Stirling SU105U User manual

Operating Manual

03.2012.1

SU105U -86˚C

Ultra Low Storage

6000 Poston Rd Athens, Ohio 45701, USA t: 740.274.7900 / 855.274.7900 f: 740.274.7901 www.stirlingultracold.com

203.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

3

t: 855.274.7900 www.stirlingultracold.com

SU105U Quick Guide

Initial Setup

1. Unpack freezer unit and included components, ensure all packaging material has been

removed from around the fan inlet and outlet holes.

2. Plug AC power cord into the main power socket at the back of the unit and then into

an electrical outlet.

3. Turn the AC power switch to the“On”position.

4. Turn on battery power. Battery switch is located in main power housing on the rear

of the freezer.

5. Ensure set point is within desired range (default is -86˚C) or change set point to user-preferred

temperature according to the control functions outlined below.

Guide to Basic GUI Functions

ON / OFF Switch the main power on, located at the back of the unit above the AC cord.

Battery Power Switch on the battery power located on the left of the Recessed Electrical

Panel. This is essential if monitoring is required in the event of a power failure.

Change Set Point Tap Home > Setup > Setup > Enter PIN > Enter > Change > Set Point > +/- > Save

Silence Alarm Tap Home > Setup > Silence

Event Log Tap Home > Setup > Event Log > Prev. Page, Next Page

Chart History Tap Home > Setup > Chart History

Guide to Advanced GUI Functions

Alarm Setup Tap Home > Setup > Setup > Enter PIN > Enter > Alarms > xxx Delay > +/- > Save

Date and Time Tap Home > Setup > PIN > Date & Time > +/- > Save

Change PIN Tap Home > Setup > Setup > Enter PIN > Enter > PIN > Enter New PIN > Enter >

Re-enter New PIN > Enter

Calibrate RTDs Tap Home > Setup > About > Service > RTD Calibr. > RTD Select > +/- > Calib.

Notice:

Before engaging door latch, ensure handle is fully rotated

down to the stop point in order to reset latching mecha-

nism. To engage door latch when closing, push outer

door IN before rotating door handle to UP position.

403.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

5

t: 855.274.7900 www.stirlingultracold.com

The model SU105U incorporates next generation free-piston Stirling engine (FPSE)

technology. FPSE technology differs from conventional compressor-based refrigeration

by providing high efficiency, deep-temperature cooling in a lightweight package.

SU105U

-86˚CUltra Low Storage

EU Authorized

Representative:

Global Cooling, BV

Lage Dijk 22,

Helmond, 5705 BZ

The Netherlands

Table of Contents:

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.1 Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Organization of this Operating Manual. . . . . . . . . . . . . . . . .7

2. FEATURES OF THE SU105U FREEZER . . . . . . . . . 8-11

2.1 Free-Piston Stirling Engine (FPSE) . . . . . . . . . . . . . . . . . . . . . .8

2.2 Cabinet Design Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.3 Temperature Monitoring Features . . . . . . . . . . . . . . . . . . . . .8

2.4 The Swift GUI Touch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5 Pictorial Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6 Included Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.7 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.7.1 Adapter Installation Procedure. . . . . . . . . . . . . . . . . . . . . . .11

3. SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . 12-13

4. UNPACKING AND INSTALLATION. . . . . . . . . . . . 14-15

4.1 Freezer Site Qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5. OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-31

5.1 Operation of the SU105U Freezer . . . . . . . . . . . . . . . . . 16-29

5.1.1 Swift touch Screen Control Panel. . . . . . . . . . . . . . . . . . . . .17

5.1.2 Control Panel Quick Guide. . . . . . . . . . . . . . . . . . . . . . . 18-19

5.1.3 Swift Graphical User Interface (GUI) Instructions. . . 20-29

5.2 Managing Freezer Contents . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.4 Calibration of the RTDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6. TRANSPORTING, MOVING AND STORAGE . . . . . . 31

7. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 32-33

7.1 Freezer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.2 Materials Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 3435

9. WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-37

10. CE DOCUMENTATION. . . . . . . . . . . . . . . . . . . . . . . . 39

603.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

1. Introduction

1.1 – Description

The Stirling Ultracold SU105U FPSE Ultra Low Temperature (-86°C) Freezer uses

proven M150A free-piston Stirling engine (FPSE) technology to provide high effi-

ciency, deep-temperature cooling.

1.2 – Applications

The SU105U freezer is designed for long-term storage of materials with ultra low,

well-regulated temperature storage requirements, such as found in clinical and bio-

logical laboratory and testing settings.

1.3 – Documentation

1.3.1 – Operating Manual

• This operating manual describes all aspects of receiving, installing, use, moving and

storage of the Stirling Ultracold SU105U Freezer. More detail on specific aspects of

operation of the freezer is available via online supplementary documentation.

• Performance of the freezer is controlled by electronic logic that is programmed

through a touch screen interface termed the Swift Graphical User Interface (GUI).

This operating manual describes use of the Swift GUI, and the appended Swift GUI

Supplement expands that description with pictorials of each screen and option.

User Advisory:

Deep temperatures are dangerous, use proper precautions when operating ultra

low temperature freezers. This ultra low temperature freezer is intended for storage

of frozen sample product or vials at deep temperatures. Stirling Ultracold, Division

of Global Cooling, Inc. cannot be held responsible for damages or loss of stored

product attributed to unintended use. In no case will Stirling Ultracold, Division of

Global Cooling, Inc. be held liable for loss of stored product resulting from electrical,

mechanical or structural failure. As with any ultra low temperature freezer, appropri-

ate back-up and redundancy considerations are the responsibility of the user.

7

t: 855.274.7900 www.stirlingultracold.com

Two Model SU105U cabinets stacked.

Shown with optional stacking adapter.

1.4 – Organization of this Operating Manual

This manual is organized as follows:

• Unpacking and installation

• Set-up

• Operation

• Transporting and moving

Please note that precautions and safety instructions are part of each section of the

manual, and must be observed to avoid damage to the freezer or harm to its users.

1. Introduction

803.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

2. Features of the SU105U freezer

2.1 – Free-Piston Stirling Engine (FPSE)

The SU105U Ultra Low Temperature Freezer uses the

state of the art Stirling Ultracold Model M150A free-

piston Stirling engine (FPSE) to provide high efficiency,

deep-temperature cooling. No HCFC or CFC refrigerants

are used in the M150A and SU105U. The M150A Stirling cycle engine uses approxi-

mately 2 grams of helium gas as a working fluid. The secondary coolant loop uses

60 - 65 grams of refrigerant, R-508B (“SUVA® 95” *), as a working fluid.

2.2 – Cabinet Design Features

The cabinet is VIP insulated with polyurethane foam support providing an internal

volume of cabinet approximately 105 liters. The blowing agent is HFC R245a. A

locking cam door latch ensures door gasket compression when closed. Door sealing

consists of three gaskets and is factory replaceable. A door defrost minimizes water

or ice deposition on the gasket interface.

2.3 – Temperature Monitoring Features

Two resistance temperature detectors (RTDs) measure the internal cabinet tempera-

ture of the SU105U. One provides input to the FPSE controller and the other provides

input for the Swift GUI display and for reporting and logging. The display RTD may be

user calibrated through the Swift GUI. The Swift GUI provides a door open timeout

alarm and monitors the temperature reporting RTD for excursions beyond high and

low limits that are set automatically or manually. Alarms are reported through an

audible alarm in the freezer enclosure and through a contact closure that may be

connected to an external alarm. The Swift GUI provides options to temporarily sup-

press alarms and set a delay time before the alarm is reported via the contact closure.

A one-time temperature alarm suppression provided by the Swift software allows for

the initial cooling of the freezer after start-up.

AC power from 90 to 264 Volts is allowable, with a maximum current draw of about

3.0 Amps at 110 V and 1.5 Amps for 240 V.

* Trademark DuPont.

9

t: 855.274.7900 www.stirlingultracold.com

2.4 – The Swift GUI Touch Screen

The Swift GUI is implemented on a touch screen control

panel on the front of the cabinet. Its capabilities are described

in detail later. General features of the control panel are:

• Set freezer control, alarm and communications parameters

• Provide password protected access to parameter changes

• Display freezer status

• Display temperature graph and event log

• Display diagnostic and service information

• Display freezer identification information

Values for the following SU105U parameters are viewed and modified through

the touch screen.

Modifiable Values Accessible Values

Temperature set point Current freezer interior temperature

Under temperature limit Temperature history chart

Over temperature limit Interior vs. FPSE temperatures

Over temperature delay after door opening Alarm status

Audible alarm silence interval Swift GUI firmware event log

External contact delay upon alarm “About” screen (general information)

Door open alarm delay Service contact information

Door defroster status Diagnostics screen

Door auto-defrost status

Manual defrost time

Password Identification Number (PIN) status

Current date

Current time

RTD calibration adjustments

2. Features

10 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

2.5 – Pictorial Tour

1. Control Panel

2. Locking Latch

3. Door Gasket

4. Fixed Stainless Steel Shelf

5. Air Inlet

6. Access Port

— For thermocouple wires, purge gas, etc.

7. Air Outlet

8. Recessed Electrical Panel

A. AC Power Connector

B. AC Power Switch

C. External Alarm Terminal Strip,

Dry Contacts (NO, NC, C)

D. Battery Power Switch

1

6

7

4

2

5

3

8

A

B

C

D

Model SU105U. Shown with optional

stainless steel inventory racks.

11

t: 855.274.7900 www.stirlingultracold.com

2.6 – Included Items

• Packing List

• Operation Manual - (this document, including Warranty Card). 1 pc

• AC Power Cord - Approx. length 1.6 meters. 1 pc

• Port Sealant

• 1 Port Plug

• 2 Keys

• 1 Wrench

2.7 – Options

• Stacking Adapter

When stacking two Stirling Ultracold SU105U FPSE Ultra Low Temperature

(-86°C) Freezers, a stacking adapter is required. The Stacking Adapter consists

of two (2) plates and twelve (12) screws.

2.7.1 – Adapter Installation Procedure

1. Remove rear casters from both freezers. Install adjustable leveling feet.

2. Move 2nd unit over the top of 1st unit sitting on floor.

Note the net weight is about 220 lbs. Three person job.

3. Adjust height if necessary.

4. Level top freezer.

5. Attach stacking plate and tighten six screws (torque 8 to 10 lb-in) at both sides.

Note that the stacking plate should not hold the weight of upper unit.

The upper unit should sit on the leveling feet.

3 holes on upper unit and 3

holes on lower unit need to

be lined up.

Clearance between bottom

of upper unit and top of

lower unit is 1.5 inches.

2. Features

12 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

3. Safety Precautions

Potential hazards associated with use of the SU105U freezer may impact the safety of

persons in the workplace in which the freezer is installed. This includes persons who

operate the freezer, and other personnel in its vicinity. The freezer itself may also be

damaged or its warranty voided by improper operation or usage. It is very important

that all personnel that install, operate, transport or place the freezer into storage read

this entire manual to understand those hazards. Likewise, it is imperative to place this

manual for ready reference adjacent to the freezer at all times.

Specific appropriate precautions are included in each section of this operating

manual. However, several important general precautions must be observed and

are described below.

• Do not disassemble, modify or repair. There are no user serviceable parts inside the

freezer unit.*

• Do not immerse in water, pour water on the unit, or operate where water may drip

or fall on the unit. Operation under extreme environmental conditions, e.g., in very

high humidity environments (RH 85% or more) also may lead to condensation or

water intrusion.*

• Warning: Unauthorized modification to the cabinet, controls or free-piston Stirling

engine will void all warranty provisions.

• Do not cut, change or modify the power cable.*

• Do not store flammable items such as gasoline, thinner or solvents in the freezer.

• The freezer is NOT rated as an explosion-proof freezer.

• Do not use hard and/or sharp objects, such as knives, screwdrivers, etc. to remove

any frost or ice that has accumulated on the inside of the freezer. The inside panels

are heat exchangers and can be damaged. Defrosting the cabinet is described later

in this operating manual.

• Do not use solvents to clean the panel or the outside or inside of the freezer.

*Doing so will void the warranty.

13

t: 855.274.7900 www.stirlingultracold.com

• When removing the power cable, hold onto the plug and not the cable.

• Do not block the air intake or air discharge vents used by the FPSE (See pictorial

on Page 10 for locations.)

• Ultra low temperature freezers are different from home freezers in that at -86°C

frostbite can occur instantly.

• For the personal safety of freezer users, safe operating procedures are essential.

— Never handle samples or freezer accessories with bare hands. Be especially

careful not to spill ultra low temperature materials onto skin or clothing.

— Do not use gloves that become brittle at ultra low temperatures.

— Nitrile and latex gloves are inadequate.

• Permeable gloves are dangerous because frozen materials can contact skin

and cause damage.

— Be especially careful that materials at low temperatures are not spilled onto

skin or clothing.

• Ultra low temperatures may adversely impact freezer contents:

— Do not put ice or liquid water directly in the freezer box; always use

suitable containers.

— Use only sample containers that have been approved or tested for ultra low

temperature use.

— Do not use glass containers when the contents might freeze and expand.

— Some plastics shatter at ultra low temperatures. Avoid splinter hazards.

— Biological and chemical hazards are still hazardous at ultra low temperatures.

Always wear proper protective equipment and follow appropriate isolation

protocols.

— Many types of labels will fall off and/or break at ultra low temperatures. Some

types of ink which stick to glass and/or plastic at room temperature lose adhesion

at ultra low temperature.

• In addition to the ULT hazards above, there are also physical hazards to consider:

— Be cautious when closing the door to avoid a pinching hazard.

— Be careful when loading the cabinet with heavy items.

3. Safety Precautions

14 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

4. Unpacking and Installation

Verify the SU105U freezer shipment by uncrating the freezer and included items,

inspecting them for damage during shipping, and compare the items to the

packing list for completeness.

4.1 – Qualify the installation site for the freezer before

placing it into service.

1. Note the shipping packaging dimensions of 31" W x 31" D x 41" H | (787 x 787

x 1,041mm) and shipping weight of 266 lbs. | (121 kg).

2. When moving the shipment from the point of receipt to the place where it

will be uncrated. The installation site must accommodate the freezer exterior

dimensions of 27" W x 28" D x 33.5" H | (686 x 711 x 851mm) and weight of

266 lbs. | (121 kg), crated ocean weight of 396 lbs. | (180 kg).

3. There are no specific required clearances for the top, back and sides of the

freezer; however allowances must be made for electrical connections to the

panel on the back of the freezer.

4. Ingress to the access port (see Page 10) is required during normal operation.

5. The freezer must be installed on a nominally level surface and leveling feet will

accommodate small variations from level. SU105U freezers are stackable up to

two high. Requires optional stacking adapter.

6. The aisle way into which the freezer door opens must be wide enough to

allow access to the contents of the freezer and not present a hazard to those

using the aisle way.

7. The facility/room lighting must not obscure the readability of the touch

screen display and must provide good visibility for working with the contents

of the freezer.

8. After the freezer is placed into its installation location, any blockages to the

air inlet and outlet must be removed. (See Page 10 for locations.)

9. Care must be taken while unpacking and installing the freezer not to injure

personnel or damage the freezer by loss of control of its motion during the

processes. Be mindful of its size and weight. Dropping the freezer is likely to

damage it.

15

t: 855.274.7900 www.stirlingultracold.com

4.2 – Set-up

1. Before switching on electrical power to the freezer, make all desired external

connections:

A. AC power connection

B. External alarm

2. Turn on the AC switch. If the DC power option has been provided please

see the supplemental instructions.

3. In normal operation, the freezer access port (see Page 10 for location)

is plugged with a rubber stopper.

4. After the freezer reaches its operating temperature and its door is opened

and closed, the partial vacuum created when warm air is admitted, then

cooled, will prevent reopening of the door until the pressure is equalized.

A vacuum relief port is provided to accelerate this process.

5. Be mindful of any electrical shock hazards associated with making electrical

connections to the freezer, especially the external alarm connection.

6. Notice: To activate the battery for the alarm system, please place the

battery switch to the “on”position. Battery switch is located in the main power

housing on the rear of the freezer.

4. Unpacking and Installation

16 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

5. Operation

5.1 – Operation of the SU105U freezer comprises four stages:

1. Monitoring temperature performance using the Swift GUI and touch screen

control panel.

2. Managing the freezer contents.

3. Cleaning and defrosting the freezer.

4. Calibrating the freezer's display RTD.

Specification of responsibilities for each of the above components of freezer opera-

tion should be part of the procedures and policy documents and guidelines for the

clinical, laboratory, or other activity for which the freezer is used. Safety requirements

are integral to these responsibilities.

17

t: 855.274.7900 www.stirlingultracold.com

5.1.1 – Swift touch screen control panel:

A Password Identification Number (PIN) may be set, but is not displayed. The default

PIN is 1234 and may be changed by the user to any four-digit numeric. Use the PIN

to control access to parameter change screens.

The Swift GUI is preprogrammed with generic default values for most parameters

listed above, so entering the date, time and temperature set point are the most

essential actions. Unless temperature limits are set manually, the software calculates

default values appropriate for the temperature set point.

The Swift GUI uses a menu system to display and modify system values. Generally,

each screen displays certain values and contains “soft” buttons that are pressed to

access other screens (according to the menu structure), and each screen has a soft

button to return to the Home screen and a “Back” soft button to return to the next

higher level of the menu (from which it was called).

5. Operation

18 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

5.1.2 – Control Panel Quick Guide

The Swift GUI menu tree below starts with the Home screen. (How to get there

is described later.) Soft buttons provide navigation to the screens on the next level

of the menu tree.

Home – display current freezer temperature.

• Setup – display Password Identification Number (PIN) status, door defrost status,

temperature set point, system date and time and alarm status. Also shown is the

Ethernet connection status, which is shown on all screens except the home screen.

–Setup – display temperature set point.

Change Set Point – display and change the temperature set point and high

and low temperature limits.

Alarm Setup – display and change the Temp. Delay (to delay an over tempera-

ture alarm after a door opening), Audible Delay (time interval to silence the

audible alarm upon request), Ext. Delay (to delay remote alarm contact closure

after alarm condition is detected) and Door Delay (period that the door may

remain open without alarm).

Network Setup – select dynamic DHCP addressing or display and change

IP address, subnet mask, gateway address, and DHCP server addresses.

Date & Time Setup – display and change system date and time.

Door Defrost – enable/disable automatic door defrosting and/or set a manual

defrost time and initiate manual defrost.

PIN Setup – disable/enable the system PIN and change the PIN.

• Silence Alarm – temporarily silence audible alarm.

• Event Log – tracks the last approximately 200 alarm conditions such as door open-

ings, temperature set point changes, over temperature condition, and power outages.

• Chart History – display the cabinet interior air temperature over the last 24 or 48

hours, or 7 days.

• About – display freezer model number, serial number, firmware version, engine

number, run hours, temperature set point, and install date.

–Service – display cabinet, control and cold-head RTD temperatures, warm-head

thermistor temperature and engine voltage, current and power.

Diagnostics – display temperature set point, engine running power as a

percentage of maximum running power, and freezer condition status.

Service Contact – provides phone, email, and web address for distributor

RTD Calibration – display RTD readings and calibration offsets to apply to

reading (used to compensate for discrepancies between Display RTD and

user-supplied temperature standards).

• Firmware Upgrade – display screen for firmware check and upgrade options.

• Alarm Test – Tests alarm.

19

t: 855.274.7900 www.stirlingultracold.com

Basic Controls

• Generally, to change a value on a screen, Tap the appropriate soft button

to highlight the parameter.

• Use the +/- buttons to enter the desired value and then use the “Save”soft button

to complete the change.

• PINs are entered through a numeric keypad screen with an “Enter” soft button

to complete the entry and an “Exit”soft button to terminate it.

• PINs may be disabled on the PIN Setup screen by leaving the new PIN value blank.

When the PIN is disabled, any person can perform all actions available via the

Swift GUI, including silencing alarms and calibrating the RTDs.

• The following examples of Swift GUI usage describe sequential button taps, e.g.,

1 > 2 means: tap button labeled “1”then tap button labeled “2”. Swift GUI display

screens are named and those names are shown in bold. Access to certain screens

requires entry of the system PIN via a numeric keypad screen; this entry is shown

as the PIN button tap.

Guide to Basic GUI Functions

ON / OFF Switch the main power on, located at the back of the unit

above the AC cord.

Battery Power Switch on the battery power located on the left of the

Recessed Electrical Panel. This is essential if monitoring is

required in the event of a power failure.

Change Set Point Tap Home > Setup > Setup > Enter PIN > Enter > Change >

Set Point > +/- > Save

Silence Alarm Tap Home > Setup > Silence

Event Log Tap Home > Setup > Event Log > Prev. Page, Next Page

Chart History Tap Home > Setup > Chart History

Guide to Advanced GUI Functions

Alarm Setup Tap Home > Setup > Setup > Enter PIN > Enter > Alarms >

xxx Delay > +/- > Save

Date and Time Tap Home > Setup > PIN > Date & Time > +/- > Save

Change PIN Tap Home > Setup > Setup > Enter PIN > Enter > PIN > Enter

New PIN > Enter > Re-enter New PIN > Enter

Calibrate RTDs Tap Home > Setup > About > Service > RTD Calibr. > RTD

Select > +/- > Calib.

5. Operation

20 03.2012.1

Operating Manual: SU105U-86˚CUltra Low Storage

5.1.3 – Swift Graphical User Interface (GUI) Instructions

1. Start Screen:

Turn On Freezer and Battery Power

• Stirling Ultracold splash screen will appear for 3 seconds

2. Home Screen:

The Home screen will be displayed next

• Tap the Setup button to proceed to system settings

Table of contents

Popular Storage manuals by other brands

FLOWTECH

FLOWTECH flowpress Operation and maintenance manual

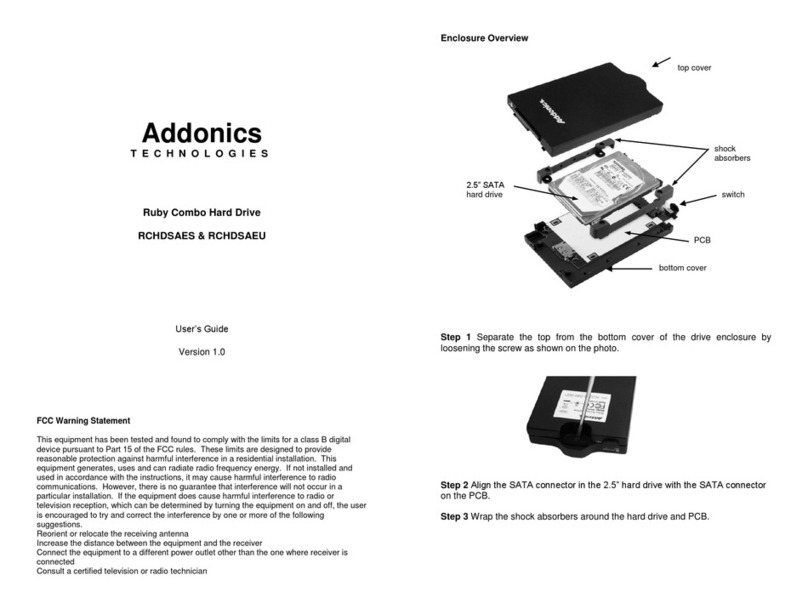

Addonics Technologies

Addonics Technologies RCHDSAES user guide

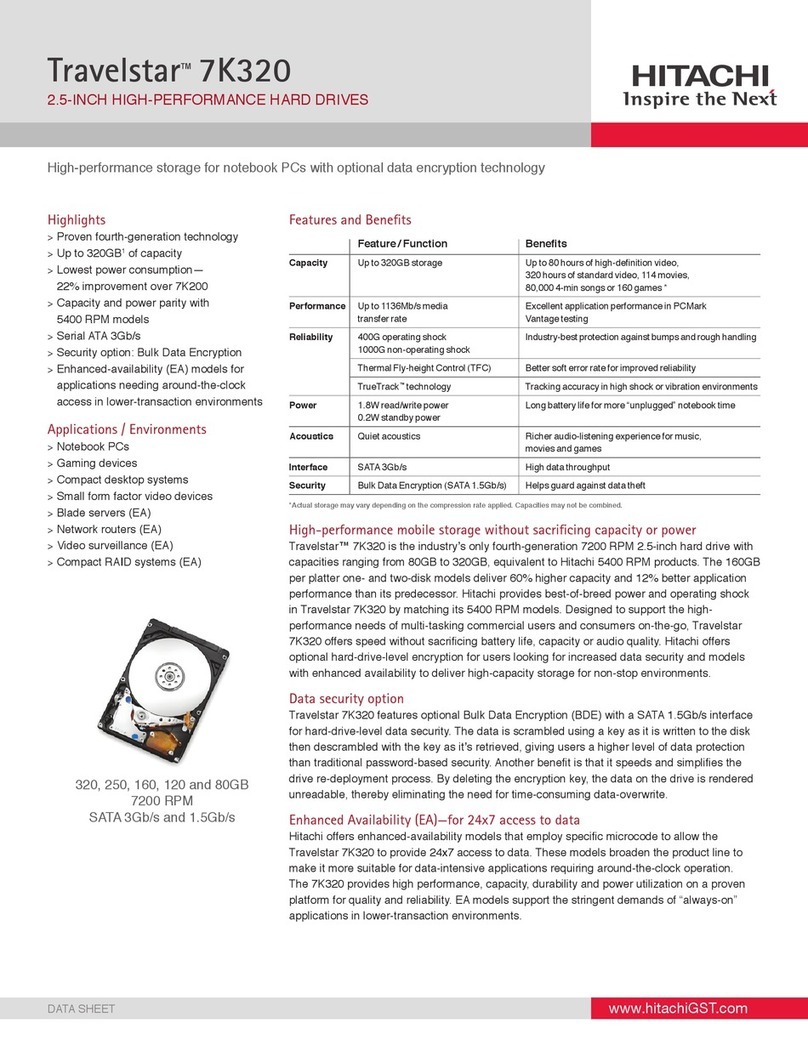

Hitachi

Hitachi Travelstar 2.5-inch HIGH-PERFORMANCE... datasheet

Dexxon

Dexxon SSD POWER PLUS X150 user guide

SimpleTech

SimpleTech SimpleDrive Deluxe Review guide

DANE-ELEC

DANE-ELEC SO MOBILE PLUS datasheet

OCZ

OCZ SYNAPSE Installation Guide and Warranty Information

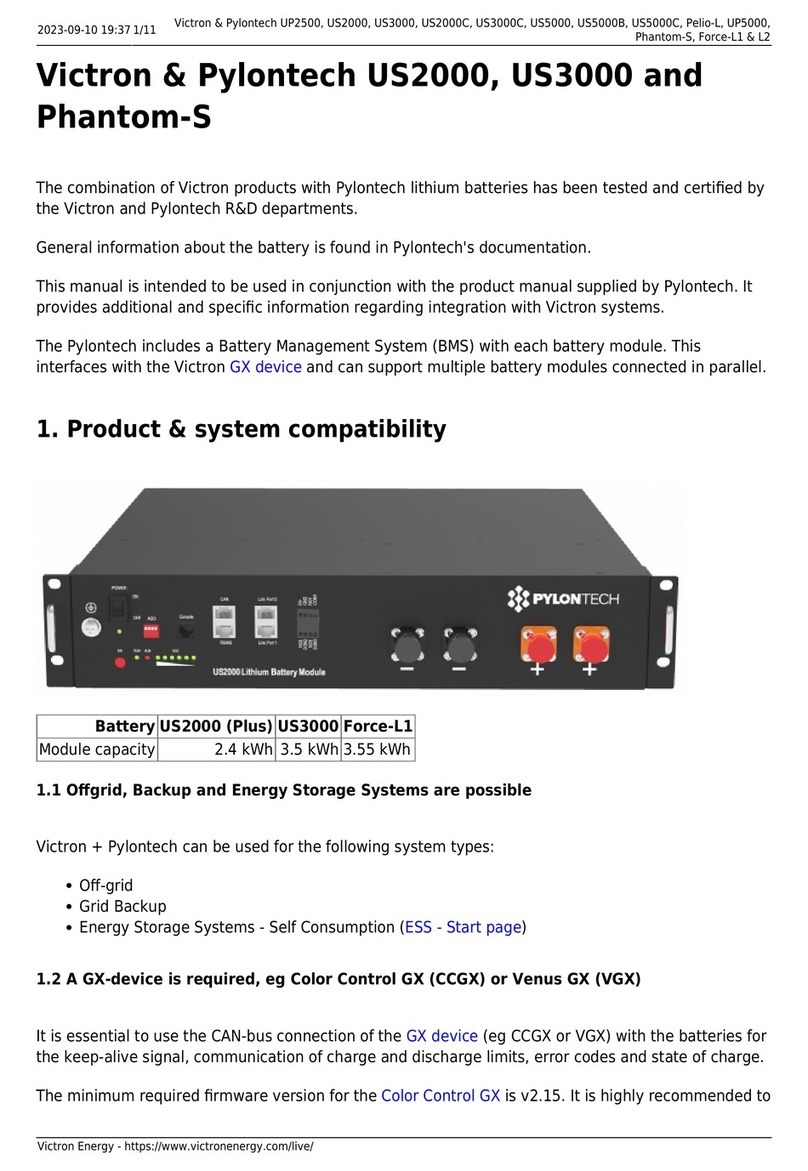

Victron energy

Victron energy US5000C manual

Seagate

Seagate FIRECUDA ST8000DX001 product manual

Seagate

Seagate STD2401LW-S product manual

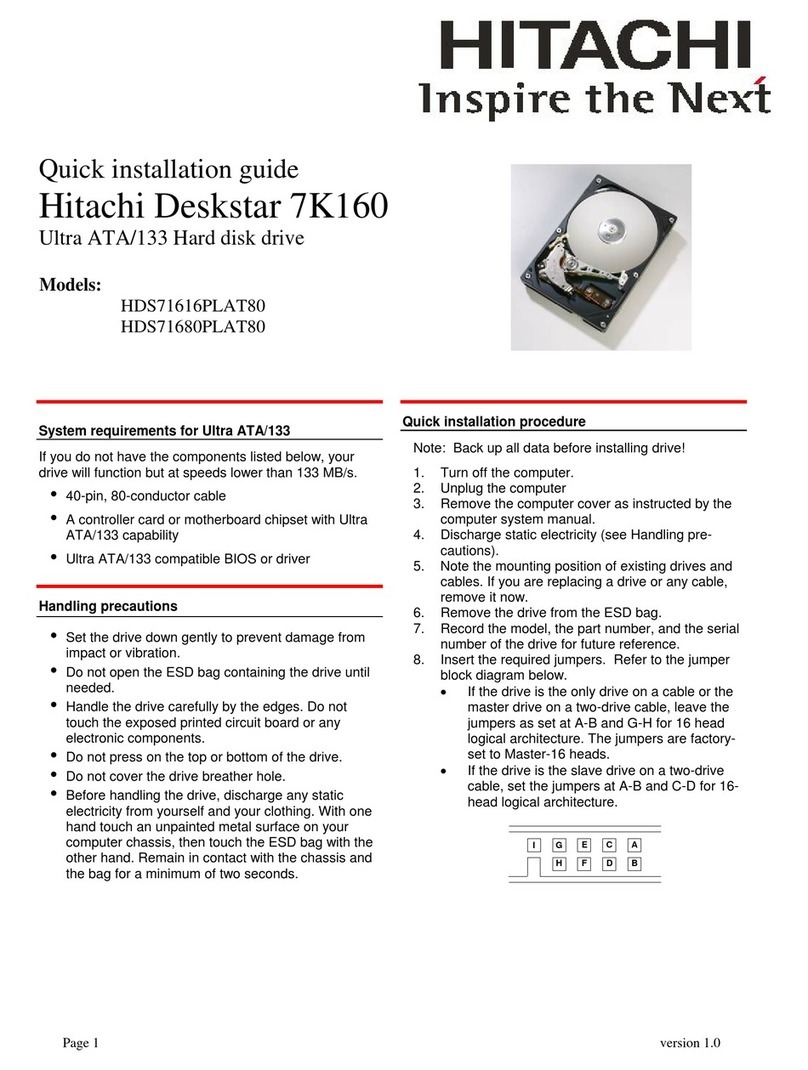

Hitachi

Hitachi Deskstar 7K160 Quick installation guide

Sun Microsystems

Sun Microsystems SPARCstation 4 Service manual