Stober POSIDRIVE FDS 5000 series User manual

POSIDRIVE®FDS 5000

Mounting Instructions CONNECTION

MOUNTING

V 5.3

01/2008 GB

MI AM

BCI Field-

bus Applications POSI

Switch®

POSIDRIVE®FDS 5000 - Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

Table of Contents

TABLE OF CONTENTS

1. Notes on Safety 1

1.1 Hardware 2

1.2 Software 3

2. Technical Data 4

2.1 Electrical 4

2.2 Mechanical 7

3. Mechanical Installation 8

3.1 Installation location 8

3.2 Mounting/mounting dimensions 8

3.2.1 Without bottom 8

3.2.2 With bottom brake resistor 9

3.3 Installation of accessories 9

3.3.1 Option module 1 (fieldbus, terminals) 9

3.3.1.1 CANopen DS-301 (CAN5000) /

PROFIBUS DP-V1 (DP5000) 9

3.3.1.2 EtherCAT (ECS5000) 10

3.3.1.3 I/O terminal module (LEA5000) 10

4. Electrical Installation 11

4.1 EMC 11

4.2 RCD circuit breaker 11

4.3 Power connection 11

4.4 DC link coupling 12

4.4.1 Basic Circuit Diagram 12

4.4.2 Combinations 13

4.4.3 Fuses 13

4.5 Safety function „safe torque off“ 14

4.5.1 Description 14

4.5.2 Use 14

4.5.3 Function test 17

4.5.4 Remaining dangers 17

4.6 Motor cable fabrication 18

4.7 Installation after storage period 18

5. Connection allocation 19

5.1 Terminal overview 19

5.3 Terminal allocation (X1 – X302) 20ff

6. Examples of connections 31

6.1 General 31

6.1.1 Brake connection with BRM 5000 for

24 V DC brakes (Imax=2 A, Pmax=48 W) 31

6.1.2 Brake connection with interface relay 32

6.1.3 Brake connection with powerbox 33

6.2 Terminals 34

6.2.1 Example 1 34

6.2.2 Example 2 34

7. Accessories 35

7.1 Accessory overview 35

7.2 Brake resistor 37

7.2.1 FZM(U) and VHPR 37

7.2.2 Bottom brake resistor RB 5000 38

7.3 Output deraters 39

5th Generation of STÖBER Inverters

STÖBER

ANTRIEBSTECHNIK

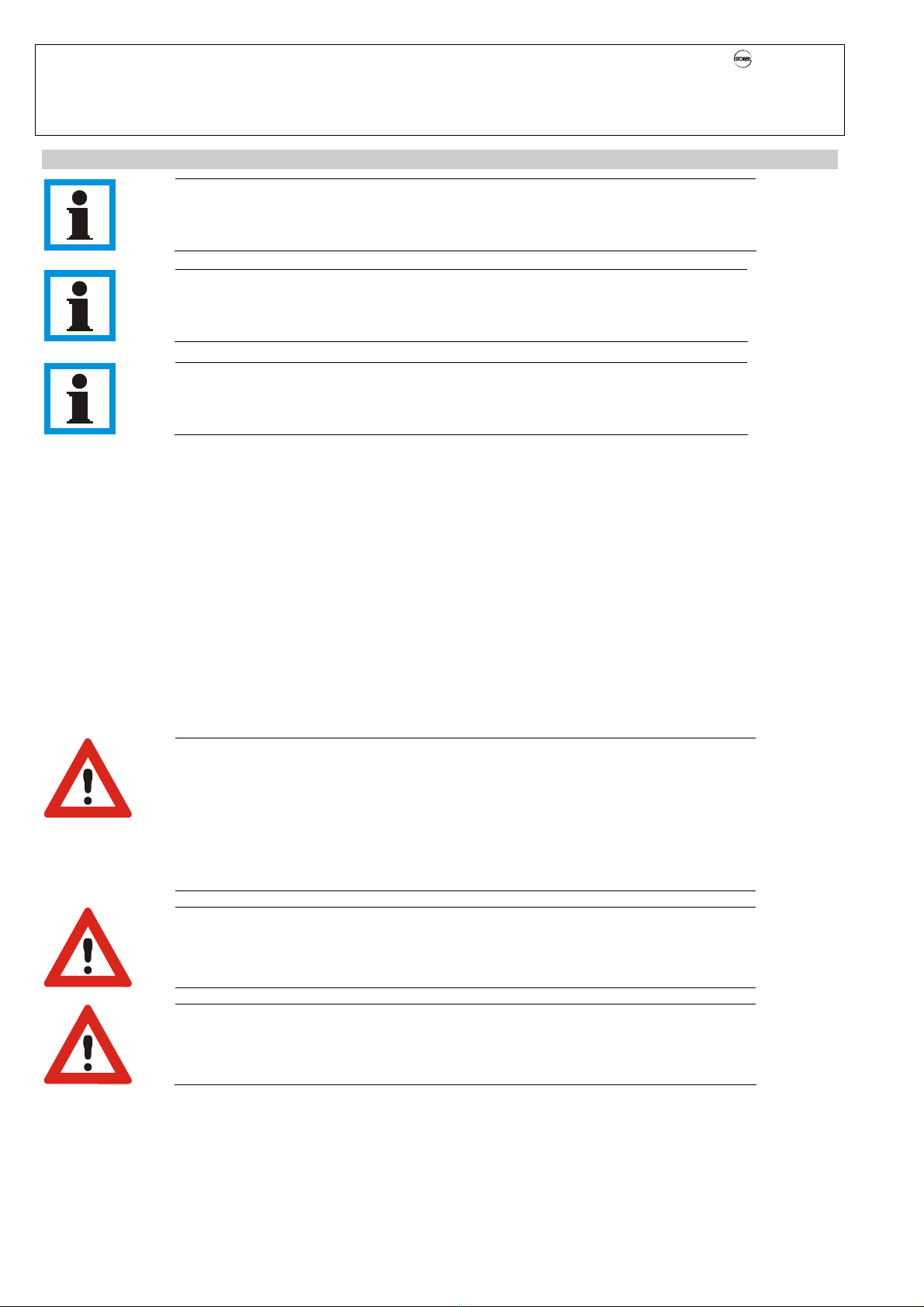

1. Notes on Safety

1

1NOTES ON SAFETY

This manual contains information which must be adhered to in order to prevent personal

injury and property damage. This information is graduated by degree of damage as

shown below.

ATTENTION

Means that an undesired result or undesired state may occur if this note is not heeded.

CAUTION

Without warning triangle: Means that property damage may occur if appropriate

precautions are not taken.

CAUTION

With warning triangle: Means that minor personal injury and property damage may occur

if appropriate precautions are not taken.

WARNING

Means that major danger of death and substantial property damage may occur if

appropriate precautions are not taken.

DANGER

Means that great danger to life and substantial property damage will occur if appropriate

precautions are not taken.

NOTE

Indicates an important piece of information on the product or the drawing of attention to a

part of the documentation requiring special attention.

ACTION

Means the description of an action which is particularly important for handling the

product.

5th Generation of STÖBER Inverters

STÖBER

ANTRIEBSTECHNIK

1. Notes on Safety

2

1.1 Hardware

WARNING

To ensure that avoidable problems do not occur during commissioning and/or operation,

be sure to read these installation and commissioning instructions before installation and

commissioning.

In the sense of DIN EN 50178 (formerly VDE 0160), the FDS and MDS model series of

POSIDRIVE®are electrical components of power electronics for the regulation of energy

flow in high-voltage systems. They are exclusively designed to power servo (MDS) and

asynchronous (FDS, MDS) machines. Utilization, installation, operation and maintenance

are only permitted under observation and adherence to valid regulations and/or legal

requirements, applicable standards and this technical documentation.

This is a product of the restricted sales class in accordance with IEC 61800-3. In a

residential zone, this product may cause high-frequency interference in which case the

user may be requested to take suitable measures.

Strict adherence to all rules and regulations must be ensured by the user.

The safety notes contained in further sections (items) and specifications must be

adhered to by the user.

WARNING

Caution! High touch voltage! Danger of shock! Danger to life!

When network voltage is applied, never under any circumstances open the housing or

disconnect the connections. When installing or removing option boards, you may only

open the inverter in the dead state (all power plugs disconnected) and only after a

waiting period of at least 5 minutes after the network voltage is switched off. Prerequisite

for the correct functioning of the inverter is the correct configuration and installation of

the inverter drive. Transport, installation, commissioning and handling of the device may

only be performed by qualified personnel who have been especially trained for these

tasks.

Pay particular attention to the following:

•Permissible protection class: Protective ground. Operation is only permitted when the

protective conductor is connected in accordance with regulations. Direct operation of

the devices on IT networks is not possible.

•Installation work may only be performed in the dead state. For work on the drive, lock

enable and disconnect the complete drive from the power. (Observe the 5 safety

rules.)

•Leave the plug for the DC link coupling connected even when the DC link coupling is

not being used (BG0-BG2: X22)!

•Discharge time of the DC link capacitors > 5 minutes.

•Do not penetrate the device's interior with any kind of object.

•During installation or any other work in the switching cabinet, protect the device

against falling parts (pieces of wire, stranded wire, pieces of metal, and so on). Parts

with conductive properties may cause a short circuit within the inverter or device

failure.

•Before commissioning, remove extra coverings so that the device cannot overheat.

The inverter must be installed in a switching cabinet in which the maximum ambient

temperature (see technical data) is not exceeded. Only copper lines may be used. The

line cross sections to be used are contained in table 310-16 of the NEC standard at

60 oC or 75 oC.

The company STÖBER ANTRIEBSTECHNIK GmbH + Co. KG accepts no liability for

damages resulting from non-adherence to the instructions or the particular

regulations.

5th Generation of STÖBER Inverters

STÖBER

ANTRIEBSTECHNIK

1. Notes on Safety

3

The motor must have an integral temperature monitor with basis insulation as per

EN 61800-5-1 or external motor overload protection must be used.

Only suitable for use on supply current networks which cannot deliver more than a

maximum symmetric, nominal, short-circuit current of 5000 A at 480 Volt.

Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the Manufacturer

Instructions, National Electrical Code and any additional local codes”, or the equivalent.

Subject to technical changes without prior notification which changes serve to

improve the devices. This documentation is purely a product description. It does

not represent promised properties in the sense of warranty law.

1.2 Software

Use of the POSITool software

The POSITool software package can be used to select an application, adjust parameters

and signal monitoring of the 5th generation of STÖBER inverters. The functionality is

specified by the selection of an application and the transmission of these data to an

inverter.

The program is the property of STÖBER ANTRIEBSTECHNIK GmbH + Co. KG and is

protected by copyright. The program is licensed for the user.

The software is provided exclusively in machine-readable format.

The customer receives from STÖBER ANTRIEBSTECHNIK GmbH + Co. KG a non-

exclusive right to use the program (license) if the program was obtained legally.

The customer has the right to utilize the program for the above stated activities and

functions and to make and install copies of the program, including one backup copy, for

support of said utilization.

The conditions of this license apply to all copies. The customer is obligated to place the

copyright note and all other ownership notes on every copy of the program.

The customer is not authorized to use, copy, change or pass on/transmit the program for

reasons other than those covered by these conditions; the customer is also not

authorized to convert the program (reverse assembly, reverse compilation) or compile

the program in any other manner, or to sublicense, rent or lease the program.

Product maintenance

The obligation to perform maintenance applies to the two last current program versions

prepared and released for use by STÖBER ANTRIEBSTECHNIK GmbH + Co. KG.

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG can either correct program errors or

provide a new program version. The choice is up to STÖBER ANTRIEBSTECHNIK

GmbH + Co. KG. If, in individual cases, the error cannot be corrected immediately,

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG will provide an intermediate solution

which, if necessary, requires adherence by the user to special operating regulations.

The claim to error correction only exists when reported errors are reproducible or can be

recorded by machine-made outputs. Errors must be reported in reconstructable form

giving useful information for error correction.

The obligation to correct errors is invalidated for such programs which the customer

changes or manipulates unless the customer can prove when reporting the error that the

manipulation is not the cause of the error.

STÖBER ANTRIEBSTECHNIK GmbH + Co. KG is obligated to keep the currently valid

program versions in a specially protected place (fire-resistant data safe, safety deposit

box at a bank).

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

2. Technical Data

4

2TECHNICAL DATA

Model key

FDS 5075/H

2.1 Electrical

General (for all sizes)

Output voltage 3 x 0 V up to connection voltage

Output frequency 0 – 400 Hz

Radio interference suppression EN 61800-3, interference emission, class C3

International certifications ---

Storage/transportation temperature -20 °C to +70 °C, max. of change: 20 K / h

Max. surrounding air temperature 0 to 45 °C with rated data,

up to 55 °C with power reduction of 2.5% / °C

Relative humidity during operation Relative humidity 85%, no condensation

Altitude of installation Up to 1000 m above sea level without restriction

1000 to 2000 m above sea level with power reduction of 1.5% / 100 m

High voltage category III in accordance with EN 61800-5-1

Degree of soil Degree of soil 2 in accordance with EN 60204 / EN 50178

Protection rating IP 20

Installation position Generally vertical

Ventilation Built in fan

5th generation

Powe

r

075 = 7.5 kW

A

uxiliary voltage, control electronics

/H ... High level, DC link

/L ... Low level, 24 V external (in preparation)

Designation

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

2. Technical Data

5

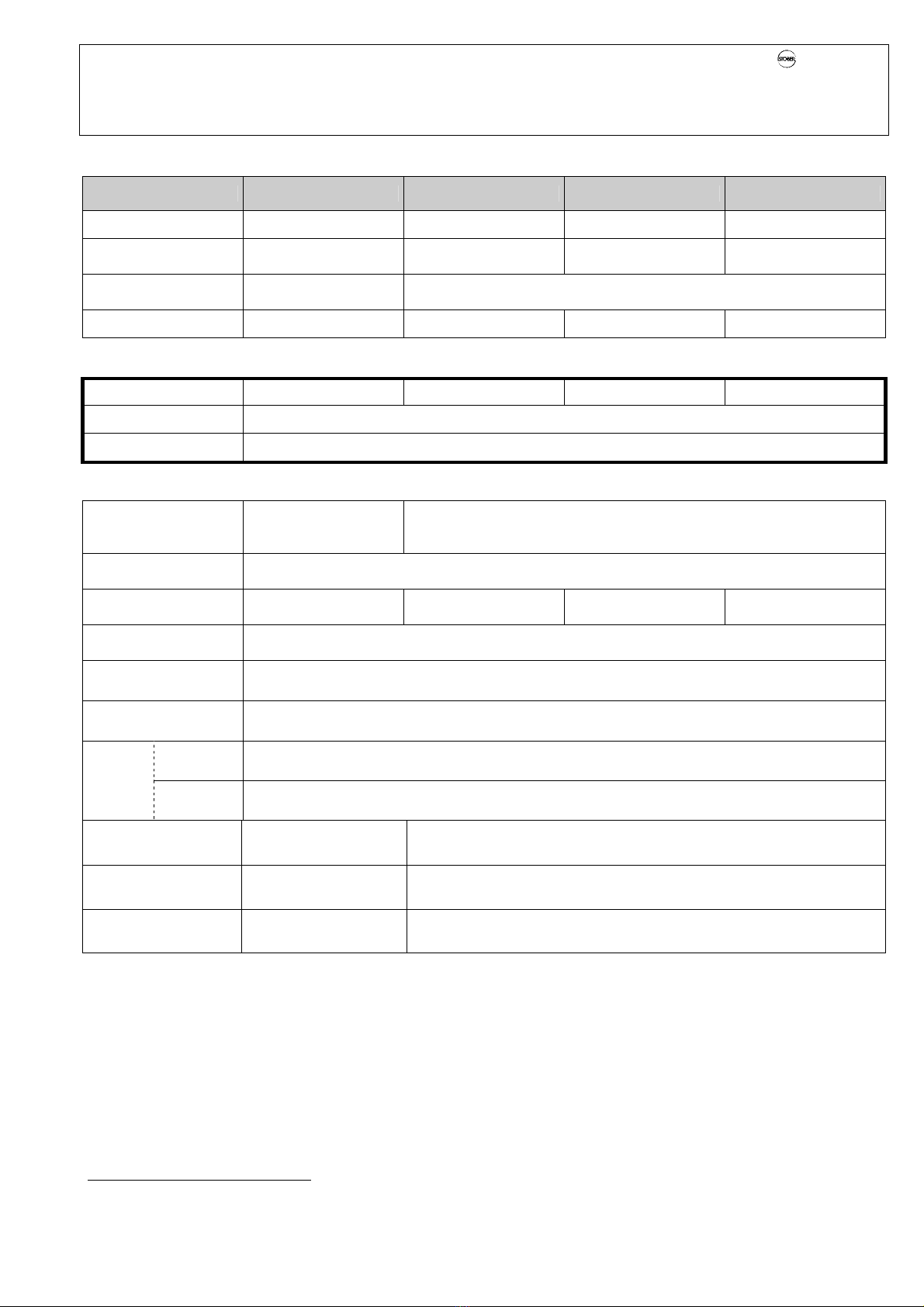

Size 0 / BG 0

Device Type FDS 5007 FDS 5004 FDS 5008 FDS 5015

ID no. 45962 45961 45963 45964

Recommended motor

power 0.75 kW 0.37 kW 0.75 kW 1.5 kW

Connection voltage (L1-N) 1 x 230 V

+20%/-40%,50/60Hz

(L1-L3) 3 x 400 V +32%/-50% 50 Hz

(L1-L3) 3 x 480 V +10%/-58% 60 Hz

Power fuses11 x 10 AT 3 x 6 AT 3 x 6 AT 3 x 10 AT

Operation with three-phase current motor (control mode V/f, VC, SLVC)

Rated current IN3 x 4.0 A 3 x 1.3 A 3 x 2.1 A 3 x 4.0 A

Imax 180% / 5 sec., 150% / 30 sec.

Clock pulse frequency 4 kHz (adjustable up to 16 kHz with derating)

Brake resistor

(accessories),

cf. chap. 7.2

100 Ω: Max. of

1.6 kW 200 Ω: Max. of 3.2 kW

Perm. motor cable

length, shielded

50 m

Output derating is required for distances of 50 m to 100 m (see chapter 7.2.3).

Power loss at Ia = IN80 W 50 W 65 W 90 W

Power loss at Ia = 0A2Max. of 30 W2

Conductor cross

section Max. of 2.5 mm2

Dimensions (H x B x T)

[mm] 300 x 70 x 157 (175)3

without

packaging 2.1

Weight

[kg] with

packaging 2.9

Upper voltage limit 440 V 830 V

Brake chopper on level 400 V / 420 V 780 V / 800 V

Brake chopper disable

voltage 360 V / 380 V 740 V / 760 V

1Line circuit breaker, tripping characteristic C, EN 60 898

Use class RK1 fuses for UL adherence: Class RK1 (e.g., Bussmann KTS-R-xxA / 600 V)

2Depends on the option boards and sensors connected (e.g., encoder)

3Depth including braking resistor RB 5000

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

2. Technical Data

6

Size 1 / BG 1

Device Type FDS 5022 FDS 5040 FDS 5055 FDS 5075

ID no. 45965 45966 45967 45968

Recommended

motor capacity 2.2 kW 4.0 kW 5.5 kW 7.5 kW

Connection voltage (L1-L3) 3 x 400 V +32%/-50% 50 Hz

(L1-L3) 3 x 480 V +10%/-58% 60 Hz

Power fuses13 x 10 AT 3 x 16 AT 3 x 20 AT 3 x 20 AT

Operation with three-phase current motor (control mode V/f, VC, SLVC)

Rated current IN3 x 5.5 A 3 x 10 A 3 x 12 A 3 x 16 A

Imax 180% / 5 sec., 150% / 30 sec.

Clock pulse frequency 4 kHz (adjustable up to 16 kHz with derating)

Brake resistor

(accessories),

cf. chap. 7.2

100 Ω: Max. of 6.4 kW 47 Ω: Max. of 13.6 kW

Perm. motor cable

length, shielded

50 m

Output derating is required for distances of 50 m to 100 m (see chapter 7.2.3).

Power loss

at Ia = IN110 W 170 W 180 W 200 W

Power loss

at Ia = 0A2Max. of 30 W2

Conductor cross

section Max. of 4 mm2

Dimensions (H x B x T)

[mm] 300 x 70 x 242 (260)3

without

packaging 3.7

Weight

[kg] with

packaging 4.8

Upper voltage limit 830 V

Brake chopper on level 780 V / 800 V

Brake chopper disable

voltage 740 V / 760 V

1Line circuit breaker, tripping characteristic C, EN 60 898

Use class RK1 fuses for UL adherence: Class RK1 (e.g., Bussmann KTS-R-xxA / 600 V)

2Depends on the option boards and sensors connected (e.g., encoder)

3Depth including braking resistor RB 5000

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

2. Technical Data

7

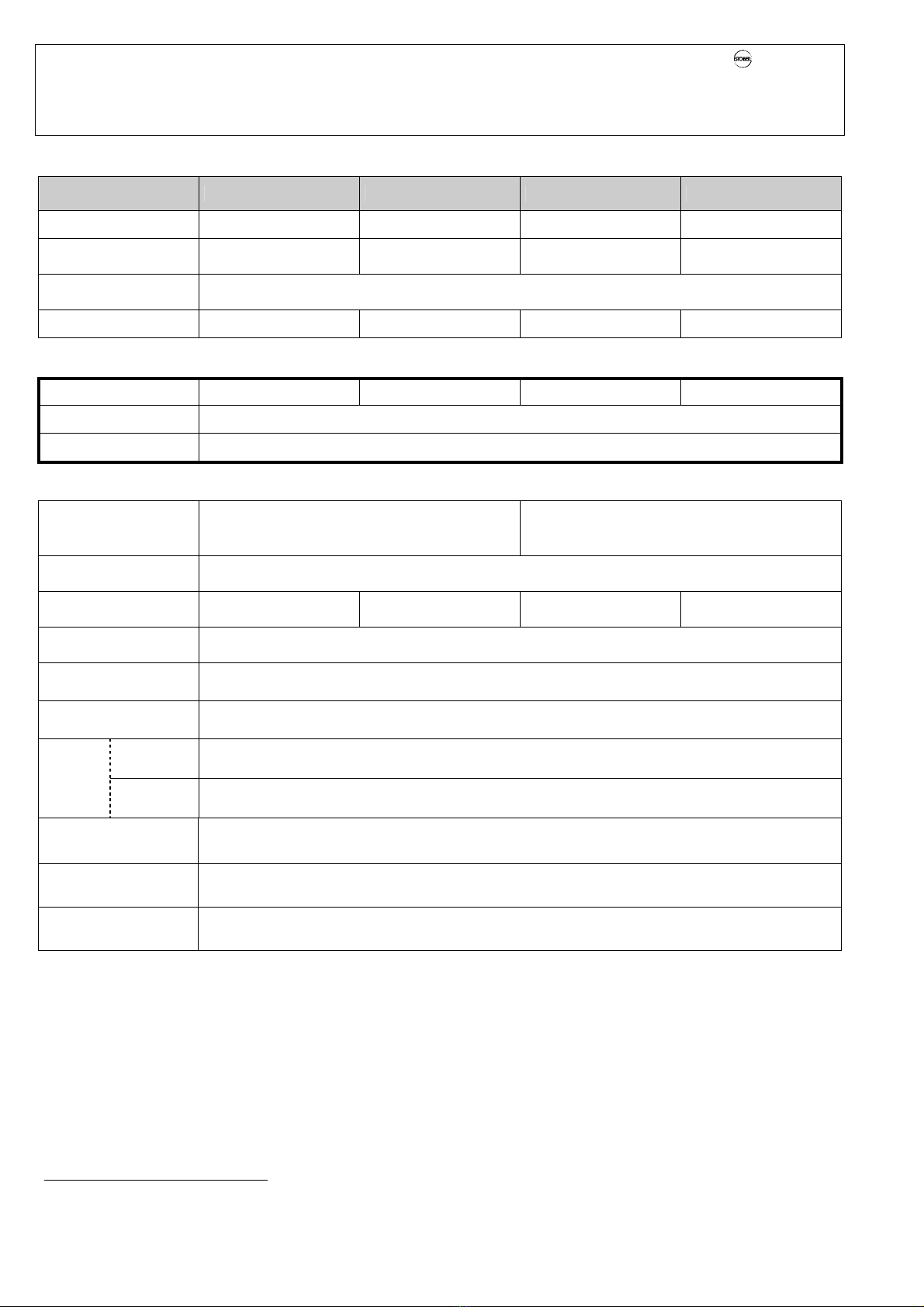

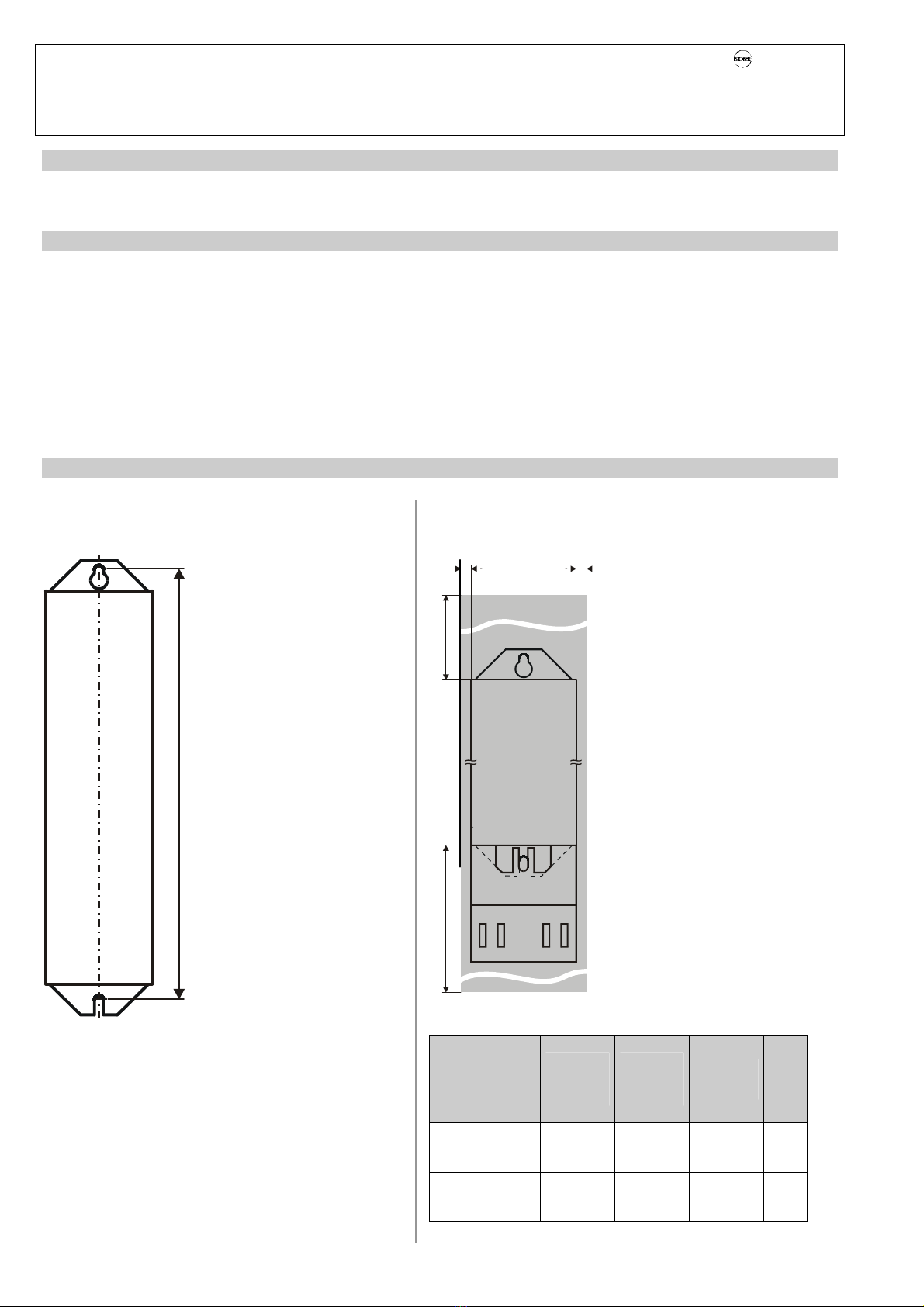

2.2 Mechanical

Dimensions in mm BG 0 BG 1

Height h 300

Height

(incl. EMC shield plate) hb 360

Width w 70

d1 157 242

EMC shield plate

Base plate

mounting holes

Weight [kg]

Depth d2* 175 260

Height e 37.5

EMC shield plate Depth f 40

Distance a 283

Mounting holes Vertical position

on the base plate b 6

Without packaging 2.1 3.7

Weight [kg] With packaging 2.9 4.8

* d2 = Depth incl. brake resistor RB 5000

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

3. Mechanical Installation

8

3MECHANICAL INSTALLATION

This chapter gives you complete information on the subject of mechanical installation.

Only specialized personnel who are qualified for this task may install, commission and operate the device.

3.1 Installation Location

•Operate only in closed switching cabinet (adhere to protection rating IP 20).

•Install inverter only in vertical position.

•Avoid installation above heat-generating devices.

•Ensure sufficient air circulation in the switching cabinet

(Adhere to minimum free spaces as per table in chap. 3.2.).

•Installation site free of dust, corrosive fumes and all liquids

(in accordance with soiling degree 2 in accordance with EN 60204 / EN 50178)

•Avoid atmospheric humidity.

•Avoid condensation (e.g., due to anti-condensation heating elements).

•To meet EMC requirements, use mounting plates with conductive surface (e.g., unpainted).

3.2 Mounting/Mounting Dimensions

3.2.1 Without Bottom

Drilling jig Free space

283

A

B

C

C

Min. Free

Space

[Dimensions

in mm]

A

Up

B

Down

C

To Right

/ Left

Screws

Without EMC

shielding plate 100 100 5 M5

With EMC

shielding plate 100 120 5 M5

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

3. Mechanical Installation

9

D

A

C

B

B

3.2.2 With Bottom Brake Resistor

The "brake resistor RB 5000" substructure is the ideal solution when space is

limited. It is placed between mounting surface and MDS 5000. This increases

the mounting depth by approx. 20 mm.

Mounting

•Secure the bottom brake resistor (A) on the mounting surface

with the included threaded bolts and spring rings (same drilling

diagram as MDS 5000) (B).

•Hook the MDS 5000 in on the four guides (C).

•Secure the MDS 5000 to the threaded bolts with the two

included screws (D).

3.3 Installation of Accessories

Only specialized personnel who are qualified for this task may install accessories (cf. chap. 7). Suitable measures must be

provided against damage by electrostatic discharging (in accordance with DIN EN 50082-2). Before installation, the device must

be disconnected from the power and, with the device version FDS 5xxx/L, the 24 V power must be turned off.

CAUTION

Immediately after the power is turned off, the DC link is still charged. Wait > 5 min. for the DC link to discharge

after turning off the power voltage. To prevent damage to device and accessory parts, install the accessory

afterwards.

CAUTION

Danger of electrostatic charges damaging the PCB!

Perform potential equalization before you touch a PCB (option module 1).

3.3.1 Option module 1 (fieldbus, terminals)

3.3.1.1 CANopen DS-301 (CAN5000) / PROFIBUS DP-V1 (DP5000)

Installation is the same for both modules.

•Make sure that the device is without power. Wait ≥5 min. for the DC link capacitors to discharge after turning off the power

supply voltage.

•Disconnect the cover plate by removing the two screws (E).

•Remove the prepunched area (A) for the sub D plug connector on the plate.

•Mount the plate on the board with the included UNC bolts (B).

•Slide the fieldbus board (C) with the gold-contacted terminal surfaces (D) into the black terminal block.

CAUTION

Be sure not to touch the gold contact surface with your fingers (danger of fouling and corrosion).

•Check correct position of the board.

•Secure the board with the two included screws (E).

•Then apply included labels (nameplate and adhesive label for switch setting (CAN)) to the cover plate.

A

D

BCAN5000

DP5000

C

E

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

3. Mechanical Installation

10

3.3.1.2 EtherCAT (ECS5000)

•Make sure that the device is without power. Wait ≥5 min. for the DC link capacitors to discharge after turning off the power

supply voltage.

•Disconnect the cover plate by removing the two screws (C).

•Slide the EtherCAT board (A) with the gold-contacted terminal surfaces (B) into the black terminal block.

CAUTION

Be sure not to touch the gold contact surface with your fingers (danger of fouling and corrosion).

•Check correct position of the board.

•Secure the board with the two included screws (C).

•Then apply included labels (nameplate) to the cover plate.

3.3.1.3 I/O terminal module (LEA5000)

•Make sure that the device is without power. Wait ≥5 min. for the DC link capacitors to discharge after turning off the power

supply voltage.

•Disconnect the cover plate by removing the two screws (C).

•Slide the board (A) with the gold-contacted terminal surfaces (B) into the black terminal block.

CAUTION

Be sure not to touch the gold contact surface with your fingers (danger of fouling and corrosion).

•Check correct position of the board.

•Secure the board with the two included screws (C).

•Then apply included labels (nameplate) to the cover plate.

LE

A

5000

A

C

B

ECS5000

C

A

B

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

11

4ELECTRICAL INSTALLATION

This chapter gives you complete information on the subject of electrical installation.

Only specialized personnel who are qualified for this task may install, commission and control the device.

4.1 EMC

This chapter contains general information on EMC-suitable installation. These are only recommendations. Depending on the

application, the ambient conditions and the legal requirements, measures in addition to the following recommendations may be

required.

•Mount device or Bottom Brake Resistor on conductive surface (unpainted).

•Install the power cables in spatially separately from the signal lines (encoder, analog/digital signal lines).

•Use only shielded cable for motor lines (corresponding cabels can be ordered from STÖBER ANTRIEBSTECHNIK.).

•Apply shield of the motor cable over a large surface in the immediate vicinity of the FDS 5000. The EMC shield plate

(EM 5000) for mounting on the bottom of the device is available as an accessory (see chap. 3.2.3 and chap. 7.1).

•With asynchronous machines, apply the shield to the terminal block over a large surface (e.g. PG shield screw connection).

•Use output deraters for motor lines > 50 m.

•When an additional transfer plug connector is to be installed in the motor cable, the cable shield may not be interrupted.

•When the brake line is installed in the motor cable, the brake line must be shielded separately.

•When the length of the cable for connection of a brake resistor is longer than 30 cm, this must be shielded and the shield

must be applied over a large surface in the immediate vicinity of the FDS 5000.

•Connect the shield of the control lines on one side with reference ground of the reference value source (e.g., PLC or CNC).

•Shield, and, if necessary, twist reference value lines before installing.

4.2 RCD (Residual Current Protective Devices)

Network phases and neutral conductors are connected with the protective conductor via Y capacitors. When network voltage is

applied, a leakage current flows over these capacitors to the protective conductor. The greatest leakage current occurs during a

malfunction (asymmetric feedin via only one phase) and during power-on (sudden change in voltage). The maximum leakage

current due to asymmetric power feedin is 40 mA (network voltage of 400 V) for FDS inverters.

If RCD circuit breakers are necessary, the problem of power-on and off can be alleviated by using selective RCD circuit

breakers (switch-off delay) or RCD circuit breakers with increased tripping current (e.g., 300 or 500 mA). Only all-current

sensitive RCD circuit breakers may be used. Operation of several devices on one RCD circuit breaker is not recommended.

4.3 Power Connection

Protection via line circuit breakers in accordance with the values listed in chap. 2 (tripping characteristic C, in accordance with

EN 60 898) or suitable, delayed safety fuse.

Use class RK1 fuses for UL conformance: Class RK1 (e.g., Bussmann KTS-R-xxA / 600 V)

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

12

4.4 DC Link Coupling

If you are using axes in a plant which operate in a network of generators and motors, the DC link coupling (DC coupling) can be

advantageous. When the DC-coupling is used, the excess energy of other axes is made available as drive power instead of

converting this excess power into heat with a brake resistor. Remember that you will need a brake resistor which can absorb the

power peaks when all drives in the DC-link network brake at the same time.

DANGER

Danger of damage to devices! When single-phase and three-phase devices are coupled,

the single-phase devices will be destroyed. Use only three-phase devices for the DC link

coupling!

CAUTION

Danger of damage to devices! When one device within the DC-link coupling network fails,

the complete DC-link coupling network must be disconnected from the power network since

other devices in the DC-link coupling network may be damaged. Be sure to adhere to the

wiring of the ready-for-operation relay shown in chapter 4.5.1 (X1.1 and X1.2). When a

failure occurs, replace all devices of one group.

NOTE

Please note that the parameter A38 DC power-input must be set before the DC link

coupling will function correctly.

Group 1: A38 = 0: inactive

Group 2 and 3: A38 = 1: active

For more details, also see the description of the parameter.

4.4.1 Basic Circuit Diagram

The following diagram shows the basic circuiting of the DC-link coupling. The inverters can be coupled together in up to three

groups. The table in chapter 4.5.2 shows the possible combinations. The combination determines the types of power fuse and

DC-link fuse.

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

MDS/FDS

5000

X10 X10 X10 X10X10 X10 X10

X1 X1 X1 X1X1 X1 X1

X22

1

X22

1

X22 X22X22

1

X22 X22

U+

RB RB U+ U+ U+U+ U+ U+U- U- U- U-U- U- U-

11111112222222

L1

L2

L3

PE

BTB

2

Figure 4-1 Basic circuit diagram for the DC link coupling

1For MDS 5000 devices of size BG3: X20, terminals DC-link +, DC-link -

2Dimension the brake resistor to fit the braking power of the DC-link network and the technical data of the device.

G

r

oup 1

G

r

oup 2

Powe

r

fuse

G

r

oup 3

DC-link fuse DC-link fuse

Floating signal

contact - must be

integrated in the

safety circuit of the

controller.

Braking

resistor

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

13

4.4.2 Combinations

The following table shows the possible combinations for the DC-link coupling. A total of 15 combinations are available.

Example: Combination no. 7

This combination lets you combine one size-1 inverter in group 1 with two size-0 devices in group 2. There is no group 3. The

power fuse must have a nominal current of 20 A. The groups are separated from each other with the type-1 DC-link fuse (see

chapter 4.4.3). Wait three minutes before turning on the devices of the DC-link coupling again.

Group 1 DC-Link

Fuse Group 2 DC-Link

Fuse Group 3 Switchon Wait

Time [min]

Type MDS/FDS 5000 MDS 5000 MDS/FDS 5000 MDS/FDS

Size BG0 BG1 BG2 BG3 BG0 BG1 BG0

Power fuse110 A 20 A 50 A 80 A – – –

Max. P-IN 4 kW 10 kW 20 kW 45 kW – – –

Combinationno.

1 max. 4 – – 1

2 max. 4 – – 5

3 3 Type 1 2 – 5

4 3 Type 1 1 – 3

5 2 Type 1 2 – 3

6 2 Type 1 1 – 4

7 1 Type 1 2 – 3

8 max.3 – – 2

9 3 Type 2 1 Typ 1 2 2

10 3 Type 1 2 – 2

11 3 Type 2 1 – 2

12 2 Type 2 1 – 2

13 2 Type 2 1 Typ 1 1 2

14 1 Type 1 1 – 2

15 max. 3 – 1

Instead of delaying the process by the switchon wait time, you can determine the switchon point in time by evaluating parameter

E14. The parameter must indicate in all-network connected devices that the charging relays are open before the voltage can be

switched through again. You can query the parameter via fieldbus or binary output.

4.4.3 Fuses

CAUTION

Danger of machine standstill! When one fuse element fails, the second fuse element is

damaged. Always replace the elements of a fuse in pairs.

Use the following fuses to protect the DC-link coupling:

Type 1 Type 2

Manufacturer SIBA Sicherungs-Bau GmbH

Borker Straße 22

D-44534 Lünen

www.siba.de

Size 10 x 38

Rated voltage AC 500 V

Rated current 10 A 20 A

Power loss per element 1.6 W 3,5 W

Art. no. of fuse 60 034 34.10 60 034 34.20

Art. no. of fuse holder 51 063 04.3

1For use conforming to UL, see specifications in the technical data.

Keep the following points in mind during installation

and operation:

•Use shielding for DC-link coupling connections

longer than 20 cm. This will prevent EMC problems.

•Use the two outer elements of the fuse holder.

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

14

4.5 Safety function „safe torque off“

NOTE

The certified version of the safety function is not available with the FDS 5000.

NOTE

The ASP 5001 may only be installed and repaired by STÖBER ANTRIEBSTECHNIK.

NOTE

When certified use is required, the inverter must be installed in a switching cabinet with a

protection rating of IP54.

4.5.1 Description

On the MDS 5000 inverter the safety function "safe torque off" can be implemented with option ASP 5001. When the safety

function is used the inverter must be able to be switched off in two different ways. The first way to switch off the inverter uses

the enable function. Diagnosis is performed via a binary output or a fieldbus system.

The second way to switch off the inverter uses the ASP 5001 option in addition. When the ASP 5001 option is activated, control

of the end stage is switched off with the positively-driven switch elements of a safety relay. The reference value input is

disabled, and the signal contact is switched to an external safety circuit (break contact). The motor cannot start up even when

there are defects in the end stage or the control circuit since the necessary phase sequence is no longer generated.

Advantages of the ASP 5001 option:

•No switching of the network voltage necessary and the DC link remains charged. This permits a faster restart.

•Less contact wear since only low voltage is switched.

•Less additional wiring work.

4.5.2 Use

WARNING

The starting lockout option only switches off the end stage. Dangerous voltages may still be

present on the motor terminals!

This means that the starting lockout option does not provide galvanic isolation from the

power network. The function does not provide protection against "electrical shock."

During maintenance or repair work an appropriate voltage-free circuit and system protection

are required.

The regulations for emergency off situations must be adhered to.

WARNING

Since the safety function ensures that the motor torque is switched off, axes that are moving

vertically must be protected against crashing down.

WARNING

Since the motor may run down in an undefined state when the starting lockout is activated

during operation, it is essential to adhere to the switchoff sequences which will be described

in the following section (1st and 2nd ways to switch off).

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

15

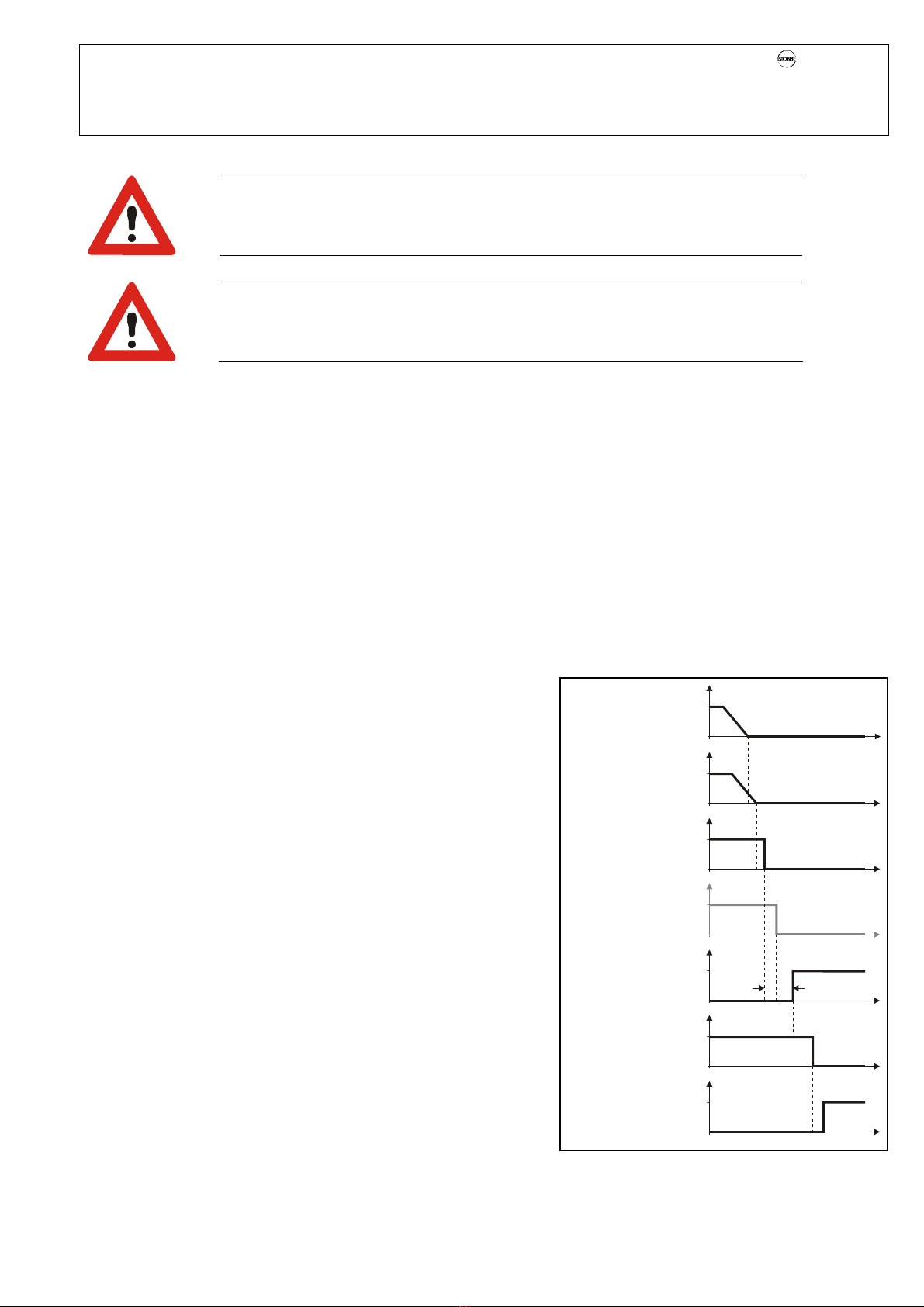

Figure 4-2 Timing diagram

1st way to switch off: Enable

WARNING

1.Switchoff distance may not take effect. If you deviate from a standard configuration, you

must ensure that the 1st switchoff distance (i.e., the enable) always takes effect.

WARNING

1. Switchoff distance did not take effect. Set A55 = 0:inactive since the 1st switchoff distance

can be made ineffective by the operator panel if you allow local mode (A55 = 1:active).

The power end stage is activated on the inverter by applying a 24 V signal to terminals X1.3 and X1.4.

The following sequence must be adhered to when turning off the inverter.

1. The output power must be shut down (reference value = 0 Rpm).

2. When the motor speed is 0 Rpm the enable must be switched off.

When the application contains an integrated brake control, a motor speed at which the brake is to be applied can be specified in

the parameter F02 brake set.

Enable switchoff must be reported back to the safety circuit of the controller. A binary output (BA1 or BA2) must used for the

response message. The parameter A900 sysEnableOut supplies the response message signal. Its coordinate A900 is entered

in parameter F61 (for output to BA1) or F62 (for output to BA2).

If the response message is sent via a fieldbus system, proceed as shown below:

1. Activate the Watchdog functionality of the bus system. See the fieldbus documentation:

CAN-Bus: Pupl.-no. 441686

PROFIBUS: Publ.-no. 441687

EtherCAT: Publ.-no. 441896

2. Read the parameter E200 Device Status Byte via fieldbus. The response message signal is supplied with bit 0 enabled.

2nd way to switch off: Use the ASP 5001 option

The second way to switch off is implemented with the ASP 5001 option.

When the ASP 5001 option is installed the safety relay must be addressed

with a 24 V signal (terminals X12.3 and X12.4) to deactivate the starting

lockout and permit the inverter to begin operation. In this case the

response message contact is opened (terminals X12.1 and X12.2).

When the safety relay is not addressed the starting lockout remains

active. The inverter reports the device state "switchon disable" (see chap.

3 of the application manual for device states). The response message

contact is closed.

The status of the ASP 5001 option can be monitored via the parameter

E67 starting lockout.

The following sequence must be adhered to (see Figure 4-2) for the 2nd

way of switching off.

nSet the reference value to 0 Upm.

ÖThe drive stops.

YWhen the speed is 0 Upm, turn the enable off.

ÖIf the application contains an activation of the halting brake, it is

disabled.

ÖThe inverter replies with a high signal indicating that the enable is

turned off (e.g., via BA1).

pAfter the inverter has responded that the enable has been turned off,

activate the starting lockout by turning off the 24 V signal on terminals

X12.3 and X12.4.

n

Ist

n

Soll

1

1

1

1

1

0

0

0

0

0

0

0t

t

t

t

t

t

t

[rpm]

[rpm]

Ref. value

Enable

A

ctivation

halting brake

(only if

integrated in

application)

ASP 5001

Response

message

(X12.

1, X12.2)

Enable response

message

(e.g. via BA1)

Speed

Activation relay

of ASP 5001

(X12.3, X12.4)

time

monitoring

X

Y

p

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

16

Remember that you must monitor the time between the enable switchoff and the high signal of the enable response message.

The maximum time for this step is:

tmax = 1s + regular time between enable switchoff and the high signal of the enable response message.

When this time is exceeded without receiving a response message from the inverter, you must always activate starting lockout!

The external safety circuit must monitor the addressing of the enable and the relay coil as well as the resulting signals of the

enable response message and the response message contact of the ASP 5001. When the ASP 5001 option is used with a host

controller it must be ensured that the output of the controller is monitored for erroneous behavior.

WARNING

When signal and ground lines are looped through during wiring there is a danger of additional

lines being interrupted if a wire break occurs.

This is why looping through is not permitted. Wire each line separately.

Figure 4-2 shows the wiring of the safety function "safe torque off." In our example the enable response message uses binary

output BA1.

3

4

16

19

GND

GND

E2

4

3

18

A1

A2

A4

2

10

17

A3

GND

E1 1

9

X1

X12

X101

Figure 4-3 Wiring of the safety function

Table 1 lists the states of the input and output signals during normal operation together with the related device states. When the

states of the signals on E1 and E2 are different from those indicated in the table, a malfunction has occurred. In such cases the

system must be put into a defined state.

A1 A2 E1 E2 Device State

0 0 1 1 Switchon disable

1 0 1 1 Switchon disable

0 1 0 1 Ready for switchon

1 1 0 0 Enabled

Table 1

InverterPLC

Safety circuit

Enable

ASP 5001

Options:

SEA 5000

REA 5000

or

XEA 5001

GND

Input

BA1

(A900 is

entered in F61)

24 V-In

A1: Address enable

A2: Address ASP 5001

E1: Response message ASP 5001

E2: Response message enable (A900)

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

17

Switching on the inverter with the option "ASP 5001 starting lockout"

Proceed as follows (Figure 4-4):

nDeactivate the starting lockout by turning on the 24 V signal on

terminals X12.3 and X12.4.

ÖThe response message of the ASP 5001 contains a low signal.

YTurn on the enable.

ÖThe inverter replies with a low signal indicating that the enable is

turned on (e.g., via BA1).

ÖIf the application contains an activation of the halting brake, it is

enabled.

pWhen the brake has released, set the reference value to the reference

speed.

ÖThe drive accelerates to reference speed.

4.5.3 Function Test

You must perform a function test for:

•First commissioning

•Re-commissioning with a change in circuiting of a plant and use of option ASP 5001

•At least once a month during maintenance

The integration in the external safety circuit must also be checked. Proceed as described below.

Test of the safety function

1. Shut down all drives. Secure the hanging loads against crashing.

2. Address the ASP 5001 option by applying a 24 V signal to terminals X12.3 and

X12.4.

3. Turn off the enable.

ÖThe enable response message must then be active as a result.

4. Disconnect plug X12 from an inverter.

ÖThis should trigger the safety circuit.

5. Connect plug X12 again. Check the safety circuit.

6. Repeat steps 2 to 5 for each inverter.

7. Document the function test in your documentation.

4.5.4 Remaining Dangers

After a short circuit of two power transistors a remaining motion of up to 180°/pole pair can occur on the motor!

(Example: 4-pole motor Öremaining motion is a maximum of 180°/2 = 90°)

Include this remaining motion is your risk analysis (e.g., with the safety function "safe standstill" for main spindle drives).

Figure 4-4 Timing diagram

1

0t

1

0t

1

0t

1

0t

n

Ist

0t

n

Soll

0t

1

0t

[rpm]

[rpm]

Ref. value

Enable

A

ctivation

halting brake

(only if

integrated in

application)

ASP5001

Response

message

(X12.1, X12.2)

Enable

response

message

(e.g. via BA1)

Speed

Activation relay

of ASP 5001

(X12.3, X12.4)

X

Y

p

POSIDRIVE®FDS 5000 – Mounting Instructions

STÖBER

ANTRIEBSTECHNIK

4. Electrical Installation

18

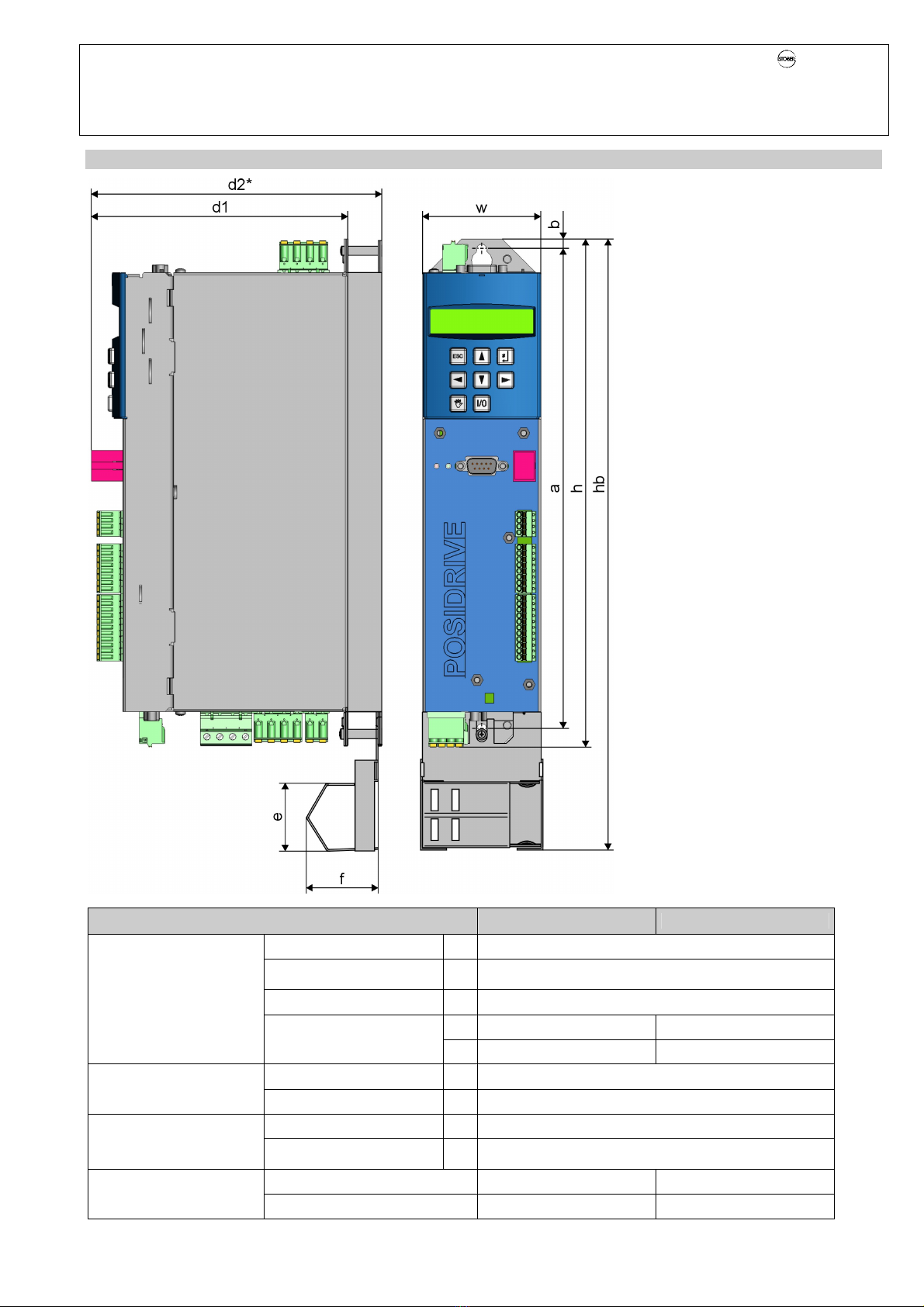

4.6 Motor Cable Fabrication

Ready-to-use motor cables can be ordered from STÖBER ANTRIEBSTECHNIK.

The following modifications must be made for connection to the different model sizes.

BG 0 BG 1

20

160

20

240

All dimensions are recommended lengths which may vary depending on the installation site. [Dimensions in mm]

4.7 Installation after storage period

WARNING

Capacitors are installed in the inverter. After storage times of one year and longer, the capacitors must be

formed. If no forming is performed, substantial property damage may occur when the inverter is turned on.

Following a longer storage period, the capacitors of the inverter must be reformed. For the requirements, see the diagram

below.

10,50

0

25

50

75

100

2468

Core end

sleeves

Shield

Motor cable 4 x motor

2 x temperature

sensor

2 x brake

110 (+3 for PE)

Core end

sleeves

Shield

Motor cable 4 x motor

2 x temperature senso

r

2 x brake

160 (+3 for PE)

Storage time, 1 – 2 years: Before release, apply to voltage for one hour.

Storage time, 2 – 3 years: Before release, form as per curve.

Storage time, ≥3 years: Before release, form as per curve.

Storage time less than 1 year: No measures required

Time [h]

Connection

voltage

[%]

Other manuals for POSIDRIVE FDS 5000 series

3

This manual suits for next models

8

Table of contents

Other Stober DC Drive manuals

Stober

Stober RD11 User manual

Stober

Stober PS6 Series User manual

Stober

Stober POSIDRIVE MDS 5000 User manual

Stober

Stober FDS 4000 Installation and operation manual

Stober

Stober ASP 5001 User manual

Stober

Stober CANopen SD6 User manual

Stober

Stober Stober CombiDrive CM150/3 Installation and operation manual