Stober PS6 Series User manual

Multi-axis drive system with SI6 and PS6

Manual

en-US

02/2019

ID 442728.05

stober.com

Table of contents STOBER

ii

02/2019 | ID 442728.05

Table of contents

1 Foreword .............................................................................................................................. 9

2 User information................................................................................................................ 10

2.1 Storage and transfer ...................................................................................................10

2.2 Described product type...............................................................................................10

2.3 Timeliness...................................................................................................................10

2.4 Original language........................................................................................................10

2.5 Limitation of liability.....................................................................................................10

2.6 Formatting conventions ..............................................................................................11

2.6.1 Use of symbols............................................................................................. 11

2.6.2 Markup of text elements ............................................................................... 12

2.6.3 Conventions for cables................................................................................. 13

2.7 Symbols, marks and test symbols ..............................................................................13

2.8 Trademarks.................................................................................................................14

3 General safety instructions .............................................................................................. 15

3.1 Directives and standards ............................................................................................15

3.2 Qualified personnel.....................................................................................................15

3.3 Intended use ...............................................................................................................15

3.4 Transport and storage ................................................................................................16

3.5 Operational environment and operation .....................................................................16

3.6 Working on the machine .............................................................................................17

3.7 Disposal......................................................................................................................18

3.8 Firefighting..................................................................................................................18

4 UL-compliant use .............................................................................................................. 19

5 System configuration........................................................................................................ 22

5.1 Hardware components................................................................................................23

5.1.1 Supply module.............................................................................................. 23

5.1.2 Drive controller ............................................................................................. 27

5.1.3 DC link connection........................................................................................ 31

5.1.4 Controller...................................................................................................... 32

5.1.5 Operating motors, encoders and brakes ...................................................... 33

5.1.6 Accessories .................................................................................................. 34

5.2 Software components .................................................................................................37

5.2.1 Project configuration and parameterization.................................................. 37

5.2.2 Applications .................................................................................................. 37

STOBER Table of contents

02/2019 | ID 442728.05

iii

6 Technical data.................................................................................................................... 38

6.1 General technical data................................................................................................38

6.2 Supply module ............................................................................................................39

6.2.1 Electrical data............................................................................................... 39

6.2.2 Dimensions................................................................................................... 42

6.2.3 Weight .......................................................................................................... 42

6.3 Drive controllers..........................................................................................................43

6.3.1 Electrical data............................................................................................... 43

6.3.2 Derating........................................................................................................ 51

6.3.3 Dimensions................................................................................................... 53

6.3.4 Weight .......................................................................................................... 54

6.4 DC link connection......................................................................................................54

6.4.1 General technical data.................................................................................. 54

6.4.2 DL6B assignment – SI6 and PS6................................................................. 55

6.4.3 Dimensions................................................................................................... 55

6.4.4 Weight .......................................................................................................... 56

6.5 Safety technology .......................................................................................................57

6.6 Operating motors ........................................................................................................58

6.7 Evaluable encoders ....................................................................................................59

6.7.1 Overview....................................................................................................... 59

6.7.2 Signal transmission ...................................................................................... 59

6.7.3 X4 ................................................................................................................. 60

6.7.4 X101 for encoders ........................................................................................ 63

6.7.5 X103 for encoders ........................................................................................ 63

6.8 Controllable brakes.....................................................................................................64

6.9 Braking resistor...........................................................................................................65

6.9.1 Braking resistor assignment – PS6 .............................................................. 65

6.9.2 KWADQU flat resistor................................................................................... 65

6.9.3 FZZMQU tubular fixed resistor ..................................................................... 67

6.9.4 FGFKQU steel-grid fixed resistor ................................................................. 69

6.10 Choke .........................................................................................................................71

6.10.1 TEP output choke......................................................................................... 71

7 Project configuration ........................................................................................................ 76

7.1 Supply module ............................................................................................................76

7.1.1 Information on design and operation............................................................ 76

7.1.2 Parallel connection of supply modules ......................................................... 77

7.2 DC link connection......................................................................................................78

7.2.1 Information on design and operation............................................................ 78

7.3 Mixed operation ..........................................................................................................79

Table of contents STOBER

iv

02/2019 | ID 442728.05

7.4 Example design for UL-compliant operation...............................................................80

7.4.1 Maximum operation on PS6A24................................................................... 81

7.4.2 Maximum operation on PS6A34................................................................... 82

7.4.3 Sample calculation ....................................................................................... 83

7.5 Order overview of the hardware components.............................................................83

8 Storage ............................................................................................................................... 85

8.1 Supply module ............................................................................................................85

8.2 Drive controller............................................................................................................85

8.2.1 Annual reforming .......................................................................................... 86

8.2.2 Reforming before commissioning................................................................. 87

9 Installation.......................................................................................................................... 89

9.1 Safety instructions for installation ...............................................................................89

9.2 Basic assembly instructions........................................................................................89

9.2.1 Drive controllers and supply modules........................................................... 89

9.2.2 Choke ........................................................................................................... 90

9.2.3 Braking resistor............................................................................................. 90

9.3 Minimum clearances...................................................................................................92

9.4 Drilling diagrams and dimensions...............................................................................93

9.4.1 Multi-axis drive system ................................................................................. 93

9.5 Length of copper rails .................................................................................................94

9.6 Installing the DC link connection.................................................................................95

9.6.1 Order overview of the components for the DC link connection .................... 95

9.6.2 Installing the DC link connection .................................................................. 95

9.7 Installing drive controllers and supply modules ..........................................................99

10 Connection....................................................................................................................... 102

10.1 Safety instructions for connection.............................................................................102

10.2 Line routing...............................................................................................................103

10.3 Protective measures.................................................................................................103

10.3.1 Power grid supply....................................................................................... 103

10.3.2 CE-compliant line fuse................................................................................ 104

10.3.3 UL-compliant line fuse................................................................................ 105

10.3.4 Grid connection .......................................................................................... 105

10.3.5 Residual current protective device ............................................................. 105

10.3.6 CE-compliant housing grounding ............................................................... 107

10.3.7 UL-compliant housing grounding................................................................ 108

10.3.8 EMC recommendations.............................................................................. 109

10.4 Supply module..........................................................................................................110

10.4.1 Overview..................................................................................................... 110

10.4.2 X10: 400V supply ...................................................................................... 111

10.4.3 X11: 24V supply ........................................................................................ 112

STOBER Table of contents

02/2019 | ID 442728.05

v

10.4.4 X21: Braking resistor .................................................................................. 113

10.4.5 X22: DC link connection ............................................................................. 113

10.4.6 X23: Temperature monitoring of braking resistor ....................................... 114

10.4.7 X100: Status output.................................................................................... 114

10.4.8 Connecting the supply module ................................................................... 115

10.5 Drive controller..........................................................................................................116

10.5.1 Overview..................................................................................................... 116

10.5.2 X2A: Brake A.............................................................................................. 117

10.5.3 X2A: Motor temperature sensor A.............................................................. 118

10.5.4 X2B: Brake B.............................................................................................. 119

10.5.5 X2B: Motor temperature sensor B.............................................................. 119

10.5.6 X4A: Encoder A.......................................................................................... 119

10.5.7 X4B: Encoder B.......................................................................................... 124

10.5.8 X9: Ethernet service interface .................................................................... 124

10.5.9 X11: 24V supply ........................................................................................ 125

10.5.10 X12: Safety technology (SR6 option) ......................................................... 126

10.5.11 X20A: Motor A ............................................................................................ 127

10.5.12 X20B: Motor B ............................................................................................ 128

10.5.13 X22: DC link connection ............................................................................. 128

10.5.14 X101: BE1 – BE4........................................................................................ 130

10.5.15 X103: BE6 – BE9........................................................................................ 131

10.5.16 X200, X201: EtherCAT............................................................................... 133

10.5.17 X200, X201: PROFINET............................................................................. 134

10.5.18 X300: Brake 24V supply............................................................................ 135

10.5.19 X700: SD slot.............................................................................................. 136

10.5.20 Connecting a drive controller...................................................................... 137

10.6 Output choke ............................................................................................................138

10.6.1 Connection description............................................................................... 138

10.7 Cables.......................................................................................................................140

10.7.1 Power cables.............................................................................................. 141

10.7.2 Encoder cables........................................................................................... 145

10.7.3 One Cable Solution .................................................................................... 155

11 Commissioning................................................................................................................ 159

11.1 Initiating the project...................................................................................................159

11.1.1 Projecting the drive controller and axis....................................................... 159

11.1.2 Configuring the safety module.................................................................... 161

11.1.3 Creating other modules and drive controllers............................................. 161

11.1.4 Specifying a module ................................................................................... 161

11.1.5 Specifying the project ................................................................................. 162

11.2 Mechanical drive model............................................................................................162

11.2.1 Parameterizing the STOBER motor ........................................................... 162

11.2.2 Parameterizing the axis model ................................................................... 163

11.3 Testing the project configuration...............................................................................165

Table of contents STOBER

vi

02/2019 | ID 442728.05

12 Communication ............................................................................................................... 167

12.1 System requirements................................................................................................167

12.1.1 Personal firewall ......................................................................................... 167

12.1.2 Protocols and ports for communication using routers ................................ 168

12.2 Direct connection......................................................................................................168

12.3 Fieldbus ....................................................................................................................168

13 Diagnostics ...................................................................................................................... 169

13.1 Supply module..........................................................................................................169

13.2 Drive controller..........................................................................................................172

13.2.1 Fieldbus state ............................................................................................. 173

13.2.2 FSoE state.................................................................................................. 175

13.2.3 Drive controller state................................................................................... 176

13.2.4 Service network connection........................................................................ 178

13.2.5 Fieldbus network connection...................................................................... 179

13.3 Events.......................................................................................................................181

13.3.1 Overview..................................................................................................... 181

13.3.2 Event 31: Short/ground............................................................................... 183

13.3.3 Event 32: Short/ground internal.................................................................. 183

13.3.4 Event 33: Overcurrent ................................................................................ 184

13.3.5 Event 34: Hardware fault............................................................................ 185

13.3.6 Event 35: Watchdog ................................................................................... 185

13.3.7 Event 36: High voltage ............................................................................... 186

13.3.8 Event 37: Motor encoder ............................................................................ 186

13.3.9 Event 38: Temperature drive controller sensor .......................................... 189

13.3.10 Event 39: Overtemperature drive controller i2t........................................... 190

13.3.11 Event 40: Invalid data................................................................................. 191

13.3.12 Event 41: Temp.MotorTMP ........................................................................ 192

13.3.13 Event 44: External fault 1 ........................................................................... 193

13.3.14 Event 45: Overtemp.motor i2t..................................................................... 194

13.3.15 Event 46: Low voltage ................................................................................ 195

13.3.16 Event 47: Torque limit................................................................................. 196

13.3.17 Event 50: Safety module ............................................................................ 197

13.3.18 Event 51: Virtual master limit switch........................................................... 198

13.3.19 Event 52: Communication .......................................................................... 199

13.3.20 Event 53: Limit switch................................................................................. 200

13.3.21 Event 54: Following error............................................................................ 201

13.3.22 Event 56: Overspeed.................................................................................. 202

13.3.23 Event 57: Runtime usage ........................................................................... 203

13.3.24 Event 59: Overtemperature drive controller i2t........................................... 204

13.3.25 Event 60: Application event 0 – Event 67: Application event 7 .................. 205

13.3.26 Event 68: External fault 2 ........................................................................... 206

13.3.27 Event 69: Motor connection........................................................................ 207

STOBER Table of contents

02/2019 | ID 442728.05

vii

13.3.28 Event 70: Parameter consistency............................................................... 208

13.3.29 Event 71: Firmware .................................................................................... 209

13.3.30 Event 72: Brake test timeout ...................................................................... 210

13.3.31 Event 76: Position encoder......................................................................... 211

13.3.32 Event 77: Master encoder .......................................................................... 214

13.3.33 Event 78: Position limit cyclic ..................................................................... 217

13.3.34 Event 79: Motor / position monitor.............................................................. 218

13.3.35 Event 80: Illegal action ............................................................................... 219

13.3.36 Event 81: Motor allocation.......................................................................... 219

13.3.37 Event 85: Excessive jump in reference value............................................. 220

13.3.38 Event 86: Unknown data record LeanMotor............................................... 221

13.3.39 Event 87: Reference lostReference loss .................................................... 222

13.3.40 Event 88: Control panel.............................................................................. 223

13.3.41 Event 89: Maximum current Lm.................................................................. 224

14 Replacement .................................................................................................................... 225

14.1 Safety instructions for device replacement...............................................................225

14.2 Replacing the drive controller ...................................................................................226

14.3 Exchanging the supply module.................................................................................227

14.4 Replacing or updating the firmware..........................................................................228

14.5 Changing the fieldbus...............................................................................................228

15 Service.............................................................................................................................. 229

15.1 STOBER electronics service ....................................................................................229

15.2 Reverse documentation............................................................................................229

15.2.1 Creating reverse documentation in a new project ...................................... 229

15.2.2 Loading reverse documentation in an existing project ............................... 230

16 Appendix .......................................................................................................................... 231

16.1 Terminal specifications .............................................................................................231

16.1.1 Overview..................................................................................................... 231

16.1.2 FMC 1,5 -ST-3,5......................................................................................... 232

16.1.3 BCF 3,81 180 SN ....................................................................................... 233

16.1.4 BFL 5.08HC 180 SN................................................................................... 233

16.1.5 BLDF 5.08 180 SN ..................................................................................... 234

16.1.6 FKC 2,5 -ST-5,08 ....................................................................................... 234

16.1.7 GFKC 2,5 -ST-7,62..................................................................................... 235

16.1.8 GFKIC 2.5 -ST-7.62.................................................................................... 235

16.1.9 SPC 5 -ST-7,62 .......................................................................................... 236

16.1.10 ISPC 5 -STGCL-7,62.................................................................................. 236

16.1.11 SPC 16 -ST-10,16 ...................................................................................... 237

16.1.12 ISPC 16 -ST-10,16 ..................................................................................... 237

16.1.13 BUZ 10.16IT 180 MF.................................................................................. 238

Table of contents STOBER

viii

02/2019 | ID 442728.05

16.2 Wiring examples .......................................................................................................239

16.2.1 Operation with 1 supply module ................................................................. 239

16.2.2 Parallel connection ..................................................................................... 240

16.2.3 UL-compliant connection of the supply module.......................................... 241

16.3 Device addressing ....................................................................................................242

16.4 DriveControlSuite......................................................................................................243

16.4.1 System requirements.................................................................................. 243

16.4.2 Installation types......................................................................................... 243

16.4.3 Installing software....................................................................................... 244

16.4.4 Updates ...................................................................................................... 244

16.5 Detailed information..................................................................................................245

16.6 Symbols in formulas .................................................................................................246

16.7 Abbreviations............................................................................................................248

17 Contact ............................................................................................................................. 249

17.1 Consultation, service and address............................................................................249

17.2 Your opinion is important to us .................................................................................249

17.3 Close to customers around the world .......................................................................250

Glossary ........................................................................................................................... 251

List of figures................................................................................................................... 254

List of tables .................................................................................................................... 256

STOBER 1 | Foreword

02/2019 | ID 442728.05

9

1 Foreword

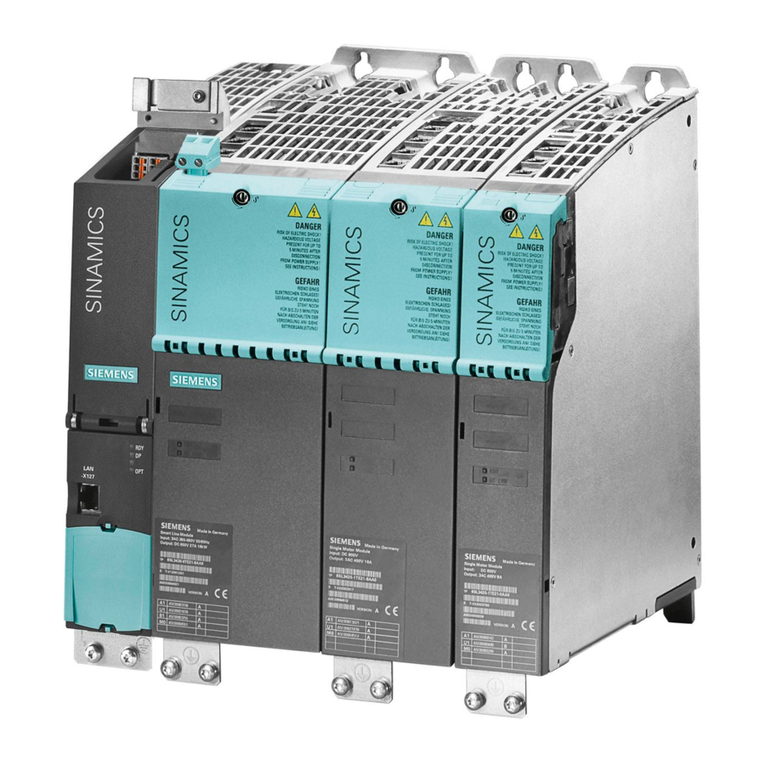

The completely re-designed STOBER multi-axis drive system consists of the SI6 drive controller

and PS6 supply module combination. Matching Quick DC-Link modules handle the energy

supply for the networked drive controllers. The SI6 drive controller is available in four sizes as a

single or double-axis controller with a nominal output current of up to 50A. The PS6 supply

module is available in two sizes with a nominal power of 10 kW or 20 kW. As an economically

attractive system with a minimized device width, the SI6 opens a new dimension in multi-axis

applications.

Features

§Sensorless position control by STOBER Lean motors

§Control of rotary synchronous servo motors, asynchronous motors and torque motors

§HIPERFACE DSL One Cable Solution

§Electronic motor nameplate via HIPERFACE DSL and EnDat 2.2 digital encoder interfaces

§Integrated EtherCAT or PROFINET communication

§STO safety technology using terminals or STO and SS1 using FSoE (Safety over

EtherCAT): SIL3, PLe (cat.4)

§Integrated brake control

§Energy supply over DC link connection

§Asymmetric load on double-axis controllers for operation of motors with different power

§Variable feed-in power using supply modules that can be connected in parallel

2 | User information STOBER

10

02/2019 | ID 442728.05

2 User information

This documentation covers the SI6 and PS6 multi-axis drive systems. You will receive support

for the assembly of the individual modules along with the associated components that you will

need for the operation of the modules in the control cabinet.

You will also find information for wiring the modules correctly and checking their functionality in

the group with an initial test.

Combinations with other 6th generation STOBER drive controllers are possible under certain

general conditions.

Information

To ensure proper functionality, we recommend using cables from STOBER that are matched to

the complete system. In case of use of unsuitable connection cables, we reserve the right to

reject claims under the warranty.

2.1 Storage and transfer

As this documentation contains important information for handling the product safely and

efficiently, it must be stored in the immediate vicinity of the product until product disposal and be

accessible to qualified personnel at all times.

Also pass on this documentation if the product is transferred or sold to a third party.

2.2 Described product type

This documentation is binding for:

SI6 drive controller and PS6 supply module in combination with

DriveControlSuite software in V 6.3-E or later and associated firmware in V 6.3-E or later.

2.3 Timeliness

Check whether this document is the most up-to-date version of the documentation. We provide

the latest document versions for our products for download on our website: http://

www.stoeber.de/en/download.

2.4 Original language

The original language of this documentation is German; all other language versions are derived

from the original language.

2.5 Limitation of liability

This documentation was created taking into account the applicable standards and regulations

as well as the current state of technology.

STOBER shall assume no responsibility for damage resulting from failure to comply with the

documentation or from use that deviates from the intended use of the product. This is especially

true for damage caused by individual technical modifications to the product or projecting and

operation of the product by unqualified personnel.

STOBER 2 | User information

02/2019 | ID 442728.05

11

2.6 Formatting conventions

Orientation guides in the form of signal words, symbols and special text markups are used to

emphasize specific information so that you are able identify it in this documentation quickly.

2.6.1 Use of symbols

Safety instructions are identified with the following symbols. They indicate special risks when

handling the product and are accompanied by relevant signal words that express the extent of

the risk. Furthermore, useful tips and recommendations for efficient, error-free operation are

specially highlighted.

ATTENTION!

Notice

This indicates that damage to property may occur

▪ if the stated precautionary measures are not taken.

CAUTION!

Caution

This word with a warning triangle indicates that minor personal injury may occur

▪ if the stated precautionary measures are not taken.

WARNING!

Warning

This word with a warning triangle means there may be a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

DANGER!

Danger

This word with a warning triangle indicates that there is a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

Information

Information indicates important information about the product or serves to emphasize a section

in the documentation that deserves special attention from the reader.

2 | User information STOBER

12

02/2019 | ID 442728.05

2.6.2 Markup of text elements

Certain elements of the body text are distinguished as follows.

Quick DC-Link module Words or expressions with a special meaning

Interpolated position mode Optional: File or product name or other name

Detailed information Internal cross-reference

http://www.stoeber.de External cross-reference

Software and display indicators

The following formatting is used to identify the various information content of elements

referenced by the software interface or the drive controller display, as well as any user entries.

Main menu

Settings

Window names, dialog names, page names or buttons,

combined proper nouns, functions referenced by the interface

Select

Referencing method A

Predefined entry

Save your

<own IP address>

User-defined entry

EVENT 52:

COMMUNICATION

Display indicators (status, messages, warnings, faults) for

status information referenced by the interface

Keyboard shortcuts and command sequences or paths are represented as follows.

[CTRL], [CTRL] +

[S]

Key, shortcut

Table > Insert table Navigation to menus/submenus (path specification)

Interpretation of parameter identification

Parameter identification consists of the following elements, where short forms are also possible,

i.e. only specifying a coordinate or the combination of coordinate and name.

E50 Drive controller G6 0

Coordinate

Name

Version

Drive controller generation/

series

STOBER 2 | User information

02/2019 | ID 442728.05

13

2.6.3 Conventions for cables

In the cable connection descriptions, core colors are shortened and used as follows.

Cable colors

BK: BLACK PK: PINK

BN: BROWN RD: RED

BU: BLUE VT: VIOLET

GN: GREEN WH: WHITE

GY: GRAY YE: YELLOW

OG: ORANGE

Formatting conventions

Two-colored core: WHYE WHITEYELLOW (white and yellow)

Single-colored core: BK/BN BLACK/BROWN (black or brown)

2.7 Symbols, marks and test symbols

The following symbols, marks and test symbols are used in this document.

Grounding symbol

Grounding symbol in accordance with IEC 60417-5019 (DB:2002-10).

RoHS lead-free mark

Marking in accordance with RoHS directive 2011-65-EU.

CE mark

Manufacturer's self declaration: The product meets the requirements of

EU directives.

UL test symbol

This product is listed by UL for the United States and Canada.

Representative samples of this product have been evaluated by UL and

meet the requirements of applicable standards.

UL recognized component mark

This component or material is recognized by UL. Representative

samples of this product have been evaluated by UL and meet applicable

requirements.

2 | User information STOBER

14

02/2019 | ID 442728.05

2.8 Trademarks

The following names used in connection with the device, its optional equipment and its

accessories are trademarks or registered trademarks of other companies:

CANopen®,

CiA®

CANopen® and CiA® are registered European Union trademarks of CAN

in AUTOMATION e.V., Nuremberg, Germany.

EnDat®EnDat® and the EnDat® logo are registered trademarks of Dr. Johannes

Heidenhain GmbH, Traunreut, Germany.

EtherCAT®,

Safety over EtherCAT®,

TwinCAT®

EtherCAT®, Safety over EtherCAT® and TwinCAT® are registered

trademarks of patented technologies licensed by Beckhoff Automation

GmbH, Verl, Germany.

HIPERFACE®HIPERFACE® and the HIPERFACE DSL® logo are registered

trademarks of SICK STEGMANN GmbH, Donaueschingen, Germany.

PLCopen®PLCopen® is a registered trademark of the PLCopen Organisation,

Gorinchem, Netherlands.

PROFIBUS®,

PROFINET®

The PROFIBUS and the PROFINET logo are registered trademarks of

PROFIBUS Nutzerorganisation e.V., Karlsruhe, Germany.

speedtec®, springtec®speedtec® and springtec® are registered trademarks of TE Connectivity

Industrial GmbH, 94559 Niederwinkling, Germany.

All other trademarks not listed here are the property of their respective owners.

Products that are registered as trademarks are not specially indicated in this documentation.

Existing property rights (patents, trademarks, protection of utility models) are to be observed.

STOBER 3 | General safety instructions

02/2019 | ID 442728.05

15

3 General safety instructions

There are risks associated with the product described in this documentation that can be

prevented by complying with the described warning and safety instructions as well as the

included technical rules and regulations.

3.1 Directives and standards

The following European directives and standards are relevant to the drive controllers:

§Machinery Directive 2006/42/EC

§Low Voltage Directive 2014/35/EU

§EMC Directive 2014/30/EU

§EN 61326-3-1:2008

§EN 61800-3:2004 and A1:2012

§EN 61800-5-1:2007

§EN 61800-5-2:2007

§EN 50178:1997

§IEC 61784-3:2010

Subsequent references to the standards do not specify the respective year in order to improve

readability.

3.2 Qualified personnel

In order to be able to perform the tasks described in this documentation, the persons instructed

to perform them must have the appropriate professional qualification and be able to assess the

risks and residual hazards when handling the products. For this reason, all work on the products

as well as their operation and disposal may be performed only by professionally qualified

personnel.

Qualified personal are persons who have acquired authorization to perform these tasks either

through training to become a specialist and/or instruction by specialists.

Furthermore, valid regulations, legal requirements, applicable basic rules, this documentation

and the safety instructions included in it must be carefully read, understood and observed.

3.3 Intended use

As defined by DIN EN 50178, SC6 drive controllers and PS6 supply modules are electrical

devices operating as power electronics to control the flow of energy in high-voltage systems.

The SI6 drive controller intended solely for the operation of STOBER LM series Lean motors,

synchronous servo motors (e.g. from the STOBER EZ series), asynchronous motors or torque

motors.

The PS6 supply module is intended solely for the supply of one or more drive controllers. Only

drive controllers of the 6th generation of STOBER drive controllers may be connected to the

PS6.

3 | General safety instructions STOBER

16

02/2019 | ID 442728.05

The connection of other electronic loads or operation outside applicable technical specifications

constitutes improper use.

When installing drive controllers in machines, commissioning (i.e. commencing intended

operation) may not be performed until it has been determined that the machine is in compliance

with provisions from the following EC and EU directives:

§Machinery Directive 2006/42/EC

§Low Voltage Directive 2014/35/EU

§EMC Directive 2014/30/EU

EMC-compliant installation

The SI6 drive controller and accessories must be installed and wired compliant for EMC

Modification

As the user, you may not make any physical, technical or electrical modifications to the SI6

drive controller and the accessories.

Maintenance

The SI6 drive controller and accessories are maintenance-free. For the safety module, take

appropriate measures to detect or prevent possible errors in the connection wiring.

Product life span

A drive controller with integrated safety module must be taken out of operation 20 years after

the production date. The production date of the drive controller is found on the accompanying

nameplate.

3.4 Transport and storage

Inspect the delivery for any transport damage immediately after you receive it. Notify the

transport company of any damage immediately. Do not put a damaged product into operation.

To ensure the faultless and safe operation of the products, they must be professionally

configured, installed, operated and maintained. If you have to transport or store the products,

you must protect them from mechanical impacts and vibrations as well as observe the

recommended transport and storage conditions in the technical data.

Store the products in a dry and dust-free room if you do not install them immediately.

3.5 Operational environment and operation

The products are subject to sales restrictions in accordance with IEC 61800-3.

The products are not designed for use in a public low-voltage network that supplies residential

areas. Radio-frequency interference can be expected if the products are used in this type of

network.

The products are designed exclusively for operation in TN networks.

The products are intended exclusively for installation in control cabinets with at least protection

class IP54.

Always operate the products within the limits specified by the technical data.

STOBER 3 | General safety instructions

02/2019 | ID 442728.05

17

The following applications are prohibited:

§Use in potentially explosive atmospheres

§Use in environments with harmful substances as specified by EN 60721, such as oils, acids,

gases, vapors, dust and radiation

Implementation of the following applications is permitted only after approval from STOBER:

§Use in non-stationary applications

§The use of active components (drive controllers, supply modules, energy recovery units or

discharge units) from third-party manufacturers

The PS6 supply module is intended only for operation on TN networks and is suitable only for

use on supply grids that are able to deliver, at most, a maximum symmetrical nominal short-

circuit current in accordance with the following table between 200 and 480VAC.

Size Max. symm. nominal short-circuit current

Size 2 and size 3 5000A

Tab. 1: Maximum symmetrical nominal short-circuit current of the supply module

3.6 Working on the machine

Before all work on machines and systems, apply the 5 safety rules in accordance with DIN VDE

0105-100 (Operation of electrical installations – Part 100: General requirements) in the order

listed:

§Disconnect (also ensure that the auxiliary circuits are disconnected).

§Ensure power cannot be switched on again.

§Ensure that everything is de-energized.

§Ground and short circuit.

§Cover adjacent live parts.

Information

Note that the you can only determine that voltage is no longer present once the discharge time

has elapsed. The discharge time depends on the self-discharge of the drive controller and, if

applicable, the fast discharge. You can find the discharge time in the general technical data.

3 | General safety instructions STOBER

18

02/2019 | ID 442728.05

3.7 Disposal

Observe the current national and regional regulations when disposing of the product! Dispose of

the individual product parts depending on their properties, e.g. as:

§Electronic waste (circuit boards)

§Plastic

§Sheet metal

§Copper

§Aluminum

§Battery

3.8 Firefighting

DANGER!

Electrical voltage! Risk of fatal injury due to electric shock!

There is a risk of fatal injury due to electric shock when using conductive firefighting equipment.

▪ Use ABC powder or carbon dioxide (CO2) for firefighting.

STOBER 4 | UL-compliant use

02/2019 | ID 442728.05

19

4 UL-compliant use

This chapter contains relevant information for use under UL conditions (UL – Underwriters

Laboratories).

Surrounding air temperature and pollution degree

The maximum surrounding air temperature for UL-compliant operation is 45°C. Use in an

environment with pollution degree 2 is permitted.

Network layout

All device types supplied with 480VAC are intended solely for operation with grounded wye

sources at 480/277VAC.

Project configuration

Observe the notes in the chapter Project configuration [}76].

You can find an order overview of the hardware components in the chapter Order overview of

the hardware components [}83].

The maximum number of devices in the device group is limited by certain variables. The

nominal output current I2N,PU of the supply module, the charging capacity CPU of the supply

module and the maximum copper rail length of 1500mm must not be exceeded.

For this purpose, observe the information in the chapter Example design for UL-compliant

operation [}80].

Line fuse

Mark each device group and observe the specifications in the chapter UL-compliant line fuse

[}105] to ensure that the line fuses of the supply modules with power are UL-compliant.

Branch circuit protection

Integral solid state short circuit protection does not provide branch circuit protection (line fuse)

upstream of the drive controller. Branch circuit protection must be provided in accordance with

the manufacturer instructions, the National Electrical Code, the Canadian Electrical Code, part

1, and any additional local codes.

Grounding

1. Protective grounding

The external motors which are connected to the inverter units SI6 units shall not be grounded

over the modular drive system. The bonding/grounding of the motor(s) shall occur in the end

use application in accordance with the requirements of applicable electrical codes/standards.

The grounding provisions present on the terminals X20A/X20B of the SI6 unit are not intended

for safety grounding of the motors. The grounding provision present on terminal X10 of the

inverter unit is not to be used for the grounding of the drive system.

The chassis of the PS6A/SI6A units is to be bonded through the M6 grounding studs on the

PS6A units (4.0Nm, 35Lb.inch).

The chassis of the SI6A units are to be bonded by means of proper mounting of the SI6A unit(s)

by means of two mounting screws on top of the DL6B unit(s). The specified tightening torque for

these mounting screws on the DL6B units is: 3.5Nm (31Lb.inch).

4 | UL-compliant use STOBER

20

02/2019 | ID 442728.05

The connection for the protective grounding on the housing is identified by the following

grounding symbol .

Observe the notes in the chapter UL-compliant housing grounding [}108] for correct

installation.

2. Functional grounding

In addition to the protective grounding, a functional grounding is required for proper operation of

the PS6 drive system in combination with SI6 and of the motor. The functional grounding of the

PS6 drive system in combination with SI6 is connected using the terminal X10. The functional

grounding of the motor is connected using the terminals X20A and X20B. The connections for

the functional grounding to terminals X10, X20A and X20B are marked with PE. For UL-

compliant operation: The connections marked with PE are intended solely for the functional

grounding.

Terminals

Note that the basic device is delivered without terminals. Suitable terminal sets are available

separately for each size. You can see an overview of the available terminal sets in the chapter

Order overview of the hardware components [}83].

Motor overload protection/motor temperature protection

Use motor overload protection/motor temperature protection. The SI6 drive controller features

connections for PTC thermistors (NAT 145°C, sensor voltage = 3.3V, sensor current = 0.6A).

The devices are only intended to be used with motors which have integral thermal protection. In

accordance with UL certification, operation without motor overload protection/motor temperature

protection in or on the motor (X2 jumpers) is not permitted! For a proper connection, observe

the terminal description for X2A in the chapter X2A: Motor temperature sensor A [}118].

Braking resistor

Use braking resistors with thermal monitoring and a resistor with at least 22Ω.

The temperature switch must be connected to terminal X21 of the PS6 supply module. If the

temperature switch reports a braking resistor overload, the PS6 supply module must be

removed from the power supply using the WARNING1 relay at terminal X100. You can find an

associated wiring example in the chapter UL-compliant connection of the supply module [}241].

Brake

Observe the technical data for the brake in the chapter Controllable brakes [}64].

Binary inputs

Observe the technical data for the binary inputs at X101 and X103 in the chapter Binary inputs

[}47].

Conductors

Power terminals: Use 60/75°C copper conductors only.

Fuses

Fuses must be approved for DC voltage in accordance with UL 248.

This manual suits for next models

10

Table of contents

Other Stober DC Drive manuals

Stober

Stober RD11 User manual

Stober

Stober CANopen SD6 User manual

Stober

Stober POSIDRIVE MDS 5000 User manual

Stober

Stober ASP 5001 User manual

Stober

Stober POSIDRIVE FDS 5000 series User manual

Stober

Stober Stober CombiDrive CM150/3 Installation and operation manual

Stober

Stober FDS 4000 Installation and operation manual