1. Safety precautions........................................................................................................................................ 1

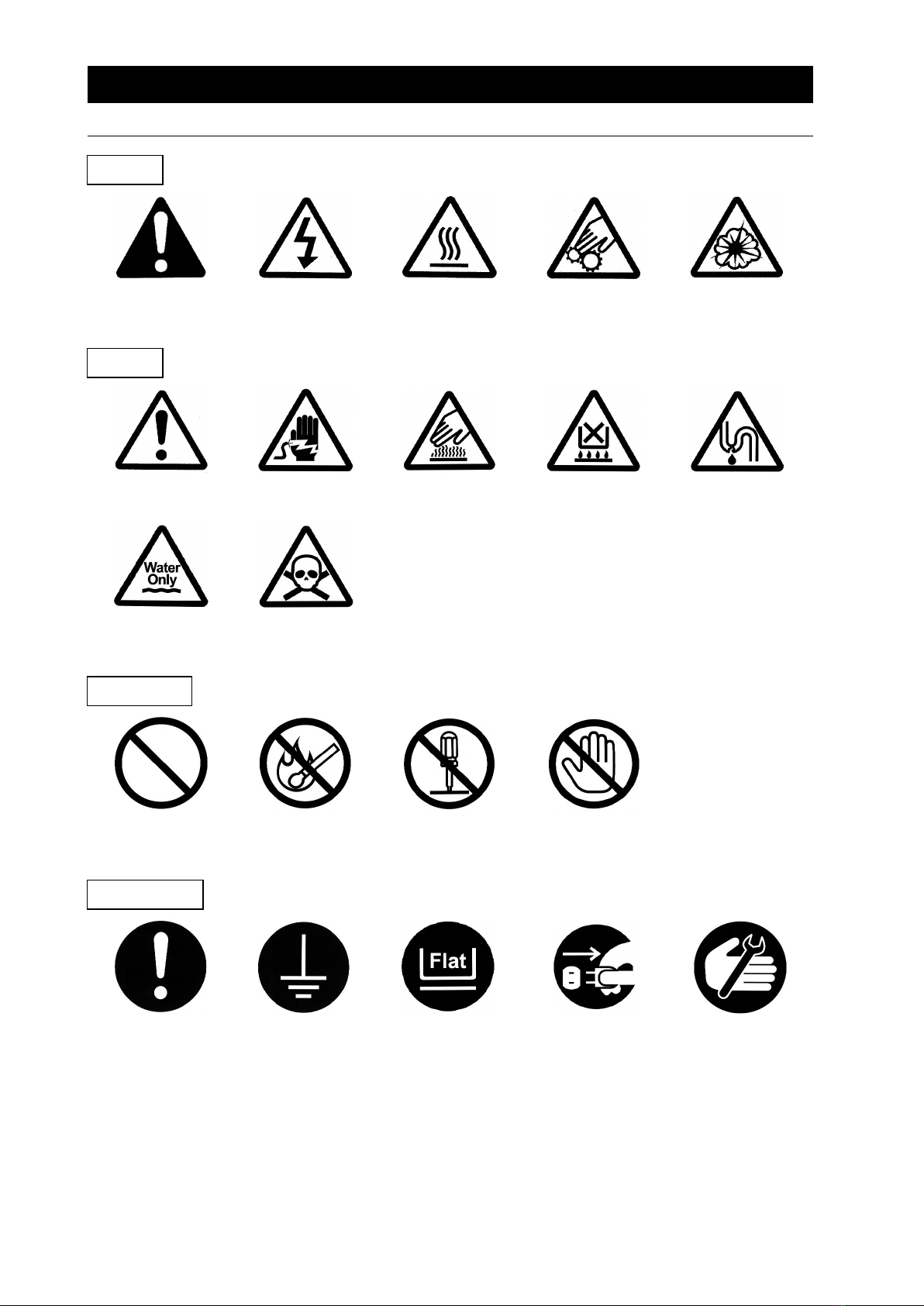

Explanation of pictograms..............................................................................................................................1

List of symbols................................................................................................................................................. 2

Warning ・Cautions....................................................................................................................................... 3

2. Before operating the unit............................................................................................................................ 4

Precautions when installing the unit.............................................................................................................4

Installation procedures ・precautions........................................................................................................ 7

3. Names and functions of parts................................................................................................................. 10

Main body....................................................................................................................................................... 10

Operation panel............................................................................................................................................. 11

Explanation of characters............................................................................................................................ 12

4. Operating procedures................................................................................................................................ 13

List of operation modes and functions.......................................................................................................13

Operation mode ・function setting keys and characters...................................................................... 15

Operating procedures (settings for overheat prevention device)..........................................................16

Operating procedures (fixed temperature operation)..............................................................................17

Operating procedures (quick auto stop operation)..................................................................................18

Operating procedures (auto stop operation)............................................................................................ 20

Operating procedures (auto start operation)............................................................................................ 22

Useful functions (calibration offset function).............................................................................................24

Useful function (setting lock function)........................................................................................................25

Useful function (power outage compensation function)......................................................................... 26

5. Cautions on handling................................................................................................................................. 27

6. Maintenance procedures...........................................................................................................................30

Daily inspection/maintenance..................................................................................................................... 30

7. When the unit is not to be used for a long time or when disposing.............................................31

When the unit is not to be used for a long time or when disposing......................................................31

Notes about disposition................................................................................................................................31

8. Troubleshooting...........................................................................................................................................32

Safety device and error codes.................................................................................................................... 32

When a malfunction is suspected...............................................................................................................33

9. After sales service and warranty............................................................................................................ 34

When requesting a repair............................................................................................................................ 34

10. Specifications.............................................................................................................................................35

11. Wiring diagram...........................................................................................................................................36

12. List of replacement parts........................................................................................................................ 36

13. List of dangerous materials................................................................................................................... 39

14. Standard installation manual.................................................................................................................40