Stingray S5000 Series Instruction Manual

5330 East 25th Street

Indianapolis Indiana 46218

Phone: (888) 445-4142

www.tepid.com

Installation &

Maintenance Manual

Certied to ANSI Z358.1

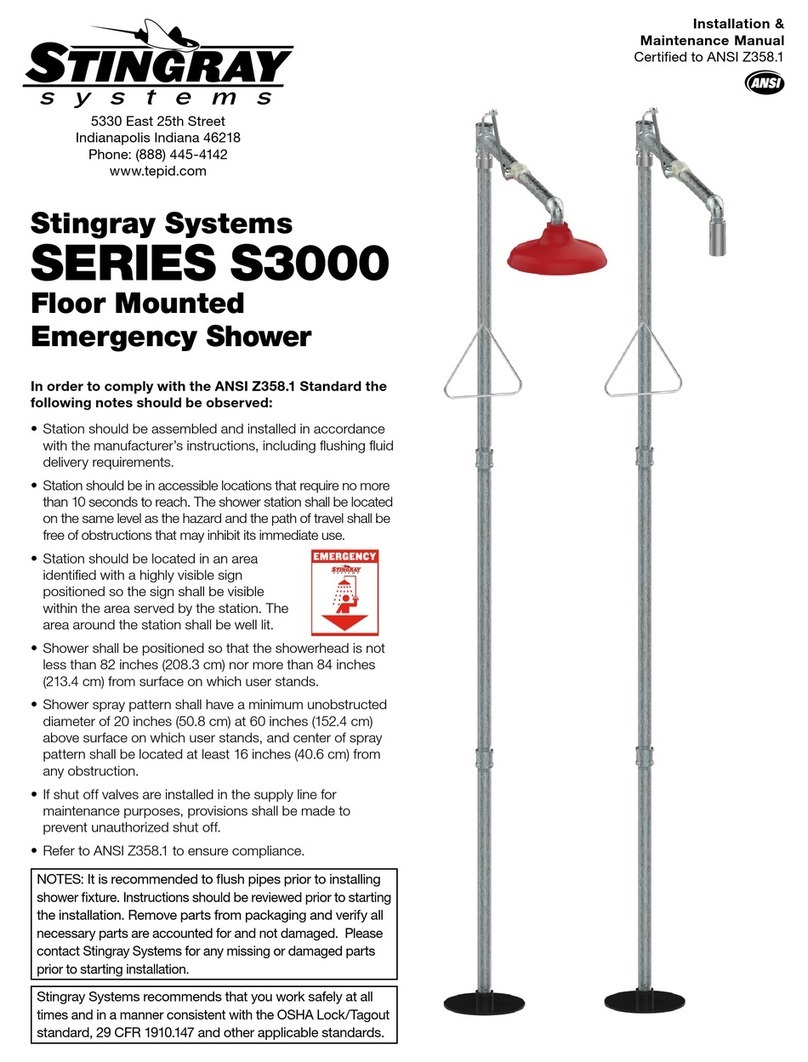

Stingray Systems

SERIES S5000

Wall Mounted Emergency

Combination Shower &

Eye/Face Wash

In order to comply with the ANSI Z358.1 Standard the

following notes should be observed:

• Station should be assembled and installed in accordance

with the manufacturer’s instructions, including flushing fluid

delivery requirements.

• Station should be in accessible locations that require no

more than 10 seconds to reach. The combination station

shall be located on the same level as the hazard and the

path of travel shall be free of obstructions that may inhibit

its immediate use.

• Station should be located in an area

identified with a highly visible sign

positioned so the sign shall be visible

within the area served by the combination

station. The area around the combination

station shall be well lit.

• Eye/Face wash shall be positioned with nozzles not less

then 33 inches (83.8 cm) and no greater than 45 inches

(114.3 cm) from surface on which user stands and 6 inches

(15.3 cm) minimum from wall or nearest obstructions.

• Shower shall be positioned so that the shower head is not

less than 82 inches (208.3 cm) nor more than 96 inches

(243.8 cm) from surface on which user stands.

• Shower spray pattern shall have a minimum unobstructed

diameter of 20 inches (50.8 cm) at 60 inches (152.4 cm)

above surface on which user stands, and center of spray

pattern shall be located at least 16 inches (40.6 cm) from

any obstruction.

• Eye/Face wash flow pattern shall be not less then 33 inches

(83.8cm) and no greater than 53 inches (134.6 cm) from

surface on which user stands and 6 inches (15.3 cm)

minimum from wall or nearest obstruction.

• If shut off valves are installed in the supply line for

maintenance purposes, provisions shall be made to

prevent unauthorized shut off.

• Refer to ANSI Z358.1 to ensure compliance.

NOTES: It is recommended to ush pipes prior to installing

emergency xture. Instructions should be reviewed prior to

starting the installation. Remove parts from packaging and

verify all necessary parts are accounted for and not

damaged. Please contact Stingray Systems for any missing

or damaged parts prior to starting installation.

Stingray Systems recommends that you work safely at all

times and in a manner consistent with the OSHA Lock/Tagout

standard, 29 CFR 1910.147 and other applicable standards.

Installation &

Maintenance Manual

Certied to ANSI Z358.1

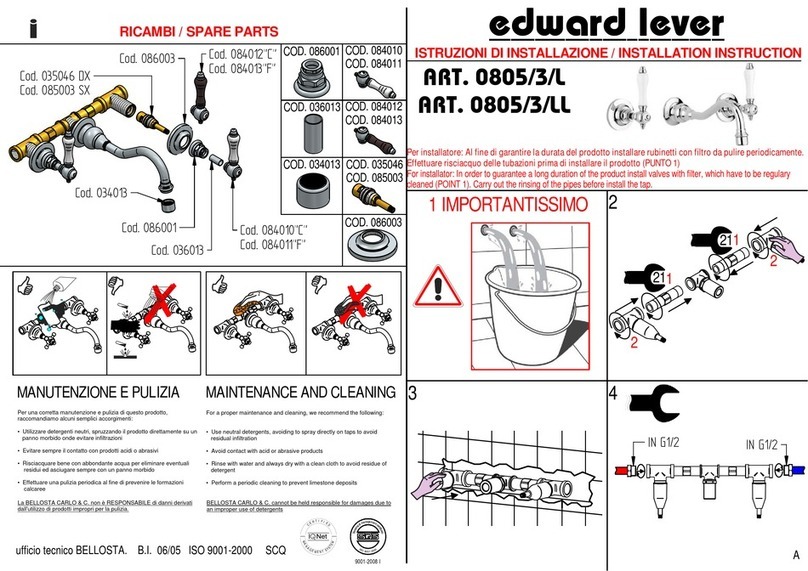

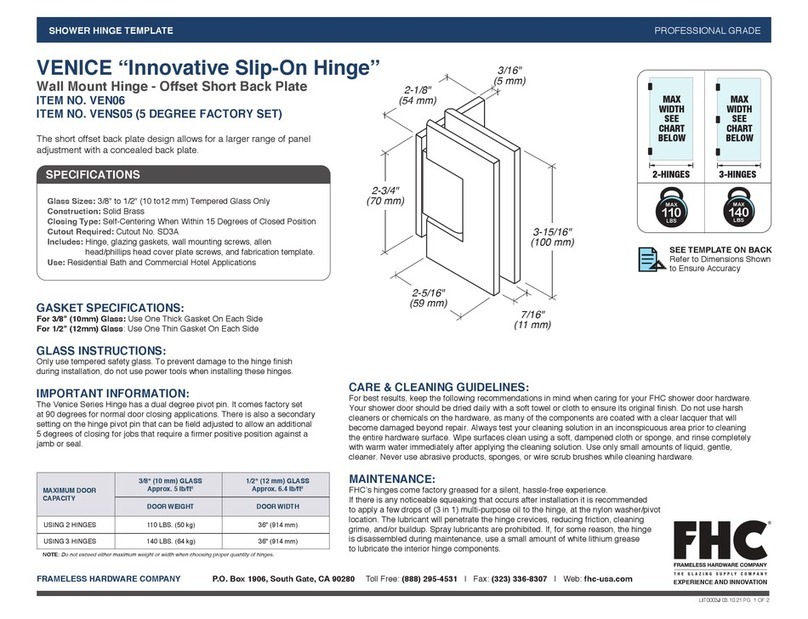

INSTALLATION SUPPLIES

2

6 7

8

10

11

2

45

3

Supplies Included:

• Wall Mount Plates (2) P

• Wall Mount Plate Screws P

• Upper Manifold Assembly P

• Lower Manifold Assembly P

• Bowl Assembly P

• Eye/Face Wash Block P

• Dust Covers P

• Shower Arm

Assembly P

• Shower Head P

• Shower Pipe P

• Drench Pull Handle P

ABS

Shower Head

Shown

Stainless

Steel

Shower

Head

9

Supplies Required (Not Included):

• Pipe Sealant or Teflon Tape - To Be Used

On All Piping Connections

• (4) 3/8” Wall Anchors Specific for Wall Substrate

WALL INSTALLATION

1. Remove loose tee with loose plug (temporarily threaded

to the Upper Vertical Assembly), and set aside.

2. Thread 30" section of Shower Pipe to Lower Manifold

Assembly. Thread Upper Vertical Assembly (shower

pipe with tee) to partially assembled unit. Retrieve loose plug

(previously set aside) and thread into partially assembled unit.

3. Attach unit to Lower Wall Mount Plate with

supplied Wall Mount Plate Screws.

4. Secure Upper Wall Mount Plate to Upper Vertical

Assembly with supplied Wall Mount Plate Screws.

5. Thread “T” onto Upper Vertical Assembly

Piping (with Mount Plate).

6. Thread Shower Arm Assembly into “T”.

7. Install Shower Head onto Horizontal Shower Assembly.

8. Locate and mount unit to wall (per ANSI standard)

using 8, 3/8" wall anchors (not included) and the

two

Wall Mount Plates

(4 anchors per plate).

9. Insert Bowl Assembly into Manifold with red drainpipe

going into drain fitting. Press fit drain fitting on Manifold

Assembly to red drainpipe on Bowl Assembly. Tighten

setscrews on side of Manifold to support tube.

10.

Loop Dust Covers onto inlet tube on Eye/Face Wash Block.

Secure the Eye/Face Wash Block to the Bowl Assembly

by ensuring the legs of the block straddle the tab on the bowl.

11.

Attach Drench Pull Handle by placing Nylon Washer on

each side of outer hole on shower activator arm. Insert

Drench Pull Handle through hole. Lock into place by

inserting Cotter Pins into holes of Drench Pull Handle.

Thread Shower Head to station. Note: For barrier free

installations, thread the two-piece pull handle together.

12.

Mount sign near (or onto) the assembled

unit at the desired location.

13.

Ensure the activator is pushed upward in the “off” position.

Then, connect 1" NPT supply piping to assembled station.

Installer to provide sufficient support of piping; assembled

station should not be relied on as piping support.

Installation &

Maintenance Manual

Certied to ANSI Z358.1

3

VALVE TROUBLESHOOTING

Problem Checklist

No hot water. Ensure hot water is on. Check pressure at both

inlets. Pressures must be near-equal, or seats will

check and only allow cold water. Need at least

30 psi at both hot and cold inlets. Need at least

a 20 degree difference between hot water and

set temperatures, as well as cold water and set

temperatures. Inspect checks for debris; clean/

replace if needed. Remove thermostat and check

for debris. Make sure liner can move. Clean

thermostat. If continues, replace thermostat.

No cold water. Ensure hot connects to hot side; cold to

cold side. Inspect checks for debris; clean/

replace if needed. Remove thermostat and

check for debris. Ensure liner can move. Clean

thermostat. Replace thermostat if needed.

No water. Ensure hot water is on. Check pressure at both

inlets. Pressures must be near-equal, or seats

will check and only allow cold water. Need at

least 30 psi at both hot and cold inlets. Need at

least a 20 degree difference between hot water

and set temperatures, as well as cold water and

set temperatures. Inspect checks for debris;

clean/replace if needed. Remove thermostat and

check for debris. Ensure liner can move. Clean

thermostat. Replace thermostat if needed.

Insufficient

flow.

Ensure hot water is on. Check pressure at both

inlets. Pressures must be near-equal, or seats

will check and only allow cold water. Need at

least 30 psi at both hot and cold inlets. Need at

least a 20 degree difference between hot water

and set temperatures, as well as cold water and

set temperatures.Inspect checks for debris;

clean/replace if needed. Remove thermostat

and check for debris. Ensure liner can move.

Clean thermostat. Replace thermostat if needed.

Temperature

fluctuation.

Ensure incoming building pressure is not

fluctuating. Inspect supply lines for other

equipment that may be reducing pressure to

the emergency fixtures. Check pressure at both

inlets. Pressures must be near-equal, or seats

will check and only allow cold water. Need at

least 30 psi at both hot and cold inlets. Need at

least a 20 degree difference between hot water

and set temperatures, as well as cold water and

set temperatures. Inspect checks for debris;

clean/replace if needed. Remove thermostat

and check for debris. Ensure liner can move.

Clean thermostat. Replace thermostat if needed.

Leaks around

thermostat.

Remove thermostat and check O-ring. If

damaged or worn, replace/tighten.

Water in

thermostat.

Check connection. Replace thermometer.

14.

Connect 1" NPT drain piping to drain

outlet at the bottom of the station.

15.

Open supply line to check for leaks. Push on activator

to insure adequate flow and drainage through Eye/

Face Wash Block. Pull back to stop water flow. Pull

down on Drench Pull Handle to insure adequate

flow through showerhead. Push up on Drench

Pull Handle to stop water flow from shower.

FIXTURE TROUBLESHOOTING

Problem Checklist

No flow. Make sure the water supply for station is on.

Verify checks of Manifold Assembly correctly

installed.

Water does

not drain

properly.

Check to see if station is installed level and

correct as needed. Make sure nothing is

blocking drain of the bowl. Remove any debris.

Double check the main waste line for the facility.

Make sure there is no blockage and that it can

handle the required drainage.

Water leaks

between

fittings or

connections.

Tighten all connections. If leak persists,

disassemble, apply additional sealant and

reassemble.

Insufficient

flow to eye/

face wash.

Turn water supply to station off. Remove the

eye pieces and clean out any debris. Make

sure diverter is fully opened. Verify pressure to

station is at 30 psi as required.

Insufficient

flow from

shower head.

Turn water supply to station off. Remove

shower head and clean out any debris. Make

sure actuator is fully opened (pull handle

completely engaged). Verify pressure to station

is at 30 psi as required.

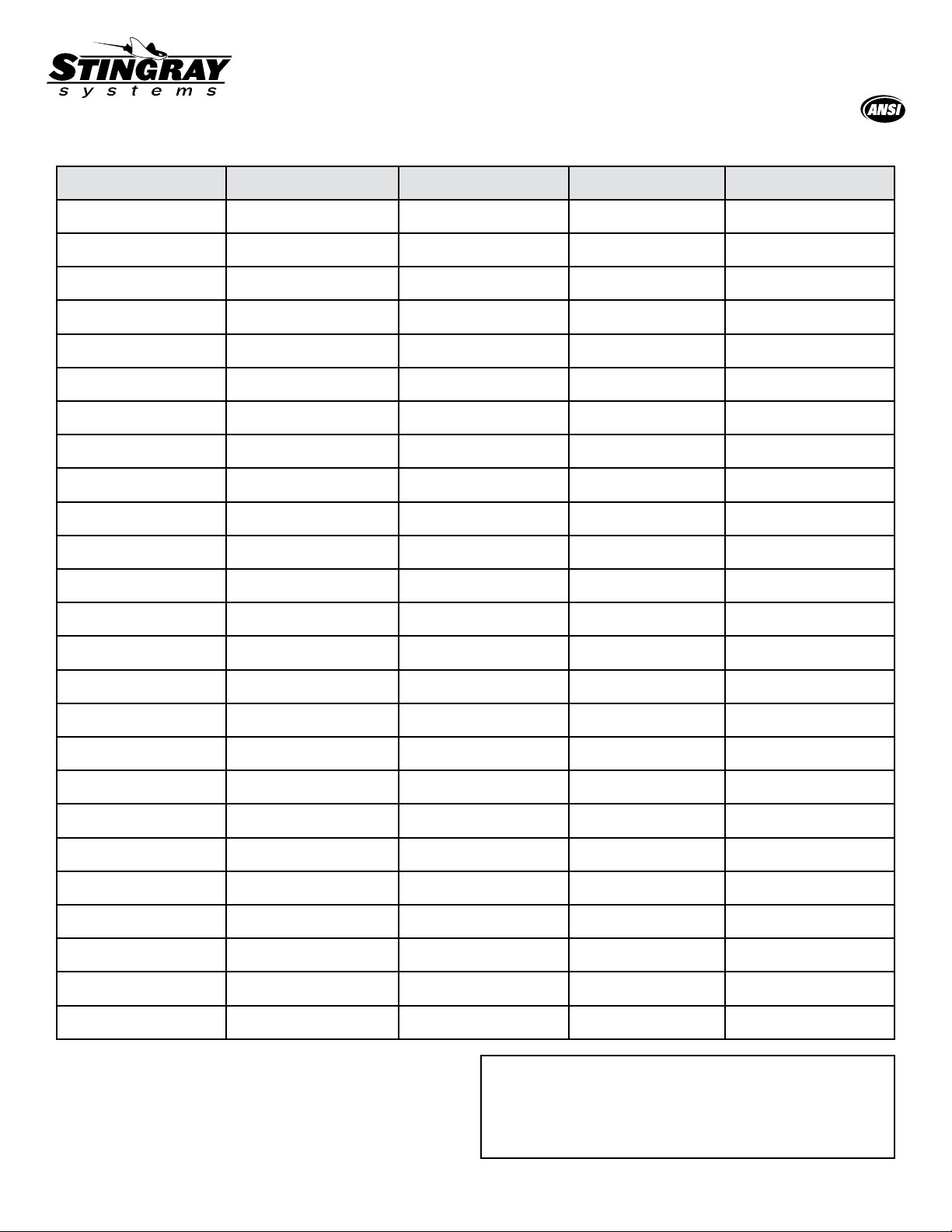

MAINTENANCE

Emergency Eye/Face Wash System shall be activated on a

weekly basis to verify operation and to flush the lines per the

American National Standards Institute (ANSI). Inspections

shall be recorded with inspector’s name and date tested.

Should the need to repair or replace any parts

on this station, please contact Stingray Systems.

Before any repairs are performed, please verify

that the water supply to the station is shut off.

GUARANTEE

We guarantee the Stingray Systems product to be free from

defects in workmanship and material, and for a period of

eighteen (18) months from date of shipment from the factory

or one (1) year from date of installation, whichever occurs

first, will replace any parts found by us to be defective. We

will not be held responsible, however, for any labor incidental

to, or for any damages caused by defective material.

With any questions, please do not hesitate in contacting us

at: 1-888-445-4142 or via email at info@tepid.com.

Installation &

Maintenance Manual

Certied to ANSI Z358.1

4

WEEKLY TEST RECORD

Month Test 1 Test 2 Test 3 Test 4

January

February

March

April

May

June

July

August

September

October

November

December

January

February

March

April

May

June

July

August

September

October

November

December

Plumbed emergency eyewashes, eye/face washes, drench

hoses, shower, and combinations systems shall be activated

and tested for a period long enough to verify operation and

ensure that flushing fluid is available.

WARNING: This product contains chemicals known to

the State of California to cause cancer and birth defects or

other reproductive harm. (Installer: California law requires

that this warning be given to the consumer.)

For more information: www.oehha.org/prop65

Other Stingray Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

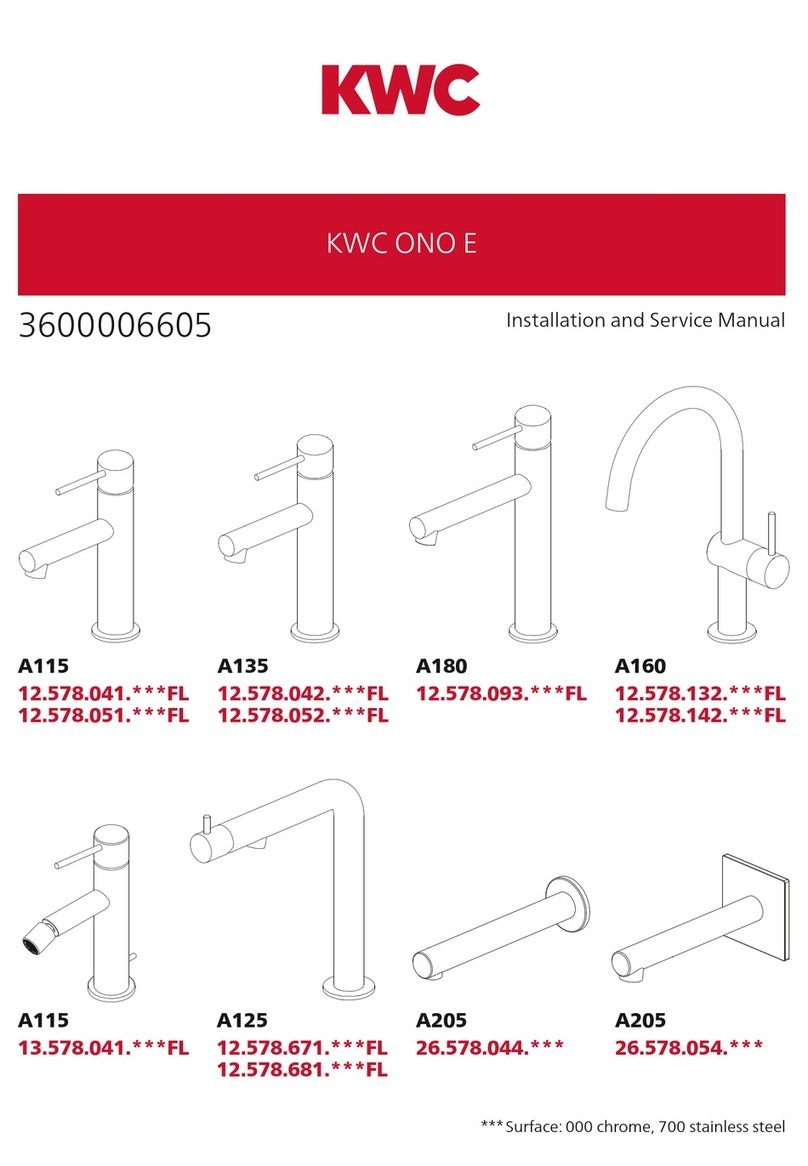

KWC

KWC ONO E A115 12.578.041.FL Series Installation and service manual

Artika

Artika Allegro SC-AL3 instruction manual

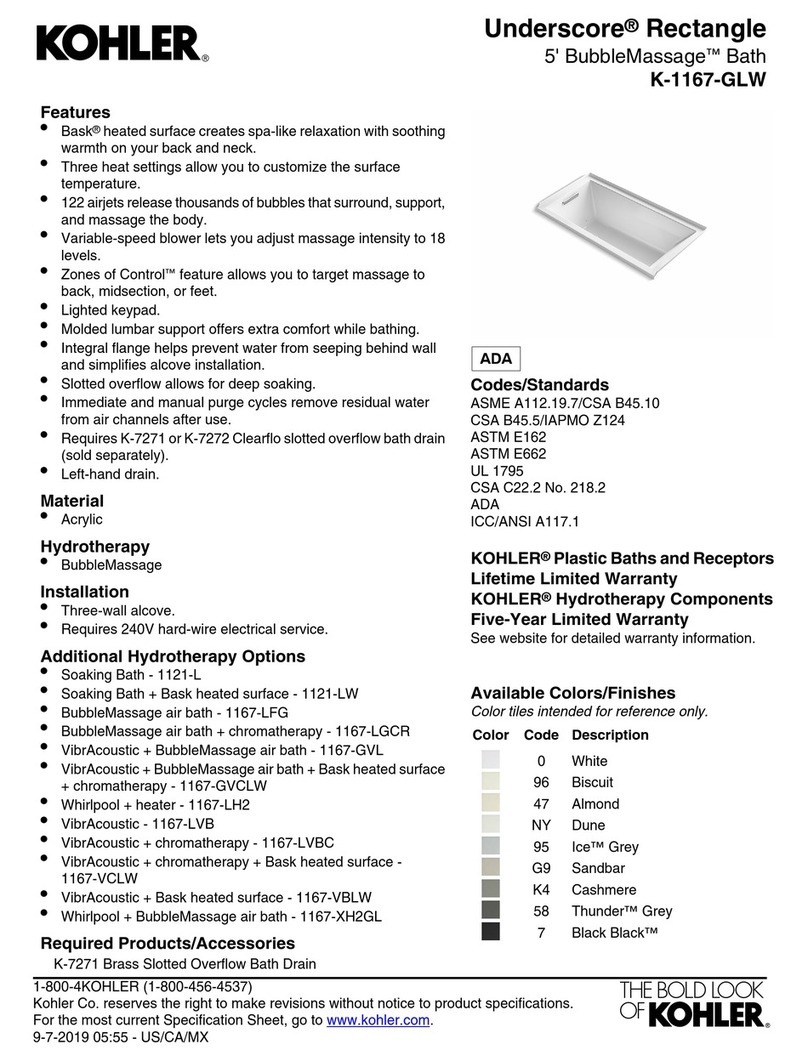

Kohler

Kohler Underscore K-1167-GLW Detailed Planning Dimensions

Hans Grohe

Hans Grohe Raindance 04731 0 Series Installation/User Instructions/Warranty

KEUCO

KEUCO Plan S Mounting instruction

Alice's Garden

Alice's Garden GUTTA SSH197CNFW manual

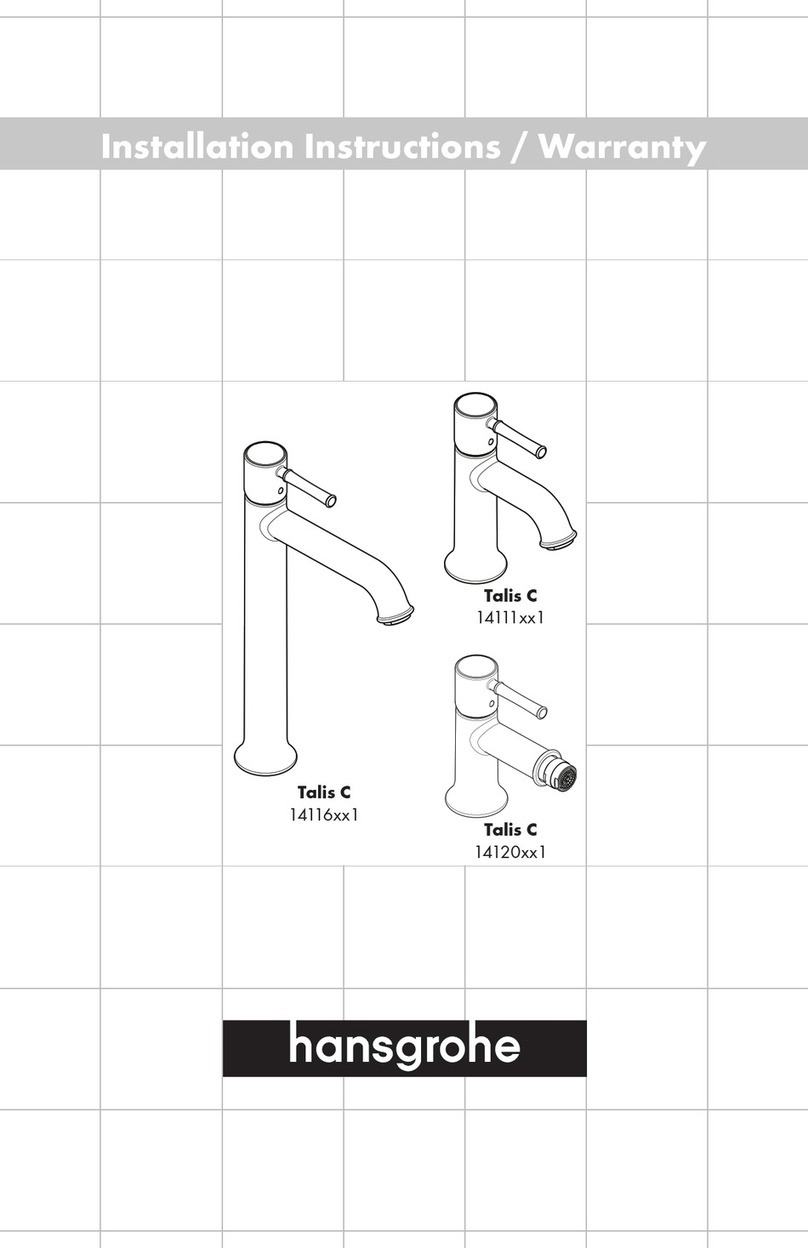

Hans Grohe

Hans Grohe Talis C 14111 1 Series Installation instructions / warranty

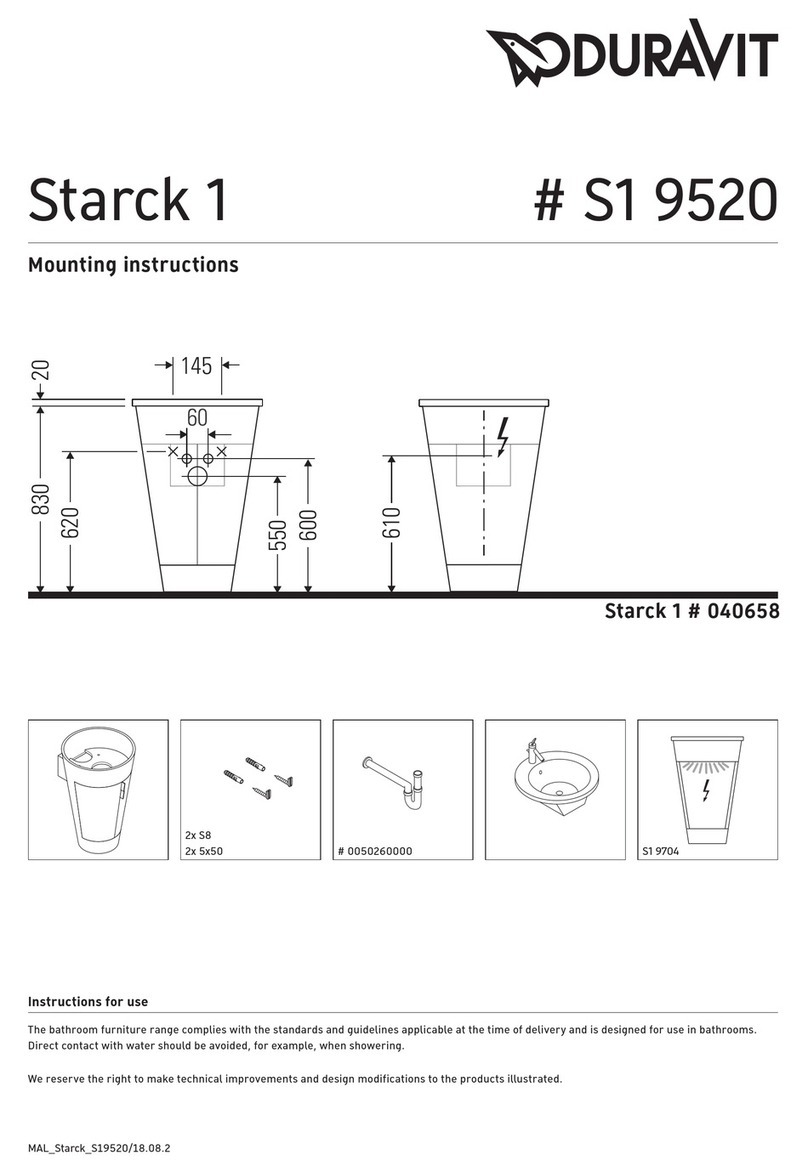

FHC

FHC VEN06 quick start guide

DURAVIT

DURAVIT Starck 1 S1 9520 Mounting instructions

Pfister

Pfister Deckard LG89-XDA Maintenance & Care Guide

Hans Grohe

Hans Grohe Logis series Instructions for use

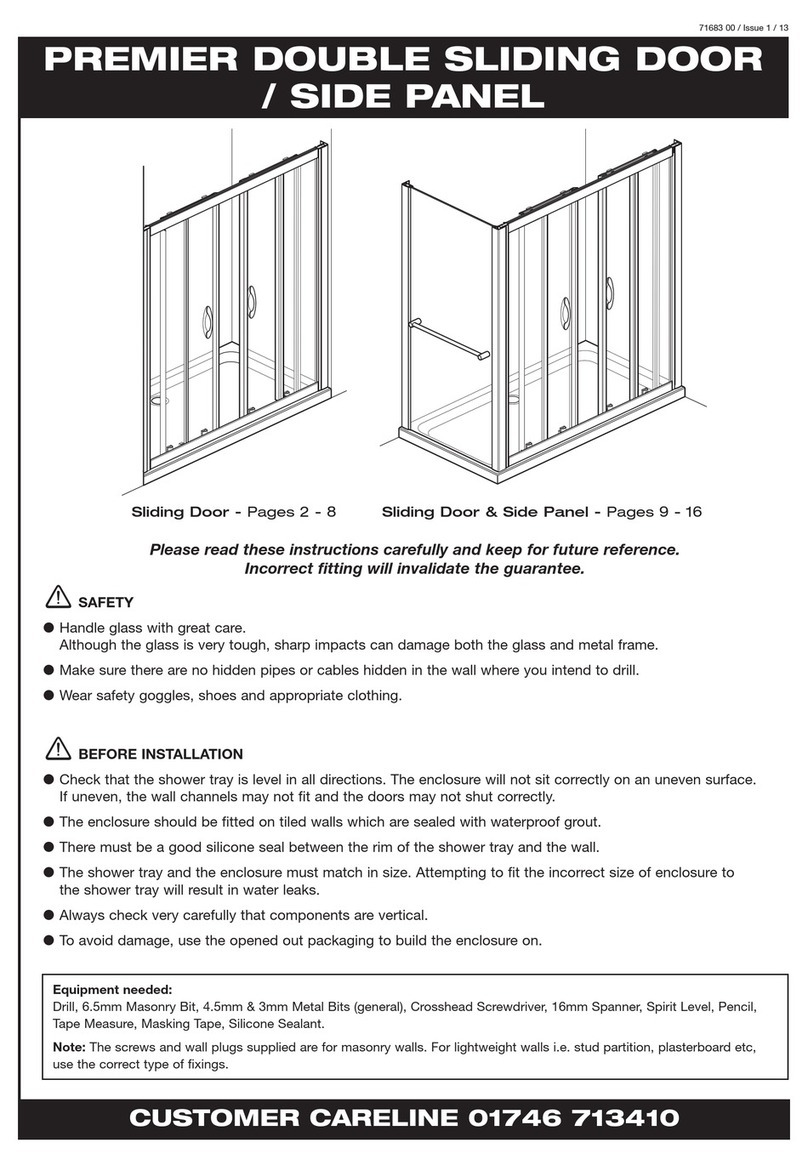

Coram Showers

Coram Showers PREMIER manual