StoneAge SA 48 User manual

1

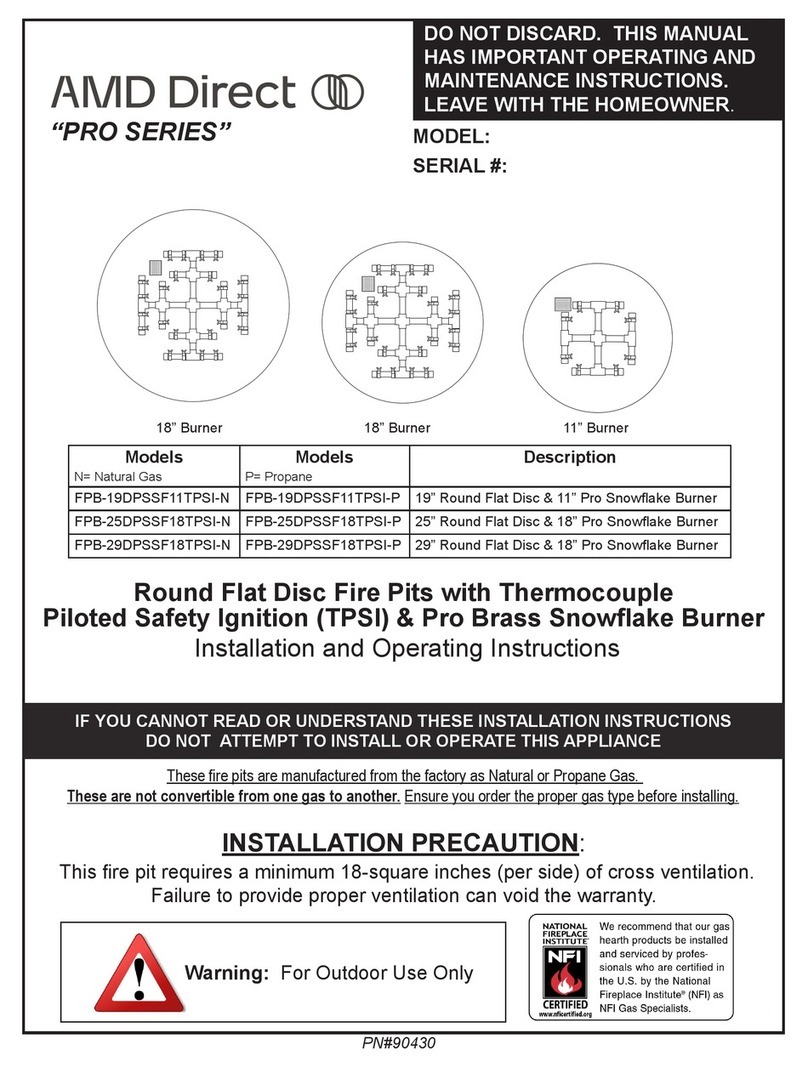

Report 307-F-01b-2

Installation and Operation

Instructions

Stone Age Outdoor Fireplace

1.0 Introduction

The following provides instructions for the installation

and operation of the Stone Age Fireplace, manufactured

by Stone Age Manufacturing, Collinsville, Oklahoma.

Three generations of fireplace knowledge and experi-

ence have gone into the design and construction of the

Standard series fireplaces. Standard Fireplaces are cer-

tified to UL127 for the US, and ULCS610 for Canada.

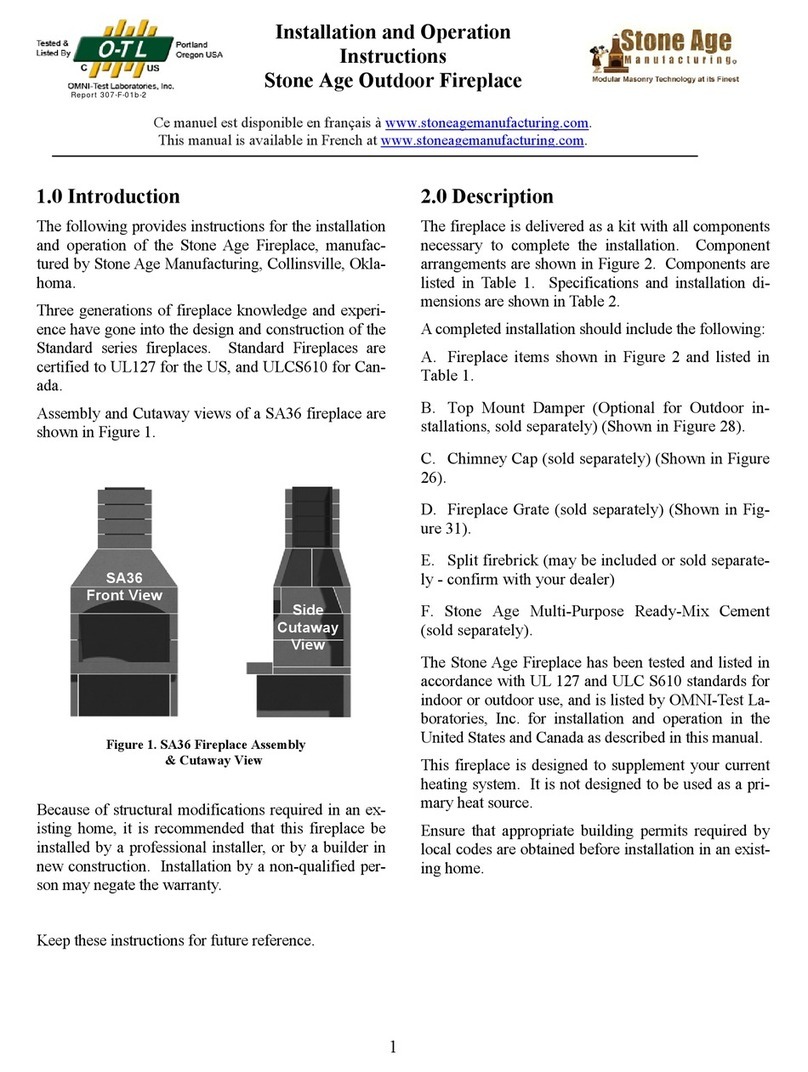

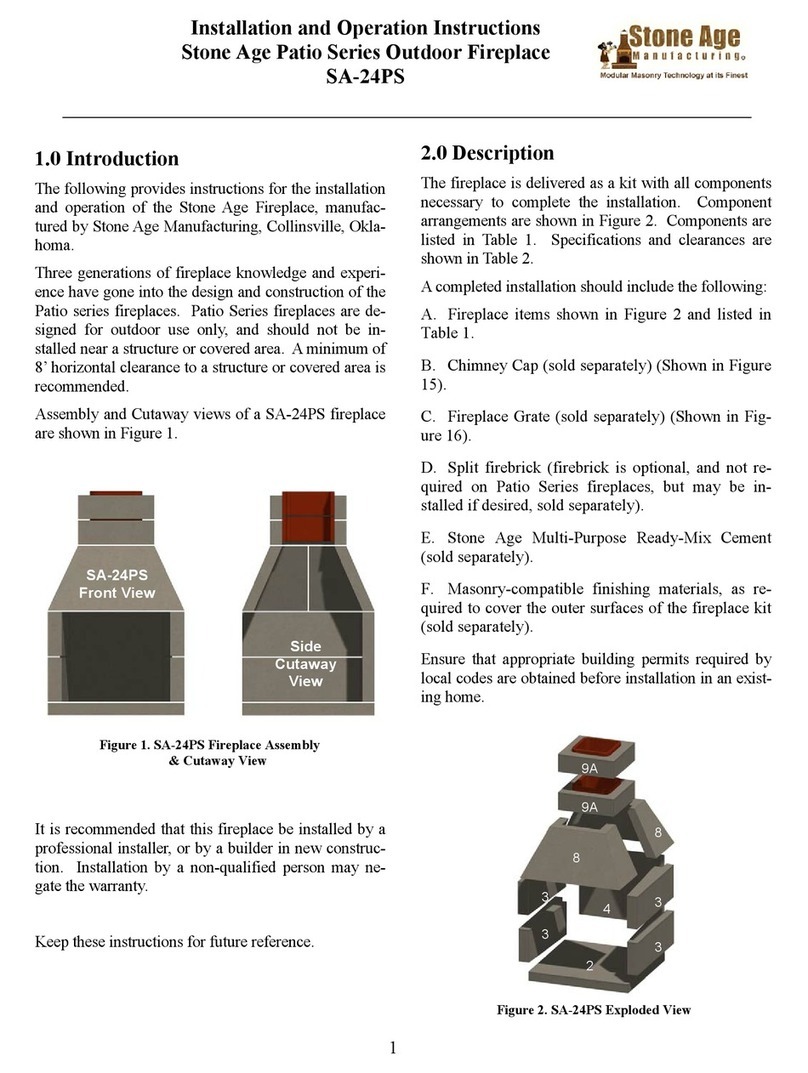

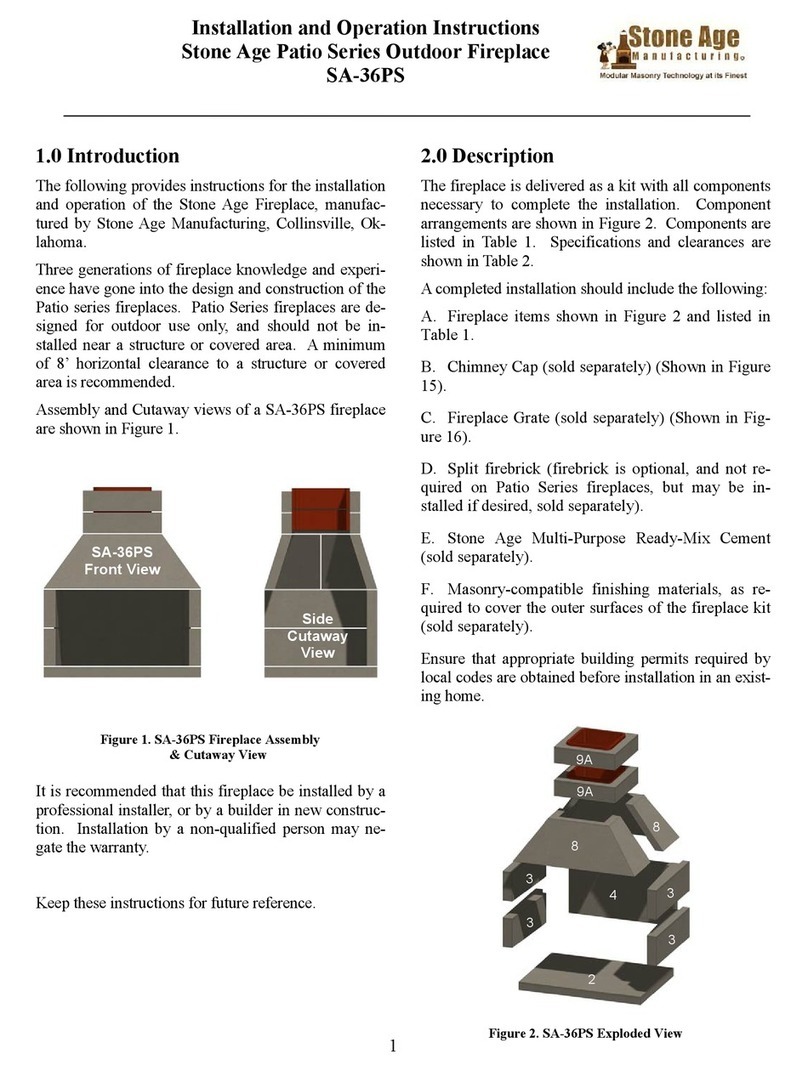

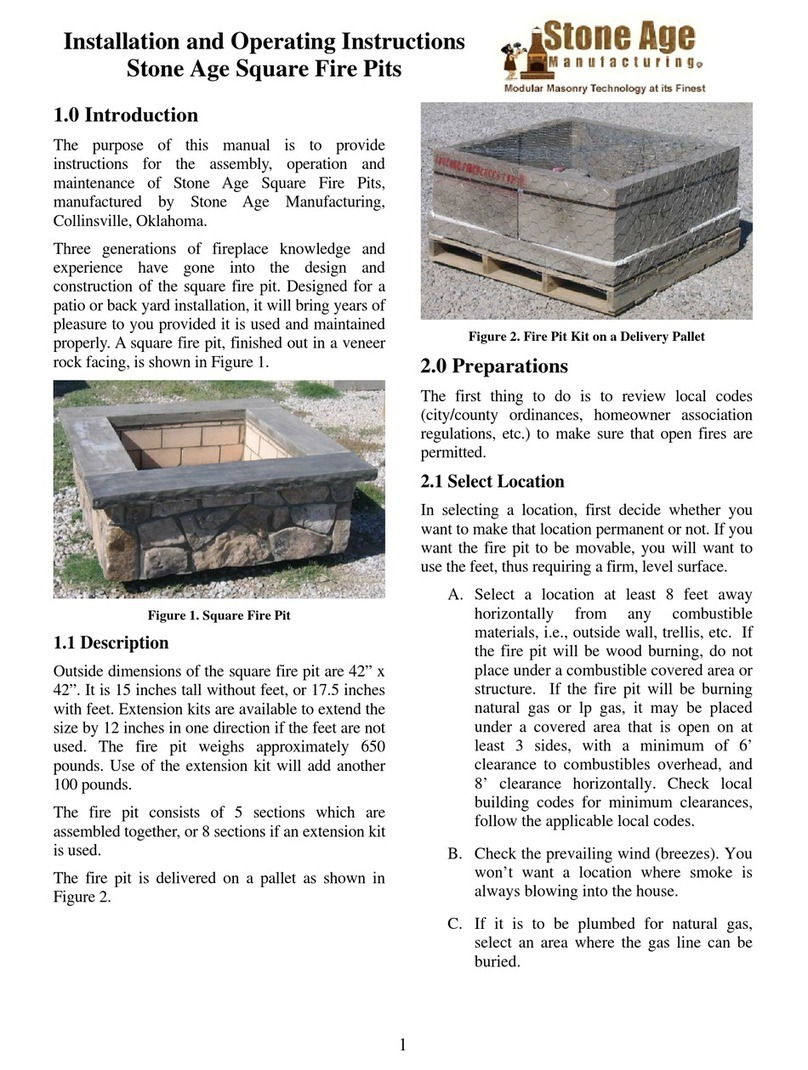

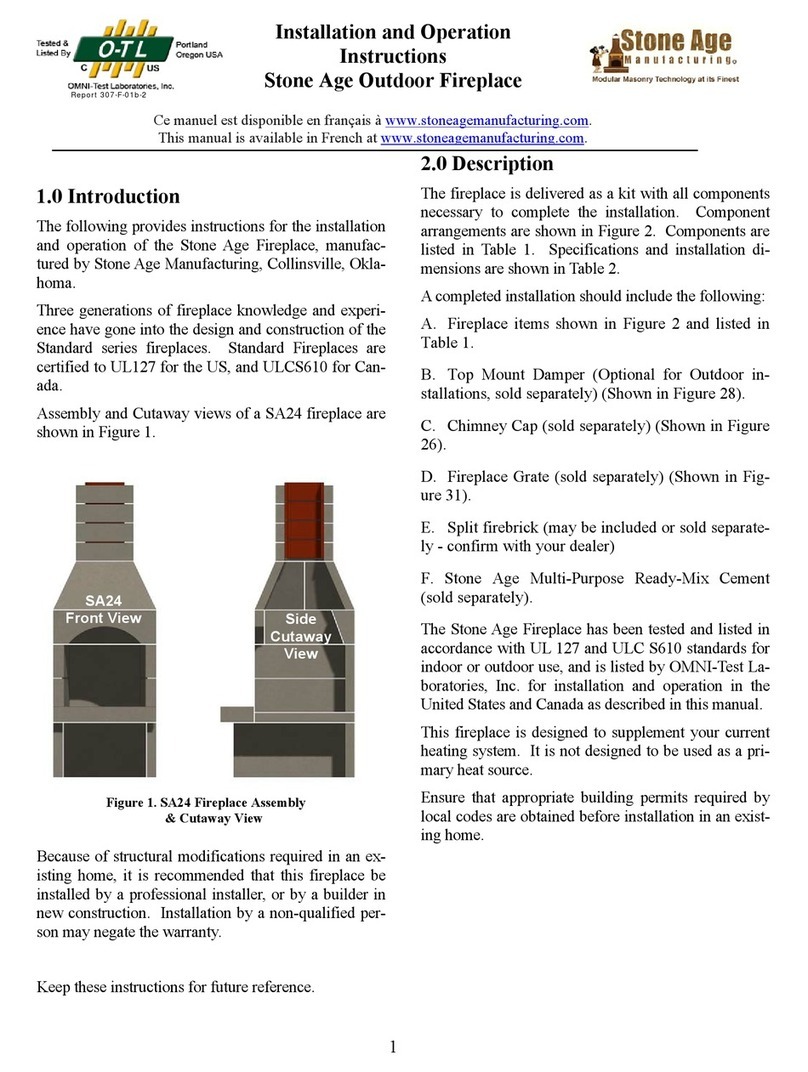

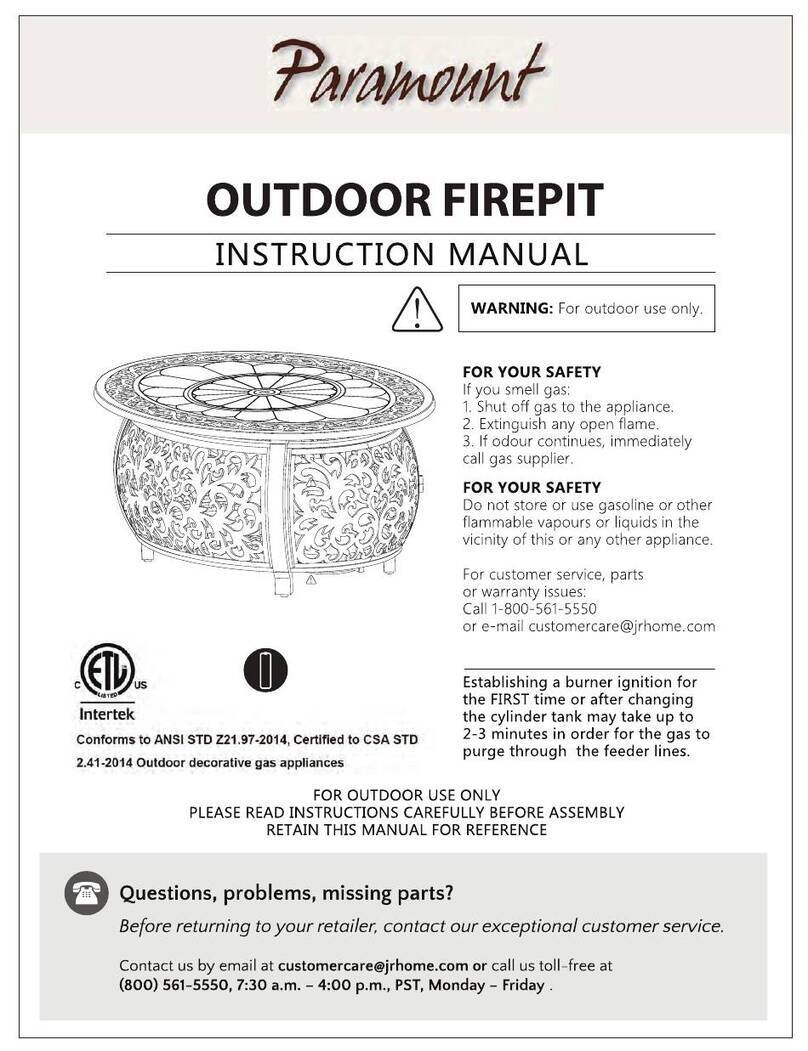

Assembly and Cutaway views of a SA48 fireplace are

shown in Figure 1.

Because of structural modifications required in an ex-

isting home, it is recommended that this fireplace be

installed by a professional installer, or by a builder in

new construction. Installation by a non-qualified per-

son may negate the warranty.

Keep these instructions for future reference.

2.0 Description

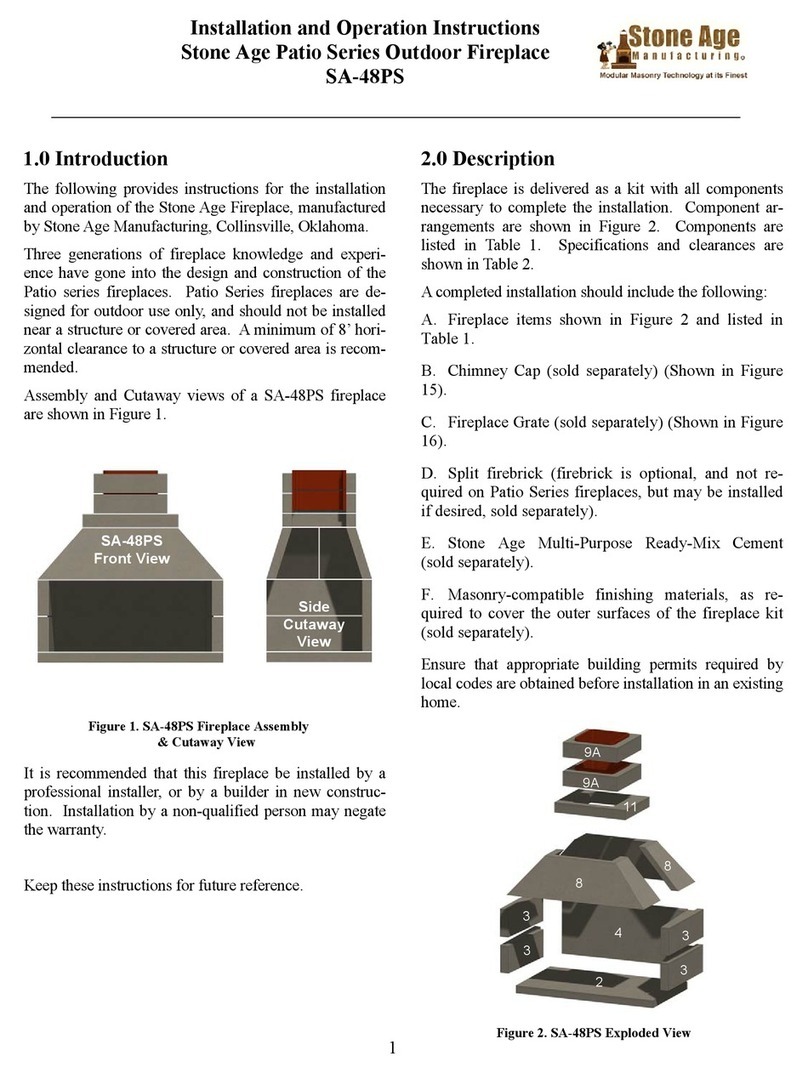

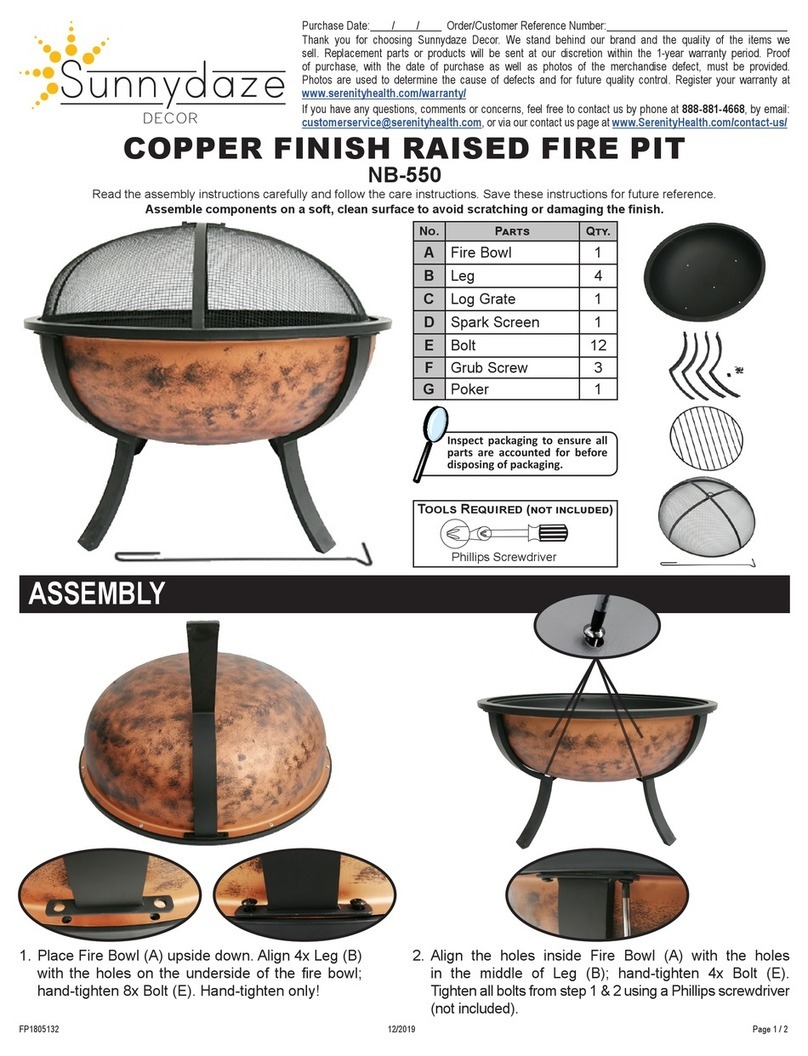

The fireplace is delivered as a kit with all components

necessary to complete the installation. Component ar-

rangements are shown in Figure 2. Components are

listed in Table 1. Specifications and installation dimen-

sions are shown in Table 2.

A completed installation should include the following:

A. Fireplace items shown in Figure 2 and listed in

Table 1.

B. Top Mount Damper (Optional for Outdoor instal-

lations, sold separately) (Shown in Figure 28).

C. Chimney Cap (sold separately) (Shown in Figure

26).

D. Fireplace Grate (sold separately) (Shown in Fig-

ure 31).

E. Split firebrick (may be included or sold separately

- confirm with your dealer)

F. Stone Age Multi-Purpose Ready-Mix Cement (sold

separately).

The Stone Age Fireplace has been tested and listed in

accordance with UL 127 and ULC S610 standards for

indoor or outdoor use, and is listed by OMNI-Test La-

boratories, Inc. for installation and operation in the

United States and Canada as described in this manual.

This fireplace is designed to supplement your current

heating system. It is not designed to be used as a pri-

mary heat source.

Ensure that appropriate building permits required by

local codes are obtained before installation in an exist-

ing home.

Ce manuel est disponible en français à www.stoneagemanufacturing.com.

This manual is available in French at www.stonea

g

emanufacturin

g

.co

m

.

SA48

Front View Side

Cutaway

V

iew

Figure 1. SA48 Fireplace Assembly

& Cutawa

y

View

2

Table 1. Fireplace Components

Item Description 48”

1 Riser Legs 18” x 40”

1A Riser Leg-Cross 18” x 51”

2 Base Plate 33” x 58”

3 Sidewall 11” x 33”

4 Back Plate 22.5” x 52”

5L/5R Slanted Sidewall 11” x 26”

6 Back Header 11” x 58”

7A/7S Lintel, Arch/Straight 11” x 58”

8 Throat 11.5” x 30”

at top

9A Flue (Note 2) 23” x 23” x 6”

10 Hearth 11” x 5” x 58”

11 Throat to Flue Adapter 23” x 30”

Note 1: Item numbers refer to component numbers in Figure

1.

Note 2: Flue sections are available but not provided in suffi-

cient quantity to reach a height of 16 feet. Flue sections

must be purchased separately.

Note: Drawings of the fireplace components,

with dimensions, are shown on page 15.

2.1 Specifications

Table 2: Clearances (See Figure 3)

Item Clearance Figure 3

Reference

Sidewall to Opening 18”

Top Trim to Opening 17” A

Side Trim to Opening 3”

Mantle to Opening 25” B

Floor to Opening 7”

Front Hearth Extension 24” C

Side Hearth Extension 12” D

Opening to Combustibles 48”

Minimum Ceiling Height 7’6”

Chimney flue (All Sides) 2”

Chimney Height from floor 16’

Note 1. This Fireplace is intended for use with solid wood fuel

or vented gas logs

Note 2: This fireplace has not been tested for use with glass

doors. To reduce the risk of fire or injury, do not install glass

doors.

Note 3: Do not use fireplace insert or other products not speci-

fied for use with this model. Use a fireplace grate when burning

wood.

Note 4: This fireplace has not been tested with an unvented gas

log. Do not install an unvented gas log set into this fireplace.

Note 5: Clay flue liners installed in flue section (item 9A, Figure

2) meet the specifications of ASTM Section C315-02.

Note 6: Make sure installation complies with local building

codes.

Note 7: Thermal Floor Protection of ½ “ of k=0.84 thermal

protection

Note 8: Floor under unit must be non-combustible to earth

Note 1: This Fireplace intended for use with solid wood fuel

or vented gas logs.

CAUTION: When using this appliance, the fireplace

damper (if present) must be set in the fully

open position.

Note 2: This fireplace has not been tested for use with glass

doors.

Note 3: Do not use fireplace insert or other products not

specified for use with this model. Use a fireplace grate when

burning wood.

Note 4: Clay flue liners installed in flue section meet the

specifications of ASTM Section C315-02.

Note 5: Ensure installation complies with local building

codes.

1

3

5R

2

3

3

3

1A

4

9A

5L 6

7A

8

8

10

1

9A

9A

9A

Figure 2. Fireplace Components

11

3

2.2 Installation of Additional Equipment

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED FOR USE WITH

DOORS. TO REDUCE THE RISK

OF FIRE OR INJURY, DO NOT

INSTALL GLASS DOORS.

A. Do not install a fireplace insert unless it is tested

with this fireplace.

B. Cutting or drilling a hole into the floor or walls for

gas supply for a vented decorative gas appliance (log),

fresh air venting, or an ash dump, is acceptable.

C. If a decorative gas appliance is installed, it must be

installed in accordance with the National Gas Fire

Code, ANSI Z223.1.

D. It must incorporate an automatic shutoff device.

E. Installation must comply with the Standard for

Decorative Gas Appliances in Vented Appliances,

ANSI Z21.60 (1991) or American Gas Association

draft requirements for Gas-Fired Log Lighters for

Burning Fireplaces, Draft No. 4 dated August 1993.

3.0 Installation of the Fireplace

WARNING: DO NOT USE SUBSTITUTE

MATERIALS IN THE ASSEMBLY,

INSTALLATION OR OPERATION

OF THIS FIREPLACE. TO DO SO

WILL VOID THE WARRANTY

AND MAY RESULT IN FIRE AND

PERSONAL INJURY.

It is most important that the Stone Age fireplace be in-

stalled according to the following instructions. It is

also important that local building codes be consulted

and followed. Improper installation could result in:

• Overheating, leading to fireplace failure

• Leakage of rainwater through and around the

chimney

• Cracks and settling because of poor founda-

tions

• Emission of smoke, sparks and gases into the

living area

• Combustion of materials adjacent to the fire-

place.

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED WITH AN

UNVENTED GAS LOG SET. TO

REDUCE THE RISK OF FIRE OR

INJURY, DO NOT INSTALL AN

UNVENTED GAS LOG SET INTO

THIS FIREPLACE.

Do not install this fireplace in a manufactured or mo-

bile home.

3.1 Preparations

Select a location in the home plans or outdoor living

area where all the minimum distances, as shown in Ta-

ble 2 and Figure 3 can be met. Proceed as follows.

Numbers in ( ) are item numbers from Table 1 and Fig-

ure 2. Ensure the base on which the fireplace is to be

installed is a solid and level foundation and is com-

posed of non-combustible material, such as concrete.

Due to varying climates, soil conditions, building

codes, construction methods and materials in different

geographical regions, Stone Age recommends installers

review local building codes, consult with local building

officials and/or a structural engineer before beginning

the construction of any Stone Age product.

Pad or footings for outdoor installations should be a

monolithic pad constructed of steel reinforced concrete.

Minimum footing specifications for fireplaces built on

stable soil, with overall height not exceeding 10 feet,

are listed in Table 3. Locations with unstable soil may

Figure 3. Clearances (Use with Table 2)

4

require a deeper footing or the addition of piers, to

reach more stable subsoil or bedrock. Areas with cold-

er climates may also require deeper footings or piers

that reach below the frost line to prevent frost heaving.

Piers should include steel reinforcement that extends

into the footing above. See Figure 4.

For taller applications, consult with an engineer to de-

termine the structural requirements based on the overall

height, and the weight of fireplace, chimney, and finish

materials. If custom hearths or additional masonry

structure is to be attached to the fireplace kit, the foot-

ing dimensions should be adjusted to include these cus-

tomizations.

If local building code exceeds the manufacturer’s speci-

fications for footings, follow the local code.

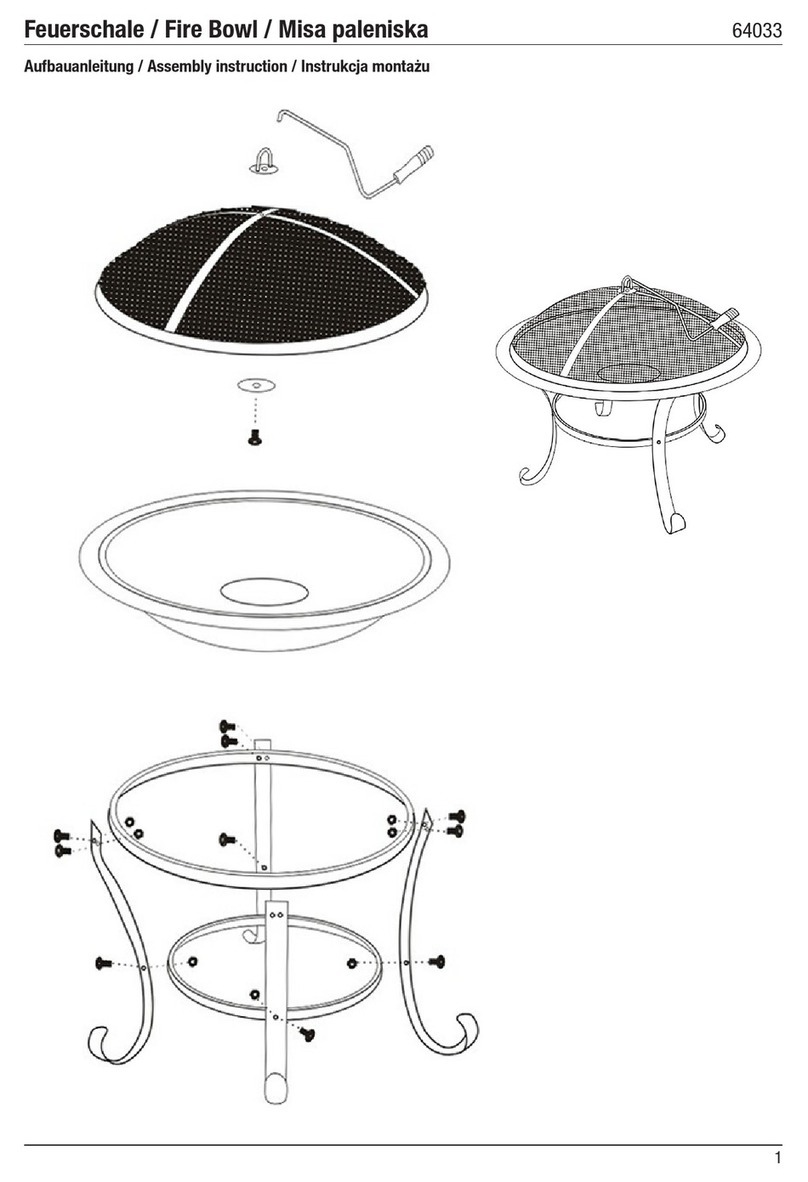

Table 3. Minimum Footing Specifications

Minimum Requirements for Footing 48”

Thinner Finishes-

Fabricated Stone, Stucco, Stain or Tile

A

B

C

8” - 10”

48”

64”

Thicker Finishes-

Full Veneer Natural Stone or Brick

A

B

C

18” - 24”

54”

70”

See Figure 5.

Footing requirements for indoor installations should be

determined based on local building code. Consult with

a structural engineer to determine the footing require-

ments based on the overall height, and the weight of

fireplace, chimney, and finish materials. If custom

hearths or additional masonry structure is to be attached

to the fireplace kit, the footing dimensions should be

adjusted to include these customizations.

Use Stone Age’s Multi-Purpose Ready-Mix, or another

high temperature fire clay or refractory cement suitable

for indoor or outdoor use, and mix according to manu-

facturer’s instructions.

Once the fireplace is constructed you must wait at least

28 days before building a fire to give adequate time to

cure. This will provide ample time for any water resi-

due to evaporate, eliminating the adverse reaction of

the combination of water and fire.

Stone Age products are designed to be assembled using

a 3/8” fully bedded mortar joint for the kit pieces. Do

not “butter the edges” of the kit pieces.

If the unit is to be installed indoors, do not use the Riser

Legs (items 1 and 1A, shown in Figure 2 and Table 1).

Instead, install the fireplace on a solid base, such as a

cement pad or concrete blocks. Two courses of 8” tall

block will be slightly shorter than the riser legs of the

kit.

WARNING: DO NOT USE RISER LEGS FOR

AN INDOOR INSTALLATION. IN

THIS INSTALLATION, THE VOID

BELOW THE FIREBOX COULD

INADVERTANTLY BE USED FOR

THE STORAGE OF

COMBUSTIBLE MATERIALS,

WHICH COULD CREATE A FIRE

HAZARD.

Figure 4. Footing with Piers - Cutaway View

Figure 5. Footing with Piers

A

B

C

Front

Piers

5

3.2 Assembly of Components

Components that become broken during shipment and

handling can be mortared back together providing the

breaks or cracks are clean and the original alignment

can be maintained. Components broken into multiple

pieces must be replaced.

If this is your first Stone Age installation, it is suggested

that you first assemble the components without mortar

to familiarize yourself with how the components fit

together. See Figure 2.

During the actual assembly with mortar, ensure each

layer of the kit is plumb, level, and square before pro-

ceeding to the next step of the assembly.

A. For Indoor installations, determine the height

above the floor you want to place the base plate (2).

The base plate, plus firebrick, will be approximately 4

1/2 inches thick. Mortar and set concrete blocks into

place to reach the desired height. Ensure the block

base is level and square. Set the base plate (2), ensur-

ing it is level and square. See Figures 6 & 7.

B. For Outdoor installations, align and set a Riser

Leg (1) and the Cross Leg (1A) on the footing, ensur-

ing they are plumb and level. See Figure 8.

C. Install the second Riser (1), ensuring it is plumb,

level and square. See Figure 9.

D. Set the base plate (2), ensuring it is level and

square. See Figure 10.

Figure 8. Riser Leg & Cross Leg

1

2

1

Figure 9. Riser Legs & Cross-Leg

Figure 10. Base Plate

1A

2

Base Plate

Concrete Block

Base

Figure 6. Block Base

For Indoor Use

Figure 7. Kit Base Plate

6

Note 6: From Step E to Step Q, the installation

procedure will be the same for indoor or outdoor

applications.

E. Install the lower sidewalls (3), ensuring they are

level and square. See Figure 11.

F. Install the middle sidewalls (3), ensuring they are

level and square. See Figure 12.

G. Install the back plate (4). See Figure 13.

H. Install upper sidewalls (5L) and (5R), ensuring

the correct piece is placed in position. The correct

position is when the inner wall, outer wall and front

are parallel with the middle wall pieces. Place each so

the front is set back 3½ inches from the front of the

middle wall piece below. See Figures 14 & 15.

3

3

5L

Figure 11. Lower Sidewalls

Figure 15. Upper Sidewalls

Figure 12. Middle Sidewalls

Figure 13. Back Plate

5R

3

3

4

5L 5R

Figure 14. Upper Sidewalls –Top View

7

I. Install Back Header (6). See Figure 16.

J. Line the firebox, using split firebrick and 1/4-inch

mortar joints. Install firebrick on the floor first, with

1/4-inch of Stone Age Multi-Purpose Ready-Mix or

other high temperature mortar. See Figure 17.

K. Install firebrick on the back wall, with the brick

laid on edge. See Figure 18.

K. Install firebrick on the side walls, with the brick

laid on edge. The brick lay up on approximately 1/3

of the upper sidewall, and a notch should be cut in the

front brick on each side, to allow them to clear the

front lintel piece (to be installed later). See Figure 19.

Figure 19. Sidewall Firebrick

Figure 18. Back Wall Firebrick

Fi

g

ure 17. Floor Firebrick

6

Fi

g

ure 16. Back Header

8

L. Install the front lintel piece, (7A, for arched lintel,

as shown) or (7S, for straight lintel kits). See Figure

20.

M. Install the tapered front and rear throat pieces (8).

See Figure 21.

N. Install the flue adapter piece (11). See Figure 22.

O. Install the first Stone Age masonry chimney sec-

tion (9A), with the tile extending upward. Fill the

void on the bottom with mortar to create a smooth

transition. See Figure 23.

7 A

8

8

9A

Figure 20. Front Lintel

Figure 21. Throat Pieces

Figure 22. Flue Adapter

Figure 23. Chimney Flue

11

9

P. Install the remaining chimney sections (9A), fully

bedding each piece in mortar, and filling in the gap

between the clay tiles in each section. Parge the joints

to create a smooth transition between each chimney

section. Note that if a tile is chipped or slightly out of

square, it may be used as long as it the joints are filled

and smoothed with high temperature mortar. See

Figure 24. If additional chimney is required to

penetrate a roof or structure, refer to Section 4.0

for more detailed instructions.

Q. Install the hearth piece (10) if using this compo-

nent, and any hearth extension. See Figure 25.

R. Ensure the Table 2 and Figure 3 clearances and

distances are maintained. Ensure that the hearth and

flooring under and in front of the hearth are made of

fully non-combustible materials, not just a non-

combustible floor covering. When the hearth installa-

tion is complete, if the chimney complete and is not

continuing through a roof or structure, you are ready

to install the exterior finish. If the chimney will be

continuing through a roof or structure proceed to Par-

agraphs 4.0 and 4.1 before beginning the finish appli-

cation.

If installing a mantel and side trim, particularly if it is

wood or other combustible materials, ensure the min-

imum distances shown in Table 2 and Figure 3 are

met.

9A

9A

Figure 25. Hearth

Figure 24. Chimney Complete

9A

10

10

3.3 Exterior finishing

The exterior of the fireplace may be finished in any

masonry-compatible material. Mantle and exterior ve-

neers may be fabricated stone, thin veneer or full bed

depth natural stone, tile, brick or stucco.

If the exterior finish will be stucco, stain, tile or manu-

factured thin stone, wrap the outside of the firebox with

metal lathe. Attach metal lathe to the firebox using

concrete nails, tapcons, masonry or concrete anchors.

Natural stone veneers (whether full bed depth or thin

veneer), full size brick, concrete pavers, CMU block,

etc., do not require metal lathe.

Ensure the same refractory mortar used to build the kit

is used to install these materials.

4.0 Installation of Chimney Through a

Roof or Structure

A. The chimney is completed by stacking as many

flue sections as necessary to reach the desired chimney

height. Chimney plumbing can either be straight

through the ceiling and through the roof, or if the fire-

place is installed on an outside wall, the chimney can

be external to the house. When needed, offset blocks

can be used for the chimney and should be engineered

to structurally support the offset with CMU or custom

fabricated steel posts and/or angle iron capable of sup-

porting the weight and height of the chimney. Never

exceed more than a 30 degree angle when offsetting a

chimney.

B. If chimney exit opening does not already exist lo-

cate the point where the chimney will exit the roof by

plumbing down to the center of the fireplace chimney.

Drive a nail into the roof to mark the center.

C. Measure to all sides of the nail and mark the re-

quired opening, and then cut a hole in the roof. Re-

member that the hole is measured on the horizontal,

and then projected to the roof. The hole may then be

larger, depending on the pitch of the roof. See Figure

26.

D. Frame the opening in the roof, maintaining the

required minimum 2” clearances to combustibles

around the chimney. See Table 2. When the chimney

passes through a ceiling to an upper floor, make sure

the 2-inch clearance is maintained with framing where

it passes through the ceiling. Exterior veneer attached

directly to the chimney measuring 2” or more is ac-

ceptable for needed clearance.

WARNING: DO NOT PACK REQUIRED AIR

SPACES WITH INSULATION OR

OTHER MATERIALS.

E. Continue to add flue sections, extending the

chimney through the roof.

F. As the chimney extends through the attic to the

roof, attach securing straps to rafters and joists to pro-

vide stability if required by local building code.

G. Install roof flashing appropriate to the roof pitch.

H. At the top of the chimney, use mortar to create a

cap, sloping away from the clay flue and running out

to the edge of the finish material, to assist with water

drainage. Install the chimney cap following instruc-

tions provided. This will protect the chimney from

rain, birds, animals and leaves. See Figure 27.

Figure 26. Roof Penetration

11

Note: If installing a damper, refer to Paragraph 4.2,

and install the damper before installing the chimney

cap.

4.1 Height of Chimney

Figure 28 illustrates the proper height of the chimney

top. Correct height depends on the chimney’s location

on the roof and distance from the peak of the roof. Sur-

rounding trees, other buildings and hills may also be a

consideration.

If the chimney top is not high enough, unusual

downdrafts may occur, resulting in undesired smoke

spillage. For a more thorough explanation of the figure

27 illustration, this is the traditional 2/10 rule. The cen-

ter of your chimney should be a minimum of two feet

higher than any roof or projection within ten feet hori-

zontally from the chimney center. This means the

chimney does not have to extend above the peak of the

roof if the peak is more than 10’ away horizontally.

Once the chimney is ten feet away and extended two

feet above roof structure at that distance, the height is

sufficient, but it should never be less than three feet

taller than the point where it penetrates the surface of

the roof.

4.2 Installing a Damper

A. If installing a damper with this model Stone Age

fireplace, use a top-mount damper, and follow the

instructions included with the damper. Properly ori-

ent the taller side of the damper with the prevailing

winds in your area. See Figure 29.

B. Connect the pull cable at the cable guide of the

damper and drop through the chimney.

C. Install bracket towards the front of the firebox

wall, about 20 inches above the firebox floor. The

bracket will capture the damper operating cable.

Use a ¼” masonry bit to avoid cracks in the

firebrick. See Figure 30.

Figure 27. Mortar Cap and Chimney Cap

Figure 28. Chimney Height

Prevailing Wind

Cable

Adhesive

Figure 29. Install Top-Mount Damper

Bracket &

Anchors

Figure 30. Install Bracket & Anchors

2’ Higher

Chimney Must be at Least 2’ Taller

Than Anything Within a 10’ Radius

10’ Radius

Chimney Must at Least 3’ Above

The Roof Penetration Point

3’ Above

12

D. Insert the pull cable through the bracket and

adjust the length per damper manufacturer’s instruc-

tions. Attach handle assembly to the bracket and

check damper for proper operation. See Figure 31.

5.0 Operating Instructions

5.1 Safety Precautions

A fireplace can bring many hours of enjoyment, com-

fort and warmth if operated and maintained properly.

Certain safety precautions must be observed to elimi-

nate the dangers associated with fire and provide a sat-

isfactory, smoke free fire.

A. When burning wood use solid, seasoned wood on-

ly. Do not use scrap wood or artificial wax based

logs, treated coal or woods dipped in pine tar or pitch.

B. Never use gasoline or other combustible liquids

when starting a fire.

C. Keep the chimney damper open while burning a

fire. Do not interrupt air flow. Ensure sufficient air is

present to support combustion. The manufacturer of

this fireplace is not responsible for interior smoke

resulting from lack of combustion air.

CAUTION: WHEN USING THE DECORATIVE GAS

APPLIANCE (VENTED GAS LOGS); THE

FIREPLACE DAMPER MUST BE SET IN

THE FULLY OPEN POSITION.

D. Keep a screen in front of the fireplace except

when tending the fire.

E. Keep combustible furniture/pillows at least four

feet from the opening.

F. Never leave the fire unattended.

G. Be extremely careful when adding wood and han-

dling fireplace tools. Never throw, kick or by any

other means force wood into the firebox as this could

damage the firebrick and fireplace walls that could

result in permanent damage and void the warranty.

Stress cracks from thermal cycling are normal.

H. Do not alter this fireplace to the extent that it

would jeopardize the structural integrity of the fire-

place. Drilling or cutting a hole for a gas line, fresh

air vent or ash dump is acceptable. Use only Stone

Age authorized equipment with this fireplace.

5.2 Selection of Wood

Use cured wood logs only. Scrap wood produces

sparks. Treated wood, coal, or woods dipped in pine tar

should not be used because they may leave a combus-

tible residue in the fireplace and chimney.

Use of seasoned wood is preferred.

The amount of heat available from logs will depend on

the type of wood, its dryness, quantity of wood and the

size of the logs. Ten pounds of twigs will produce as

much heat as a 10 pound log, but will produce it much

faster because the air supply is more available.

5.3 Softwood vs. Hardwood

Wood is divided into two classes, hard and soft woods.

Each has a use in a fireplace and each has advantages

and disadvantages.

The hardwood category includes such woods as oak,

walnut, birch, elm and maple. Softwoods include pine,

fir, cedar and spruce.

Selection of wood depends on the type of fire you

want. Softwoods are good to offset a morning chill

because the fire develops faster. Hardwoods are prefer-

able for a slower burning and uniform heat output.

Softwoods contain a highly flammable resin that will

leave creosote soot in the chimney flue. This often re-

sults in sparking. Burning softwood exclusively will

require more frequent inspection and cleaning of the

chimney.

Experienced fire builders often use small amounts of

softwood kindling and newspaper when starting a split

hardwood log fire.

Figure 31. Bracket and Handle Assembly

Handle

Assembly

13

5.4 Seasoned Wood

Most freshly cut “green” wood will not burn well and

will smoke. The pressure of moisture and resin inside

green wood will build under heat and explode as

sparks. Therefore, it is recommended that only sea-

soned wood be used in your fireplace.

Most wood requires 9 to 12 months of seasoning and

drying to reduce the moisture content enough to pro-

duce good steady fires. Ensure that you buy only sea-

soned wood, or if you buy green wood (usually

cheaper), store it properly to aid in the seasoning pro-

cess. The following steps will assist in the seasoning

process.

A. Stack wood loosely to permit maximum air circu-

lation.

B. Do not stack wood on the ground. Use a wood

rack or stack on scrap lumber. Storage on the ground

will cause rotting and insect infiltration.

C. Cover wood stacks with a tarp so that it is not ex-

cessively exposed to the elements such as snow and

rain.

D. Do not stack wood against the walls of your

home.

5.5 Building a Fire

A. Use a log grate (sold separately) with your fire-

place. This will contribute to good air circulation

around the wood, and keep the wood out of the ash.

This grate is shown in Figure 32.

B. Close windows located near the fireplace when

first lighting a fire to reduce the possibility of smok-

ing. It can be reopened once a draft has been created

through the chimney.

WARNING: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN

FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID OR SIMILAR

LIQUIDS TO START OR

“FRESHEN UP” A FIRE IN THE

FIREPLACE. KEEP ALL SUCH

LIQUIDS WELL AWAY FROM

THE FIREPLACE WHILE IT IS IN

USE.

C. Do not overload the wood grate with wood. Three

to four logs on the fire at one time are sufficient. Too

much wood on the fire at one time can result in “over

firing,” and too much heat in the firebox, causing

damage to the fireplace.

D. When lighting a fire in a cold chimney, a

downdraft may be created, letting a little smoke into

the room. To correct this, hold a wadded newspaper

in the firebox and light it. This will create an updraft

and clear the flue of cold air.

E. Remove any excess ash from the fireplace. Exces-

sive ash may reduce airflow. Some owners prefer to

leave a small layer to insulate the cold refractory brick

below the grate, helping fire starting.

F. Open and close the damper to ensure it operates

properly. Leave it in the full open position when

starting a fire and while the fire is burning.

G. Center the grate over the bottom hearth of the

firebox.

H. Crumble several newspapers across the fire area

below the grate. Criss-cross kindling wood on top of

the grate, above the newspaper.

I. Lay three logs on the grate; two side by side and

the third in pyramid fashion on top. Split logs will

start faster. Ensure there is space between the logs for

air circulation. As the air is heated, it is drawn up-

wards through the space between the logs, creating

more combustion.

J. Light the paper at both sides of the firebox.

Caution: The fireplace requires air for operation.

Ensure there is sufficient air so that other fuel

burning appliances are not starved of com-

bustion, ventilation, and dilution air.

K. Set the screen in front of the firebox to prevent

the escape of sparks and embers.

L. Ensure the fire remains centered in the firebox.

Don’t let it move to the front part. Move it back with

the poker.

Figure 32. Log Grate

14

M. Add wood to the fire as necessary.

CAUTION: Be extremely careful when adding wood

to the fire. Use proper fireplace tools and

wear gloves. Un-split logs will be less stable

and may be more likely to roll out of the fire-

place if not placed carefully on the log grate.

6.0 Cleaning, Inspection and

Maintenance

As is the case with most other equipment, cleanliness is

the best maintenance practice and will contribute too

many hours of warmth and pleasure.

WARNING: DO NOT CLEAN THE FIRE-

PLACE WHEN IT IS HOT.

A. Creosote – Formation and Removal. When wood

is burned slowly, it produces tar and other organic

vapors, which combine with expelled moisture to

form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow burning fire.

As a result, creosote residue accumulates on the flue

lining. When ignited, this creosote makes an extreme-

ly hot fire. The chimney shall be inspected at least

twice a year during the heating season to determine

when a creosote buildup has occurred. If a significant

layer of creosote has accumulated (3 mm or more), it

should be removed to reduce the risk of a chimney

fire.

B. Disposal of ashes - Ashes should be placed in a

metal container with a tight-fitting lid, and taken out-

side and placed on the ground, well away from all

combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the

closed container until all cinders have thoroughly

cooled.

C. The grate may be removed from the firebox for

cleaning. However, ensure it is returned prior to lay-

ing the next fire.

D. Keep the fireplace screen clean so air flows freely

through it.

E. Spot check the refractory bricks and mortar for

small cracks. It will expand slightly with the heat,

and then contract as it cools. Replace refractory

bricks when the cracks open more than ¼”; or when

pits become extensive and deeper than 3/16”; or when

any piece of refractory larger than 2 inches in diame-

ter becomes dislodged.

F. If creosote has accumulated, it should be removed

to reduce the risk of a chimney fire. Clean the chim-

ney as outlined below or have the chimney cleaned by

a professional chimney sweep.

WARNING: DO NOT USE CHEMICAL

CHIMNEY CLEANERS THAT

ARE POURED ON A HOT FIRE.

THE CHEMICAL CLEANER CAN

BE DANGEROUS AND

GENERALLY WILL ONLY WORK

ON THE FLUE SECTION

NEAREST THE FIRE, LEAVING

THE REST OF THE FLUE

UNAFFECTED.

G. Inspect the top cap and opening in your chimney

top and remove any debris that could clog it. If pos-

sible, birds will often nest there, and it must be kept

clear of nest material.

H. Check the metal flashing and seals around the

chimney. Seal any cracks or loose nail heads to pre-

vent roof leaks.

I. Cover the firebox opening with a damp sheet and

seal with masking tape to retain soot in the firebox

while cleaning.

J. Inspect the entire flue from the top down for ob-

structions. Use a flexible handled cleaning brush. If

the chimney contains offset/return elbows, clean from

the top down to the offset, then from the firebox up to

the offset.

K. Check the flue from inside the fireplace with the

damper open for obstructions.

L. After completion of cleaning, use a vacuum

cleaner to remove all soot and residue from the fire-

box.

15

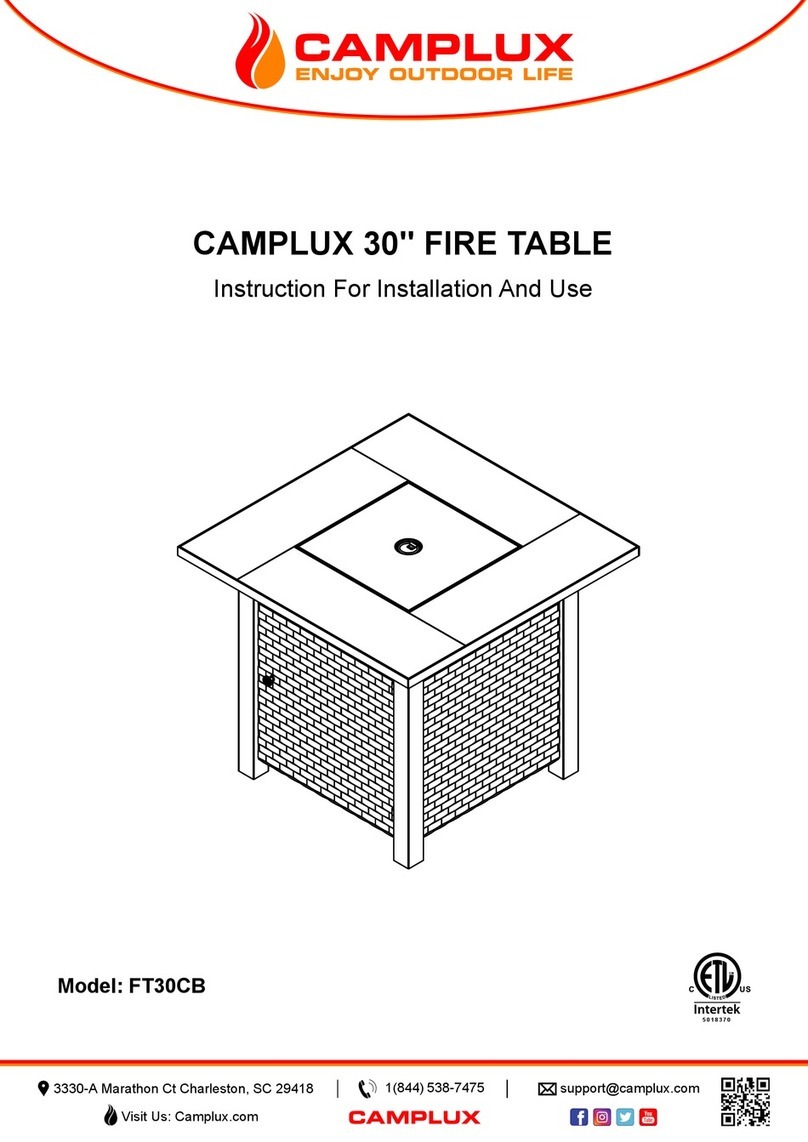

7.0 Finishing Specifications

Approximate finishing specifications, firebrick count,

and mortar coverage are estimated in Table 4 below.

Coverage amounts may vary due to weather conditions,

type of finish material, size of mortar joints, and skill

and efficiency of the mason or installer.

Table 4 does not account for waste. Add the appropri-

ate waste factor for your material type and skill level.

Table 4. Finishing Requirements

Kit Components

Surface Area

Corner Length

62 square feet

26 Linear feet

Ready-Mix Mortar Required for

Kit Assembly 4 Buckets/Bags

Mortar Required for Kit Finishing 2 - 4 Buckets/Bags

Firebrick Required 70 Split Brick

Additional Chimney (Per Chimney Section)

Surface Area:

Corner Length:

4 square feet

2 Linear feet

Ready-Mix for Assembly 1/8 Bucket/Bag

Ready-Mix Mortar Required for

Finishing

1/8 - 1/4

Buckets/Bags

This Space Intentionally Left Blank

This Space Intentionally Left Blank

16

4

Back Plate

8

Throat

1A

Cross Leg

6

Rear Header

3

Lower/Middle

Side Wall

10 Hearth

7S

Straight Lintel

7A Arched Lintel

5L &R

Upper Side Wall

Fireplace Components

SA48/SA48-STR

23”

23”

58”

5”

52”

40”

22.5”

11

”

58”

7

”

11”

51”

22”

26”

58”

23”

58”

30”

18”

18”

58”

11”

58”

11”

1

Riser Leg

2

Base Plate

9A

Flue

23”

11

Flue

Adapter

1A

Cross Leg

33”

7S

Straight Lintel

33” 6

Rear Header

6

Rear Header

8

Throat

17

18

Stone Age Fireplace Instructions

Models SA48/SA48-STR

Revised 10/2018

Printed in USA © 2013-2018, All Rights Reserved

Stone Age Manufacturing, Inc

LIMITED WARRANTY

The products of Stone Age Manufacturing, Inc. (“Stone Age”) have

been carefully manufactured and the components assembled to give the

customer a quality product. Stone Age warrants to the original pur-

chaser the materials that it provides to the customer against defects in

manufacture for a period of twenty-five (25) years from the date of pur-

chase on UL-127 listed fireplaces, for a period of five (5) years from the

date of purchase on all unlisted fireplaces, fire pits, and other masonry

components. Other accessory items or components offered, but not

produced by Stone Age Manufacturing, Inc., shall be covered by their

manufacturer’s warranties. This Limited Warranty covers only actual

manufacturing defects in the Stone Age product and does not cover de-

fects or faulty workmanship in the installation of the product or the ma-

sonry or other structure in which it is installed. Also this warranty does

not cover items that have been damaged due to over-heating, modifica-

tion, improper storage or maintenance. Stone Age shall repair or re-

place, at its option, any defective Stone Age product component upon

receipt of written notice addressed to Stone Age. This Limited Warran-

ty covers only replacement of any defective components within the

product itself occurring during the warranty period and does not cover

the cost of installation or removal from a fixed location. NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARE MADE, INCLUDING

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSES WHICH ARE SPECIFICALLY

DISCLAIMED. Stone Age is not liable for damages or injury to per-

sons or property or other incidental or consequential damages.

Stone Age Manufacturing, Inc.

11107 E. 126th St. N., Collinsville, OK 74021

WWW.Stoneagefireplaces.com

Table of contents

Other StoneAge Outdoor Fireplace manuals

Popular Outdoor Fireplace manuals by other brands

pleasant hearth

pleasant hearth OFW106R manual

Moebelix

Moebelix 64033 Assembly instruction

Camplux

Camplux FT30CB Instructions for installation and use

Backyard Creations

Backyard Creations SRGF11610 owner's manual

Uniflame

Uniflame GAD1338SP owner's manual

Home Decorators Collection

Home Decorators Collection 52537 Use and care guide

pleasant hearth

pleasant hearth OFP24WG manual

Outdoor Plus

Outdoor Plus FLORENCE manual

Astonica

Astonica 40100047 instruction manual

AMD DIrect

AMD DIrect Pro Series Installation and operating instructions

Gilbert & Bennett

Gilbert & Bennett SH101 user manual

Outland Living

Outland Living FRASER FMPPC2E-435 owner's manual