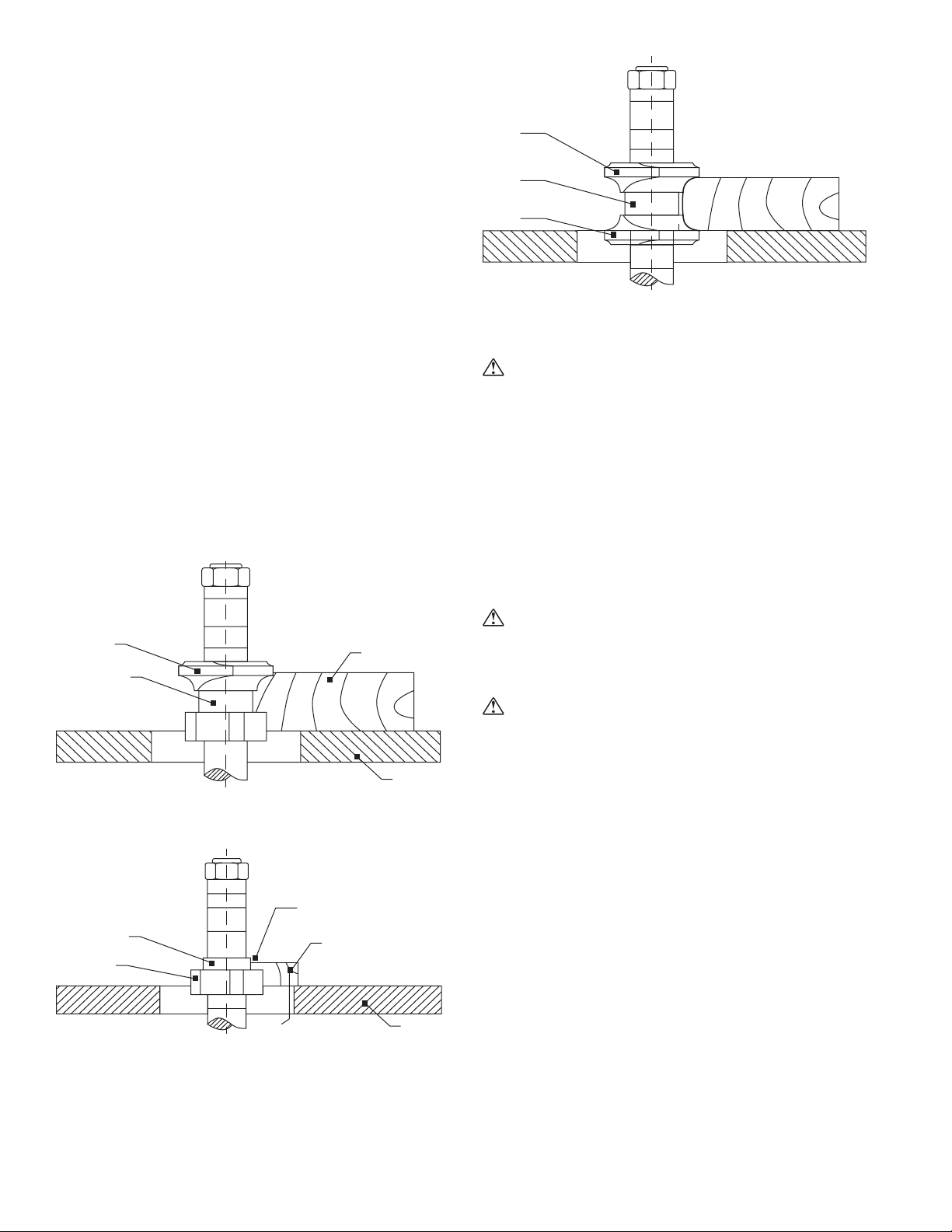

Table

Cutter

Collar

Workpiece

Collar below cutter:

the progress of the cut

can be seen throughout

the operation.

Table

Collar

Cutter

Workpiece

Be sure there’s enough

bearing surface and that

the workpiece is not too

short and light.

Insufficient

bearing surface

Workpiece

is too small

WRONG

Cutter

Cutter

Collar between two

cutters: used where

both edges are to be

molded

Collar

8.6 Tenoning

WARNING

Keep guards in place and in working order.

The miter gauge and clamp provided with the machine can be used

for tenoning operations.

If your machine is equipped with a tenoning carriage, the tenoning

hood fitted with adjustable sections is used to guard the tool from

above the workpiece and from the sides.

Various tenoning carriages are available. For more details contact

Stiles Machinery.

8.7 Tool Adjustments

WARNING

Tools are extremely sharp. Be careful when working with tooling as

serious injury may occur.

CAUTION

Always disconnect the machine from its power source before

making any adjustments.

To reduce kickback, use only tools that conform to EN 848-1:2005

and EN 848-2:2001, and that are marked MAN.

Refer to the tool manufacturer’s recommendations for clamping and

setting of tools.

To ensure safe and efficient cutting, the tooling should be suitable for

the material being cut. The tools should be sharp and properly set

with carefully balanced tool holders.

Use extra precautions when handling tools and always use

tool carriers.

8.8 Noise Reduction

• Always use hearing protection.

• Make sure tooling is in proper working condition.

• Properly position material and guards.

• Use proper tooling speed.

Table of contents