STODDART Giorik Movair MTE5WRT User manual

Revision: A - 22/10/2020

ESSENCE OF EVOLUTION COMBI OVENS

SPECIFICATION, INSTALLATION

& OPERATION MANUAL

(READ ALL INSTRUCTIONS BEFORE USE)

Electric Models:

MTE5WRT / MTE5WLT

MTE7XWRT / MTE7XWLT

MTE10XWRT / MTE10XWLT

Page 1

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Introduction

Your New Giorik Product . . . . . . . . . . . . . . . . . . . 3

Australia and New Zealand Warranty . . . . . . . . . . . . . 4

Warranty Period

Warranty Registration

General Precautions . . . . . . . . . . . . . . . . . . . . . 5

General Warnings

Installation

Setting Up Information . . . . . . . . . . . . . . . . . . . . 6

Handling

Unpacking

Disposal

Stacked Installation

Positioning

Electrical Connection . . . . . . . . . . . . . . . . . . . . . 9

Information

Wiring

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chloride Test

Total Dissolved Solids (TDS) Test

Filtration System

Positioning

Water Connection - BWT Filter

Water Connection - Reverse Osmosis Filter

Drainage Connection

Liquid Detergent Connection

Oven Commissioning . . . . . . . . . . . . . . . . . . . . 17

Testing

Specification

Technical Drawing . . . . . . . . . . . . . . . . . . . . . 18

MTE5WRT

MTE5WLT

MTE7XWRT

MTE7XWLT

MTE10XWRT

MTE10XWLT

Operation

General Overview. . . . . . . . . . . . . . . . . . . . . . 21

Control Interface

Cooking Methods

Cooking Screen Icons:

Setup - Configuration Menu . . . . . . . . . . . . . . . . 24

Date and Time / Language

System Info

Manual Cooking . . . . . . . . . . . . . . . . . . . . . . 25

Initial Settings

Selecting The Cooking Method

Selecting The Temperature

Setting Preheating

Time Setting:

Core Probe:

Delta T(Δt):

Fan Rotation Speed

Manual Adjustment of Vent

Setting Humidity Percentage for Combi Mode

Steam Tuner Function

Holding Phase

Setting Multiple Cooking Phases (optional)

Cooling Phase

Smoking Phase

To Delete a Phase

Saving a Recipe

Delete a Cooking Program

Rename a Cooking Program

Move a Cooking Program

Automatic Cooking . . . . . . . . . . . . . . . . . . . . . 36

Cooking Program Selection

How To Use The Automatic Cooking Program

Rack Control - Manual Setting

Rack Control - Menu Setting

Rack Control - Easy Service

Special Functions. . . . . . . . . . . . . . . . . . . . . . 40

Cooling Of The Chamber

Delayed Start

One Touch . . . . . . . . . . . . . . . . . . . . . . . . . 41

Importing / Exporting Recipes and Log To USB . . . . . . . 42

Import / Export

Display LOG . . . . . . . . . . . . . . . . . . . . . . . . 43

HACCP Protocol . . . . . . . . . . . . . . . . . . . . . . 43

Page 2

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Cleaning and Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cleaning Schedule

Materials Required

General Information

Corrosion Protection

Surface Finish

Automatic Cleaning

Start the Wash Program

Stop the Wash Program

Control panel ventilation filter

Cleaning Glass Door

Cleaning Internal Rack

Cleaning external surfaces

Water Filtration . . . . . . . . . . . . . . . . . . . . . . . 48

BWT Filter Cartridge

Reverse Osmosis Filter Cartridges

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 49

Common Problems

Door Micro Switch

Motor Thermal Breaker

Safety Thermostat Of The Oven Chamber

Technical Problems / Alarm Code

Scheduled Maintenance Service History . . . . . . . . . . 51

Service Log

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 52

Spare Parts

Page 3

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Introduction

Carefully read this instruction booklet, as it contains important advice for safe installation, operation and maintenance.

Keep this booklet on hand in a safe place for future reference by other operators or users.

Stoddart design, manufacture & distribute Food Service Equipment (appliances) exclusively for the commercial market.

This appliance is not designed nor intended for household or domestic use and must not be used for this purpose.

This product is intended for commercial use, and in line with Australian electrical safety standards the following warnings are provided:

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the product by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the product

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid

a hazard

The manufacturer and distributor cannot be held responsible or liable for any injuries or damages of any kind occurred to

persons, units or others, due to abuse and misuse of this unit in regards to installation, removal, operation, servicing or

maintenance, or lack of conformity with the instructions indicated in this documentation.

Disclaimer

All units made by the manufacturer are delivered assembled, where possible, and ready to install. Any installation, removal,

servicing, maintenance and access or removal of any parts, panels or safety barriers that is not permitted, does not comply

in accordance to this documentation, or not performed by a TRAINED AND AUTHORISED SPECIALIST will result in the

IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer cannot be held responsible or liable for any unauthorised modifications or repairs. All modifications or

repairs must be approved by the manufacturer in writing before initiating. All modifications or repairs performed to this unit

must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Thank you for choosing this quality Giorik product.

All Giorik products are designed and manufactured to meet the needs of food service professionals. By caring for and maintaining this new

Giorik product in accordance with these instructions, will provide many years of reliable service.

Stoddart is a wholly Australian owned company, which manufactures and/or distributes a comprehensive range of food service equipment for

kitchens, food preparation and presentation. Stoddart products are manufactured and/or engineered in Australia to provide excellent results

whilst offering value-for-money, ease-of-use and reliability.

Your New Giorik Product

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty & Registration

Page 4

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Introduction

Carefully read this instruction booklet, as it contains important advice for safe installation, operation and maintenance.

Keep this booklet on hand in a safe place for future reference by other operators or users.

Stoddart design, manufacture & distribute Food Service Equipment (appliances) exclusively for the commercial market.

This appliance is not designed nor intended for household or domestic use and must not be used for this purpose.

This product is intended for commercial use, and in line with Australian electrical safety standards the following warnings are provided:

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the product by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the product

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid

a hazard

The manufacturer and distributor cannot be held responsible or liable for any injuries or damages of any kind occurred to

persons, units or others, due to abuse and misuse of this unit in regards to installation, removal, operation, servicing or

maintenance, or lack of conformity with the instructions indicated in this documentation.

Disclaimer

All units made by the manufacturer are delivered assembled, where possible, and ready to install. Any installation, removal,

servicing, maintenance and access or removal of any parts, panels or safety barriers that is not permitted, does not comply

in accordance to this documentation, or not performed by a TRAINED AND AUTHORISED SPECIALIST will result in the

IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer cannot be held responsible or liable for any unauthorised modifications or repairs. All modifications or

repairs must be approved by the manufacturer in writing before initiating. All modifications or repairs performed to this unit

must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Thank you for choosing this quality Giorik product.

All Giorik products are designed and manufactured to meet the needs of food service professionals. By caring for and maintaining this new

Giorik product in accordance with these instructions, will provide many years of reliable service.

Stoddart is a wholly Australian owned company, which manufactures and/or distributes a comprehensive range of food service equipment for

kitchens, food preparation and presentation. Stoddart products are manufactured and/or engineered in Australia to provide excellent results

whilst offering value-for-money, ease-of-use and reliability.

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty & Registration

Warranty Registration

Warranty Period

Australia and New Zealand Warranty

Page 5

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

• All units MUST be installed according to the procedures stated in the installation section of this manual

• In the case of new personnel, training is to be provided before operating the equipment

• DO NOT use this unit for any other purpose than its intended use

• DO NOT store explosive substances such as aerosol cans with a flammable propellant in or near this unit

• Keep fingers out of “pinch point” areas

• Unit is not waterproof DO NOT use jet sprays, hoses or pour water over/on the exterior of the unit

• Only use this unit with voltage specified on the rating label

• DO NOT remove any cover panels that may be on the unit

• DO NOT use sharp objects to activate controls

• If any fault is detected, refer to troubleshooting

• The manufacturer declines any liability for damages to persons and/or things due to an improper/wrong and/or unreasonable use of the

machine

• Only specifically trained/qualified Technicians (Stoddart, one of our service agents, or a similarly qualified persons) should carry out any

and all repairs, maintenance and services

When using any electrical unit, safety precautions must always be observed.

Our units have been designed for high performance. Therefore, the unit must be used exclusively for the purpose for which it has been designed.

General Precautions

Introduction

General Warnings

• DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS APPLIANCE

• DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION

• DO NOT MODIFY THIS APPLIANCE

• DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

The equipment complies with the essential requirements of the Low Voltage Directive 2006/95/EC.

It meets the provisions of the following electrical and Gas standards:

• AS/NZS 60335.1

• AS/NZS 60335.2.42

• AS/NZS 4563, AS/NZS 5601

• AS/NZS 1869

• WMTS -101

The equipment complies with the essential requirements of the Electromagnetic Compatibility Directive 2004/108/EC.

Page 6

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

• All units MUST be installed according to the procedures stated in the installation section of this manual

• In the case of new personnel, training is to be provided before operating the equipment

• DO NOT use this unit for any other purpose than its intended use

• DO NOT store explosive substances such as aerosol cans with a flammable propellant in or near this unit

• Keep fingers out of “pinch point” areas

• Unit is not waterproof DO NOT use jet sprays, hoses or pour water over/on the exterior of the unit

• Only use this unit with voltage specified on the rating label

• DO NOT remove any cover panels that may be on the unit

• DO NOT use sharp objects to activate controls

• If any fault is detected, refer to troubleshooting

• The manufacturer declines any liability for damages to persons and/or things due to an improper/wrong and/or unreasonable use of the

machine

• Only specifically trained/qualified Technicians (Stoddart, one of our service agents, or a similarly qualified persons) should carry out any

and all repairs, maintenance and services

When using any electrical unit, safety precautions must always be observed.

Our units have been designed for high performance. Therefore, the unit must be used exclusively for the purpose for which it has been designed.

Installation

Disposal

• At the end of the appliance’s working life, make sure it is scrapped & components recycled properly

• Current environmental protection laws in the state/country of use must be observed

• Doors must be removed before disposal

• Power supply cable must be removed before disposal

• For further information on the recycling of this product, contact the local dealer/agent or the local body responsible for waste disposal

Setting Up Information

Handling

Unpacking

• Use suitable means to move the unit:

- For smaller items use two people

- For large items a fork lift, pallet trolley or similar (the forks should reach completely beneath the pallet)

• Check the unit for damage before and after unpacking. If unit is damaged, contact the distributor and manufacturer

• Should any item have physical damage, report the details to the freight company and to the agent responsible for the dispatch within

seven (7) days of receipt. No claims will be accepted or processed after this period

• The unit is supplied fully assembled

• Remove all protective plastic film, ties and packers before installing and operating

• Clean off any remaining residue from the interior/exterior of the unit using a clean cloth dampened with warm soapy water

WARNING

Improper installation, adjustments, alterations, service or

maintenance can cause property damage, injury or death

Stacked Installation

IMPORTANT

For stacked oven installations, this manual is to be used in

conjunction with the stacking installation manual

(supplied with stacking kit)

Page 7

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Heat Source

WALL

WALL

50mm

250mm

250mm

300mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Heat Shield

Heat Shield

Service Compartment

50mm

500mm

500mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Service Compartment

300mm

WALL

50mm

300mm

NON - HEAT

SOURCE OVEN

50mm

Service Compartment

Heat Source With Heat Shield

IMPORTANT

DO NOT install unit under a bench

Under Bench installation will void warranty

Positioning

The room where the equipment will be positioned must:

• Be ventilated and not exposed to atmospheric agents;

• Have a smooth, level floor which can bear the weight of the appliance at full load.

• Have a temperature above +4°C;

• Have maximum humidity of 70%;

• Comply with the regulations in force in terms of safety in the workplace and the systems;

• Not contain potentially explosive materials or substances;

• Be dedicated to food preparation. In addition, a gas-fired appliance requires, by law, rooms with a surface area and ventilation that are

suitable for the power of the oven and that have a means of externally evacuating flue gases

• Please consult national and local standards to ensure that your unit is positioned in accordance with any existing requirements

• Do not allow cables or other items to rest/hang over the exhaust vents

• Service compartment Heat Source: 500mm clearance from another heat source, in order to protect the oven control components and

allow access to the service panel. For distances under 500mm, it is mandatory for Stoddart heat shields to be fitted (for a minimum

distance of 300mm from the service compartment). Failure to adhere to minimum clearances will void the oven warranty and add

service costs due to lack of access

Page 8

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

WALL

WALL

50mm

250mm

250mm

300mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Heat Shield

Heat Shield

Service Compartment

50mm

500mm

500mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Service Compartment

300mm

WALL

50mm

300mm

NON - HEAT

SOURCE OVEN

50mm

Service Compartment

Non-Heat Source

• Service compartment Non-Heat Source: 300mm clearance from a non-heat source to allow access to the service panel. Any distance

under 300mm, will add service costs due to lack of access

• Do not install unit under a bench

• Please consult national and local standards to ensure that your unit is positioned in accordance with any existing requirements

• Do not allow cables or other items to rest/hang over the exhaust vents

Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Electrical Connection

Information

Three Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 3Ø + N + E

On-site Connection:

• The electrical supply must comply with the rating plate data

• Ensure that the machine is connected to a suitably rated power source

• Disconnection must be incorporated in the fixed wiring in accordance with the wiring rules

• To connect the power, the unit has a terminal block supplied inside the service compartment

This unit must be installed in accordance with AS/NZS 60335.1

Some procedures in this manual require the power to the equipment to be turned off and isolated.

Turn the power OFF at the power point and unplug the power supply lead by the plug body. If the

power point is not readily accessible turn the equipment off at the isolation switch or the circuit

breaker in the switchboard. Attach a yellow “CAUTION-DO NOT OPERATE” tag. This must be

performed where relevant unless the procedures specify otherwise.

FAILURE TO DO SO MAY RESULT IN ELECTRIC SHOCK.

WARNING

Single Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 1Ø + N + E

• Supplied and fitted with an appropriately rated plug and lead

Notes:

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a

hazard. Please contact Stoddart for parts and we will advise how to do this in order to avoid any electrical hazard

• The power cable should be dry and/or isolated from moisture or water

Page 10

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Three Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 3Ø + N + E

On-site Connection:

• The electrical supply must comply with the rating plate data

• Ensure that the machine is connected to a suitably rated power source

• Disconnection must be incorporated in the fixed wiring in accordance with the wiring rules

• To connect the power, the unit has a terminal block supplied inside the service compartment

This unit must be installed in accordance with AS/NZS 60335.1

Some procedures in this manual require the power to the equipment to be turned off and isolated.

Turn the power OFF at the power point and unplug the power supply lead by the plug body. If the

power point is not readily accessible turn the equipment off at the isolation switch or the circuit

breaker in the switchboard. Attach a yellow “CAUTION-DO NOT OPERATE” tag. This must be

performed where relevant unless the procedures specify otherwise.

FAILURE TO DO SO MAY RESULT IN ELECTRIC SHOCK.

WARNING

Single Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 1Ø + N + E

• Supplied and fitted with an appropriately rated plug and lead

Notes:

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a

hazard. Please contact Stoddart for parts and we will advise how to do this in order to avoid any electrical hazard

• The power cable should be dry and/or isolated from moisture or water

1. Remove service compartment cover

2. Connect electrical wiring, following the below wiring diagram.

After connecting wires, use a multimeter to check:

• There is no electrical dispersion between the phases and the earth

• For electrical continuity between the external casing and the mains earth

3. Reinstall service compartment cover

4. Secure wiring cable by fastening the cable gland nut

Wiring

2 3 4 51 2 3 4 51

415V 3N

50/60 Hz

230V 1N

50/60 Hz

L1

L1

N

N

N

L1

L1

L2

L3

N

PE

PE

1

2

3

4

5

6

1

2

3

4

5

6

Installation

Model MTE5WRT MTE5WRT MTE7XWRT MTE7XWLT MTE10XWRT MTE10XWLT

Weight (kg) 65kg 65kg 105kg 105kg 112kg 112kg

Power (kW)

6.3kW

415V 3Ø + N + E

(3 x 9A)

230V 1Ø + N + E

(1 x 27A)

6.3kW

415V 3Ø + N + E

(3 x 9A)

230V 1Ø + N + E

(1 x 27A)

12.6kW

415V 3Ø + N + E

(3 x 18A)

12.6kW

415V 3Ø + N + E

(3 x 18A)

17.6 kW

415V 3Ø + N + E

(3 x 25A)

17.6 kW

415V 3Ø + N + E

(3 x 25A)

The links provided must be in this configuration

for single phase.

Fan rotation does not need to be checked

Page 11

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Chloride Test

1. Remove Titrator from bottle and replace bottle cap

immediately

2. Insert lower end of the Titrator into water to be

tested (approx 20mm of water). DO NOT allow

water to touch yellow completion band at top of

Titrator

3. Allow water to completely saturate the wick of

Titrator. Reaction is complete when yellow band

turns dark

4. Note where the white chloride peak falls on the

scale. This represents the unit value

5. Refer to the table to convert the Titrator units into

salt concentration

* Readings greater than 1.4 (32PPM) require a

Reverse Osmosis Unit to be installed

* Readings less than 1.4 (32PPM) require

the Total dissolved solids (TDS) be tested

Total Dissolved Solids (TDS) Test

1. Remove the cover from the TDS meter, turn on by

pressing the On/Off button. The display should read

000

2. Insert lower end of the TDS meter into water to be

tested (approx 20mm of water). DO NOT completely

submerge

3. Wait 5-10 seconds

4. The number displayed on meter is the TDS (Total

Dissolved Solids) of the water expressed in PPM

(parts per million) e.g. TDS = 70PPM

• Contact Stoddart if reading is lower than 20ppm

5. When finished, turn the TDS meter off

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

0.005

0.006

0.007

0.009

0.010

0.011

0.013

0.014

0.016

0.017

0.019

0.021

0.023

0.025

0.027

0.030

32

39

45

53

60

68

77

86

95

106

116

128

140

152

166

180

4.6

4.8

5.0

5.2

5.4

5.6

5.8

0.032

0.035

0.038

0.041

0.044

0.048

0.051

196

212

229

248

267

288

311

6.0 0.055 335

6.2 0.060 361

6.4 0.064 389

6.6 0.069 419

6.8 0.074 452

7.0 0.080 487

7.2 0.087 525

7.4 0.093 567

7.6 0.101 613

Units %NaCI CI Units %NaCI CI

ppm(mg/L)

Limit*

ppm(mg/L)

Installation

IMPORTANT

Selection of the correct water ltration system to suit local wa-

ter conditions is CRITICAL. Failure to install the correct system

according to the following guidelines will void warranty.

Installation

Page 12

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Water

Supply Test

Call

Stoddart

1300 307 289

Chloride

(Cl)

TDS

Greater Than

32PPM (Parts Per Million)

BWT Unit

Reverse Osmosis Unit

Less Than

32PPM

Less Than

20PPM

Greater Than

20PPM

Filtration System

• After testing the quality of your water supply use the below chart to determine you water filter requirements.

Installation

Page 13

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Positioning

• The oven must be installed under an

extraction canopy that meets

AS 1668.2.

• To allow access to service panel and

protection of the control components,

the left hand side of the Combi oven

must have the following minimum

clearances:

Heat Source:

- 500mm clearance from another heat

source, in order to protect the oven

control components and allow access

to the service panel.

Non-Heat Source:

300mm clearance from a non-heat

source to allow access to the service

panel.

• Failure to adhere to these clearances

will potentially void the oven warranty

or add service costs due to lack of

access.

• Using a spirit level, ensure that the

Combi oven is level. Adjust the foot

height to level Combi oven.

• If using a stand, level the stand by

adjusting the feet, then level the Combi

oven.

WALL

WALL

50mm

250mm

250mm

300mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Heat Shield

Heat Shield

Service Compartment

50mm

500mm

500mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

Service Compartment

300mm

WALL

50mm

300mm

NON - HEAT

SOURCE OVEN

50mm

Service Compartment

Page 14

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

OVEN

WASH

SYSTEM

OVEN

STEAM

GENERATION

Installation

COLD WATER CONNECTION

WITH ISOLATION VALVE

(EXISTING CONNECTION)

OVEN

WASH

SYSTEM

OVEN

STEAM

GENERATION

A

J

I

I

FF

DD

D

H

C

B

E

G

G

Water Connection - BWT Filter

IMPORTANT

This oven must be installed in accordance with AS/NZS 3500.1

The Oven must be installed with the supplied Dual Check Valve,

Water Filter and Pressure Limiting Valves

• Water connections are labelled on the oven

• Isolation valve must be installed at the water

supply outlet

• Water Temperature: Min 10°C, Max 35°C

• Steam Generation: The Combi oven requires

filtered water supplied to its steam generation

system. Water pressure must be 300-350 kPa

(43-51 psi) at oven connection. This is controlled

with the supplied PLV

• Wash System: The Combi oven requires

unfiltered water supplied to its wash system.

Water pressure must be 300-350 kPa (43-51 psi)

at oven connection. This is controlled with the

supplied PLV

• Refer to the BWT user manual for filter setup

Supplied Components

(Plumbing Kit / Water Filter Kit)

A. 1 x BWT Filter

B. 1 x Dual Check Valve

C. 1 x 4 Way Manifold

D. 3 x 3/4” BSP To 3/8” Tube Connector

E. 1 x 1/2” BSP To 3/8” Tube Connector

F. 2 x 3/8” John Guest Stem Elbow

G. 2 x Pressure Limiting Valve 300-350 Kpa

H. 1 x Nipple, 3/4” Male

I. 1 x 3m 3/8 Tube (Water)

J. 12 x John Guest Locking Clip

Page 15

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

OVEN

WASH

SYSTEM

OVEN

STEAM

GENERATION

Installation

OVEN

WASH

SYSTEM

OVEN

STEAM

GENERATION

COLD WATER CONNECTION

WITH ISOLATION VALVE

(EXISTING CONNECTION)

A

KL

JJ

F F

D D

D

B

C

H

E

G

I

Water Connection - Reverse Osmosis Filter

Supplied Components

(Plumbing Kit / Water Filter Kit)

A. 1 x Ro Unit

B. 1 x Dual Check Valve

C. 1 x 4 Way Manifold

D. 3 x 3/4” Bsp To 3/8” Tube Connector

E. 1 x 1/2” Bsp To 3/8” Tube Connector

F. 2 x 3/8” John Guest Stem Elbow

G. 1 x Pressure Limiting Valve 300-350 Kpa

H. 1 x Pressure Limiting Valve 350-600 Kpa

I. 1 x Nipple, 3/4” Male

J. 1 x 5m 3/8 Tube (Water)

K. 1 x 3m 1/4 Tube (Drain)

L. 11 x John Guest Locking Clip

IMPORTANT

This oven must be installed in accordance with AS/NZS 3500.1

The Oven must be installed with the supplied Dual Check Valve,

Water Filter and Pressure Limiting Valves

• Water connections are labelled on the oven

• Isolation valve must be installed at the water

supply outlet

• Water Temperature: Min 10°C, Max 35°C

• Steam Generation: The Combi oven requires

filtered water supplied to its steam generation

system. Water pressure must be 300-350 kPa

(43-51 psi) at oven connection. This is controlled

with the Stoddart RO system

• Wash System: The Combi oven requires unfiltered

water supplied to its wash system.

Water pressure must be 300-350 kPa (43-51 psi)

at oven connection. This is controlled with the

supplied PLV

• Refer to the RO user manual for filter setup

Page 16

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Drainage Connection

• Drain kit is supplied with oven as illustrated. Any

modification or extension to the kit must be able

to resist temperatures up to 100°C

• Plumb supplied waste pipes to the Tundish

• Tundish needs to be a minimum of 300mm from

the outlet on the service side of the oven

• Tundish should never be located directly below

the waste outlet, or close to or under the oven

control compartment. Steam from drainage

should not be allowed to rise up underneath the

oven control compartment

• Waste pipe must sit 25mm above the Tundish

• Secure waste pipe to the Combi oven. Securing

bracket is attached to top of the Combi oven.

Remove screw, reposition bracket, then secure in

place with previously removed screw

25mm

300mm

25mm

• Connect the Stoddart recommended oven cleaner

(See order form)

• Place oven cleaner bottle in close proximity to the

oven (for optional side mount bracket, see order

form)

• Cleaning products must not exceed 10% Sodium

Hydroxide. Exceeding 10% Sodium Hydroxide will

void warranty

• Wear appropriate PPE

Liquid Detergent Connection

IMPORTANT

Stoddart recommended oven cleaner should be used.

Other products may lead to voidance of warranty!

Page 17

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Oven Commissioning

Testing

Before putting the oven into operation, carefully carry out all the necessary checks to ascertain the conformity of the equipment and

installation of the appliance as provided by law and according to the technical and safety instructions given in this manual.

Check the compliance of the following:

• The ambient temperature in the location where the oven is installed should be greater than + 4°C

• The oven chamber should be empty

• All packaging must have been completely removed, including the protective film applied to the oven’s walls

• The vents and slits should be open and free of obstructions

• Any parts of the oven that were disassembled for installation purposes should be reinstalled

• The unit should be off and the water shut-off valve upstream of the unit must be opened

The oven should be tested by completing a cooking cycle to verify that the equipment works properly, without any anomalies or problems.

Turn on the oven (See Page 21)

Set a cooking cycle with temperature to 150°C, time set to 10min. and humidity to 25% (See “Manual Cooking” Page 25).

Press “Start/Stop”.

Carefully check the points given in the following list:

• Press the “LED Door Light” icon (See Page 21), the LED door lights illuminate the oven chamber, press again to turn off

• The oven will stop if the door is opened and starts to work when the door is closed

• The thermostat that regulates the temperature in the cooking chamber is triggered when the set temperature is reached and the

heating element is shut off temporarily

• The fan motor reverses the direction of rotation automatically; reversal takes place every 3minutes (time varies depending on the

cooking time)

• For the ovens with two fans in the cooking chamber, the motors have the same direction of rotation

• Check for water leaks in the direction of the fan fitted on the tube that inputs moisture in the oven chamber

• At the end of the cooking cycle the oven emits an audible alarm

Installation

Page 18

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Technical Drawing

MTE5WRT

MTE5WLT

Specification

*Clearance requirements

*Drain line must be vented

907

77566 66

670

643

811

749

1496

752

195

74

87

20 375

Ø32

108

Ø50

266

Ø50

520

126

ACD

E

B

50mm

500mm

50mm

F

*Clearance requirements

*Drain line must be vented

907

775

66 66

670

643

811

749

1496

752

195

74

87

20

375

Ø32

108

Ø50

110

Ø50

520126

A

C

D

F

E

B

500mm

50mm

50mm

F

Specifications

Model MTE5WRT

W x D x H (mm) 907 x 811 x 670

Weight 112kg

Capacity 10 X 1/1GN

Power 6.3 kW

415V 3Ø + N + E (3 x 9A)

230V 1Ø + N + E (1 x 27A)

Waste Connection 32mm

Cold Water

Connection

3/4 BSP, 300-350 kpa

Specifications

Model MTE5WLT

W x D x H (mm) 907 x 811 x 670

Weight 112kg

Capacity 10 X 1/1GN

Power 6.3 kW

415V 3Ø + N + E (3 x 9A)

230V 1Ø + N + E (1 x 27A)

Waste Connection 32mm

Cold Water

Connection

3/4 BSP, 300-350 kpa

Legend

AElectrical connection

BSteam generation water inlet (3/4” BSP)

CWash system water inlet (3/4” BSP)

DDrain connection

EHumidity vent

FDetergent line inlet

Legend

AElectrical connection

BSteam generation water inlet (3/4” BSP)

CWash system water inlet (3/4” BSP)

DDrain connection

EHumidity vent

FDetergent line inlet

Page 19

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

MTE7XWRT

MTE7XWLT

Specification

*Clearance requirements

*Drain line must be vented

907

77566 66

850

823

1496

752

811

749

195

74

87

20 375

Ø32

108

Ø50

266

Ø50

520126

AC D

E

50mm

500mm

50mm

F

B

*Clearance requirements

*Drain line must be vented

907

77566 66

850

823

1496

752

811

749

195

74

87

20

375

Ø32

108

Ø50

110

Ø50

520126

A

D

E

B

500mm

50mm

50mm

F

C

Specifications

Model MTE7XWLT

W x D x H (mm) 907 x 811 x 850

Weight 112kg

Capacity 10 X 1/1GN

Power 12.6 kW

415V 3Ø + N + E

(3 x 18A)

Waste Connection 32mm

Cold Water

Connection

3/4 BSP, 300-350 kpa

Specifications

Model MTE7XWRT

W x D x H (mm) 907 x 811 x 850

Weight 112kg

Capacity 10 X 1/1GN

Power 12.6 kW

415V 3Ø + N + E

(3 x 18A)

Waste Connection 32mm

Cold Water

Connection

3/4 BSP, 300-350 kpa

Legend

AElectrical connection

BSteam generation water inlet (3/4” BSP)

CWash system water inlet (3/4” BSP)

DDrain connection

EHumidity vent

FDetergent line inlet

Legend

AElectrical connection

BSteam generation water inlet (3/4” BSP)

CWash system water inlet (3/4” BSP)

DDrain connection

EHumidity vent

FDetergent line inlet

Other manuals for Giorik Movair MTE5WRT

1

This manual suits for next models

5

Table of contents

Other STODDART Oven manuals

STODDART

STODDART Giorik SEH061WT User manual

STODDART

STODDART GIORIK MOVAIR MTE523WRT User manual

STODDART

STODDART Giorik Movair MTE5WRT User manual

STODDART

STODDART Giorik SEHE061WT User manual

STODDART

STODDART Giorik Kore Mini-Touch KB061WT User manual

STODDART

STODDART Giorik Minitouch KM061WT User manual

Popular Oven manuals by other brands

Fisher & Paykel

Fisher & Paykel Aerotech OB30 Series user guide

AEG Electrolux

AEG Electrolux U88106 user manual

Bosch

Bosch HBJ538E 0M Series instruction manual

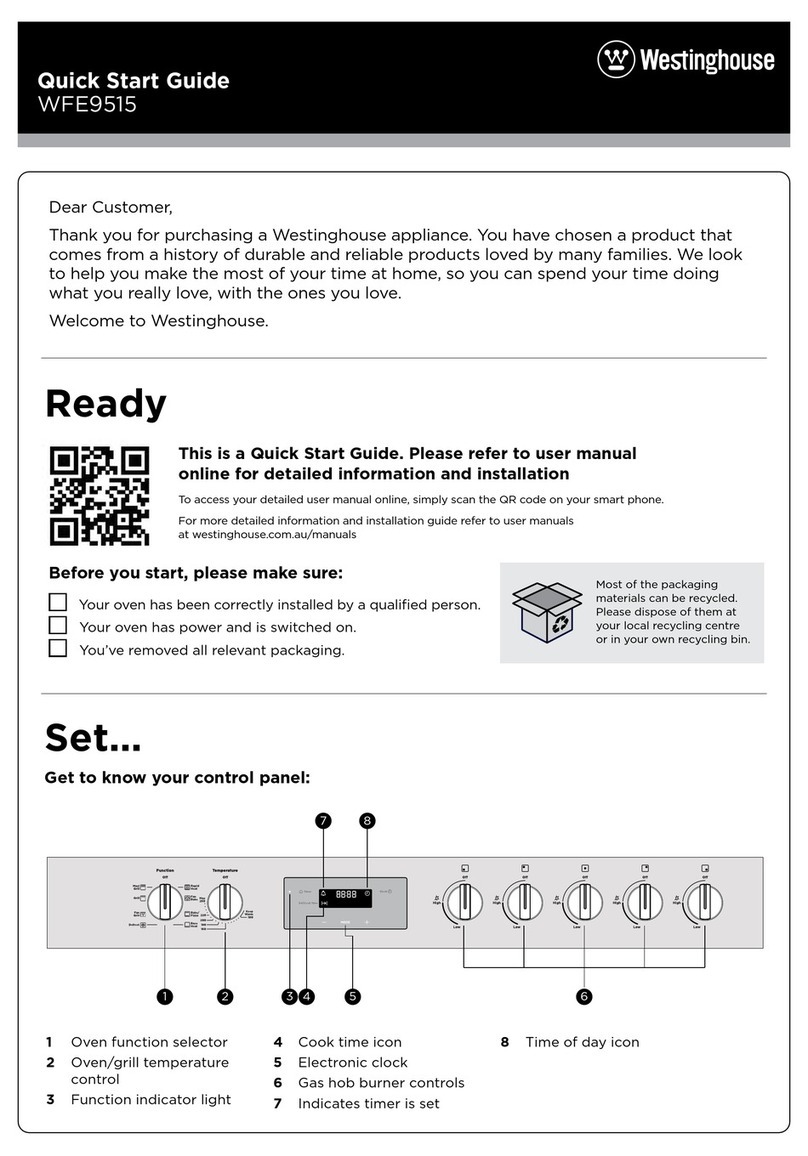

Westinghouse

Westinghouse WFE9515 quick start guide

Euro Appliances

Euro Appliances EO60MPYX Usage and care guide

Miele

Miele H2561BP Operating and installation instructions