Stoane Lighting Iris Type S User manual

Stoane Lighting Ltd

20 Dryden Road Bilston Glen Ind Est.

Loanhead Midlothian EH20 9LZ UK

T: +44 (0) 131 440 1313

F: +44 (0) 131 440 0049

www.stoanelighting.com

VAT No GB682885284

Limited Company 188910

Iris Type S

Installation and Maintenance

Instructions

IMPORTANT: All wiring connections must be made before switching on mains power.

European Conformity

Please retain these instructions for future reference

This product should not be disposed of in your general waste IP65 Dust tight and protected against low power jets of water.

Class III - Extra Low Voltage

SL Type S 2.85VF1.4W @ 500mA

All of our in-house printed paper

is 100% recycled and recyclable

Iris S.pdf 1 19/01/2021 14:37:21

Electrical Supply

Installation must be carried out by a qualified electrician in

accordance with BS 7671:2008 Wiring Regulations.

230/240V AC 50/60Hz mains supply to a suitable SELV

LED Driver.

Site conditions: LED equipment is more susceptible to

static damage and over voltage than previous technology.

Before handling or connecting to the mains supply ensure

that all Stoane Lighting (SL) products are protected from

static discharge and that the mains supply is to regulation.

(230V +10 -6%)

Mains cables must be double insulated, strain relieved

and separated from E.L.V output cables.

This unit requires a constant current driver. 500mA Max.

Observe polarity:

Positive (+) is marked as RED.

Incorrect supply or reverse polarity can cause irreparable

damage.

All connections must be made before switching on mains.

If the supply is energised prior to making the connections

to the fitting then the resulting surge will damage the LED.

Multiple LEDs should be wired in series, refer to driver

instructions for minimum/maximum load.

The entire dimming control circuit source must be of SELV

insulation class.

Maintenance:

All lighting equipment is delicate and easily damaged

through misuse or inappropriate installation (mechanical

or electrical). Repairs and replacements may cause

delays and will be chargeable. Contact SL for support if

required.

All Stoane Lighting products are covered by a five year

Warranty and a 25 year Duty of Care. Products are

designed to be upgraded, adapted and refreshed using

our comprehensive ReNew service. For more information

on our ReNew service and for full Warranty terms and

conditions visit stoanelighting.com or contact us at the

address shown.

The IP rating stated is applicable only when the fitting has

been installed as per these instructions.

The light source contained in this luminaire shall only be

replaced by the manufacturer or his service agent or a

similar qualified person.

Installation

Check that the mounting surface is suitable for the

installation of this fitting.

A 33mm diameter cutout is required.

Step 1 Make mains connections to SELV LED driver

and extra low voltage connections to the

fitting.

Step 2 Retaining Wings: Hold in the springs and

push into the cutout. Once released the

springs will hold the fitting in place.

OR

Retaining Ring: Insert fitting into cutout and

secure by screwing the retaining ring onto the

rear of the fitting.

Ensure supply driver and connectors are housed

indoors OR in a suitably IP rated enclosure. Cable

ends must be suitably waterproofed. Inspect supply

cables before installation to ensure there is no

damage which will allow water to enter the fitting.

After opening the sealed portion of the luminaire for

any reason, SL recommends running the fitting for 15

minutes with the lid open to expel moisture before

closing it up. This will prevent condensation on the

lens and protect the fitting from corrosion.

Ensure that the installation of this fitting does not

compromise any fire barrier offered by your ceiling.

Intumescent downlighter fire hoods should be used to

maintain the integrity of the barrier in the event of a

fire.

Do not cover the luminaire with insulation. Heat sinks

and fan assisted lamps must be kept free from dust

and well ventilated to ensure long term reliability and

light quality.

WARNING: Do not look at exposed LED lamps in

operation. Eye injury can result.

Cleaning:

Fully isolate the fitting and allow to cool.

Clean the fitting with a slightly damp lint free cloth

from a mild solution of soap and water. The fitting

must be completely dry before reconnecting power.

Incompatible or abrasive chemicals can damage the

fitting, contact SL for advice if required.

Iris S.pdf 2 19/01/2021 14:37:21

12

or

Retaining

Wings

OUTPUT 2

Connect to Mains

Connect to

fittings

33mm cut out

Min 4mm

Max 17mm

Min 1mm

Max 9mm

Iris S.pdf 3 19/01/2021 14:37:21

1

2

LENS / SNOOT CHANGE

Fully isolate and allow fitting to cool sufficiently before

handling.

Step 1 Lock the fitting at a non-tilted position and use

the specialist tool provided to unwind the ring

anti-clockwise to remove it from the tube.

Step 2 The lens and or snoot can now be removed

from the fitting and replaced with one of suitable

specification.

Ensure the O-ring sits neatly, is not twisted, stretched or

deformed in any way and sits neatly in its groove. It must

be free from debris of any kind. If needed, remove the

O-ring, clean it and the groove and replace with fresh

grease (Loctite Superlube). Failure to do so may result in

water ingress and premature failure of the luminaire

Reverse process to re-assemble.

1.5mm Allen Key

Tilt Adjustment

To adjust, loosen the M2 fixings with the supplied

1.5mm Allen key. A single turn should be sufficient to

unlock, do not remove the fixings.

Once adjustment is complete, tighten the fixings to

lock in place.

Optic

Bezel

Optic

Holder

Optic

spacer

Tool

Iris S.pdf 4 19/01/2021 14:37:21

Stoane Lighting firmly believe that we have a responsibility as environmental

custodians, we believe that lighting equipment should be built to last, to be

repaired and to be reused. As a BCorp we believe that we must look to operate in

a business not aiming to just be best in the world but a business best for the world.

Stoane Lighting believe that the circular economy is a fundamental aspect of how

we approach the challenges we face. If you read this at the end of the product life

we encourage you to consider how you can ensure these products see an

extended life.

All Stoane Lighting products are supplied with a 5 year warranty and a 25 year

duty of care.

Stoane Lighting operate a ReNew division, which can take your existing fittings

and refurbish or upgrade without the need for replacing what you already have.

Through the ReNew service, Stoane Lighting provides general repair, deep cleans

and electrical safety checks on luminaires, as well as possible repainting if needed.

We will replace components that are nearing end of life, such as drivers, LEDs,

and optics. If the fittings are to be used in a new area, or the existing space is

undergoing a change in use, ReNew can offer a different mounting method or light

technical performance (such as colour tuning), if needed, alongside the addition of

on-board wireless control.

Once fittings have been repaired or upgraded through ReNew, they will start a new

five-year warrantly period, and any unwanted parts will be recycled.

For more information the Warranty, Duty of Care or ReNew service please visit stoanelighting.com

or contact us at the address shown.

Iris S.pdf 5 19/01/2021 14:37:21

Table of contents

Other Stoane Lighting Light Fixture manuals

Popular Light Fixture manuals by other brands

ACME

ACME LPB-4P user manual

STSLITE

STSLITE M SPOT 200 user manual

BlissLights

BlissLights StarPort USB-RED-STN user guide

Federal Signal Corporation

Federal Signal Corporation STREETHAWK FHL4856R Wiring and maintenance Instructions

Philips

Philips 6910114PH Instruction leaflet

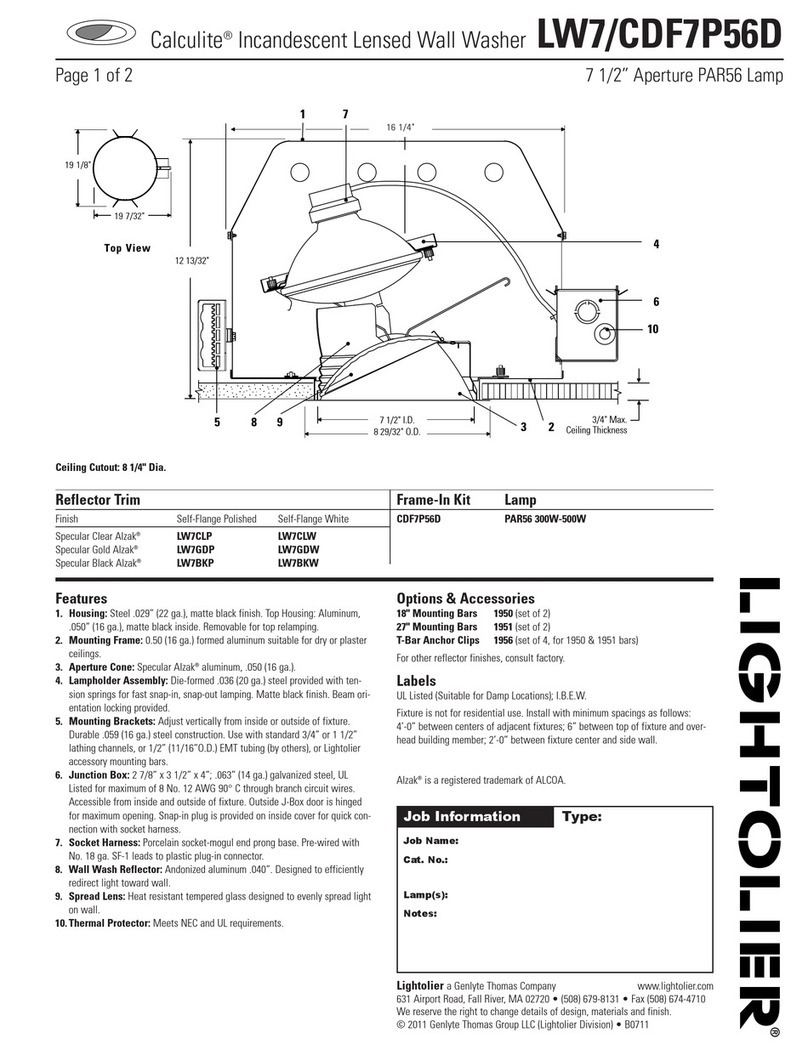

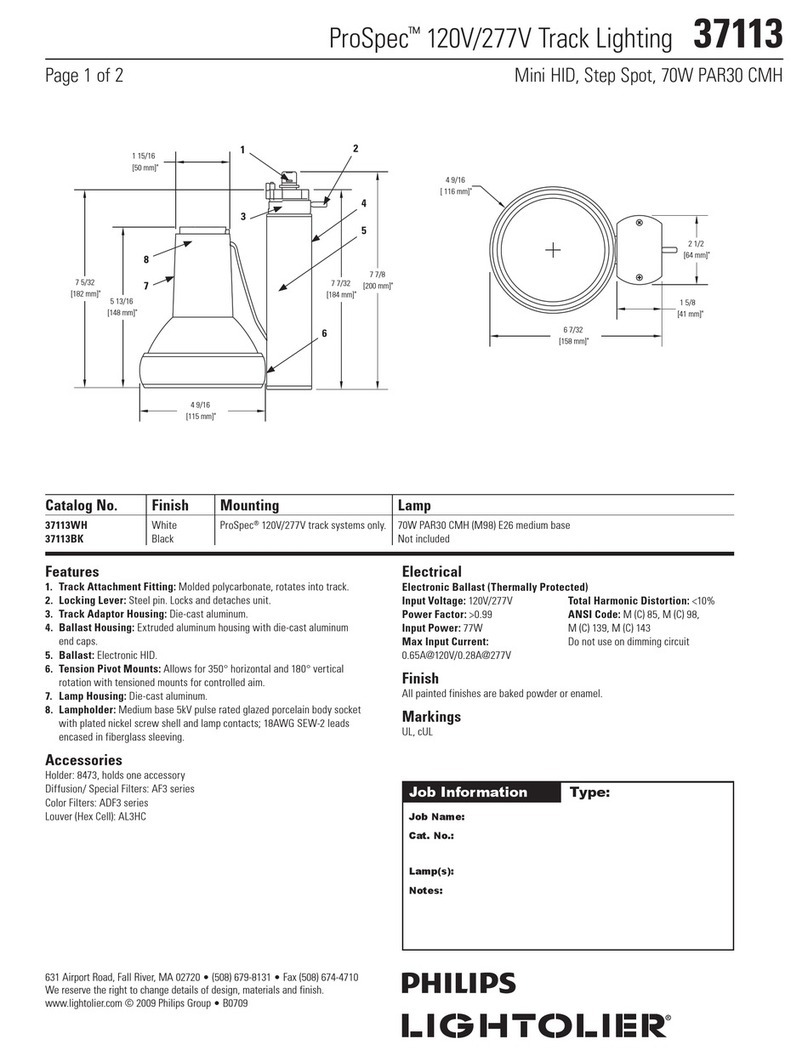

Lightolier

Lightolier LOW VOLTAGE FRAME-IN KIT instructions