STODDART Giorik Kore Mini-Touch KB061WT User manual

Revision: A - 05/08/2022 - 01

Electric Models:

KB061WT / KB101WT

KM061WT / KM101WT / KM0623WT

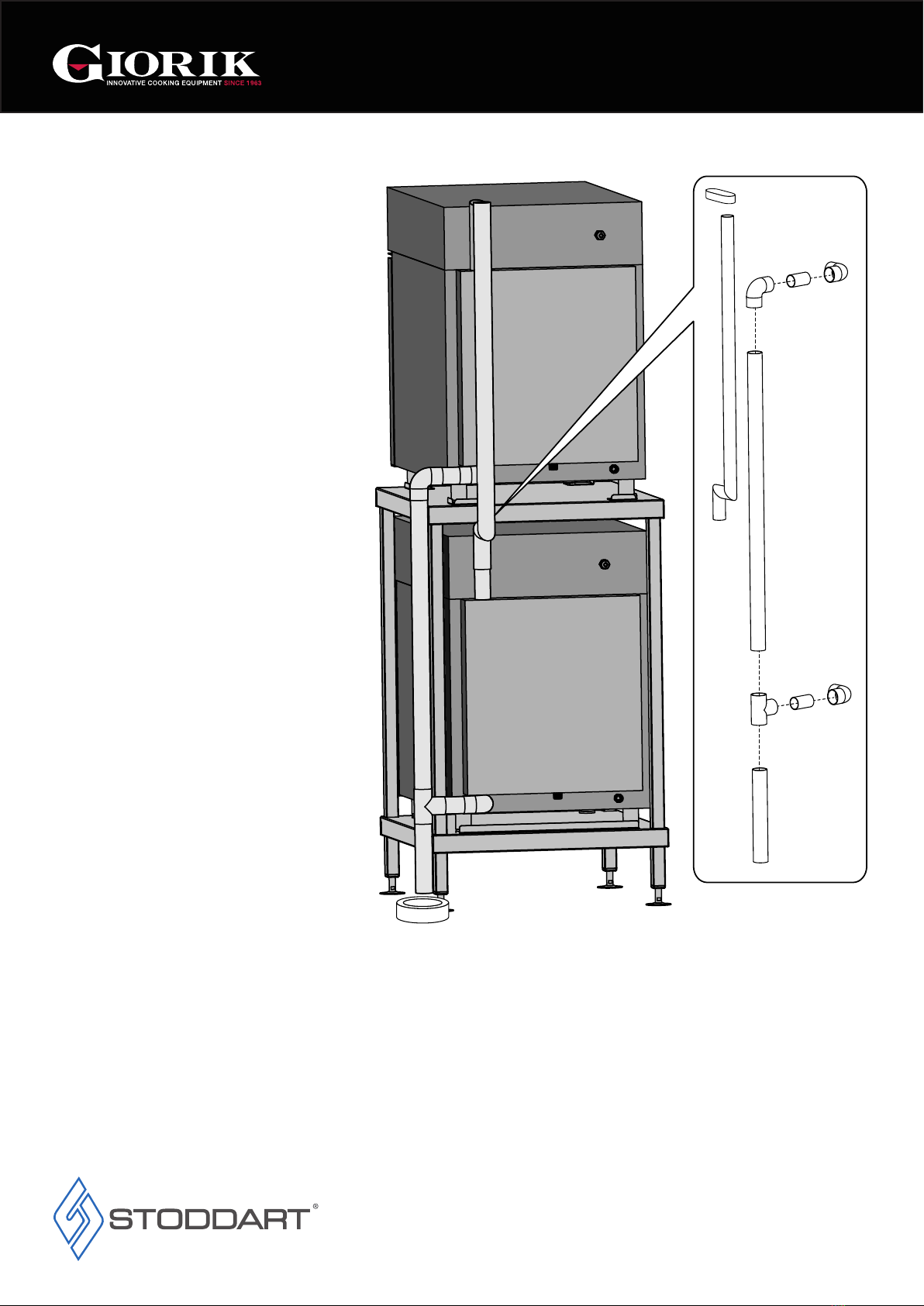

ESSENCE OF EVOLUTION COMBI OVENS

STACKED INSTALLATION

(READ ALL INSTRUCTIONS BEFORE USE)

TO BE USED IN CONJUNCTION WITH USER MANUAL SUPPLIED WITH OVEN

Page 1

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Setting Up Information . . . . . . . . . . . . . . . . . . . . . 2

Handling

Unpacking

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information

Spacing

Levelling

Water Connection - BWT Filter

Water Connection - Reverse Osmosis Filter

Drainage Connection

Contents

Page 2

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

IMPORTANT

THIS MANUAL IS TO BE USED IN CONJUNCTION WITH THE

USER MANUAL SUPPLIED WITH THE OVEN

Installation

Setting Up Information

Handling

Unpacking

• Use suitable means to move the unit;

- For smaller items use two people

- For large items a fork lift, pallet trolley or similar (the forks should reach completely beneath the pallet)

• Check the unit for damage before and after unpacking. If unit is damaged, contact the distributor and manufacturer

• Should any item have physical damage, report the details to the freight company and to the agent responsible for the dispatch within

seven (7) days of receipt. No claims will be accepted or processed after this period

• Remove all protective plastic film, ties and packers before installing and operating

• Clean off any remaining residue from the interior/exterior of the unit using a clean cloth dampened with warm soapy water

WARNING

Improper installation, adjustments, alterations, service or

maintenance can cause property damage, injury or death

IMPORTANT

To be installed only by an authorised service technician

Page 3

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

IMPORTANT

DO NOT install unit under a bench.

Under Bench installation will void warranty

Positioning

• The oven must be installed under an extraction canopy that meets AS 1668.2.

• Have a smooth, level floor which can bear the weight of the appliance at full load

• Have a room temperature above +4°C with a maximum humidity of 70%;

• Comply with the regulations in force in terms of safety in the workplace and the systems;

• Not contain potentially explosive materials or substances;

• Be dedicated to food preparation. In addition, a gas-fired appliance requires, by law, rooms with a surface area and ventilation that are

suitable for the power of the oven and that have a means of externally evacuating flue gases

• Please consult national and local standards to ensure that your unit is positioned and ventilated in accordance with any existing

requirements

• Do not allow cables or other items to rest/hang over the exhaust vents

• Do not install unit under a bench

• No equipment is to be installed/placed on the Service compartment (top of oven) excluding stacked applications using a Stoddart

stacking kit and/or Stoddart Recirculating Hood. The service compartment must be easily accessible. Failure to adhere may add service

costs due to lack of access.

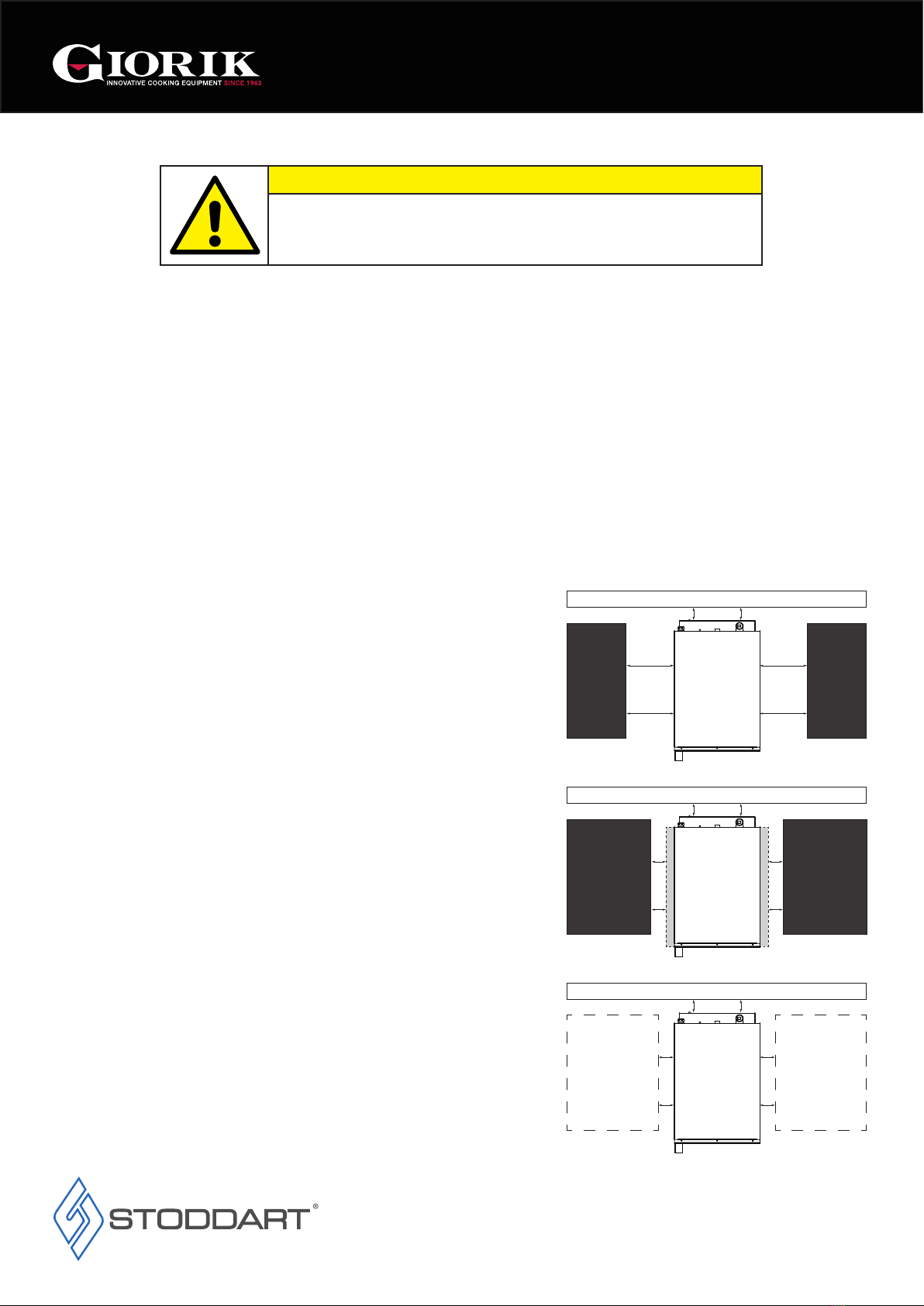

The sides of the Combi oven must have the following minimum clearances:

Heat Source

500mm clearance from another heat source, in order to protect the oven

components.

For distances under 500mm, it is mandatory for Stoddart heat shields to be

fitted (for a minimum distance of 50mm from the surface of the oven). Failure

to adhere to minimum clearances may void the oven warranty.

Non-Heat Source

50mm clearance from a non-heat source to the surface of the oven. Failure

to adhere to minimum clearances may void the oven warranty.

WALL

Heat Shield

Heat Shield

50mm

500mm

500mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

WALL

50mm

50mm

50mm

HEAT

SOURCE

HEAT

SOURCE

OVEN

WALL

50mm

OVEN

50mm

50mm

NON - HEAT

SOURCE

NON - HEAT

SOURCE

General Information

Spacing Heat Source

Heat Source With Heat Shield

Non - Heat Source

Page 4

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

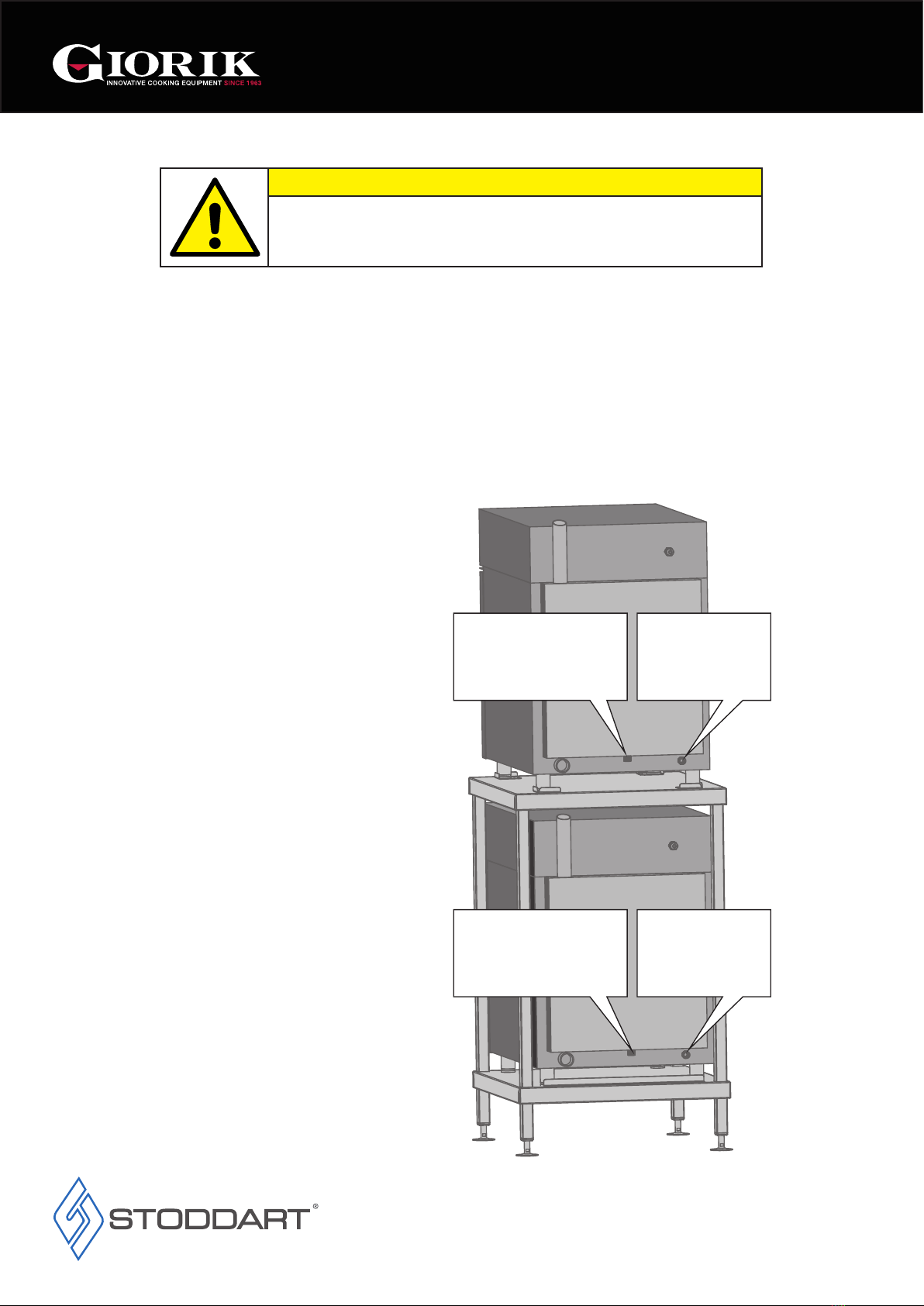

Installation

Using a spirit level, ensure that the stand is level. Adjust the feet height to level. Once levelled place both ovens onto the stand.

Using a spirit level, ensure that both Combi ovens are level. Adjust the feet height to level Combi ovens

Note: When using the 10 tray stacking kit, the 10 tray oven sits directly on the ground. The 10 tray feet must be change to the 150mm feet.

Levelling

IMPORTANT

DO NOT STORE ANY ITEMS BETWEEN THE OVEN AND STAND

THE AIR INTAKE IS LOCATED AT THE BASE OF THE OVEN

DO NOT BLOCK AIR INTAKE

WHEN STACKING A GAS OVEN

THE GAS OVEN MUST BE POSITIONED ON TOP

Page 5

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

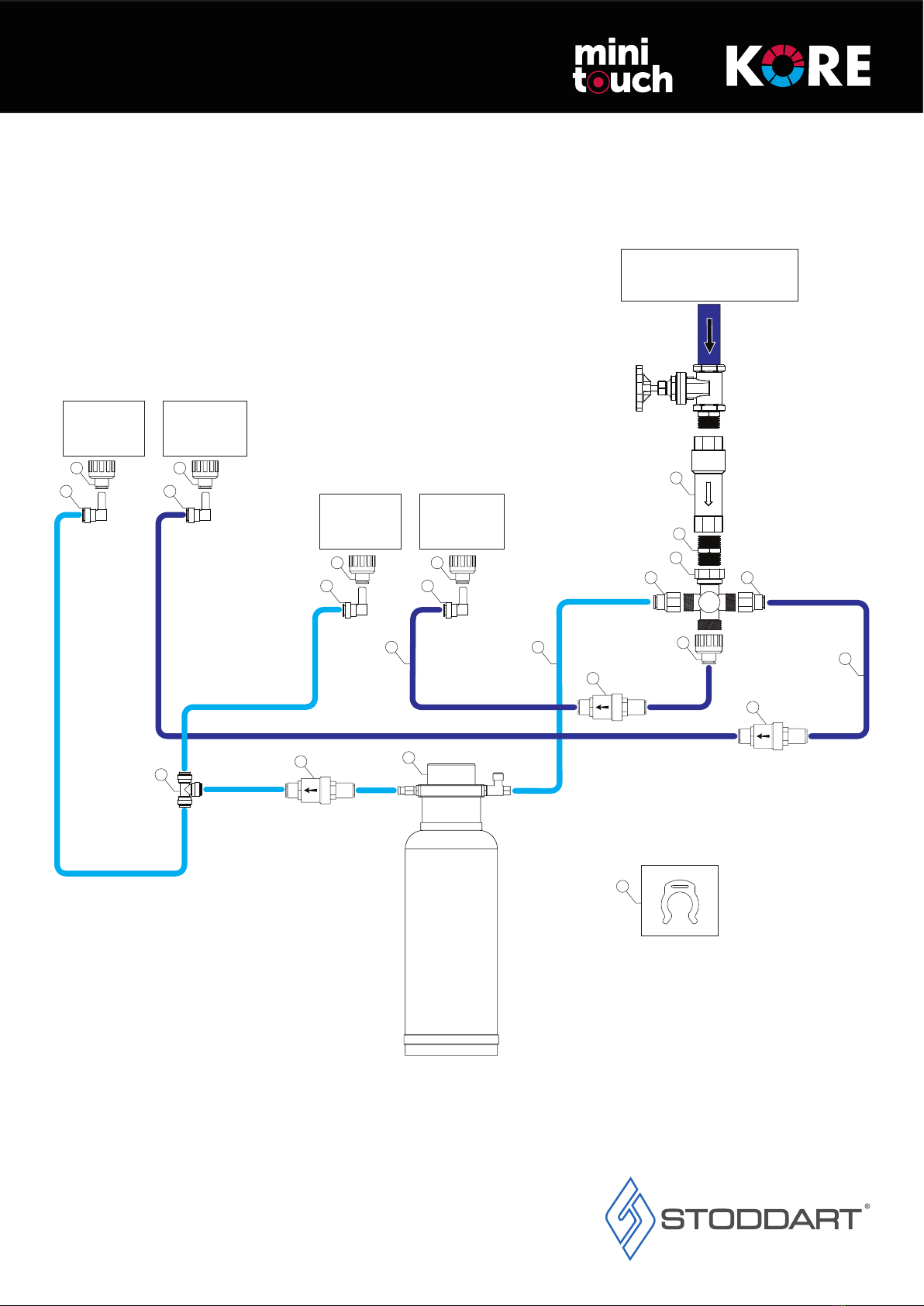

Installation

Water Connection - BWT Filter

IMPORTANT

This oven must be installed in accordance with AS/NZS 3500.1

The Oven must be installed with the supplied Dual Check Valve,

Water Filter and Pressure Limiting Valves

LOWER OVEN

WASH SYSTEM

INLET

LOWER OVEN

STEAM GENERATION

INLET

UPPER OVEN

WASH SYSTEM

INLET

UPPER OVEN

STEAM GENERATION

INLET

• Water connections are labelled on the oven

• Isolation valve must be installed at the water supply outlet

• Water Temperature: Min 10°C, Max 35°C

• Steam Generation: The Combi oven requires filtered water supplied to its steam generation system. Water pressure must be:

- Kore 150-350 kPa (22-51 psi) at oven connection (This is controlled with the supplied PLV)

- Mini Touch 300-350 kPa (43-51 psi) at oven connection (This is controlled with the supplied PLV)

• Wash System: The Combi oven requires unfiltered water supplied to its wash system.

Water pressure must be:

- Kore 150-350 kPa (22-51 psi) at oven connection (This is controlled with the supplied PLV)

- Mini Touch 300-350 kPa (43-51 psi) at oven connection (This is controlled with the supplied PLV)

• Refer to the BWT user manual for filter setup

Supplied Components

(Plumbing Kit / Water Filter Kit)

A. 1 x BWT Filter

B. 1 x Dual Check Valve

C. 1 x 4 Way Manifold

D. 5 x 3/4” BSP To 3/8” Tube Connector

E. 2 x 1/2” BSP To 3/8” Tube Connector

F. 4 x 3/8” John Guest Stem Elbow

G. 3 x Pressure Limiting Valve 300-350 Kpa

H. 1 x Nipple, 3/4” Male

I. 1 x 3/8 Tube (Water)

J. 21 x John Guest Locking Clip

K. 1 x John Guest T section

Page 6

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

UPPER OVEN

WASH

SYSTEM

UPPER OVEN

STEAM

GENERATION

LOWER OVEN

WASH

SYSTEM

LOWER OVEN

STEAM

GENERATION

COLD WATER CONNECTION

WITH ISOLATION VALVE

(EXISTING CONNECTION)

A

J

I

II

K

D

H

C

B

E E

G

G

G

F F

F F

D D

D D

Page 7

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

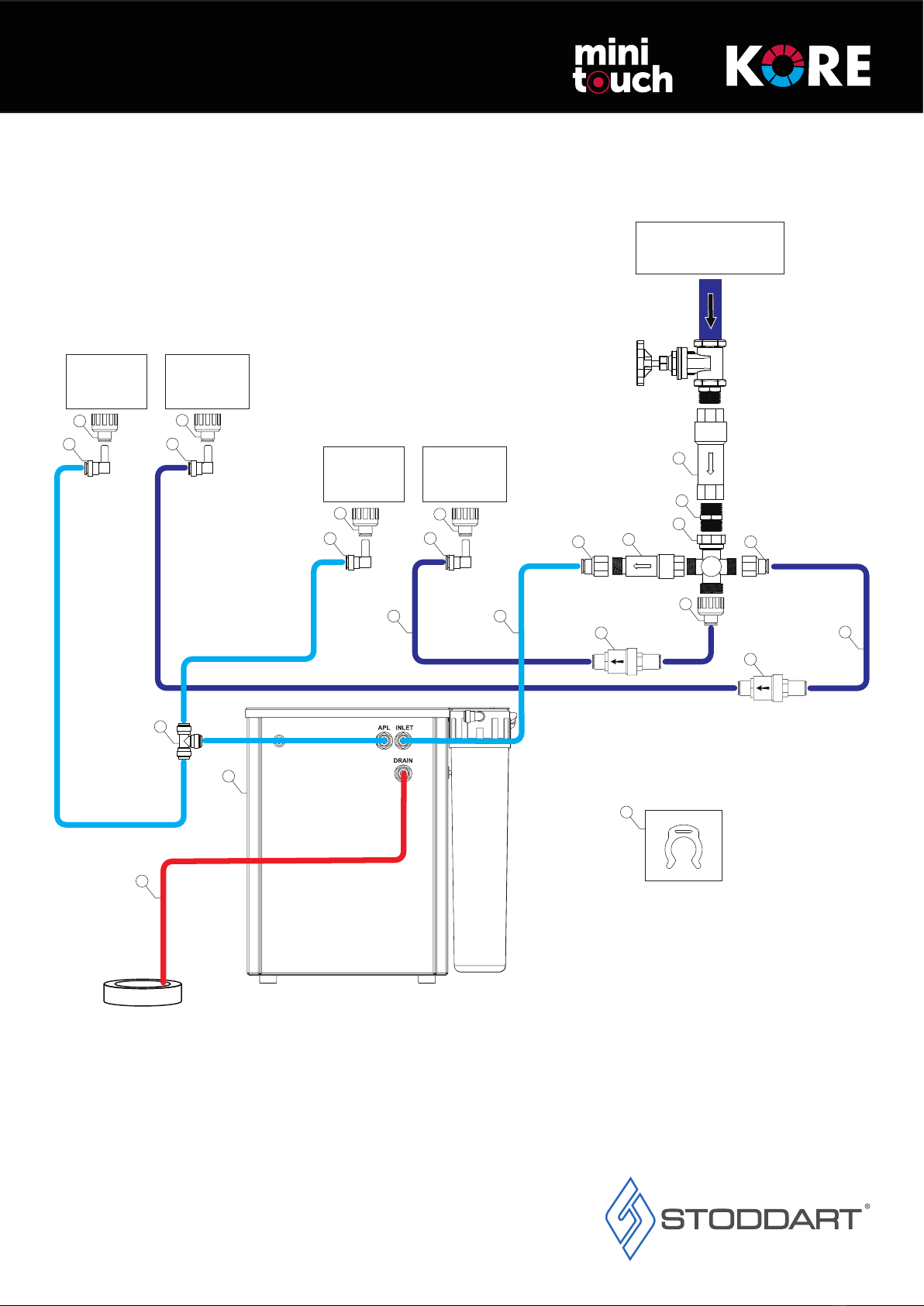

Installation

Water Connection - Reverse Osmosis Filter

Supplied Components

(Plumbing Kit / Water Filter Kit)

A. 1 x Ro Unit

B. 1 x Dual Check Valve

C. 1 x 4 Way Manifold

D. 5 x 3/4” Bsp To 3/8” Tube Connector

E. 2 x 1/2” Bsp To 3/8” Tube Connector

F. 4 x 3/8” John Guest Stem Elbow

G. 2 x Pressure Limiting Valve 300-350 Kpa

H. 1 x Pressure Limiting Valve 350-600 Kpa

I. 1 x Nipple, 3/4” Male

J. 1 x 3/8 Tube (Water)

K. 1 x 1/4 Tube (Drain)

L. 21 x John Guest Locking Clip

M. 1 x John Guest T section

IMPORTANT

This oven must be installed in accordance with AS/NZS 3500.1

The Oven must be installed with the supplied Dual Check Valve,

Water Filter and Pressure Limiting Valves

LOWER OVEN

WASH SYSTEM

INLET

LOWER OVEN

STEAM GENERATION

INLET

UPPER OVEN

WASH SYSTEM

INLET

UPPER OVEN

STEAM GENERATION

INLET

• Water connections are labelled on the oven

• Isolation valve must be installed at the water supply outlet

• Water Temperature: Min 10°C, Max 35°C

• Steam Generation: The Combi oven requires filtered water supplied to its steam generation system. Water pressure must be:

- Kore 150-350 kPa (22-51 psi) at oven connection (This is controlled with the supplied PLV)

- Mini Touch 300-350 kPa (43-51 psi) at oven connection (This is controlled with the supplied PLV)

• Wash System: The Combi oven requires unfiltered water supplied to its wash system.

Water pressure must be:

- Kore 150-350 kPa (22-51 psi) at oven connection (This is controlled with the supplied PLV)

- Mini Touch 300-350 kPa (43-51 psi) at oven connection (This is controlled with the supplied PLV)

• Refer to the RO user manual for filter setup

Page 8

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

K

L

WATER CONNECTION

WITH ISOLATION VALVE

(EXISTING CONNECTION)

UPPER OVEN

WASH

SYSTEM

UPPER OVEN

STEAM

GENERATION

LOWER OVEN

WASH

SYSTEM

LOWER OVEN

STEAM

GENERATION

A

I

JJ

M

D

I

C

B

HEE

G

G

FF

FF

DD

DD

Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Drainage Connection

• 40mm Ø drain kit is supplied with oven to be

used with stacked drain kit. Any modification

or extension to the kit must be able to resist

temperatures up to 100°C

• Plumb supplied waste pipes to the Tundish.

(Waste Kit Supplied)

• Waste pipe must sit 25mm above the Tundish.

• Connect vent extension to the lower oven. Place

the bracket over the vent extension and upper

oven vent, secure vent extension

Page 10

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

www.stoddart.com.au

International

Sales

Tel: +617 3440 7600

Email: [email protected]

Service / Spare Parts

Tel: +617 3440 7600

Email: [email protected]

Email: [email protected]

Service Request

www.stoddart.co.nz

New Zealand Business Number: 6837694

New Zealand

Sales

Tel: 0800 79 1954

Email: [email protected]

Service / Spare Parts

Tel: 0800 935 714

Email: [email protected]

Email: [email protected]

Service Request

www.stoddart.com.au

Australian Business Number: 16009690251

Australia

Sales

Tel: 1300 79 1954

Email: [email protected]

Service / Spare Parts

Tel: 1300 307 289

Email: [email protected]

Email: [email protected]

Service Request

This manual suits for next models

4

Table of contents

Other STODDART Oven manuals