Owner’s Manual #513625 3 SU412 Model Machines

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautionsand operating instructionsinthis manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The la-

bels have been put there to help maintain a safe working

environment.Thelabelshavebeendesignedtowithstand

washing and cleaning. All labels must remain legible for

thelifeofthemachine.Labelsshouldbecheckedperiodi-

callytobesuretheycanberecognizedaswarninglabels.

If danger, warning or caution labels are needed, indicate

thepartnumber,typeoflabel,locationoflabel,andquantity

required along with your address and mail to:

STOELTING, INC.

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

Themachinehasbeenassembled,operatedandinspected

at the factory. Upon arrival at the final destination, the

entire machine must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the machine should

arriveinexcellentcondition.THECARRIERISRESPON-

SIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill

until the machine has been checked for damage. Have

the carrier note any visible damage on the freight bill. If

concealeddamageand/orshortageisfound later,advise

the carrier within 10 days and request inspection. The

customer must place a claim for damages and/or short-

ages in shipment with the carrier. Stoelting, Inc. cannot

make any claims against the carrier.

2.3 MACHINE INSTALLATION

WARNING

Installation must be completed by a qualified

electrician/refrigeration specialist.

Incorrect installation may cause personal injury,

severe damage to the machine and will void fac-

tory warranty.

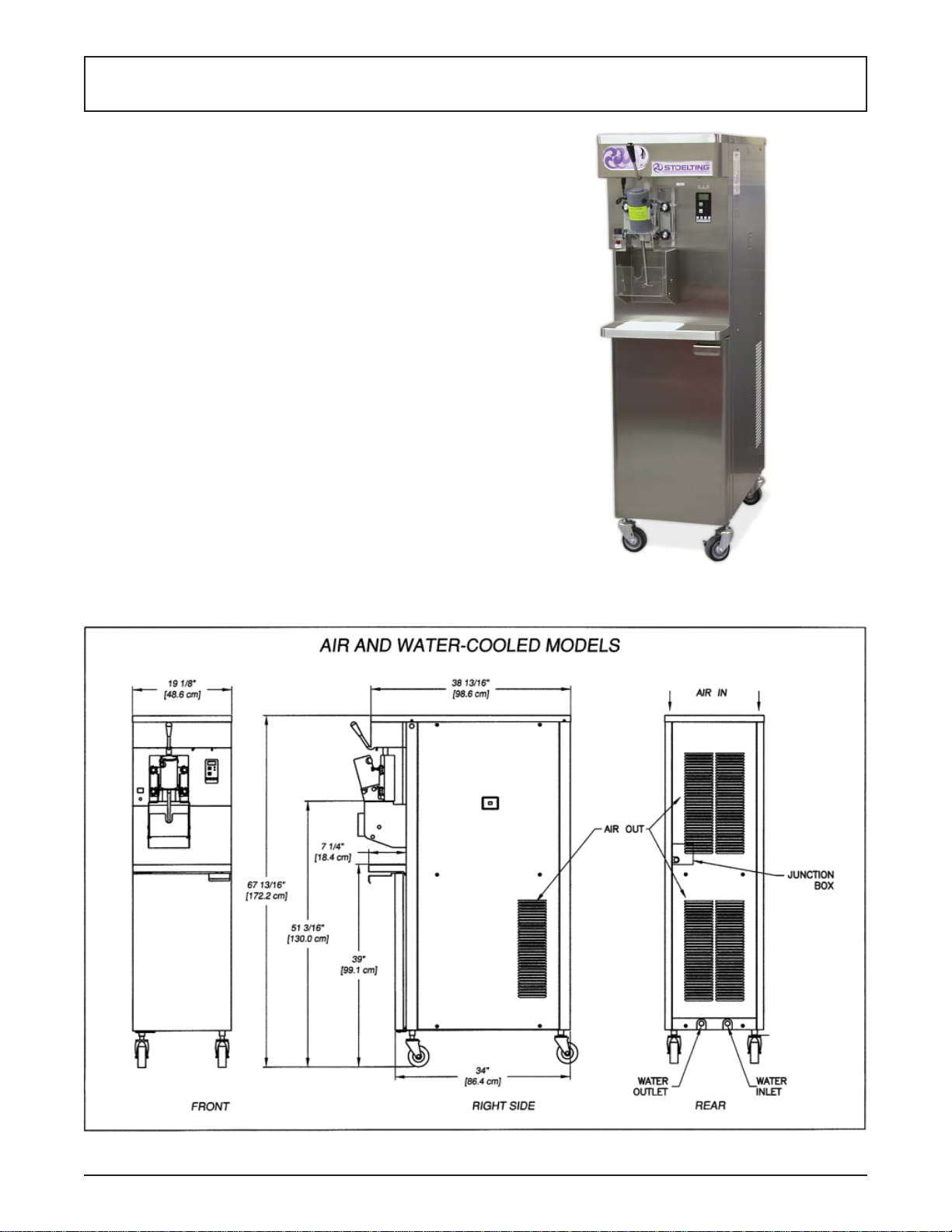

Installation of the machine involves moving the machine

close to its permanent location, removing all crating, set-

ting in place, assembling parts, and cleaning.

A. Uncrate the machine.

B. Install the four casters. Turn the threaded end

intothemachineuntilnothreadsareshowing.To

level,turnoutcastersnomorethan1/4”maximum,

then tighten all jam nuts.

C. The machine must be placed in a solid level

position. NOTE

Accurate leveling is necessary for correct drainage

of freezing cylinder and to insure correct overrun.

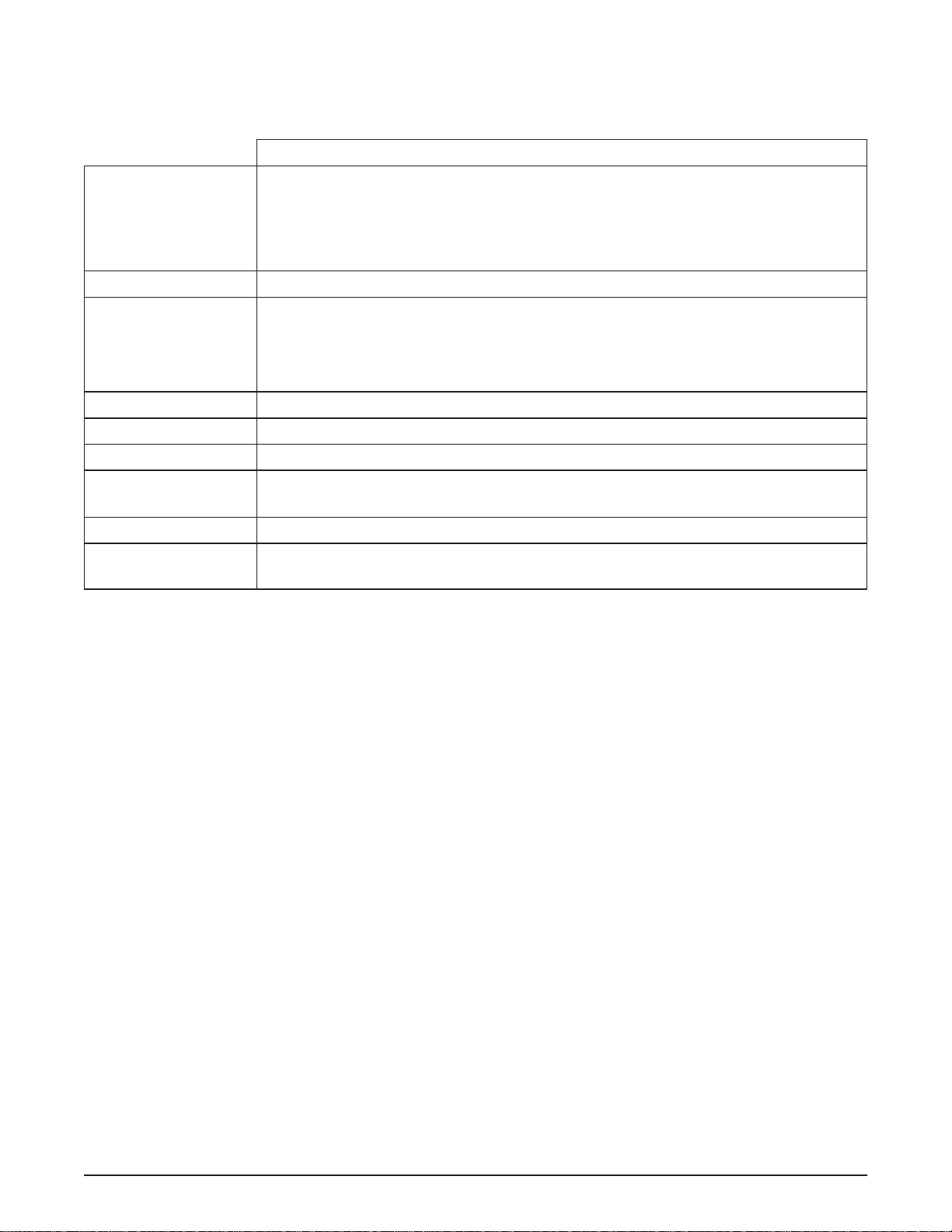

D. Machines with air cooled condensers require a

minimum of 3” (7,5cm) of space on all sides and

10” (25cm) at the top for proper circulation. (Fig.

2-1)

E. Machines that have a water cooled condenser

require 1/2” NPT supply and drain fittings.

2.4 INSTALLING PERMANENT WIRING

To install wiring follow the steps below:

A. Refer to the nameplate on the side panel of the

machineforspecificelectricalrequirements.Make

sure the power source in the building matches

the nameplate requirements.

B. Remove the back panel and the junction box

cover located at the bottom of the machine.

C. Install permanent wiring according to local code.

Figure 2-1 Space and Ventilation Requirements