STOCK-ade ST-315i Instruction Manual

IMPULSE ST-315i FENCING STAPLER

OPERATOR’S SAFETY & OPERATING

INSTRUCTION MANUAL

DANGER

READ AND OBEY ALL SAFETY AND OPERATING

INSTRUCTIONS BEFORE OPERATING TOOL.

GAS POWERED, LOW VELOCITY

PISTON TYPE FASTENING TOOL

®

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

An Overview of the Impulse ST-315i Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Battery and Charging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Fuel Cel

l....................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Preparing and Use of the Impulse ST-315i To o l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..11

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Maintenance and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

ST-315i TOOL OPERATING MANUAL

This manual is intended to acquaint you with the STOCK-ade ST-315i tool. Unlike other power fastening tools,

the

ST-315i

tool

is

powered by a

linear internal combustion motor. In simpler terms, your ST-315i tool is

powered by a motor similar to the one that powers an automobile. The tool ignites a fuel and air mixture to

As you will see, the ST-315i tool

It carries its own fuel supply and battery, along with a supply of fasteners.

For ease of use, this manual is divided into sections (see Table of Contents). Each section of the manual is

written with you, the tool operator, in mind. We have left out all of the technical terms so that you can readily

understand how to get the maximum performance from your ST-315i

tool, and how to avoid

damaging the

But, to accomplish this, we need you to do two things:

1. READ THE MANUAL FROM COVER TO COVER BEFORE USING THE TOOL.

2. FOLLOW ALL INSTRUCTIONS IN THE MANUAL.

The ST315i

tool should be handled like other power fastening tools that you use.

When used properly, it will

meet your fastening needs. And, like most of your tools, when used improperly it can cause injury. If you

are going to allow others to use the ST-315i

tool, it is your responsibility to make sure that they also read

and comply with the instructions in this manual before attempting to operate the tool.

Should you have questions about the ST-315i system, or wish to obtain additional copies of this manual,

please feel free to contact your

Distributor Sales Representative.

TABLE OF CONTENTS / INTRODUCTION

2

produce the energy to drive the motor, which in turn drives the fastener.

is totally self-contained.

tool or injuring yourself.

STOCK-ade

®

®

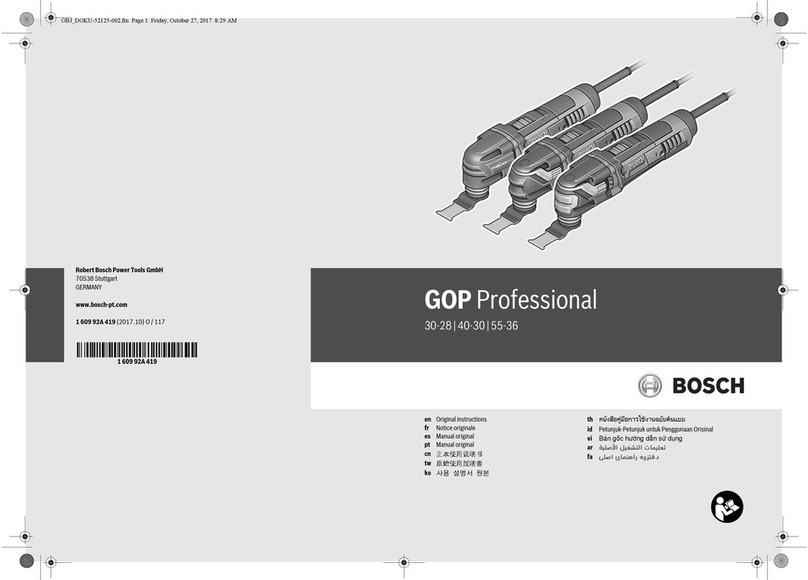

DESCRIPTION

The ST-315i

tool is a self-contained, full

y portable

tool that uses liquid hydrocarbon fuel to power a

a unique linear drive internal combustion motor.

In order for you to fully understand the information

contained in this manual, you need a basic under-

standing of the tool

.

As you can see in the illustration

below, the ST-315i

tool is made up of three assem-

blies: the Handle, the Motor, and the Magazine.

As you examine the ST-315i tool, become familiar

with the three major assemblies and the various

components located in each of them.

The Handle Assembly contains the Fuel Cell, the

Battery Voltage Indicator Light, Battery and the

Trigger.

The Motor Assembly contains the Cover and Filter,

the Motor Housing, and the nose assembly.

The Magazine Assembly contains the Magazine,

follower assembly, and bracket.

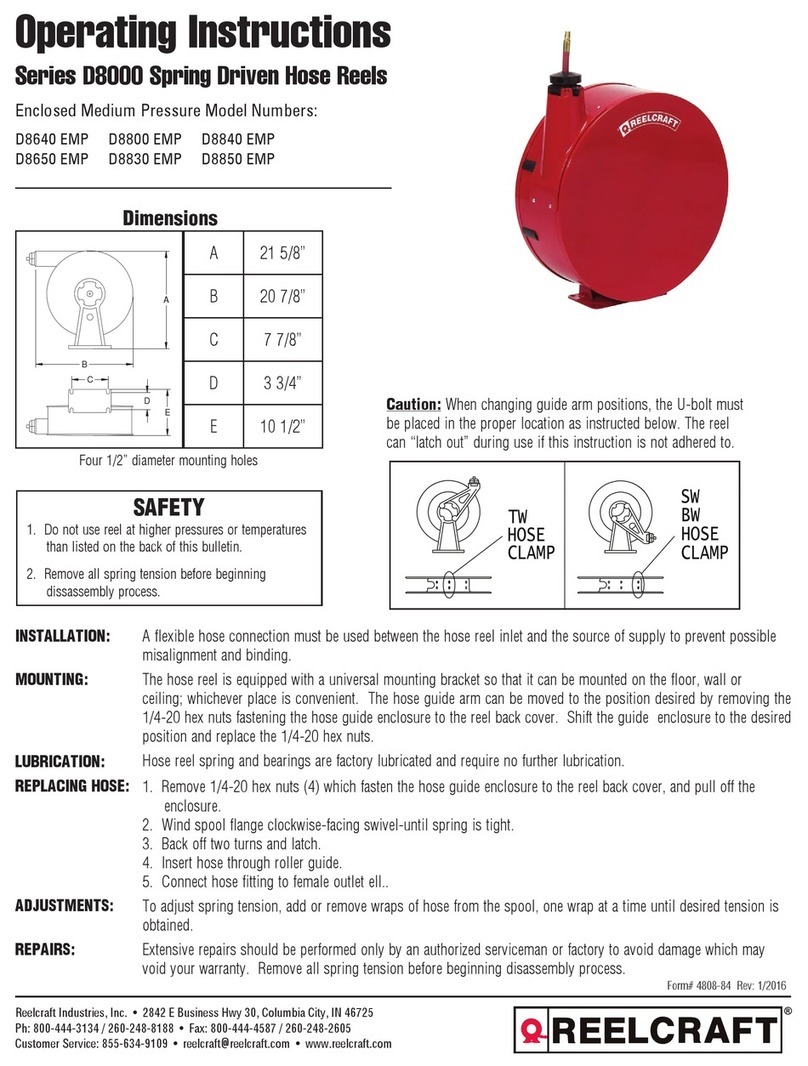

SPECIFICATIONS

Dimension:

Height 15 inches

/ 381mm

Length 15 inches / 381mm

Weight: 7.9 pounds / 3.6 kg

Cycle Rate:

Intermittent Operation 2 to 3 staples per

second.

Continuous Operation 1000 staples per hour.

NOTE:

Exceeding these rates could cause the tool

to overheat, resulting in loss of performance or dam-

age to tool components.

By using the ST-315i tool at its recommended oper-

ation rate you will be able to drive several thousand

fasteners in a typical workday.

Maximum Fastener Length:

40mm

Magazine Capacity:

52 staples. (Two Strips)

Battery: 6 volts D

.

C

.

—Provides enough energy to

drive approximately 3000 fasteners on one charge

. .

Fuel Cell:

Liquid hydrocarbon—Provides enough

fuel to drive up to 1000 fasteners.

.

AN OVERVIEW OF THE ST-315i TOOL

3

AN OVERVIEW OF THE ST-315i TOOL

SAFETY INSTRUCTIONS

4

The following safety instructions have been included

in this manual to provide you with basic information

necessary for safe operation of the ST-315i tool.

DANGER

Do not attempt to operate this

tool until you have read and

understood all safety precautions

and manual instructions.

Failure to follow all safety precautions and instructions

may result in a permanent loss of vision, serious

personal or even fatal injury, property damage

and/or tool damage.

The ST-315i Tool is an internal

combustion device. It produces

hot exhaust gases that may

ignite mmable

materials.

This tool must not be used in a combustible

environment or in the presence of combustible

materials, such as mmable chemicals,

adhesives, gasoline, or solvents.

Do not expose the tool to

temperatures in excess of

120°F (49°C). Fuel and/or the

battery may burst, releasing

mmable gas.

This tool must be operated only

in a well-ventilated environment,

because the tool exhausts carbon

monoxide similar to a gas chain

saw or lawnmower

.

Exposure to

carbon monoxide may cause dizziness, nausea,

or unconsciousness.

ALWAYS keep the ST-315i

Tool, fuel cell, battery and

battery charger out of the

reach of children.

1. READ THIS MANUAL FROM COVER TO COVER.

Always turn to this manual for information about

the safe operation and servicing of the

ST-315i

tool.

If any portion seems unclear, or you have

any questions, contact your Distributor Represnt-

ative immediately.

2. WEAR EYE AND HEARING PROTECTION.

Always wear hearing and eye

protection devices when you are

operating the ST-315i tool or

working in the vicinity of this tool.

Also, your eye protection must

meet the requirement of ANSI

Standard Z87, and should have side shields for

increased protection.

3. NEVER ASSUME THE TOOL IS EMPTY.

Every time you pick up the ST-315i

tool, check the

Magazine for fasteners

.

Never point the tool at

anyone or yourself, even if you are absolutely sure

there are no fasteners in the tool. The fastener you

did not see is the fastener that can injure you or

someone else.

4. NEVER ENGAGE IN “HORSEPLAY” WITH THE

TOOL.

The ST-315i

tool is not a toy

. . .

it is

a power fastening tool. It is designed to drive a

a fastener into wood base material. To accomplish

this task, it generates a tremendous amount of

Fooling around, even when you are absolutely

sure there are no fasteners in the tool, is asking

for an accident.

energy.

SAFETY INSTRUCTIONS

In addition to these instructions, additional training

may be necessary, depending upon the type of

fastening you wish to do

.

Contact your distributor

representative for additional information.

5. NEVER CARRY THE TOOL WITH YOUR

FINGER ON, OR DEPRESSING, THE TRIGGER.

You must remember that the tool operates in a

sequence. The work contacting element acts

as an operating feature that blocks the trigger

from completing the ignition circuit.

Should you unintentionally depress the work con-

tacting element while pulling the trigger as you are

carrying the tool.......it could discharge a fastener.

6. NEVER OPERATE A TOOL THAT IS

MALFUNCTIONING.

If you determine that the tool

is not working properly, and the problem is more

iately and refer to the Servicing Section of this

If the problem cannot be corrected with

one of the steps covered in the Servicing Section,

report the problem to your supervisor or distributor

Do not attempt to make any additional repairs

to the ST-315i tool.

7. OPERATE THE TOOL ONLY ON THE WORK

SURFACE.

The tool should be

operated only

when it is in contact

work surface. Always

hold the tool rmly and perpen-

against the surface to be

8.

DO NOT LOAD FASTENERS WITH THE

TRIGGER OR WORK CONTACT DEPRESSED.

When loading fasteners into the ST-315i tool,

you

must avoid pulling the trigger or while having

the

WORK CONTACT ELEMENT depressed. when

the tool

is placed on a bench or other surface,

the work

contact might be depressed. When you

are loading fasteners, you could accidentally pull

the trigger

by grasping the handle to steady the

tool.

These two actions will cause the tool to

9. FASTENER REMOVAL OR CLEARING JAMS.

With the tool pointed away from you and others,

it locks in the rear position.

Refer to the Servicing Section of this manual.

10. NEVER ATTEMPT TO OPERATE THE

ST-315i TOOL IF PARTS ARE LOOSE,

DAMAGED, OR MISSING. Make sure al

l screws

and nuts are properly tightened and all parts are

properly installed and in good working order. If

parts are missing, don’t attempt to make tempor-

rary repairs...contact

mediately.

11.

NEVER DRIVE FASTENERS ON TOP OF

OTHER

FASTENERS OR TOO CLOSE TO OTHER

FASTENERS.

Fastening on top of or too close to

other fasteners can cause the fastener to ricochet

and cause serious injury. Fasten only in area

s where

the entire shank can penetrate.

12. NEVER FIRE INTO VERY HARD OR

BRITTLE MATERIALS SUCH AS CAST IRON,

TILE, GLASS, OR ROCK. These materials can

shatter, causing sharp fragments and/or the fas-

tener to freely.

SAFETY INSTRUCTIONS

5

SAFETY INSTRUCTIONS

with the

dicular

fastened.

than a simple fastener jam, stop using it immed-

manual.

representative.

pull back on the follower on the magazine until

Remove all staples.

If needed, unlatch cover assembly and remove.

Clear all jammed staples.

your Sales Representative im-

operate, discharging a fastener.

13. NEVER CARRY FASTENERS OR OTHER

HARD OBJECTS IN THE SAME POCKET OR

CONTAINER WITH FUEL CELL. The Fuel Cell

could be punctured, causing serious injury.

14. NEVER ALLOW ANYONE TO USE THE

ST-315i TOOL UNLESS THEY READ AND

UNDERSTAND THE TOOL MANUAL AND ALL

SAFETY INSTRUCTIONS.

It is the tool owner’s

responsibility to make sure that all tool users

read and

fully understand all tool

operation,

safety andmaintenance instructions.

15. FUEL CELL STORAGE.

Fuel Cells contain mmable

gases which are under pressure

and must be stored in an area

where they will not be exposed

to an open , sparks, or

temperatures above 120°

Fahrenheit (49° Centigrade). Exposure to temperatures

above 120°F (49°C) may cause the Fuel Cells to

leak or burst, releasing the mmable gases and

creating a risk of or explosion.

16. FUEL CELL DISPOSAL.

Never attempt to

puncture, crush, burn or r a Fuel Cell. Always

dispose of empty cells with trash that will not be

burned.

Also, never place the Fuel Cell with other

materials for reclamation or recycling.

17. TOOL STORAGE. At the end of every workday,

remove the Battery and store it in the carrying case.

Recharge the Battery only if required as indicated

by a red charge light in the handle.

18. KEEP THE TOOL CLEAN.

At the end of each

workday, take a minute to wipe the tool with a clean

rag.

A dirty tool is more likely to jam or malfunction.

19. NEVER PLACE YOUR

HAND OR FINGERS OVER

THE NOSE OF THE TOOL.

The fastener or piston can

seriously injure your hand

in the event of an accidental

discharge.

SAFETY INSTRUCTIONS

6

SAFETY INSTRUCTIONS

BATTERY AND CHARGER

The rst step in preparing a new tool for operation

is to fully charge the new Battery. New Batteries

are shipped discharged and must be charged for

24 hours before rst use. All subsequent charges

will require at most a 2 hour charge.

WARNING

Important Charging Notes

CHEMICAL/EXPLOSION

HAZARD Read ALL instructions

before charging or using battery.

Failure to follow ALL instructions may result in re,

severe burns, or release of toxic materials.

Battery Disposal: The EPA cer RBRCQ

®

Battery Recycling Seal on the nickel-cadium

(Ni-Cd) battery indicates Stockade is voluntarily

participating in an industry program to collect and

recycle these batteries at the end of their useful

life, when taken out of service in the United States

or Canada. The RBRCQ

®

program provides a

convenient alternative to placing used Ni-Cd

batteries into the trash or the municipal waste

stream, which may be illegal in your area. Please

call 1-800-8-BATTERY™ (1-800-822-8837) for

information on Ni-Cd battery recycling and disposal

in your area. STOCK-ade’s involvement in this program

is part of our commitment to preserving our envi-

ronment and conserving our natural resources.

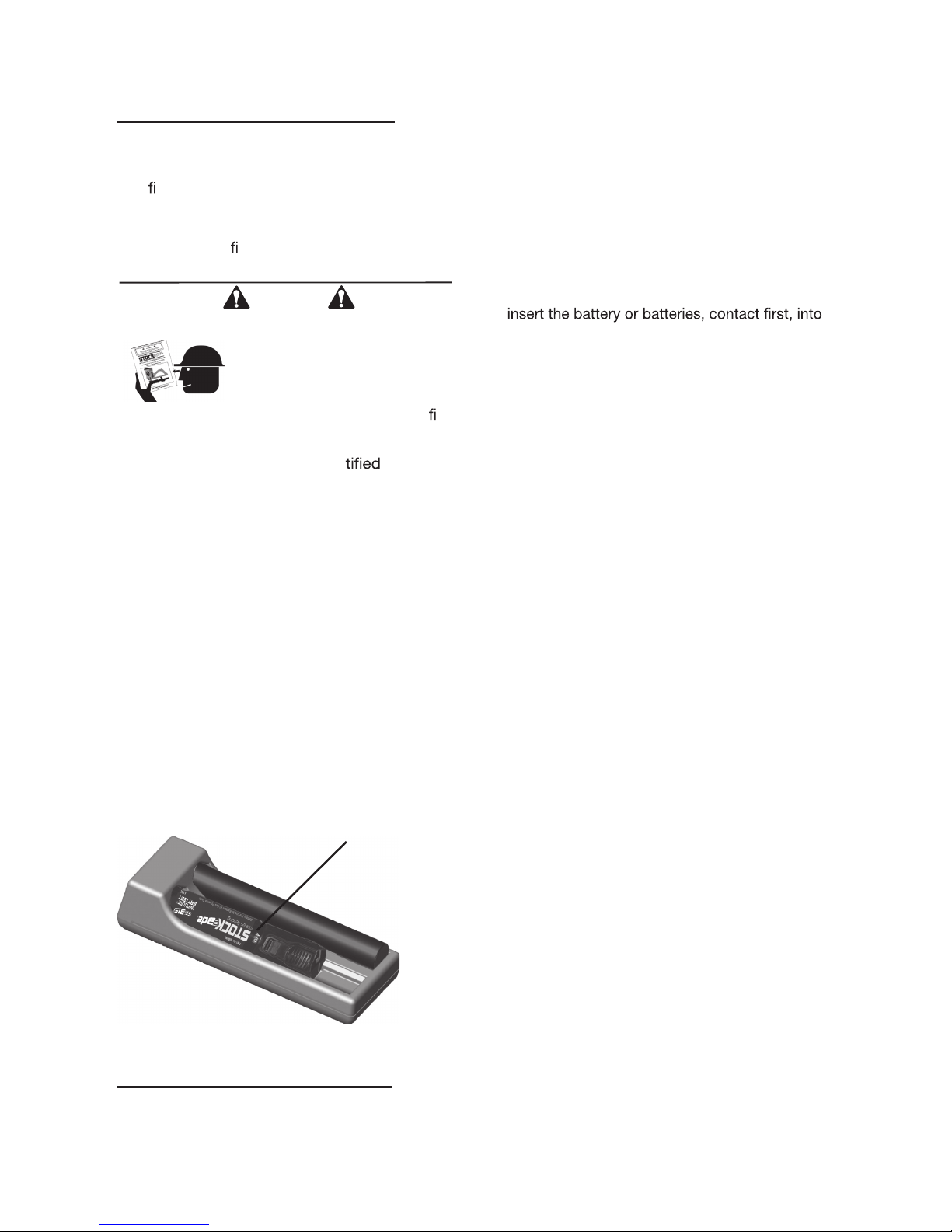

CHARGING INSTRUCTIONS

1. Connect the round plug of the wall mount unit

to the front of the charger base and plug the

wall mount unit into any 120V AC or 240V AC

A LED by

the plug indicates the base unit has power.

outlet depending on your location.

2. Set the charger base on a stable surface and

the opening of the charger base.

3. The

charger incorporates a charge level indicator

to inform the user of the battery charge level.

A red light will illuminate at all times during

a charge cycle.

One green light

= battery at 50% capacity

Two green lights

= battery at 75% capacity

Three green lights

= battery at FULL capacity

The red light will not be lit when the battery

is at full charge.

CHARGING DONT’S

Do not charge battery when

temperature is below 40°F (5°C).

• drop battery or charger.

allow metal objects to come in

contact with battery terminals.

• Do not puncture or attempt to open battery

case or cells.

• Do not store battery where it will be subjected

to temperatures above 120°F (49°C).

• incinerate battery.

Do not

Do not use a defective battery charger, one

that overheats and/or smokes when plugged

in.

THE BATTERY AND CHARGING SYSTEM

7

THE BATTERY AND CHARGING SYSTEM

Battery Charger

Holds two

ST-315i

Batteries

•

Do not

Do not•

•

THE BATTERY AND CHARGING SYSTEM

THE BATTERY AND CHARGING SYSTEM

8

INSTALLING THE BATTERY

•

Insert the battery into the tool as shown

1. The “OFF” position-as shown in

picture #1 to the right.

2. The “RUN” position-as shown in

picture to the right.

•

•

#1

#2

NOTE:

Battery fully inserted into tool

NOTE: OFF position

shown in small window

#3

NOTE: LED Light

OFF

RUN

•

If the light flashes green, the tool is powered.

•

•

on the right with the clip faceing out.

• The battery has two positions in the tool:

•

To operate the tool be sure the battery is

fully inserted into the tool. After installing

the battery, note the LED light on the right

side of the handle.

If the light flashes red, the battery requires

charging.

If the light is solid green and the fan is running,

the tool is ready to take the next shot.

If the light fis solid red, and the fan is not on

the battery need to be recharged.

If the tool will not be used for a short period

of time, click the battery back into the “OFF”

position. This will prevent the tool from being

fired.

•

If the tool will not be used for extended periods

case.

of time, remove the battery and store in the tool

FUEL CELL

9

FUEL

CELL

Fuel Cell

DANGER

EXPLOSION/FIRE HAZARD

Read ALL safety instructions

before using or handling the

fuel cell.

Failure to follow ALL

instructions may result in ex-

plosion or re. This may cause severe personal

injuries or property damage.

Keep the fuel cell away from

heat, sparks and open me.

Exposure to temperatures above

120°F (49°C) may cause the fuel

cell to burst, releasing e

gas

.

WARNING

• Sunlight can raise the inside temperature of

an unventilated truck or van to above 140°F

(60°C).

• Do not puncture or attempt to open the fuel

cell; it is non-refillable.

• Do not

incinerate,

reclaim

or

recycle

the fuel

cell.

• Do not

smoke

while

installing

or

removing

the fuel cell.

.

• Do not

inhale the spray.

• Keep out of the reach of children.

• Store fuel

cell(s)

in

well-ventilated

areas

only.

There is a second container inside the fuel cell. The

inner container holds the fuel.

The space between

the inner container and the outer cylinde

with a gas, called the propellant, which is under pres-

sure.

To eject the fuel, propellant pressure squeezes the

inner fuel container, much as you squeeze a tube

of toothpaste.

This squeezing action ensures that

all the fuel is used, and that the ST-315i tool can

operate in any position.

Because of this container-within-a-container design,

you might hear the sound of when shaking

the fuel cell after all the fuel has been used. This

is the propellant, which remains between the con-

tainers even after all the fuel has been expelled.

If you expose the empty fuel cell to extreme tem-

peratures, the propellant gas will expand and could

cause the container to burst, releasin

gases.

FUEL CELL

FUEL CELL

10

INSERTING FUEL CELL

You complete the loading of Fuel Cell in the ST315i

tool by closing the Actuator Cover.

You do this by

pushing down until the Actuator Cover

snaps into

OUTDOOR WEATHER AND THE

ST 315i TOOL

Use the tool outdoors, in clear weather, When the

Tool, Fuel Cell, and Battery are between 20°F (-7°C)

and 120°F (49°C).

Colder temperatures may damage

the Tool and Battery.

Hotter temperatures may damage

the Tool and Fuel Cell.

Fuel should be stored out of

surroundings less than 120°F (49°C).

After extended

periods of continuous use, cool the

the Fan Motor.

Operation when the Tool is less than 20°F (-7°C) may

damage the tool

.

Fuel Cells at cold temperatures

lose the required propellant force. Bring the Tool,

Battery, and Fuel Cell above minimum operating

temperature without direct exposure to me, and

check the Battery.

CAUTION

The ST315i tool should not be used in the rain or

where excessive moisture is present. These con-

ditions may result in damage to tool components

and cause tool to malfunction.

direct sunlight in

Tool by running

swinging it up and over the Fuel Cell Assembly and

position.

1. Press Up

2. Pull Out

Lift the fuel cartridge adaptor and insert the fuel

cartridge into the tool.

Release the adaptor so it is centered on the fuel

cartridge.

1. Swing Up

2. Push down

INCREASE THE DEPTH OF DRIVE

FASTENERS

The ST315i tool can drive only

STOCK-ade

®

fas-

teners. Any other fastener will cause tool damage

and void your warranty.

LOADING FASTENERS

1. Pull the follower back on the rail of the maga-

zine until it locks in the rear position.

2.

Insert the fence batten staples onto the maga-

zine rail.

3.

Control the release of the follower and gently

allow it to move forward until it contacts the

staples.

4.

You are now ready to start driving staples.

TOOL

OPERATION

Proper technique

assures smooth

operation of the tool.

Three easy steps to

actuated the tool are:

1. ENGAGE THE TOOL

PLACE the ST315i ADJUSTABLE NOSEPIECE

AGAINST WORK SURFACE. Then press down to

close tool.

Fan Motor will tur

n on,

LED will be steady green.

Fuel is injected into the

Combustion Chamber

and mixed with air by

the Fan.

2.

SQUEEZE THE TRIGGER The Spark Plug

sparks and fuel/air mixture ignites. Combustion

powers the Piston Assembly, driving the fastener.

3. RELEASE TRIGGER - LIFT THE TOOL

The Combustion Chamber opens. Fan exhausts

hot gases and cools internal components.

N

OTE: If no additional cycles are made, fan will

run for 7 seconds and then shut off.

TO PREVENT UNINTENTIONAL TOOL OPERATION,

AND POSSIBLE INJURY TO YOURSELF OR

ANYONE IN THE WORKING AREA, BE SURE

TO RELEASE THE TRIGGER AS SOON AS YOU

HAVE FINISHED DRIVING FASTENERS. NEVER

PRESS THE ADJUSTABLE NOSEPIECE AGAINST

ANY OBJECT EXCEPT THE MATERIAL TO BE

FASTENED.

DEPTH OF DRIVE

REMOVE BATTERY AND FUEL FROM THE TOOL

BEFORE MAKING ANY ADJUSTMENTS.

DECREASE THE DEPTH OF DRIVE

PREPARING AND USE OF ST315i TOOL

PREPARING AND USE OF ST315i TOOL

11

prior to commencing work.

tool for depth of staple drive on waste timber

Depress the work contact element and squeeze

the trigger. Note the depth of drive.

ADJUST THE DEPTH OF DRIVE

Loosen the adjustment socket headed cap screw

located near the tip of the work contacting element.

Slide the work contact element away from the body

of the tool to decrease the depth of drive.

the tool to increase the depth of drive.

Slide the work contact element towards the body of

SERVICING

SERVICING

12

Field service should be restricted to

the following:

CHECKING THE ENERGY LEVEL

OF THE BATTERY

RECHARGING THE BATTERY

CHECKING THE FUEL CELL AND

EXPIRATION DATE.

REPLACING THE FUEL CELL

CLEANING THE AIR FILTERS

CLEARING A JAM

Attempts to go beyond these procedures could

result in serious personal injury or damage to the

ST315i tool and voiding of the warranty.

There are certain problems that you may encounter

when you are using the ST315i tool that you will

be able to correct on the work site. The follow-

ing service procedures are the only service

procedures you should attempt.

Anything else

that may appear wrong with the tool should only

be diagnosed and repaired by a fully trained

service technician. If you have any reason to be-

lieve that your problem is beyond the service

procedures in this manual, contact your Sales

Representative immediately.

DANGER

Never attempt any maintenance of the ST315i

BATTERY CHECK

Periodically check on the LED Battery Voltage

Indicator Light—the LED in the Handle of the

ST315i tool. When encountering a problem, the

rst step should always be to make sure the

Battery has enough energy to operate the tool.

If the light is red, recharge the Battery. If the light

is glowing green, indicating that the Battery is

charged, check the ignition system.

FUEL CELL CHECK

Another typical service condition will occur when

the Fuel Cell becomes empty. A typical symptom

will be when the tool’s Fan operates and the LED

is green, but the tool does not drive fasteners

In this case, take the Fuel Cell out

of the tool, check to see if the Fuel Cell still con-

fuel and is within the expiration date.

To determine is there is any fuel left in the Fuel

Cell simply place the Metering Stem against a

solid object, and gently push about three or four

A small amount of fuel should be released

Never perform this test near an open

or sparks, while smoking, or where the Fuel

may get into your eyes. If fuel is not released with

Valve, there is no

it must be re-

Dispose of the empty Fuel Cell properly.

AIR FILTER

Remove the grille from the cap and remove the

The

Air Filter simply lift out.

GENTLY to remove any dust. You should check

days.

tool without rst removing the Fuel Cell, Bat-

tery and Fasteners. Maintenance should only

be started after the tool is completely inoper-

ative.

completely.

times.

each time.

each operation of the Metering

more fuel left in the cylinder and

placed.

and clean the Air Filter every two

tains

SERVICING / MAINTENANCE

13

SERVICING /MAINTENANCE

CLEARING A JAM

A typical problem you may encounter is having a

jammed fastener

.

Because of the unique design

of the ST315i tool, clearing a jammed fastener

is easy

.

Damage to parts and/or excessive ac-

cumulation of dirt are principle causes of jams.

If a jam should occur, proceed as follows:

1. Remove the battery and fuel cell.

2.

Remove all fasteners.

(If needed, unlatch the cover assembly and re-

move.)

4.

Clear all jammed fasteners.

5.

If the tool continues to jam, or you cannot clear

a particularly ult jam, have it serviced by

an Authorized STOCK-ade Distributor..

If you that the tool’s Fan does not operate

after clearing a jam:

Check the condition of your Battery.

If the Handle LED indicator emits a constant red

glow when depressing the tool, recharge the

Battery.

MAINTENANCE

COLD WEATHER OPERATING PRECAUTIONS

Keep the tool in a warm area until you are ready

to use it. If the tool is already cold, bring it into a

warm area, and allow it to warm up before using it.

DO NOT OPERATE THE TOOL WHEN IT IS COLD

UNLESS FASTENERS ARE BEING DRIVEN INTO

A WORKPIECE.

EXTERNAL CLEANING

The external parts may be cleaned as follows:

1. Remove the battery and fuel cell.

2.

Pull the follower back and remove all fasteners.

3.

Remove all dirt and grit from the magazine and

nose of the tool.

4.

Clean the outside of the tool using a soft cloth

and a mild degreasant like n.

CAUTION

Never use highly volatile solvents such as gasoline

to clean the tool. Do not allow any solvent to enter

the interior of the tool. Solvents may cause O-rings

to deteriorate, and possibly swell, causing a tool to

malfunction, and creating a possible safety hazard.

5.

Important: It is extremely important for safety

reasons that all dirt and foreign materials be

removed from around the Work Contacting

.

The Work Contacting Element must be

free to move in and out without sticking or binding.

MALFUNCTIONS

Be alert for tool problems. A malfunctioning tool

must be immediately withdrawn from use and not

used again until it has been repaired by

service technician. Operating a tool which malfunc-

Stop using the tool, and have it re-

SERVICE AND REPAIR

Except as y described in other sections

of this manual, this tool must not be disassembled,

serviced, repaired, or reassembled by anyone except

service personnel. Incorrect servicing, repairs

and assembly of this tool may result in

to the user and/or damage to the tool. Please con-

tact your local sales person, or authorized

Distributor for assistance and repair.

Pull the follower back on the magazine until it

locks in the rear position.

3.

tions is unsafe.

paired.

serious injury

Element

STOCK-ade®

The Magazine and Work Contact Element are all

designed to operate without lubrication.

®

MAINTENANCE

14

MAINTENANCE

END-OF-WORKDAY ROUTINE

At the end of each workday, conduct an end-of-

workday routine. These simple steps are based on

maintaining the safety and operational ncy

of the ST315i tool..

Before you leave the worksite:

1. Remove the Battery and store in the tool case.

Always use the tool case for transporting and

storing the tool.

2. Dispose of all empty Fuel Cells. Remember

to dispose of these cells where they will not

be found by children, crushed, punctured, or

burned.

3. Place the Battery in its Charger only if it needs

charging as indicated by the red charge light

in the handle.

4. Wipe your tool with a clean, soft cloth.

5. Check Adjustable Nosepiece Element to ensure

it is operating freely.

These simple steps will not only ensure that your

ST315i tool is ready to go to work the next day,

but will also ensure that you get the maximum

y from your tool.

ST315i CORDLESS COIL TOOL

ACCESSORIES

A variety of accessories are available for the ST315i

tool:

•Battery (2)

Hex Key for Depth of Drive Adjustment•

Battery Charger

Contact your Distributor Sales

Representative for additional information.

•

Clear Safety Glasses•

Disposable Ear Plugs•

Charger Car Adapter•

STOCK-ade

®

SYMPTOM POSSIBLE PROBLEMS SERVICE

Preparing Tool for Operation—Battery/Charger Problems

Normal Stage of Operation

Pre-Combustion/Combustion Stage of Operation

—Fan does not run

—tool LED is off.

—Fan does not run, or

runs slower than normal

—tool LED is red.

—Battery is not charged.

—Battery Terminals are

oily, dirty, or corroded.

—Battery is discharged.

—

Charge Battery according to Operating Manual

.

—Clean Battery terminals.

—Charge Battery.

TROUBLESHOOTING

TROUBLESHOOTING

15

—Work Contact Element

does not depress fully

—tool does not operate.

—Tool will not cycle-fan

runs, LED is green.

—Head or Sleeve Steel

—Fuel Cell is empty.

—Spark Wire out of spark

plug.

—Spark does not occur.

—

Contact Authorized Distributor Sales

Representative for service.

—Replace Fuel Cell.

—

Contact Authorized Distributor Sales

Representative for service.

—

Contact Authorized Distributor Sales

Representative for service.

—Battery does not appear

to accept charge. Green

charger light does not

come on.

—Flashing lights on

charger base unit.

—Inoperative indicator

lights on charger.

—Battery damaged or

cycle life exhausted.

—Damaged charger.

—Damaged Battery

—

Try Battery in tool after 3 hours on charge cycle

.

If tool LED is green, charger lights are not working

properly.

Replace charger, monitor charging time

to ensure Battery has adequate time for recharging.

It’s normal for Battery to feel warm after properly

charging.

—Replace Battery.

—

Discontinue use immediately and unplug from

power source.

Replace charger and tag or dis-

pose of charger to prevent accidental reuse or

connection to power source.

—Replace Battery

Rings damaged.

—Staple Jammed or, —

Clear Staple Jam.

STOCK-ade

®

STOCK-ade

®

STOCK-ade

®

SYMPTOM POSSIBLE PROBLEMS SERVICE

Power/Exhaust Stage of Operation

Returning/Purging Stage of Operation

If the ST315i tool will not operate after following the above service directions,

return the tool to a Distributor Sales Representative for service.

www.stock-ade.com

— Battery is discharged.

— Fuel Cell is low.

— There may be loss of seal

in combustion chamber.

— No More Fasteners

— Jammed fastener.

— Fuel Cell is low.

— Spark Plug wire is loose.

— Filter element is dirty,

causing tool to overheat.

— Tool Sleeve or Steel Rings

are dirty.

— Tool operates properly,

but fasteners do not

drive fully.

— Tool operates, but no

fastener is driven.

— Tool operates erratically

or appears to be

losing power—tool

LED is green.

— Charge Battery.

—

Check Fuel Cell according to Operating Manual

and replace as required.

—

piece for one minute.

Pull trigger. If fastener

there is a leak that requires service.

— Insert a New Strip of Fasteners

— Clear jam according to Operating Manual.

—

Check Fuel Cell according to Operating Manual

.

— Contact Distributor Sales Represent-

ative for Service.

—

Remove Filter element and clean according to

Operating Manual.

Use safe cleaning solution to

remove stubborn debris.

— Clean tool per Cleaning Procedure.

TROUBLESHOOTING

16

TROUBLESHOOTING

— Tool operated and

drove fastener, but

piston did not return

to start position.

— Tool does not open

after tool cycles.

— Built-up dirt and debris on

Driver Blade or in Nose bore.

— Tip.

— Exhaust ports on the

Sleeve are dirty or clogged.

— Tool (Sleeve) or Steel Rings

are dirty.

— Tool is dirty.

—

Clean Driver Blade and

Nose bore with safety

solvent

.

—

Contact your Distributor Sales

Represent

-

ative for service..

— Return tool to Authorized Distributor

Sales Representative for service.

—

Contact your Sales Representative

— Clean tool or replace Work Contacting Element

as required.

Press the Work Contact Element against a work-

does not drive,

— Fastener strip may be

binding.

— Use only fasteners meeting

Damaged Driver Blade

STOCK-ade

®

STOCK-ade

®

STOCK-ade

®

STOCK-ade

®

for service.

STOCK-ade

®

STOCK-ade

®

warrants

that new

ST-315i power

fastening tools, parts and accessories will

be free from defects in material and work-

manship

for the period shown below.

TWO-YEAR/50,000 SHOT WARRANTY

A two-year/50,000 shot warranty, which

ever comes first, will apply to all parts, except

those listed below as normal wearing parts,

or

parts which are specifically covered by an

extended warranty.

SIX-MONTH/10,000 SHOT WARRANTY

A six-month/10,000 shot warranty applies to

the following parts, which are considered

nor-

mal wearing parts:

• Bumper

• Piston Assembly

• Steel Rings

• Piston Rings

The warranty period is based off of tool build

date, determined from the tool serial number.

Sockade may extend the warranty time frame

from the date of purchase with a qualifying

document proving date of purchase.

WARRANTY STATEMENT

STOCK-ade’s sole liability hereunder will be to

replace any part or accessory which proves

to be defective within the specific time period.

Any replacement part or accessory provided

in accordance with this warranty will carry

a warranty for the balance of the period of

warranty applicable to the part it replaces.

This warranty does not apply to part replace-

ment required due to normal wear.

This warranty is void as to any tool which has

been subjected to misuse, abuse, accidental

or intentional damage, use with

fasteners,

fuel, battery, or battery chargers not meeting

STOCK-ade’s specification, size, or quality, im-

properly maintained, repaired with other than

genuine ST315i replacement parts, damaged

in transit or handling, or which, in Stockade’s

opinion, has been altered

or repaired in a way

that affects or detracts

from the performance

of the tool.

STOCK-ade®

MAKES NO WARRANTY, EXPRE

S-

SED OR IMPLIED, RELATING TO MERCHANT-

ABILITY,

FITNESS, OR OTHERWISE,

EXCEPT

AS STATED

ABOVE and the liability AS STATED

ABOVE AND AS ASSUMED ABOVE is in lieu

of all other warranties arising out of, or in con-

nection with,

the use and performance of the

tool, except to

the extent otherwise provided

STOCK-ade ®

SHALL IN NO EVENT BE LIABLE

FOR ANY DIRECT, INDIRECT, OR

CONSEQUEN-

TIAL DAMAGES, INCLUDING,

BUT NOT LIMIT-

ED TO DAMAGES WHICH MAY ARISE FROM

LOSS OF ANTICIPATED PROFITS OR PRODUC-

TION, SPOILAGE OF MATERIALS, INCREASED

COST OF OPERATION OR OTHERWISE.

reserves the right to change spec-

ifications, equipment, or designs at any time

without notice and without incurring obligation.

WARRANTY

WARRANTY

17

STOCK-ade

®

GAS TOOL SYSTEMS WARRANTY AND LIMITATIONS

by applicable law.

STOCK-ade

STOCK-ade

®

FOR TOOL REPAIR SERVICE CONTACT YOUR LOCAL

AUTHORIZED STOCK-ade®DISTRIBUTOR OR TO FIND

YOUR NEAREST STOCK-ade®TOOL REPAIR CENTER

VISIT OUR WEB SITE AT WWW.STOCK-ade.COM

OR CALL +64 9 477 3000

Buy with Confidence...

Buy From Your Authorized Distributor

PRINTED IN THE U.S.A. Form No. 905556-1

01/15

IMPULSE ST-315i FENCING STAPLER

®

PELIGRO

ANTES DE UTILIZAR LA HERRAMIENTA LEA Y SIGA TODAS

LAS INSTRUCCIONES DE SEGURIDAD Y FUNCIONAMIENTO.

CLAVADORA ENGRAPADORA PARA CERCAS

IMPULSE ST-315i

DE INSTRUCCIONES DE FUNCIONAMIENTO

Y SEGURIDAD DEL OPERADOR

HERRAMIENTA DE FIJACI!N ALIMENTADA CON GAS,

DE TIPO PIST!N DE BAJA VELOCIDAD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.

2.

2

NDICE/INTRODUCCIÓN

Introducci n

Perspectiva general de la herramienta Impulse ST-315I

Instrucciones de seguridad

Sistema de carga y baterías

Celdas de combustible

Preparaci n y uso de la herramienta Impulse ST-315i

Reparaci n

Mantenimiento y localizaci n y resoluci n de averías

Garantía

MANUAL DE FUNCIONAMIENTO DE LA HERRAMIENTA ST-315i

El objetivo de este manual es que usted se familiarice con la herramienta ST-315i de

STOCK-ade®.

A diferencia de otras herramientas de fijaci n, la herramienta ST-315i funciona con un motor

lineal de combusti n interna. En términos sencillos, su herramienta ST-315i funciona con un

motor similar al de un autom vil. La herramienta prende fuego a una mezcla de aire y combustible

para producir la energía que hace funcionar el motor, la cual a su vez impulsa el elemento de

fijaci n. Como usted podrá ver, la herramienta ST-315i trae todo lo que necesita. Viene con su

propia batería y suministro de combustible, junto con un suministro de elementos de fijaci n.

Para una mayor facilidad en su uso, este manual está dividido en secciones (consulte el

Índice).

evitar dañar la herramienta o herirse. Para lograr esto, necesitamos que usted haga dos cosas:

Cada secci n de este manual se ha escrito teniéndolo en cuenta a usted, el operador de la

herramienta. Hemos dejado afuera todos los términos técnicos de manera que usted pueda

entender fácilmente c mo lograr el máximo desempeño de su herramienta ST-315i y c mo

ANTES DE UTILIZAR LA HERRAMIENTA, LEA EL MANUAL DE PRINCIPIO A FIN.

SIGA TODAS LAS INSTRUCCIONES DEL MANUAL.

La herramienta ST-315i debe manejarse como otras herramientas de fijaci n que usted usa. Si

la usa adecuadamente, podrá satisfacer sus necesidades de fijaci n. Y, como la mayoría de sus

herramientas, si se usa incorrectamente puede causar heridas. Si va a permitir que otras personas

utilicen la herramienta ST-315i, es su responsabilidad asegurarse de que también lean y sigan las

instrucciones de este manual antes de intentar manejar la herramienta.

En caso de que tenga alguna pregunta sobre el sistema ST-315i, o si desea obtener copias

adicionales de este manual, comuníquese con el representante de ventas de su distribuidor de

STOCK-ade .

®

Table of contents

Languages:

Other STOCK-ade Power Tools manuals