Stingray SV107 Series Instruction Manual

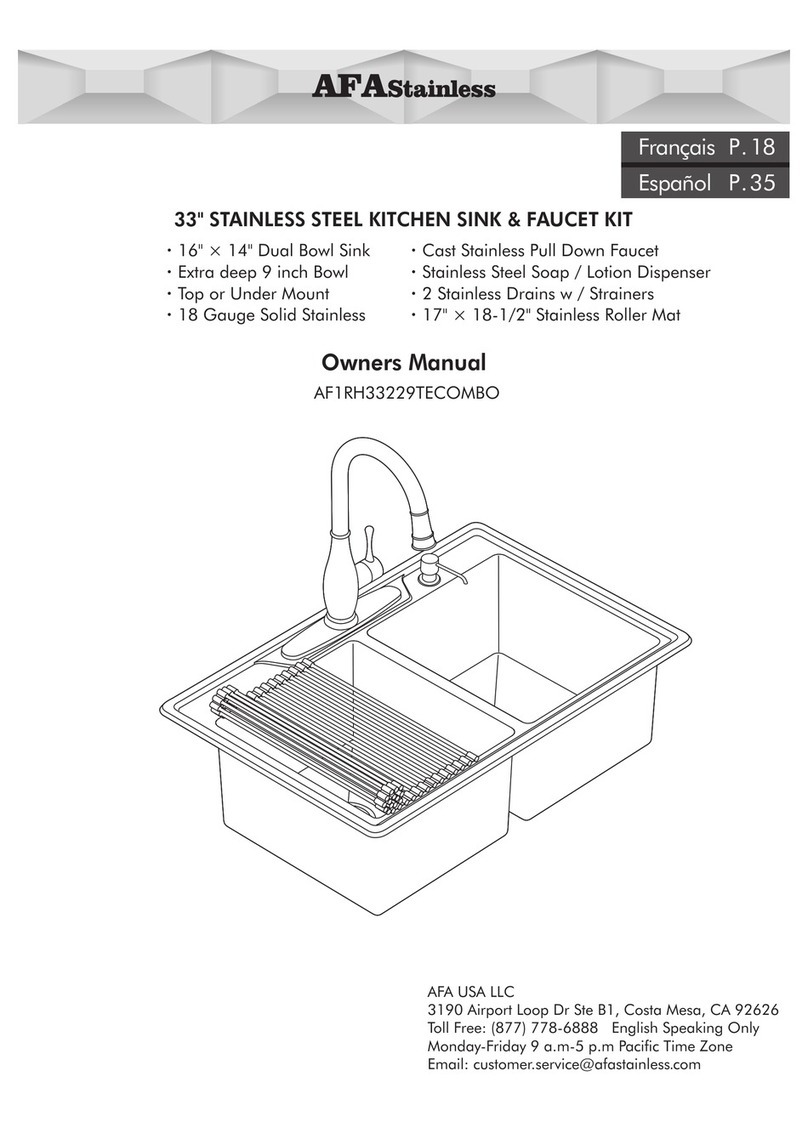

Series SV107

Emergency Eye Wash Valve

(1)

Installation &

Maintenance Manual

M EFV D

Setting the Mixing Valve

Caution: When maintaining and adjusting the mix-

ing valve, all xtures should be isolated from use.

Stingray Systems recommends that you work safely

at all times and in a manner consistent with the

OSHA Lock/Tagout standard, 29 CFR 1910.147

and other applicable standards.

This mixing valve has been set at the factory

to deliver 85°F outlet ow. Should the valve require

adjustment, or an application require a different set

temperature, proceed as follows:

1. Contact the proper medical and safety authorities

to determine the correct water temperature for

the specic application (ie. chemicals).

2. Remove the rounded cover nut on front of the

valve body.

3. Create a draw on the mixing valve by opening a

downstream eye wash xture.

4. Insert a 5/32″ allen key into the stem opening of

the valve and seat in the adjustment screw (not

shown). Set the outlet temperature by turning the

adjustment screw clockwise to reduce tempera-

ture, counterclockwise to increase temperature.

Use the dial thermometer to measure the outlet

temperature.

5. Replace rounded cover nut.

Operating Principle

This Series SV107 Emergency Eye Wash/Face Wash

mixing valve is made of a thermostat element with

a stainless steel sliding piston and liner housed in a

bronze casting. The thermostatic cartridge responds

to temperature changes in the hot and cold water

supplies. In the event the thermostatic element fails

or the hot water supply fails, the valve will provide

full cold water bypass ow.

Note: Valve must be installed with check valves.

If shut off valves are installed in the shower line

for maintenance purposes, provisions shall be

made to prevent unauthorized shut off.

Caution: When maintaining and adjusting the mix-

ing valve, the delivered ushing uid temperature

shall be 60°F (15°C) to 95°F (35°C). In circum-

stances where chemical reaction is accelerated

by ushing uid temperature, a medical advisor

should be consulted for the optimum temperature

for each application.

www.tepid.com

CAPACITIES – MODEL SV107

Pressure Drop PSI 510 20 30 45

Tempered Flow 235710

Cold Water Bypass 12457

30

40

50

60

70 80

90

110

120

130

ASSE 1071 Approved

5330 East 25th Street

Indianapolis Indiana 46218

Phone: (888) 445-4142

(2)

Testing the Mixing Valve

The mixing valve and the emergency xtures it serves

should be tested weekly for proper operation.

Valve temperature test procedure is as follows:

1. Activate eye wash xture to observe and record

the temperature of the dial thermometer. If the

temperature of the thermometer is not correct,

readjust the mixing valve according to the section

“Setting the Mixing Valve”.

2. Observe the ow from the emergency xtures to

ensure an adequate ow of water.

In addition to testing for proper temperature, the cold

water by-pass and hot water shut down features of

the mixing valve should be tested weekly.

The test procedure is as follows:

1. Test valve temperature as described in Step 1

and Step 2 above.

2. Shut off the hot water supply to the mixing valve.

Observe the outlet ow from the emergency x-

tures to ensure an adequate ow of cold water.

A slight drop in ow may occur after shutting

down the hot water supply to the mixing valve;

however, the drop should be minimal and for a

short duration.

3. Open the hot water supply to the mixing valve.

The thermometer should return to the set tem-

perature.

4. Shut off the cold water supply to the mixing valve.

The ow of water should shut down rapidly.

5. Open the cold water supply. The thermometer

should return to the set temperature.

Note: The thermometer should be checked at least

every six months.

Replacing the Thermostat Element

The thermostat replacement procedure is as follows:

1. Shut off the hot water supply and cold water

supply to the mixing valve.

2. Remove the four cover screws (#9) and remove

the front cover (#26) of the valve.

3. Remove thermostat (#11) from the valve body.

No special tools are necessary.

4. Insert a dowel rod, pencil (eraser-end), or narrow

pen into the open end of the thermostat. Push on

the dowel rod with your hand. If the thermostat

feels spongy or springy, the thermostat has lost

its charge. If the thermostat feels solid or hard,

the thermostat is good and operable.

5. Be sure that the stainless steel piston (#15)

moves freely up and down within the liner (#21).

Lime or calcium buildup should be cleaned with

vinegar, green scotch pad, or ne emery cloth.

DIMENSIONS: 1/2″inlets & outlets

Valve

Number A B C

SV107 9″4″8″

30

40

50

60

70 80

90

110

120

130

A

B

C

Note: Gallon per minute ratings may vary de-

pending upon incoming water temperatures and

pressures. Hot and cold water inlet pressures

must be equal.

Provisions shall be made to thermally isolate

the valve.

PRESSURE DROP, POUNDS PER SQUARE INCH

FLOW OF WATER, GALLONS PER MINUTE

70

5

60

40

35

30

25

20

15

8

7

6

9

10

45

50

1 2 3 4 5 6 7 8 9 10 15 20 30 3

5

1/2

≤

MED

CAPACITY OF TYPE SV107

THERMOSTATIC MIXING VALVE

FOR EMERGENCY EYE/FACE WASH

(3)

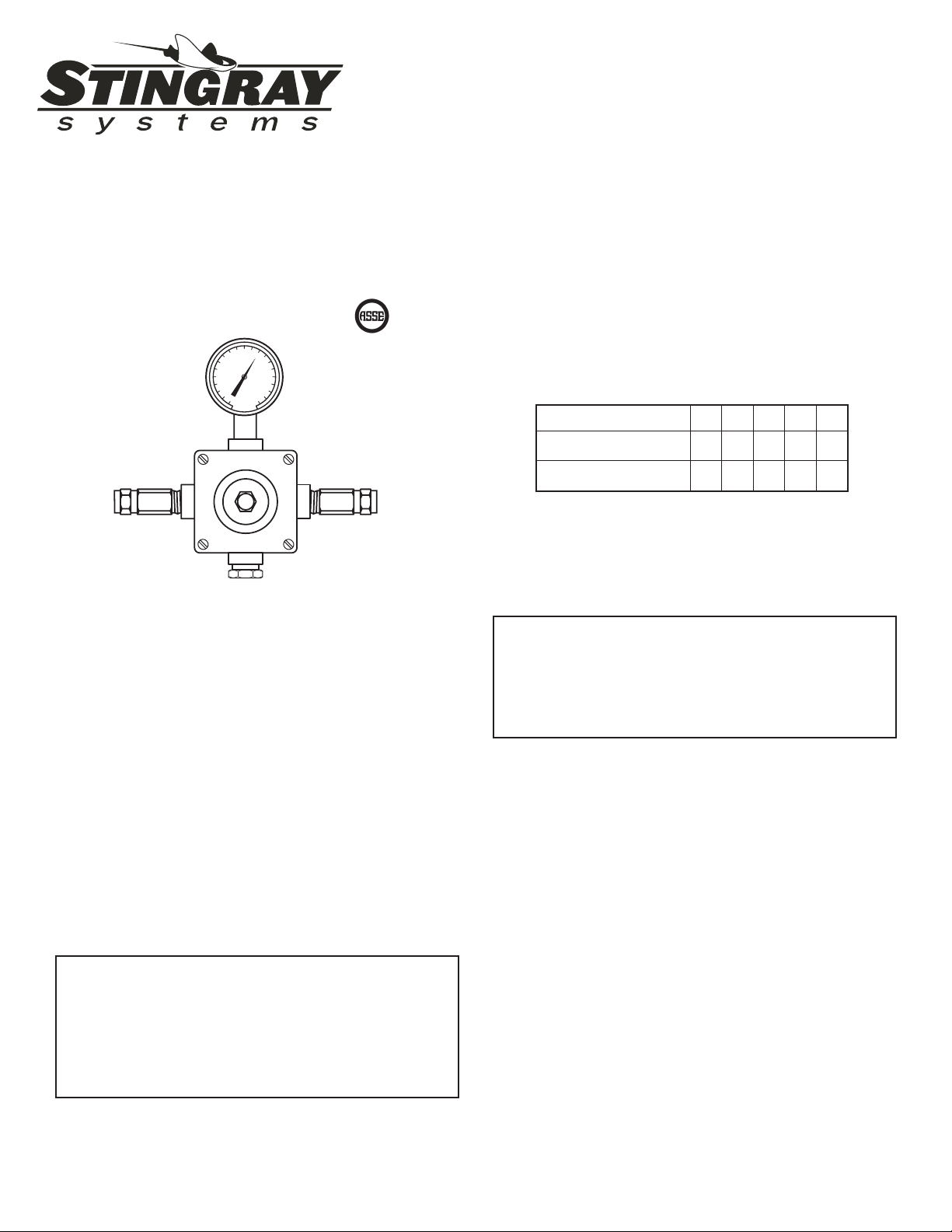

Figure 1

Typical installation. Valve must be

installed with check valves.

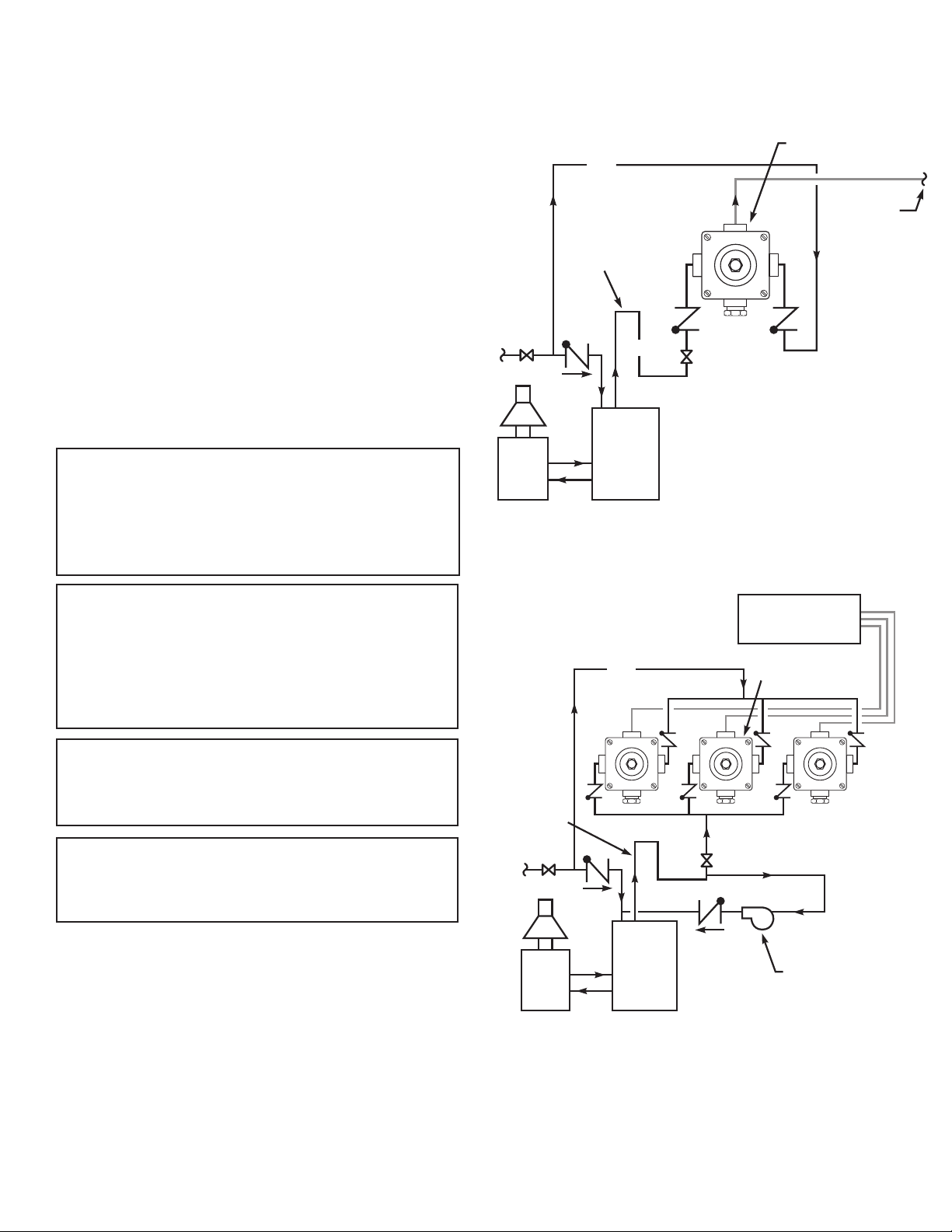

Figure 2

Typical installation. Valve must be

installed with check valves.

Installation

After installing the mixing valve, be sure to ush the

system of debris. Stingray Systems recommends

isolation and check valves for proper maintenance.

Typical Installation Figure 1

When installed without a recirculation system:

Install the valve as shown in Figure 1 with the mixing

valve positioned below the hot water tank or heater.

If this is not possible, pipe in heat trap as shown.

Typical Installation Figure 2

When installed with a recirculating pump on the hot

water supply line only:

Note: If the valve is installed 20 feet or more from

the water heater, it is important to recirculate the hot

water supply to the mixing valve.

Install the mixing valve as shown in Figure 2. The

non-circulated loop should be limited to 10 feet and

must be ushed periodically.

Caution: The cold water line must be installed so

that it is not affected by excessively hot ambient

temperatures. Provisions shall be made to ther-

mally isolate the valve. Cold water pipe installed in

the ceilings of boiler rooms or rooms that increase

ambient temperature require a recirculating pump.

GUARANTEE

Note: The mixing valve must be installed with

inlet check valves and the Eyewash/Facewash

xture should be installed 4 to 10 feet from

the mixing valve.

Note: The valve body must be maintained at an

ambient room temperature of above 50°F to pre-

vent premature closure of the safety back-seat

mechanism.

Maximum Inlet Pressure: 125 PSI.

Recommended Supply Pressure: 65 PSI.

Recommended Inlet Temperature: 120°F.*

*When supplying 140°F or greater, additional outlet

controls should be used.

Warning: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

(Installer: California law requires that this warning be

given to the consumer.)

For more information: www.oehha.org/prop65

We guarantee the Stingray Systems Mixing Valve to be free

from defects

in workmanship and material, and,

for a period of one year from date of pur-

chase, will replace any parts found by Sting-

ray Systems, to be defective. We will not be held

responsible, however, for any labor incidental to,

or for any damages caused by, defective material.

Each mixing valve is thoroughly inspected and tested

under actual conditions at our factory.

Water

Heater

Storage

Tank

Series SV107

CW

Heat Trap

27” Drop

Recirculating Pump

1 valve per

eye wash fixture

Water

Heater

Storage

Tank

Eye/Face

Wash

Series SV107

CW

Heat Trap

27” Drop

HW

(4)

Date T1

Jan

Feb

March

April

May

June

July

Aug

Sept

Oct

Nov

Dec

Jan

Feb

March

April

May

June

July

Aug

Sept

Oct

Nov

Dec

Jan

Feb

March

April

May

June

July

Aug

Sept

Oct

Nov

Dec

YEAR YEAR

Series SV107 Test Record

Location _______________________

YEAR

Repair Kits and Assemblies

Item Description Contains Part No.

A Repair Kit 11-12-15-18-21+B 79854-00

B O-Ring & Gasket Kit 10-14-17-22-27 79961-00

C Cover Assy. 4-5-10-26 78271-00

D Piston & Liner Assembly 14-15-21-18-17 72904-60

E Thermostat Assy. 10-11-27 78490-00

Parts Break Down

9

26

4

10

5

12

15

25

27

22

14

21

18

11

17

IMM001503

Before you use this chart please make a copy for future testing records.

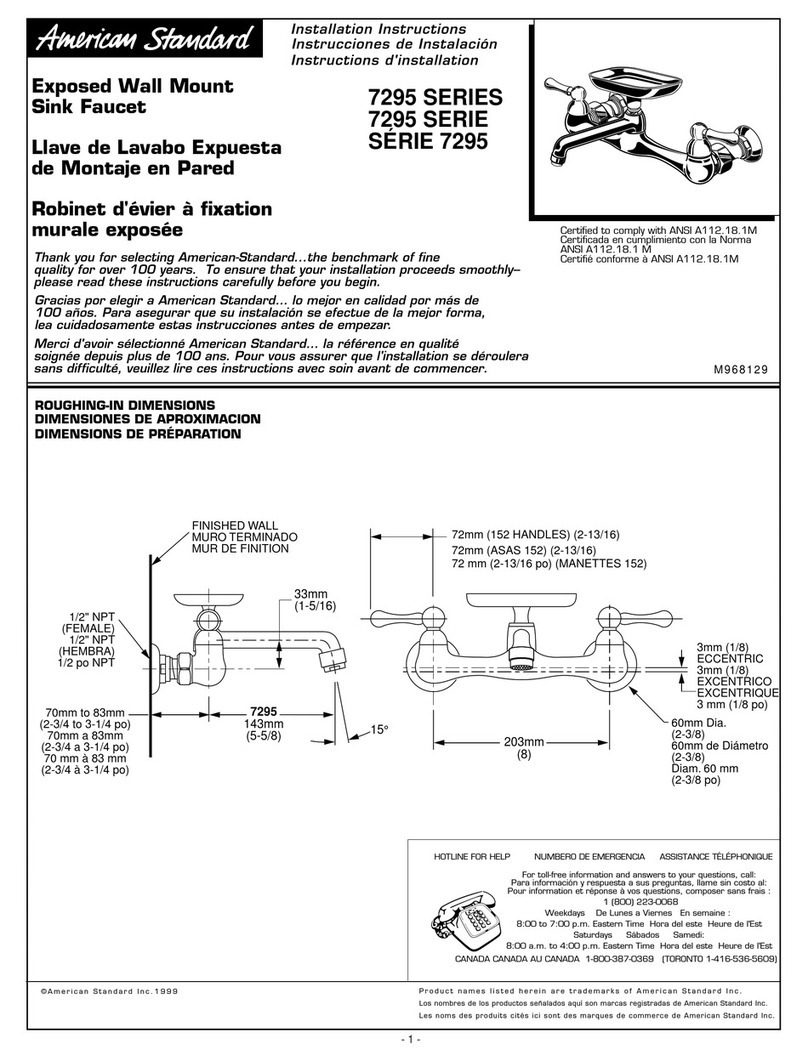

Popular Plumbing Product manuals by other brands

American Standard

American Standard 7295 Series installation instructions

Tres

Tres Elegance 1.18.103 Technical Characteristics

VIGOUR

VIGOUR DEPSMCH derby plus 185 90 01 quick start guide

American Standard

American Standard Standard 4251S Specification sheet

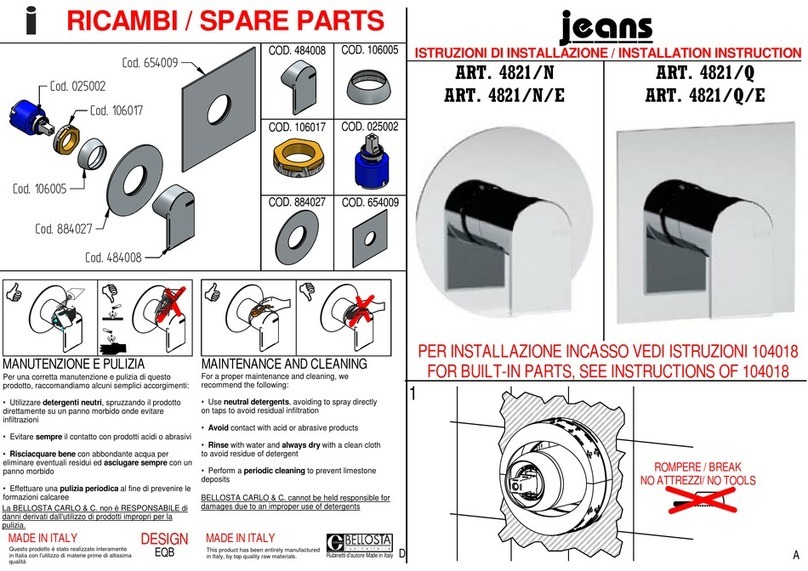

BELLOSTA

BELLOSTA jeans 4821/N Installation instruction

Hornbach

Hornbach Modell 4 manual

Hans Grohe

Hans Grohe AXOR Steel 35202800 Instructions for use/assembly instructions

Sanela

Sanela SLWN 12 Mounting instructions

Officine Gullo

Officine Gullo ACUTAOG03 L Instructions for installation and use

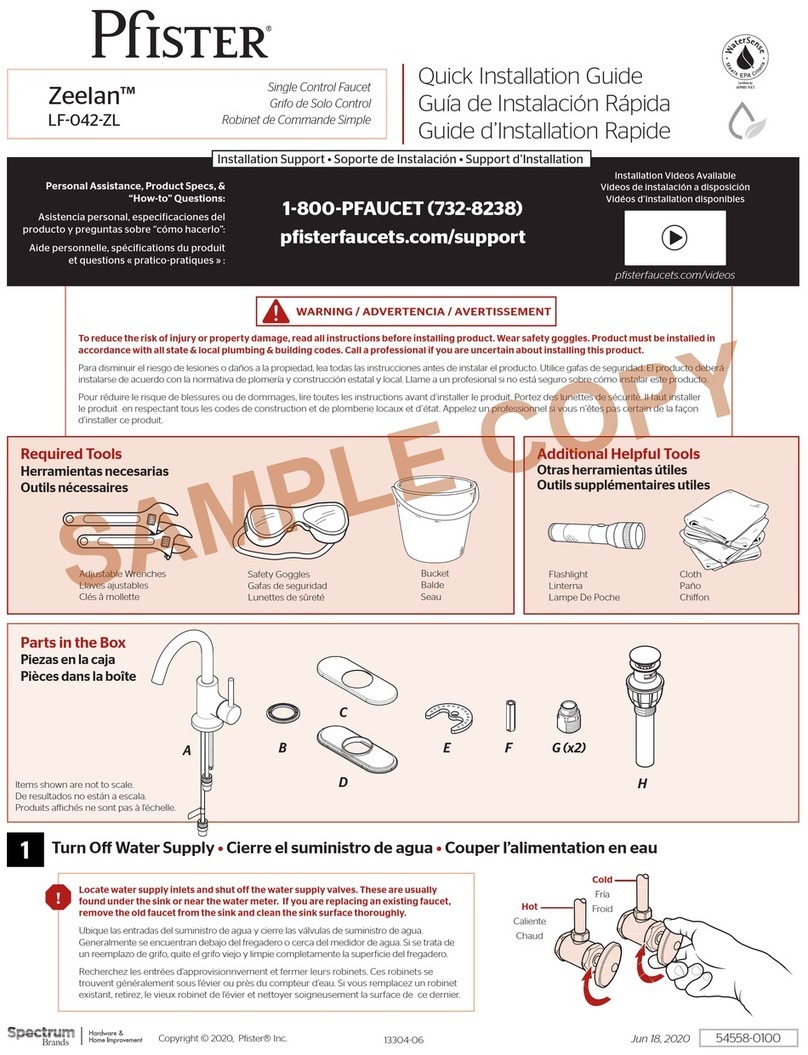

Pfister

Pfister Zeelan LF-042-ZL Quick installation guide

Aqua

Aqua SAHARA quick start guide

Kohler

Kohler MINIMA K-45805T installation instructions