STMicroelectronics STEVAL-IHP005V1 User manual

May 2013 DocID024383 Rev 1 1/56

UM1619

User manual

General purpose ST7540 power line modem module based on

ST7540 PLM and STM32 microcontroller

Introduction

This document explains how to use and setup the firmware and the software designed for

the STEVAL-IHP005V1 board and all the necessary setup for using the hardware.

The application firmware uses the ST7540 power line modem firmware stack driver

described in the UM1573: “ST7540 power line modem firmware stack”, and is organized in a

layer structure. A dedicated layer allows the user to design his own application interfacing to

the module features with very simple and easy to use APIs. A dedicated software graphical

user interface (GUI) allows the user to use all the embedded features interfacing the PLM

module with the PC via an RS232 communication port.

This firmware is developed using STM32F10x Standard Peripherals Library Rel.3.5.0 and

IAR Embedded Workbench® IDE for STM32 microcontrollers Rel. 6.3

The STEVAL-IHP005V1 hardware module embeds an ARM 32-bit Cortex™-M3 core-based

STM32F103xB and a FSK power line transceiver ST7540.

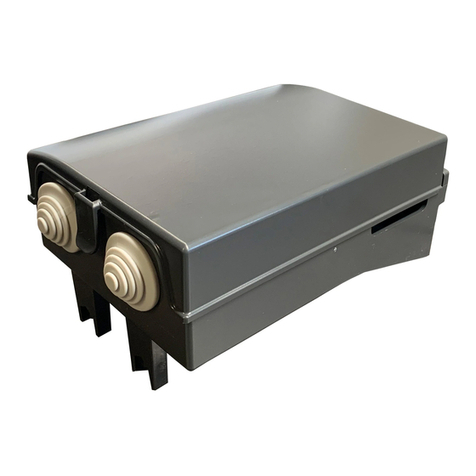

Figure 1. STEVAL-IHP005V1

www.st.com

Contents UM1619

2/56 DocID024383 Rev 1

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Hardware installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Software GUI description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Configuration tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Dongle tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Operations tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5 Program tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 Service tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.7 Sniffer tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Remote firmware update (RFU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Firmware download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 Firmware data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6 Firmware frame types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6.1 Data Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6.2 Ping Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6.3 Error Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.6.4 Acknowledgment Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.5 Programming Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.6 Programming Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.6.7 Embedded module features APIs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DocID024383 Rev 1 3/56

UM1619 Contents

Appendix A Schematic diagrams and bill of material . . . . . . . . . . . . . . . . . . . . . 47

A.1 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix B CRC 16 calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

List of figures UM1619

4/56 DocID024383 Rev 1

List of figures

Figure 1. STEVAL-IHP005V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. STEVAL-IHP005V1 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Three phase connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. User interface connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5. Programming connector JTAG adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. Installation window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7. License window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8. Destination folder window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 9. Installation status window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 10. RS232 connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 11. GUI options tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 12. GUI configuration tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. GUI dongle tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14. GUI operations tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 15. GUI program tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 16. GUI service tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 17. PLM communication parameters window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 18. GUI sniffer tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 19. Sniffer information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 20. Module firmware structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21. Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22. RFU flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23. Active project selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 24. Workspace structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 25. Schematic diagrams (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 26. Schematic diagrams (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 27. Schematic diagrams (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DocID024383 Rev 1 5/56

UM1619 Features

1 Features

•Configurable FSK power line modem interface with an embedded firmware stack for a

complete power line communication management

•8 user configurable general purpose input/output pins

•USART and SPI communication channel for module interfacing

•Internal configurable RTC module with lithium backup battery

•Programmable user data and PLM parameters Flash memory area

•Remote firmware update

•Embedded AES 128 encryption module with programmable AES Key

Hardware description UM1619

6/56 DocID024383 Rev 1

2 Hardware description

The STEVAL-IHP005V1 block diagram is shown in Figure 2. The general purpose power

line modem module is based on an ST7540 FSK power line modem transceiver and an

ARM 32-bit Cortex™-M3 core-based STM32F103xB microcontroller. The PLM module

board is a fully functional communication module, with 8 programmable I/Os, a real-time

clock and a Flash memory area for modem parameters and user data storage. The firmware

structure is made up of several layers, each dealing with a different feature. The application

layer engine is the general interface between the user program and all the parts of the

module. It manages the communication ports, the module peripherals such as SPI, SCI,

RTC, I/Os, LEDs and timing management. It is also the interface between the PLM stack

and the user program. The PLM stack, itself made up of several layers, implements and

manages the power line communication, manages the conflicts, timing and repetitions, the

addressing, and so on. Please refer to UM1573 for details on the firmware stack driver.

Some features are managed directly by the application engine, and are transparent to the

user, such as the RTC management or the module parameter update, as well as the module

programming and configuration, which is done by particular programming or service

commands managed and acknowledged directly by the application engine. Even the remote

firmware update is managed by the application engine and allows the firmware module

being update remotely by power line module.

The user layer is fully customizable by using some easy-to-use APIs available for user

application implementation. User data can be easily addressed to the PLM or to the other

communication interface by simply changing the destination channel in the user data

structure.

The STEVAL-IHP005V1 is powered by a dual regulated DC power source, +12 VDC (pin 1)

and +3.3 VDC (pin 2) from the power supply connector (J2). Pin 3 is the ground.

The communication is done via power line, which is applied to the board using the J1

connector, where pin 1 must be connected to the neutral wire and pin 3 to the phase wire

(refer to Appendix A).

Figure 2. STEVAL-IHP005V1 block diagram

<hWddZz

W>D

DKh>/EdZ&

^dDϯϮ

Z^ϮϯϮ

WKtZ>/E

DocID024383 Rev 1 7/56

UM1619 Hardware description

It is possible to connect the module in a three phase line (in case of communication modules

are connected in all three phases), in this case an external capacitor of 68nF X1 must be

connected to any additional phase, and then the other side of capacitors together with the

common pin 5 of the J1 connector, following the schematic shown in the Figure 3, and the 0-

Ohm resistor R1 must be mounted.

Figure 3. Three phase connection

The GP PLM module is provided with a user interface (J4) shown in Figure 4 where,

connected the SPI interface pins (MOSI, MISO, SCK and NSS), are the RS232 interface

pins (Tx and Rx), the USB interface pins (D+ and D-) and the user programmable general

purpose I/O pins. Note that these pins are directly connected to the microcontroller, so

ensure that the insulation and protection is appropriate for the use of these pins.

It is possible to power the PLM using the +3.3 VDC (pin 19), +12 VDC (pin 20 or 22) and

GND (pins 17, 23,20 and 24) of this connector instead of the connector J2, using only a

single connector for power supply and control signals.

A lithium backup battery mounted on the module and a 32 KHz quartz allows use of the full

functionality of the internal RTC of the microcontroller, permitting precise time-based

operations.

dž

ϲϴŶ&yϭ

LJ

ϲϴŶ&yϭ

W,^Z

W,^^

W,^d

EhdZ>

:ϭ

ϱ

ϯ

ϭ

Ϯ

ϲϴŶ&yϭ ϭ

^Dϲdϭϱ

>ϭ

ϮϮƵ,

dϭ

dZ&Kϭϭ

Zϭ

ϬZ

Hardware description UM1619

8/56 DocID024383 Rev 1

Figure 4. User interface connector

A three-color LED allows the signaling of some module operations, such as data

transmission and reception, programming phase, and so on. The user can also use these

LEDs for his own application needs by means of dedicated APIs.

Finally, a programming connector allows firmware download and debug, even if it is possible

to use the remote firmware update feature to remotely update the firmware using the PLM,

as described further in this user manual. If the IAR - JLINK/JTRACE is used for the firmware

downloading, a simple JTAG adapter is necessary. Figure 5 shows the adapter schematics.

Figure 5. Programming connector JTAG adapter

DocID024383 Rev 1 9/56

UM1619 Getting started

3 Getting started

3.1 System requirements

In order to use the GP PLM module demonstration board with a Windows® operating

system, a recent version such as Windows XP or Windows 7 must be installed on the PC.

The version of the Windows OS installed on your PC may be determined by clicking on the

“System” icon in the control panel.

3.2 Software installation

To install the PC GUI software “Remote Console for GP ST7540 PLM module”, please

download the STEVAL-IHP005V1_Setup from www.st.com, then follow the steps below.

The installed folders include the GUI executable file.

1. Click the STEVAL-IHP005V1_Setup.exe icon. The following window opens:

Figure 6. Installation window

Getting started UM1619

10/56 DocID024383 Rev 1

2. In the customer information window, insert the required customer data and click “Next”.

Read the license file and click the “Yes” button if you accept the license agreement.

Figure 7. License window

3. In the next window, click “Install”. In the following window, select the folder in which to

install the software package. By default, the software is installed in the path:

"C:\...\STMicroelectronics\ IHP005-V1.

Figure 8. Destination folder window

DocID024383 Rev 1 11/56

UM1619 Getting started

4. after selecting the folder and clicking the “Next” button, installation of the software

starts.

Figure 9. Installation status window

5. When installation is complete, click “Finish”. The GUI is located in the folder “Software -

Remote Console 5.5”.

Hardware installation UM1619

12/56 DocID024383 Rev 1

4 Hardware installation

Connect a regulated dual DC power supply to the power connector J2 or use the power

source pins of connector J4 as described previously and power the module.

In order to download the firmware, plug the programmer adapter (Figure 5) into the

programming connector J3 and the IAR JLink programmer in the JTAG connector of the

adapter.

Refer to Section 6: Firmware description for the firmware download procedure. As soon as

the application is launched, the LEDs should quickly switch on and off sequentially, and at

the end the orange LED should be switched on, indicating that the module needs to be

configured.

In order to configure the module, connect an RS232 DB9 female connector to one of the

available PC COM ports and the J4 connector as indicated in Figure 10.

Figure 10. RS232 connection

Run the “Remote Console for GP ST7540” GUI. Click the OPTIONS tab and select the

correct COM port from the list shown in the COM port option box (Figure 11).

In the CONFIGURATION tab, press the CONNECT button. The orange LED of the module

will flash twice and will stay switched on.

DocID024383 Rev 1 13/56

UM1619 Hardware installation

Figure 11. GUI options tab

The module is now in programming mode; the “Programing mode” message will flash at the

bottom of the interface, near the connected COM port indication.

Software GUI description UM1619

14/56 DocID024383 Rev 1

5 Software GUI description

5.1 Introduction

The software GUI is a demonstration tool that allows to program and set up the GP power

line modules and test all the embedded features.

The GUI is composed of several tabs, each one grouping different functions. A log window

is present at the bottom of the GUI and is common to all tabs. Each operation performed by

the user, by the modules and each error are logged in this window. The decimal view check

box allows swapping of the data display from hexadecimal to decimal mode. Independent of

the visualization, each item of data can be inserted by the user in decimal or hexadecimal

mode (starting the latter with the token 0x).

5.2 Configuration tab

This tab (Figure 12) is dedicated to the module configuration. As soon as the GUI is started

(and the COM port selected as described in the Hardware Installation paragraph), press the

CONNECT button. The module enters the programming mode, the orange LED flashes

twice and stay switched on. In the GUI the orange message “Programming Mode” flashes at

the bottom of the window.

In this tab there are several configuration panels, described hereafter.

•Dongle Parameters

In the dongle parameters panel it is possible to assign an address to the device. The

configuration is able to group certain modules with other and form a sub network (group)

independent from other groups, sharing the same power line. If the grouping feature is used,

select the grouping box in the working mode box, and assign the same group number to

each module belonging to the same sub network. If the grouping feature is not used, the

group fields are considered as the highest part of a 6 bytes address.

The address field is a 4 bytes address of the module if the grouping is used, otherwise is the

lowest 4 byte part of a 6 bytes address if the grouping is not used.

DocID024383 Rev 1 15/56

UM1619 Software GUI description

Figure 12. GUI configuration tab

•Working Mode

The working mode panel is used to specify the working mode of the power line

communication. The communication between two or more modules can be with or without

acknowledgment and with or without back acknowledgment. Select the respective check

box in order to enable or disable the ACK/bACk frames on a communication.

Checking the REPEATER box, the module works also as a repeater in case a data frame is

not addressed to itself. In this case, after a certain delay, if the targeted module does not

reply with an ACK to the sender, the module repeats the data frame as it was previously

sent. The repetition for a given frame is done only once per each module.

If the STATIC REPEATER check box is checked, the module repeats statically each sensed

frame without checking if the frame has been received/acknowledged or not. In both cases

the anti-collision mechanism (explained in the UM1573) is always adopted.

The GROUPING check box allows the creation of sub nets (group of modules interacting

only among those with the same group number). The group number has to be specified in

the group field of the dongle parameters panel.

The ENCRYPTION (AES128) check box enables the encryption mode: all the data

exchanged by the module are encrypted using the standard AES128 encryption algorithm.

The 128 bit encryption key is configurable in the AES key panel.

The HOP LEVEL check box allows to assign a hierarchical level to each module that is

enabled to work also as a repeater. Each time a data frame is repeated, the hop is

decremented by one. Only the modules with lowest hop level will repeat the same frame.

Please refer to user manual UM1573: ST7540 power line modem firmware stack for more

details on PLM protocol parameters.

Software GUI description UM1619

16/56 DocID024383 Rev 1

•AES key

The 128 bits of the AES key are set here in this panel. In order to enable the AES key panel,

before to connect the module, check the relative option USE ENCRYPTION (AES 128) in

the option tab.

•Dongle description

This box is used to associate a description of the programmed module to the node address.

The description together with the module will be displayed everywhere in the GUI each time

a node list is displayed. The description is stored in a local database, so if you run the GUI

with a programmed node in another PC, the description is missing. The node list file is

located in the directory C:\Program Data\STMicroelectronics\Remote

Console\1.0.0.0\settings\donglelist.l

It is possible to manually edit this file using a text editor, adding in each line the following

text:

0xg1.0xg0.0xa3.0xa2.0xa1.0xa0 -> description

where g1 and g0 are the group byte values (in hexadecimal) and the a3, a2, a1 and a0 are

the address byte values (in hexadecimal). The description is what will appear in the dongle

description panel and in all node list of the GUI.

•Hardware

In the hardware panel there are the connection and disconnection buttons. As soon as the

CONNECT button is pressed, if the module is connected the “Programming Mode” message

will flash at the bottom of the window, and the module enters programming mode. The

disconnect button disconnects the GUI from the COM port.

•Dongle mode

As soon as the module is connected, the two buttons RUN and PROGRAM of the dongle

mode panel switches the module modes respectively in run mode and in programming

mode.

•Commands

In the commands panel the SET button is used to download the chosen configuration

described previously, while the GET button is used to get the configuration present in the

module. If a module has never been programmed before, the group and the address field

are filled with 0xFF values and the run button will not have an effect.

As soon as the module is in run mode, the set to remote address button is enabled. This

button is used to configure a remote node connected via power line, working in the same

manner as the SET button. This procedure has effect only if the node has never been

programmed before (or if the remote address is set to 0xFF both in the group and address

box). Of course, only one module must be present with this address in the same power line,

otherwise the selected configuration (and the chosen new address and group) will be

assigned to each of these nodes.

DocID024383 Rev 1 17/56

UM1619 Software GUI description

If the module (dongle) is in programming mode, all the other tabs are locked. In order to

unlock all the tabs, press the RUN button. The GUI and the module will enter in run mode,

and the run mode message will appear in green at the bottom of the window. The module

LED will be switched off.

5.3 Dongle tab

The DONGLE tab (Figure 13) is where to set up and use two features embedded in the

module, the real-time clock (RTC), and the general purpose inputs/outputs pins.

The node time indicates the value of the internal RTC of the module. Press the GET TIME

button in the commands panel to know the actual time of the module. In order to modify the

time, write the new time in the node time panel and click the SET TIME button. The module

time can be synchronized with the PC time shown in the current time panel. In this case,

simply check the SET CURRENT option in the node time panel before pressing the SET

TIME button.

The module has 8 general purpose input/output pins that can be configured individually

either as input pin or as output pin. In order to know the actual configuration, press the GET

IO CFG button in the commands panel. If a pin is configured as input, the Input x (where x is

the number of the pin) appears in the input status panel with the respective check box

checked, and a red or a green LED is shown. the color of the LED specifies if in the module

pin is applied a high level (+3.3 V), in this case the LED is red, or a low level (GND) in this

case the LED is green.

If the pin is configured as output, the output x (where x is the pin number) is shown in the

input status panel, and the corresponding check box is unchecked. A toggle pushbutton is

than associated to each output, indicating if the correspondent pin in the module must be

set high (+3.3 V), in this case the pushbutton must be pressed before to press the set

outputs button in the commands panel, or must be set low (GND) releasing the pushbutton

before press the set outputs button in the commands panel.

Software GUI description UM1619

18/56 DocID024383 Rev 1

Figure 13. GUI dongle tab

As soon as the pin configuration is set by the user (checking or unchecking the

corresponding check box), the SET IO CFG button must be pressed before the

configuration has effect. After that, each output can be set/reset and each input can be

checked.

All those operations can be done in different way: in broadcast mode, in this case if the

BROADCAST check box in the commands panel is selected before press any button, each

“set” operation will be executed by each node connected in the same power line. The

command will be sent by the module connected to the GUI via the power line to all the other

nodes. In order to configure a single node (a remote node or the one connected to the GUI),

the node must be selected in the AVAILABLE NODE LIST window before to press any

command button. In broadcast mode the get operations are not allowed.

Last, the STOP button resets the connected dongle if some remote operations are ongoing

and the user wants to interrupt the operation.

Be aware that the I/O pins are not protected and directly wired with the microcontroller Poi's

pins. So if the pins are electrically connected in a wrong way a serious damage can be

caused in the module.

5.4 Operations tab

The OPERATIONS tab (Figure 14) is the place where to test a communication between two

modules connected to the same power line. In the Message window is possible to write a

text message, select the target node in the available node list, and send the message by

pressing the SEND MSG button.

DocID024383 Rev 1 19/56

UM1619 Software GUI description

Figure 14. GUI operations tab

If the message has to be sent in broadcast, the BROADCAST check box must be checked.

As soon as the send message is sent, the green LED of the module connected to the GUI is

switched on. When the LED is switched off the message has been sent to the target module

or an error has occurred. The operation result is shown in the log window.

If the target device is connected to a PC with a running GUI, the received message is shown

in the log window.

Software GUI description UM1619

20/56 DocID024383 Rev 1

5.5 Program tab

The PROGRAM tab shown in Figure 15 is used to store permanently user data in the

module flash memory. Actually is possible to store 20 bytes as example, but modifying a

constant in the firmware (#define USER_SETTINGS_SIZE directive) in the interfaceconfig.h

file it is possible to store more then 800 bytes of user data.

Figure 15. GUI program tab

As previously described for other features, the command to store data can be sent in

broadcast or to a precise module listed in the AVAILABLE NODE LIST window by pressing

the SET button.

The get button instead reads the stored data from the selected node.

Table of contents

Other STMicroelectronics Control Unit manuals

Popular Control Unit manuals by other brands

Pelican

Pelican PM5-277 installation guide

Whelen Engineering Company

Whelen Engineering Company WeCanX V2V installation guide

Beninca

Beninca CP.B24 manual

Johnson Controls

Johnson Controls VF Series installation instructions

ARMANO

ARMANO DAS operating instructions

Bitzer

Bitzer CM-RC-01 Maintenance instructions