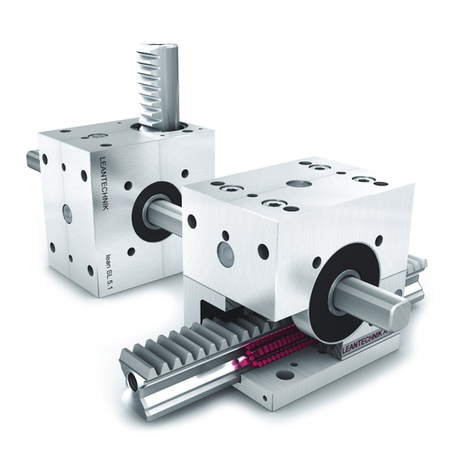

The fork diagram shown to the side indicates the centre of gravity of the load that, however, must be distributed as

uniformly as possible along the whole length of the fork!!

5. TRANSPORT AND SET UP

Transport

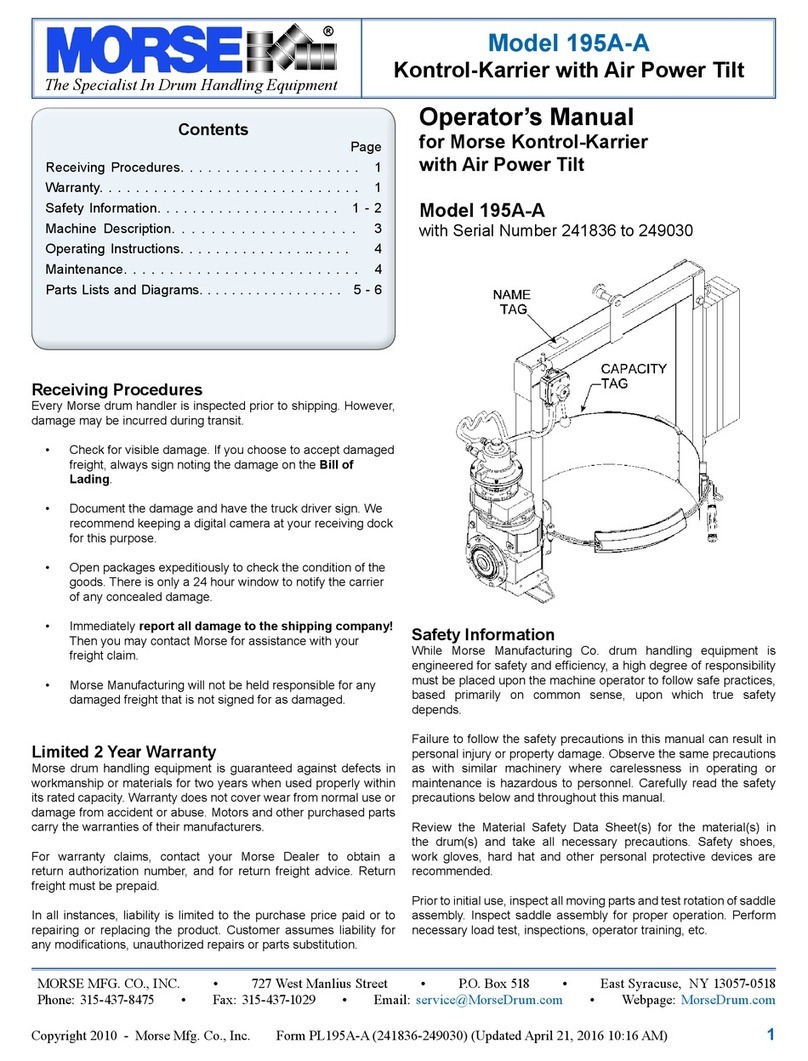

To transport the truck, a sling point is marked on the type “C” shield (fig. 3), while its weight is marked on the type

“A” shield (fig. 3). While driving, make sure the truck is firmly fixed, so as to avoid its tilting. Make sure that no acid

nor vapour is leaking from the battery (if any).

Set up

Before starting the machine check that all the parts are in perfect condition, check the per-formance of all the units

and the safety devices.

6. USE

The driver must carry out the following instructions of use in the driving position in way to remain reasonably distant

from the dangeuros zones (such as masts, forks, chains, pulleys, driving and stabilizing wheels and any other

movable part), that can cause the crushing of hands and/or foots.

Safety Regulations

The truck must be used according to the following regulations :

- The driver of the machine must be aware of the instructions for use of the vehicle and wear appropriate clothing

and a helmet.

- The driver responsible for the fork lift truck must not allow unauthorised personnel to drive the truck or to step onto

the forks. He must keep unauthorised personnel away from the area where the truck is working and immediately

warn people if they are in danger; if, in spite of this warning there is still someone in the work area the driver must

immediately stop the truck.

- It is forbidden to stop in areas where there are moving parts and step on the fixed parts of the truck.

- When driving the driver must pay attention and make sure that visibility is good.

- If the truck is transported in lifts he must enter them with the loading forks in front (first make sure the lift

has a sufficient load).

- It is absolutely forbidden to disconnect or dismount the safety devices. If the truck is used in areas with a high risk

of fire or explosion, it must be approved for this kind of use.

- The loading capacity of the truck must in no case be exceeded. The driver must ensure that the load is well placed

on the forks and in perfect order; the load must not jut out more than 50 mm from the end of the forks.

- It is forbidden to tow the truck with electrical or mechanical means of traction; it may only be moved by hand.

- It is forbidden to move the truck with the forks in their upper position. This is allowed only when manoeuvring

to put down and pick up loads.

- Before beginning work the driver of the truck must check : the performance of the parking brake ; that the loading

forks are in perfect order ; that the wheels and the rollers are not damaged.

- The truck must always be used or parked sheltered from rain and snow and in no case must it be used

in very damp areas.

- Temperature of use 0°C / + 40°C.

- It is forbidden to transport foodstuffs in direct contact with the truck.

- The machine does not need to be in a specially lighted area. However provide adequate lighting to comply

with applicable working norms.