Stones Sound Studio Ribbon 260 User manual

STONES SOUND STUDIO

RIBBON SPEAKER KIT

MANUAL

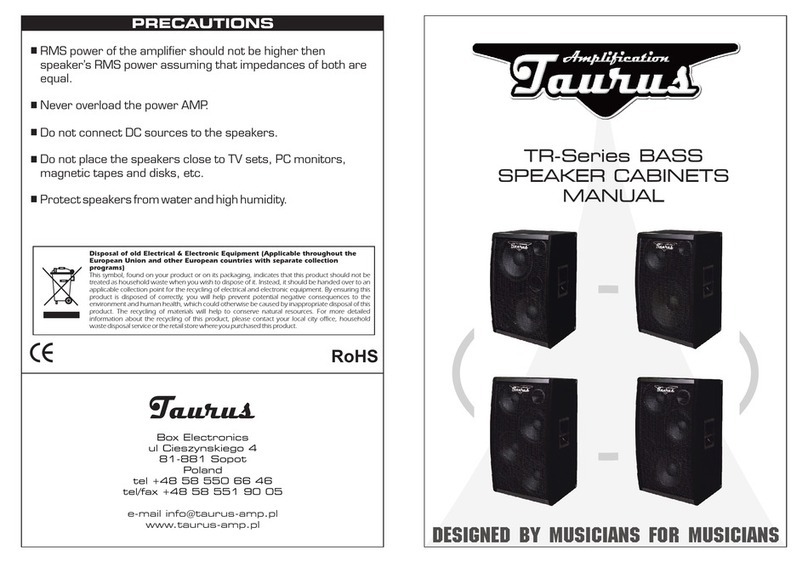

260C 360 260

Designed

By

Russell Storey

(Version V6) 19/1/08

2

Loudspeaker Description and Building Instructions

3

CONTENTS

Loudspeaker Description

The Ribbon Speaker Performance………………………………………………………………….4

Ribbon Speaker Kit Design Concept………………………………………………………………..5

Tweeter: Fountek Ribbon……………………………………………………………………………5

Woofer: Peerless Bass/Midrange……………...........................................................................5

The Ribbon Speaker Enclosures…………………………………………………..........................6

Centre Speaker………………………………………………………………………………………..6

Enclosure Bracing Rib………………………………………………………………………………...6

Enclosure Felt Damping………………………………………………………………………………6

Enclosure Rear Port & Port Flare ……………………………………………………………………7

Enclosure Bracing and Felt Acoustic Damping…………………………………………………….7

Grill Panel………………………………………………………………………………………………7

Enclosure Features Summary………………………………………………………………………..7

Crossover 260 260C 360……………………………………………………………………………..8

Crossover Features Summary……………………………………………………………………….8

Speaker Cable type internal wiring & amplifier……………………………………………………..8

Loudspeaker Connection

Speaker Cable Wiring (Standard) ……………………………………………………………………9

Speaker Cable (BI Wiring)…………………………………………………....................................10

Building Instructions

Crossover Board (Bottom) 260-260C 360…………………………………………………………..11

Woofer (Bottom) 260 260C 360……………………………………………………………………...11

Fountek Jp3.0 Ribbon Tweeter………………………………………………………………………11

Ribbon 260 360 Fronts………………………………………………………………………………..11

Woofer (top) 260 260C………………………………………………………………………………11

Ribbon 260C Centre Speaker………………………………………………………………………..11

Location of Crossover PCB and Wiring 260 360 260C…………………………………………...12

Testing the Finished Speaker Box…………………………………………………………..13

Bass Speaker phase test (dc only)………………………………………………………………….13

Crossover Network Resistance (dc only) (optional)……………………………………………….13

Digital Multi Meter (DMM) Readings………………………………………………………………...13

Testing the Speaker Box Photos 2 &3 ……………………………………………………………...14

Installation Photographs…….………………………………………………………15.to.27

Fully Assembled 260 260C……………………………………………………………………………28

Fully Assembled 360…………………………………………………………………………………..29

Recommended Loudspeaker Room Location.................................30

How to make Port and Port Flare & Enclosure Felt Damping………..31 to 38

4

Loudspeaker Description

The Ribbon Speaker Performance

Here at Stones Sound Studio we have engineered Super High Definition Ribbon Speakers

to reproduce all analogue and digital stereo programs including CD, HD-DVD,SACD analogue

turntables and multi channel A/V home theatre sound systems

The 260 260c & 360 Ribbon Speakers provide excellent depth of field, holographic 3D sound

staging, fast tight bass midrange, crystal clear top end detail, extreme dynamic range with very

low distortion on any type of program material from low to high volume levels

The 260C centre channel speaker complements the 260 and 360 ribbon speakers for high-end

Home Theatre A/V systems. I recommend complementing the ribbon speakers with the high

quality R1000 12” subwoofer for very low frequency articulate bass for medium to large rooms

The 260 and 360 ribbon speakers have been designed to become a sound reference for both

home theatre and audio systems enabling listeners to hear finer instrument detail in analogue

and digital recordings

The low distortion, wide bandwidth and large dynamic range provided by this Ribbon Speaker

series enables listeners to appreciate the effects of any upgrades or changes made to their

electronic equipment , cables ,components and program material providing many years of

enjoyable listening.

Russell Storey

5

Loudspeaker Description

Ribbon Speaker Kit Design Concept

The aim of a good high definition loudspeaker is to reproduce any instrument or sound as realistically and as close as

possible to the original sound source .While these attributes are achievable to a degree using a standard woofer /soft,

dome tweeter combination an even better solution is a woofer /ribbon tweeter loudspeaker. I chose a Pure Ribbon

tweeter because of the speed low mass and detail to enable a speaker design with true super high definition sound

reproduction of any instrument or sound effect

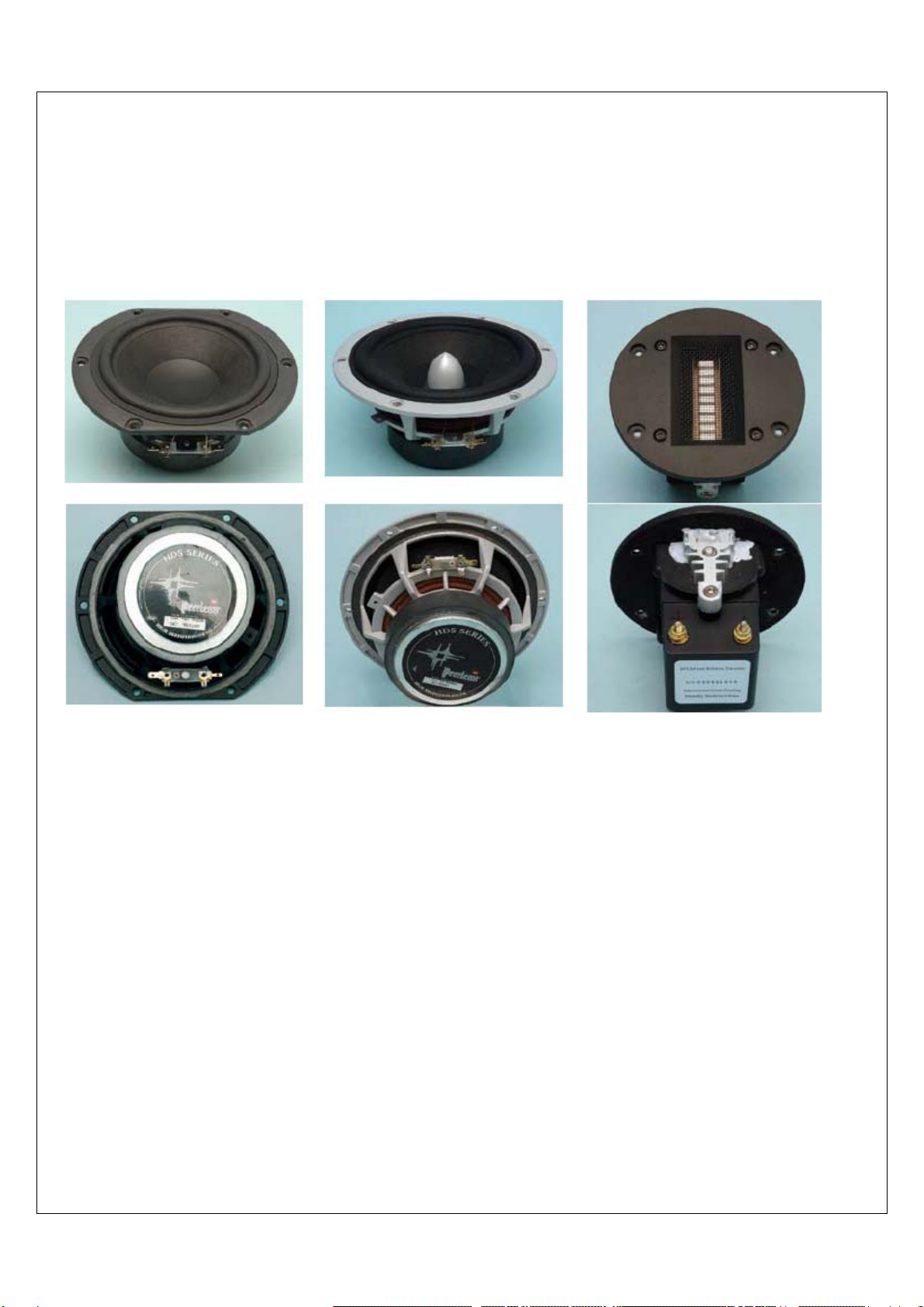

832873 5’’ 830883 6.5’’ JP3.0

Tweeter: Fountek Ribbon

The Fountek Jp3.0 pure ribbon tweeter with high frequency transformer has the ability to deliver extremely fast

transient detail and low distortion from very low to high volume levels and enables a truly realistic sound when

compared to planar ribbon or dome tweeters.

The Jp30 ribbon tweeter diaphgram has a very low moving mass of only 11mg (dome tweeter > 300mg) and is fitted

with High Flux density rare earth neo magnets. To convert very the low impedance of the ribbon diaphgram to an

8-ohm primary the Jp3.0 is fitted with an ultra wide bandwidth 120 KHz transformer, resulting in a flat frequency

response minimum phase change from 1 to 40 kHz.

Woofer: Peerless Bass/Midrange

To complement the speed ,dynamics and accuracy of the JP3.0 ribbon tweeter the Peerless HDS 832873 5''

and HDS 830883 6.5” with Nomex paper cones were selected for their natural sound signature, excellent bass

lower mid range detail very low distortion , wide dynamic range , fast transient time , phase and frequency response.

6

Loudspeaker Description

The Ribbon Speaker Enclosures

The Bass Reflex enclosure was developed using LEAP 5 wave diffraction analyzer and FFT vibration analysis

An Extended Bass Shelf ( EBS) / Butterworth low pass filter response was implemented with the enclosure to ensure

optimum low extended bass and fast transit speed from the woofers

The Enclosures feature flush mounted ribbon tweeter, rear port and are manufactured from 18mm MDF

The Front Baffle is 36mm thick laminated MFD which ensures minimum movement of driver chassis and maximum

enclosure damping for very tight bass and low cabinet resonance.

Centre Speaker

The 260C Centre Speaker has a wide horizontal sound field due to the use of an MTM speaker configuration and

provides excellent detail of voice and home theatre effects .The enclosure and crossover network are the same as

the 260 except the ribbon tweeter has been rotated 90degs on the front baffle to complement the woofer sound

fields

Enclosure Bracing Rib

Acoustically bullet shaped internal bracing ribs are fitted the side and top panels to provide strength and further

improve bass transients and reduce panel resonance modes

Enclosure Felt Damping

The enclosure is fitted with acoustic felt damping to the top bottom left & right and rear internal panels of the woofer

chamber to reduce internal mid frequency standing waves and slightly damp the mid frequency back waves from of

woofer cones. In addition, two layers of acoustic felt are fitted inside back panel

R360 R260

R260c

7

Loudspeaker Description

•Enclosure Rear Port

A rear port was employed in the ribbon speaker design to ensure a reduction of overall transducer distortion and

cross modulation generated by front ports.

With a front port a form of speaker (low frequency) distortion and cross modulation is generated by the chamber

compressed air exiting the port out of phase with the woofer creating (modulation) interference of the woofer cone

and ribbon diaphgram .This interference of the woofer cone occurs at medium to high playback levels (port

velocity) and is one of the factors reducing over all dynamic range or head room of the transducers and

speaker system.

This mechanical process is similar in principal to FM & AM radio wave modulation only in this case, the radio

carrier wave is the transducer cone or ribbon diaphgram and the modulator is the low frequency compressed air

radiated from the port.

Port Flare

A simple 63 mm (ID) port size with small flared ends was chosen over large flared ports to provide minimum port

velocity, cone excursion and minimum woofer power compression at average to high volume levels.

At average to high volume levels, large radius ports cause eddy current airflow resistance at the inlet, exit flare,

and thus more power compression, less dynamic range and increased driver distortion.

Enclosure Bracing and Felt Acoustic Damping:

An MDF timber acoustic bracing rib was designed with a bullet round over on the edges to reduced unwanted

chamber resonance, standing waves (pressure particle bunching) caused by the back waves of the bass/ mid

woofer and to reduce unwanted side panel resonant modes

Grey Felt 6mm thick acoustic material is fitted to the top,bottom,left,right and rear panels and carefully folded

over the bracing rib to act as an absorber ( air brake) on lower midrange frequencies that cause modulation of

the cone and port vent . Two layers of 6mm felt are added to the inside of the rear panel and further damping is

added the rear of the ribbon tweeter to reduce air turbulence of the rear port and interference from the back of

tweeter magnet assembly

Grill Panel

The grill panel is located on the front baffle by grill pegs and cups and incorporates the use of low loss acoustic

grill cloth. The grill frame features round over of the timber grill frame internal and external edges which reduce

diffraction of the sound generated by the speaker drivers .A special low loss grill cloth has been used to reduce

attenuation of high frequencies from the ribbon tweeter and woofer. “

To enable the very best sound quality and

listening experience I recommend the grill panel be removed from the speaker box “

Enclosure Features Summary:

•Low resonance baffle design with 36mm thick laminated 18mm MDF

•High volume level High Velocity low compression port with round over at both ends

•MDF acoustic bracing rib with bullet shaped round over on edges

•Acoustic felt damping on all walls and rear panel

•Acoustic Felt cover behind ribbon tweeter

•Acoustic grill panel cloth Low loss

•Grill panel frame internal & external frame round over’s

• woofer hot cut outs 16mm roundovers on inside edge

8

Loudspeaker Description

Crossover 260 260C 360

The Linkwitz Riley (Bessel /Butterworth) crossover unit was developed to enable good linear phase and minimum

THD distortion through the pass band and over lap regions of both the woofer and ribbon tweeter whilst providing

wide dynamic range and excellent low mid and high level continuity of detail .

A 2nd order low pass with a 3rd order high pass filter slope was chosen after evaluating many different design

combinations to provide optimum isolation between low and high frequencies. Time compensation of the driver xyz

location and rising peaks response in the woofer and tweeter on and off axis were reduced buy fine tuning crossover

component values thus enabling coherent coupling from bass to tweeter combination through out the crossover

region. The fully finished crossover PCB includes all components, high quality internal wiring and Velcro mounting

tabs

Components used in the Ribbon Speaker crossover are High quality Non-Inductive resistors, Copper Air core

Inductors, SCR 400V metalized MKP capacitors.OFC 384 strand copper wiring

Crossover Features Summary

•Fully finished PCB includes all components and wiring ready to install

•Soldering: None required Wiring cable: Internal speaker cable high quality OFC 384 strand with push on

connections

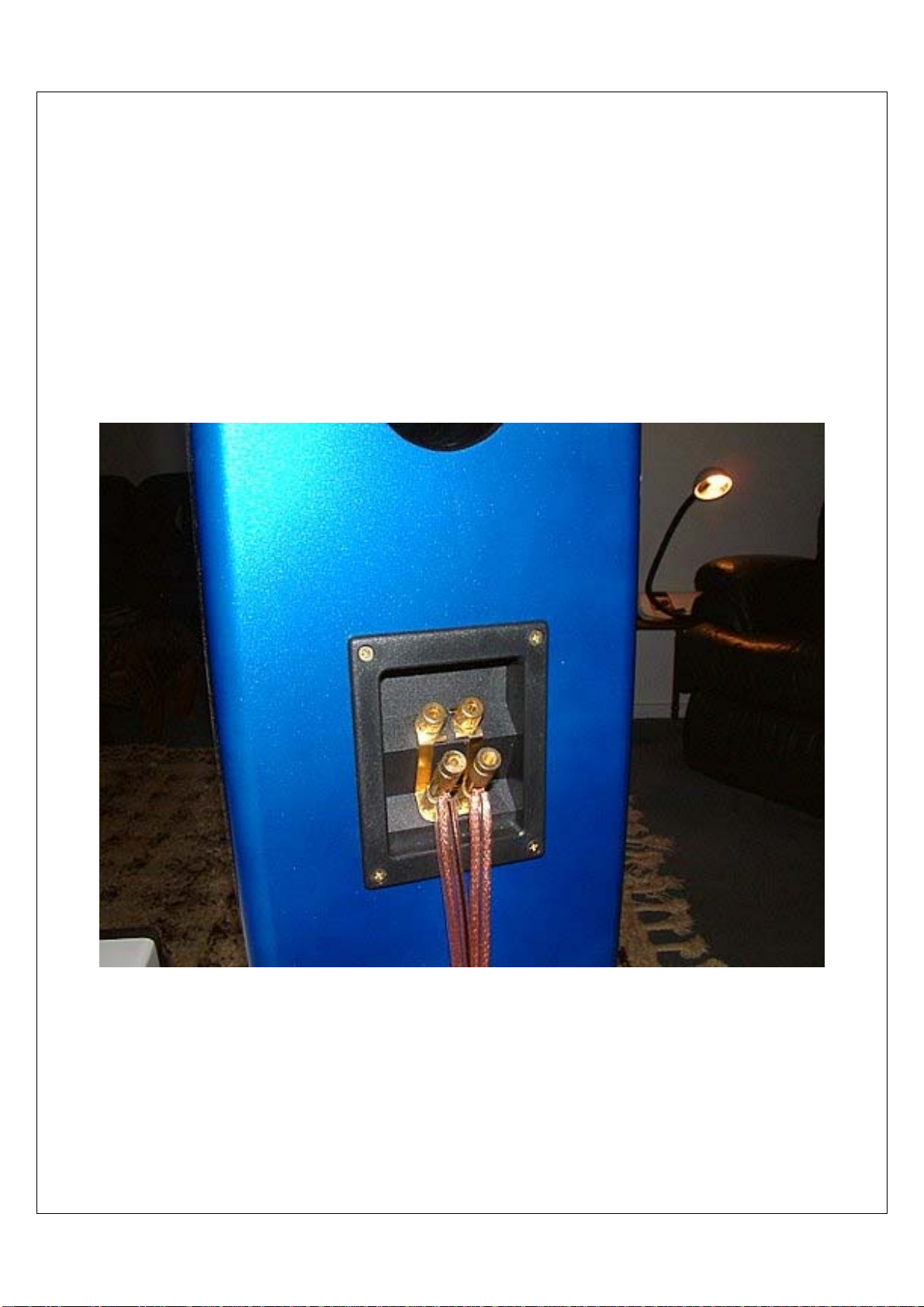

•Speaker terminals: 4mm twin gold plated binding post

•Filter 2 way off set Bessel / Butterworth, linear phase

•Frequency: 260 260c 3.8 KHz 360 Freq 3.2Khz

•Order: 2nd Lp, 3rd Hp

Speaker Cable type internal wiring & amplifier

OFC 384-speaker cable is made from a low loss pure OFC copper. The cable is a type of Litz wire construction

formed from 384 thin copper wires woven into a low profile flat rectangular shape and then insulated with a clear

polymer jacket. This excellent combination of shape and size ensures the OFC 384 speaker cable has minimal

HF loss from the skin effect found in round conductors and also enables a lower overall impedance which

provides better bass depth, midrange transients and dynamics.

Other speaker cable I recommend to are QED Nordost Chord Kimber Audio Quest

9

Loudspeaker Connection

260 260C 360

Speaker Cable Wiring (Standard)

Connect the speaker cables to the bottom pair of terminals on the rear speaker terminal cup for a standard connection

to your amplifier

10

Loudspeaker Connection

260 260C 360

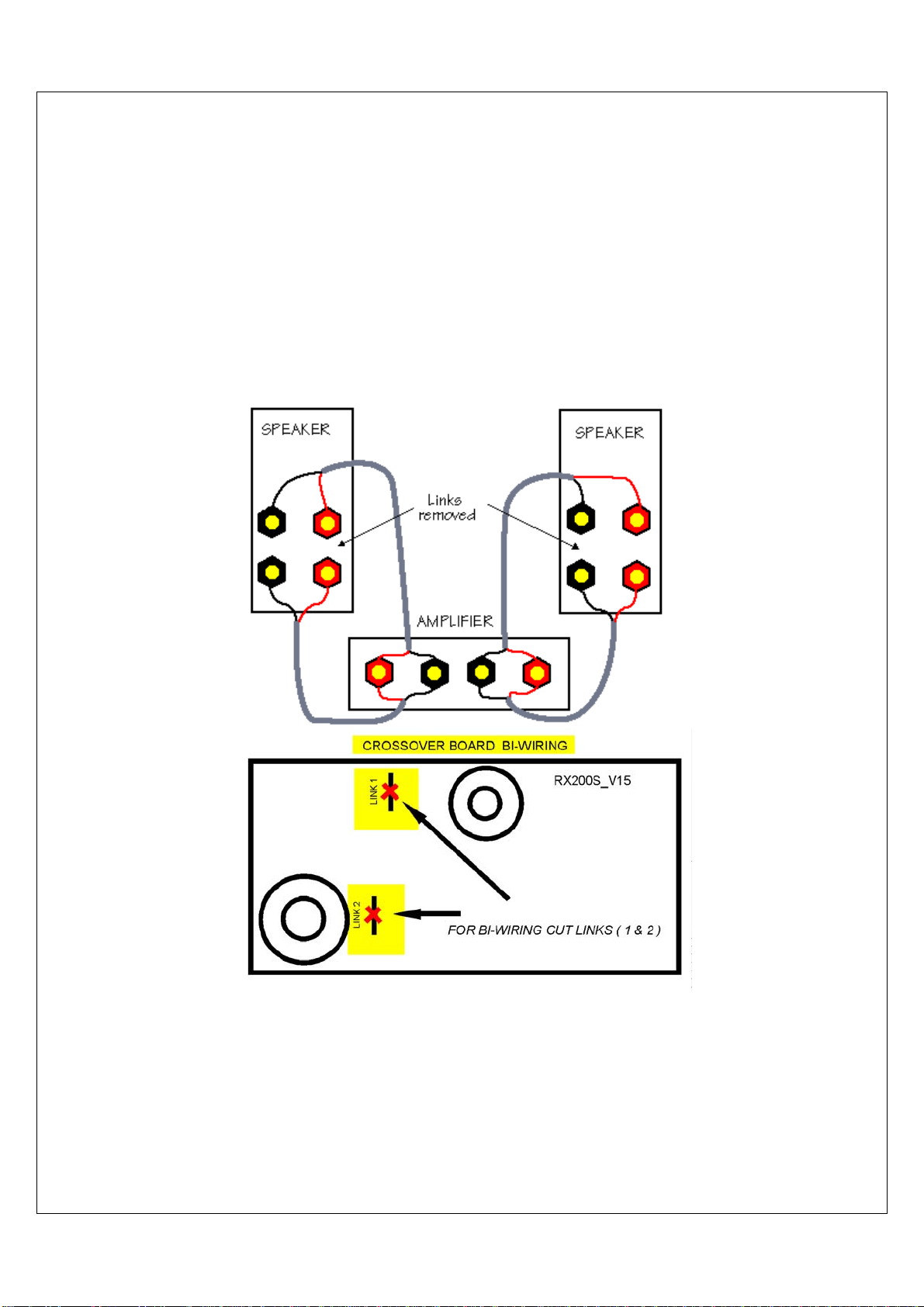

Speaker Cable (BI Wiring)

The term bi-wire simply refers to the fact that you will be running

two sets

of loudspeaker cables from your amplifier to

each

of your speakers.

9Remove the 2 links from the

rear

speaker terminal cup .

9Cut links (1,2,) on the

internal

crossover board

.

11

Building Instructions

260 260C and 360

Installation of the Woofer & Crossover PCB

1) Crossover Board (Bottom) 260-260C 360

9Fit Velcro Tabs to underside of the crossover PCB (see p17)

9Fit crossover assembly through lower woofer hole and secure with 5 Velcro tabs onto the felt at bottom of speaker

box (see p18)

9Fit speaker 4 terminal plate through felt and rear panel mounting hole then secure with 4 MDF countersunk wood

screw(see p19 p20)

2) Woofer (Bottom) 260-260C 360

9Fit Lower bass /mid speaker crossover cables through the front baffle hole (see p21)

9Fit push on connectors from the crossover speaker cables Red (+V) and Black (-ve) to the speaker terminals of the

lower woofer (see p21)

9Fit lower bass /mid speaker to the front baffle with six Allen head screws using a 3mm Allen key

9Re check all driver screws but do not over tighten (see p22 23)

3) Fountek Jp3.0 Ribbon Tweeter (Installation Check List)

9 Check acoustic felt cover is fitted behind tweeter cut out hole before installing tweeter

9 Do not connect a battery or dc ( direct voltage) across ribbon terminals .Ribbon has been pre tested in factory

9

Do not remove Ribbon protection label until speaker box the installation and dc testing

is completed

(see 27

4) Fountek Jp3.0 Ribbon Tweeter 260-260C 360

9Fit ribbon tweeter crossover cables through the bottom edge of felt cup through the front baffle hole and secure

the 2 cable lugs Red (+V) and Green (-ve) to the ribbon terminal posts with a small wrench and tighten nuts firmly

but do not over tighten See (photo p24)

Hint: Angle tweeter cable lugs to allow enough room between felt cover and back of the tweeter when installing

9Fit ribbon tweeter to the front baffle with four Allen head screws using a 3mm Allen key Re check all screws

but do not over tighten

5) Woofer (Top) 260 260C

9Fit upper bass /mid speaker crossover cables through the top front baffle hole

9Fit push on connectors from the crossover speaker cables Red (+V) and Black (-ve) to the speaker terminals of the

top woofer (see p21)

9Fit upper bass /mid speaker to the front baffle with six Allen head screws using a 3mm Allen key

9Re check all driver screws but do not over tighten

96) Ribbon 260C Centre Speaker

9Fit Crossover Board ,bottom woofer , top woofer and ribbon tweeter as per 260 Installation steps ( 1,2,3,4,5) above

(see Centre Speaker tweeter location p22 ,23)

12

Building Instructions

Location of Crossover PCB and Wiring

13

Building Instructions

260 260C and 360

Testing the Finished Speaker Box

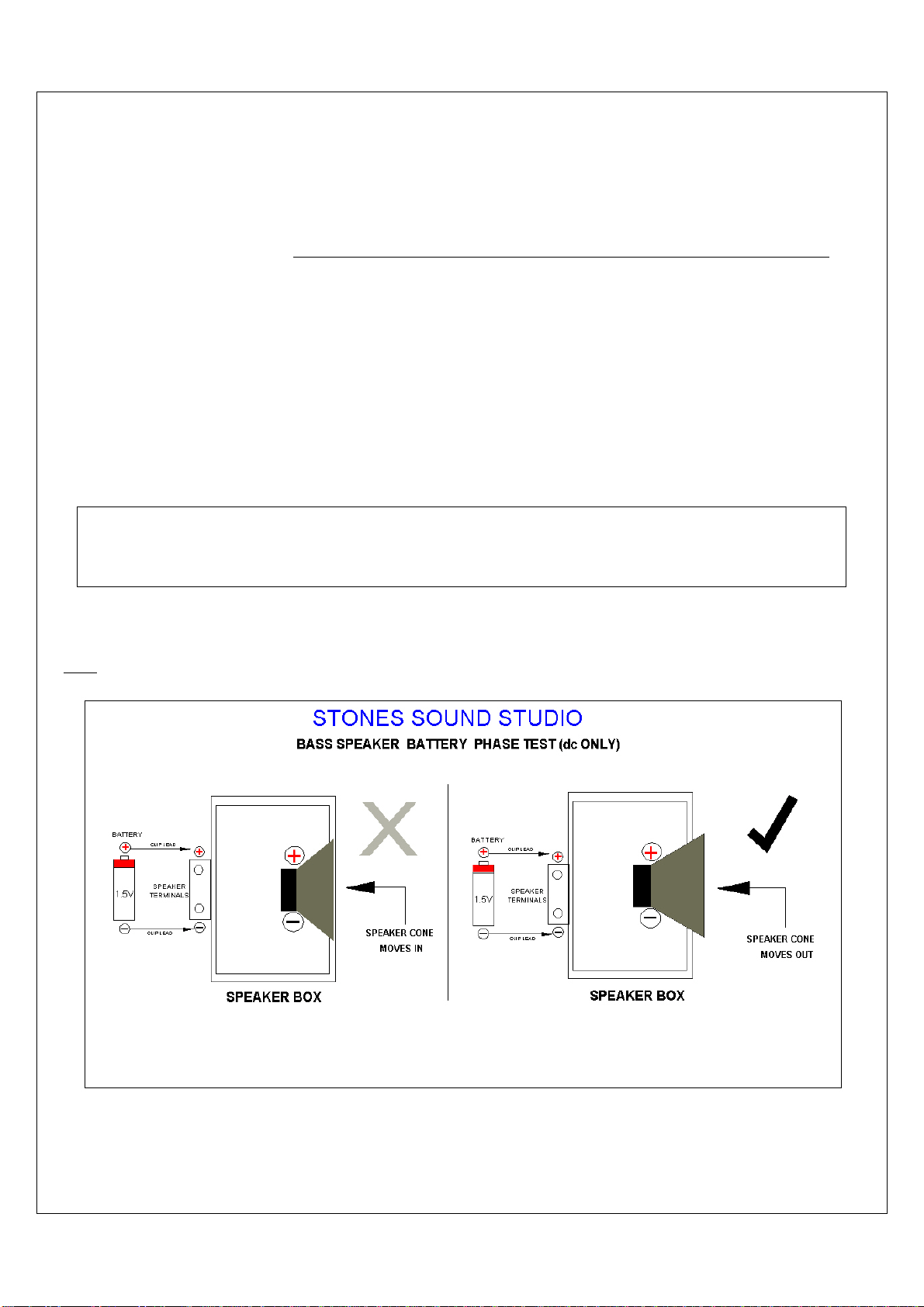

Bass Speaker phase test (dc only).is all that is normally required to test the pre built crossover wiring and speakers

Connect a 1.5v battery with a pair of clip leads across the bottom pair of speaker terminals (+ve to +ve ) RED and ( –

ve to –ve) BLACK. Check that the battery is connected as per photo (Photo 2 page 14).

Observe that the woofers cone moves out as per (Fig1 below).

This means the speaker and crossover wiring is connected in phase.,

If the speaker cone moves in then the connection of the bass speaker or crossover wiring are incorrect out of phase

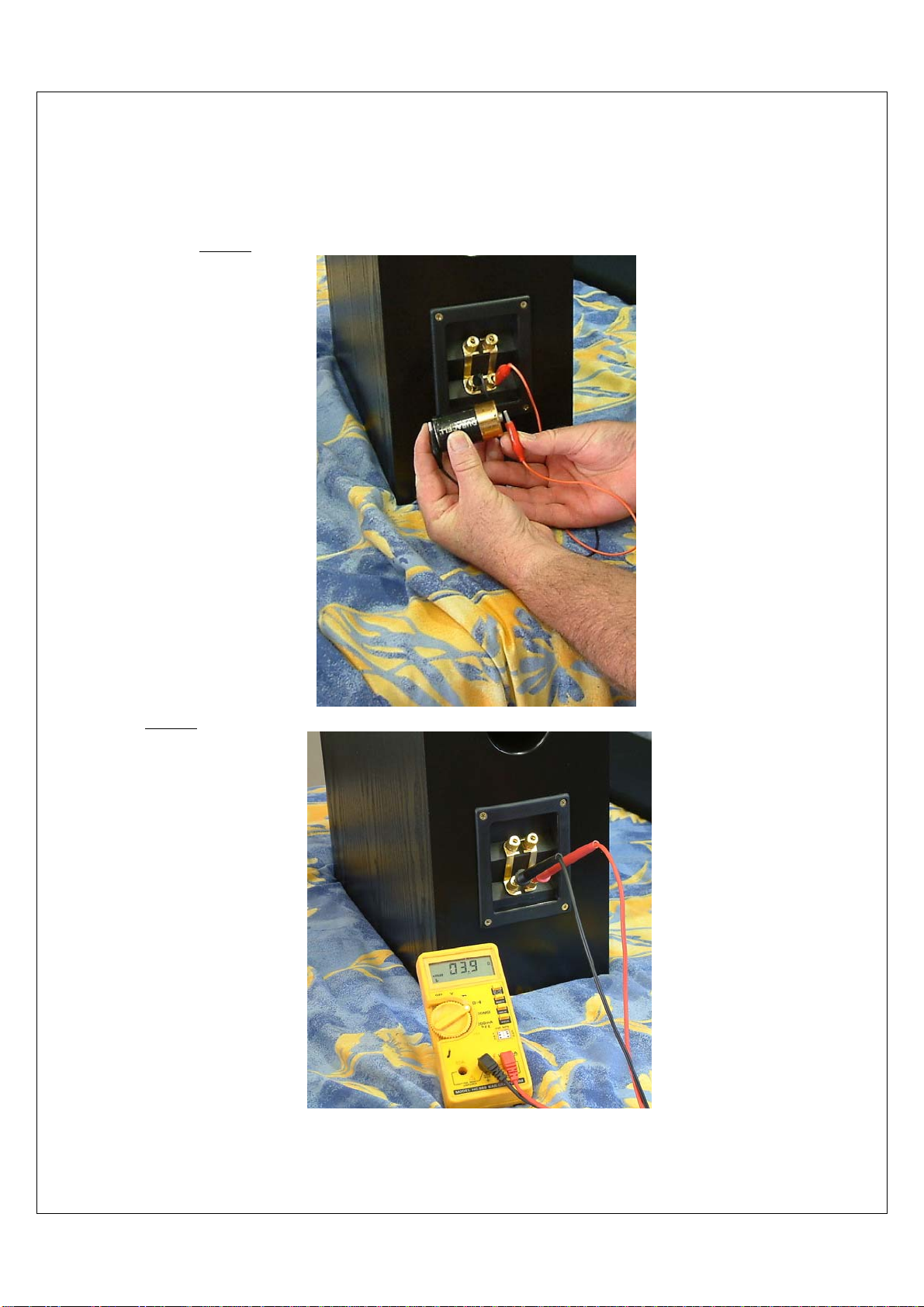

Crossover Network Resistance (dc only). (DIY optional extra for experienced Diy speaker builders and technicians)

Connect a DMM (digital multi-meter) across the bottom pair of speaker terminals then switch the DMM to the ohms

range and measure the (dc resistance) of the crossover network. see DMM photo (Photo 3 page 14)

Warning: If the DMM meter ohm readings are lower than the range given above then contact the Kit dealer for advice

Fig 1

Digital Multi Meter (DMM) Readings (average)

260 260c DMM reading range > 3.4 to 4.4 ohms (Nominal 3.9 ohm)

360 DMM reading range > 5.8 to 6.7 ohms (Nominal 6.1 ohm)

14

Building Instructions

260 260C and 360

Testing the Speaker Box Photos 2 &3

Photo 2 Bass Speaker Battery phase test (dc only)

Photo 3 DMM ohm measurement of the 260-260C speaker Crossover Network Resistance (dc only)

DMM ohm measurement 3.9 ohms 260-260C speaker

DMM ohm measurement 6 ohms 360 speaker

15

Building Instructions

260 260C and 360

Installation Photographs

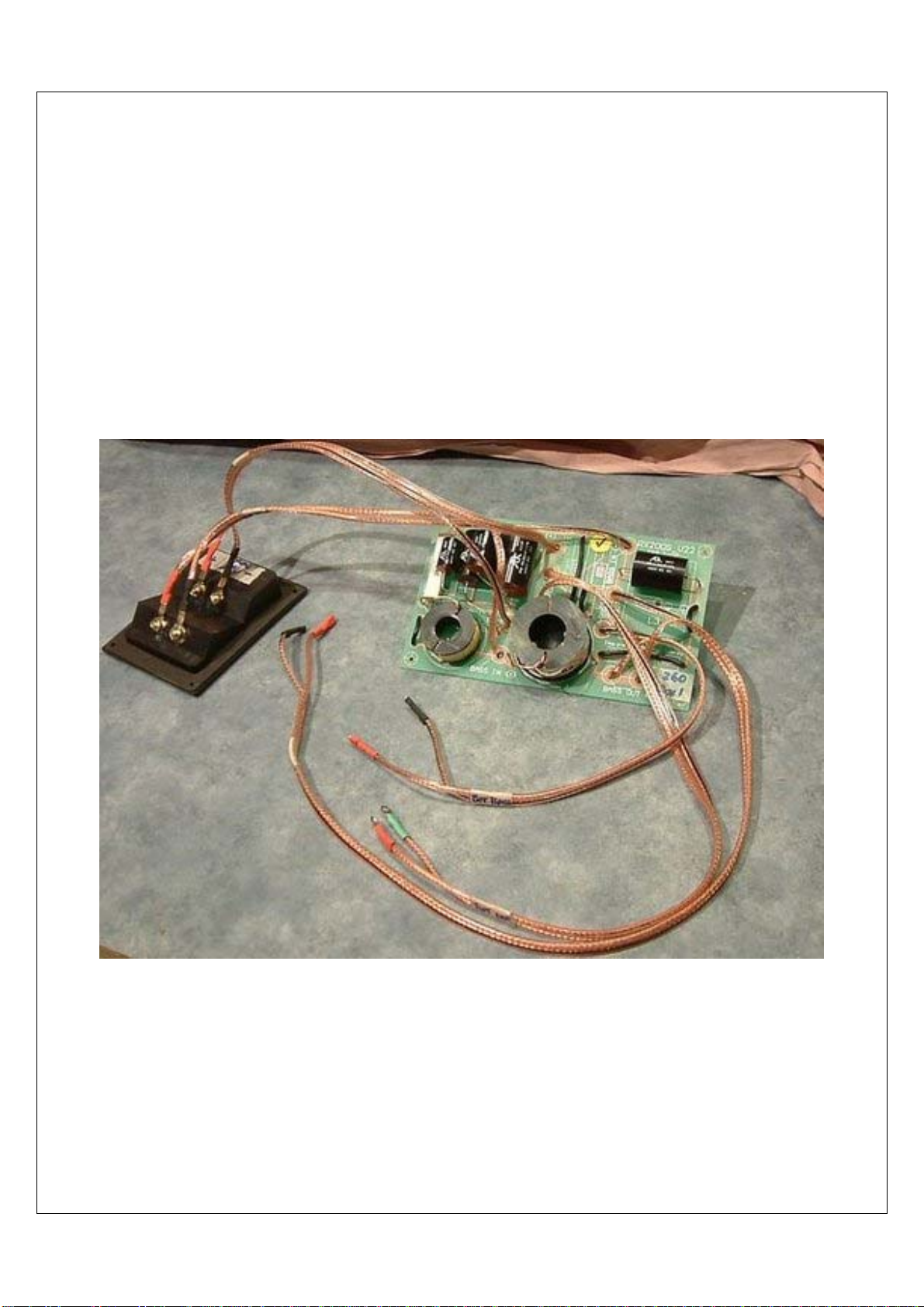

Crossover PCB assembly includes pre-wired (soldered) 4 terminal speaker cup

16

Crossover PCB assembly with 260 enclosure

17

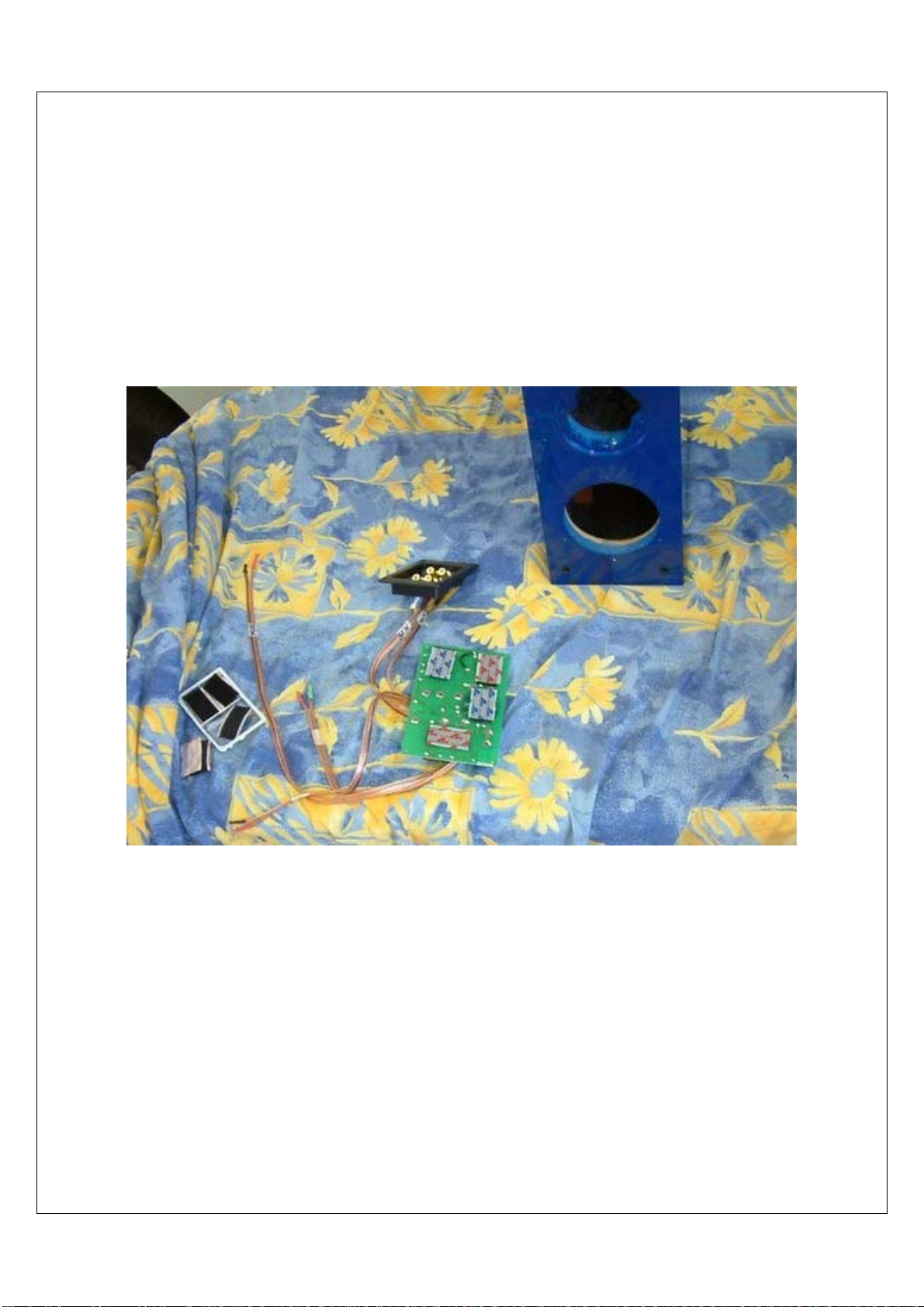

Fit crossover assembly through lower woofer hole and secure with the Velcro tabs onto the felt at bottom of speaker box

18

Fit crossover assembly through lower woofer hole and secure with six Velcro tabs

19

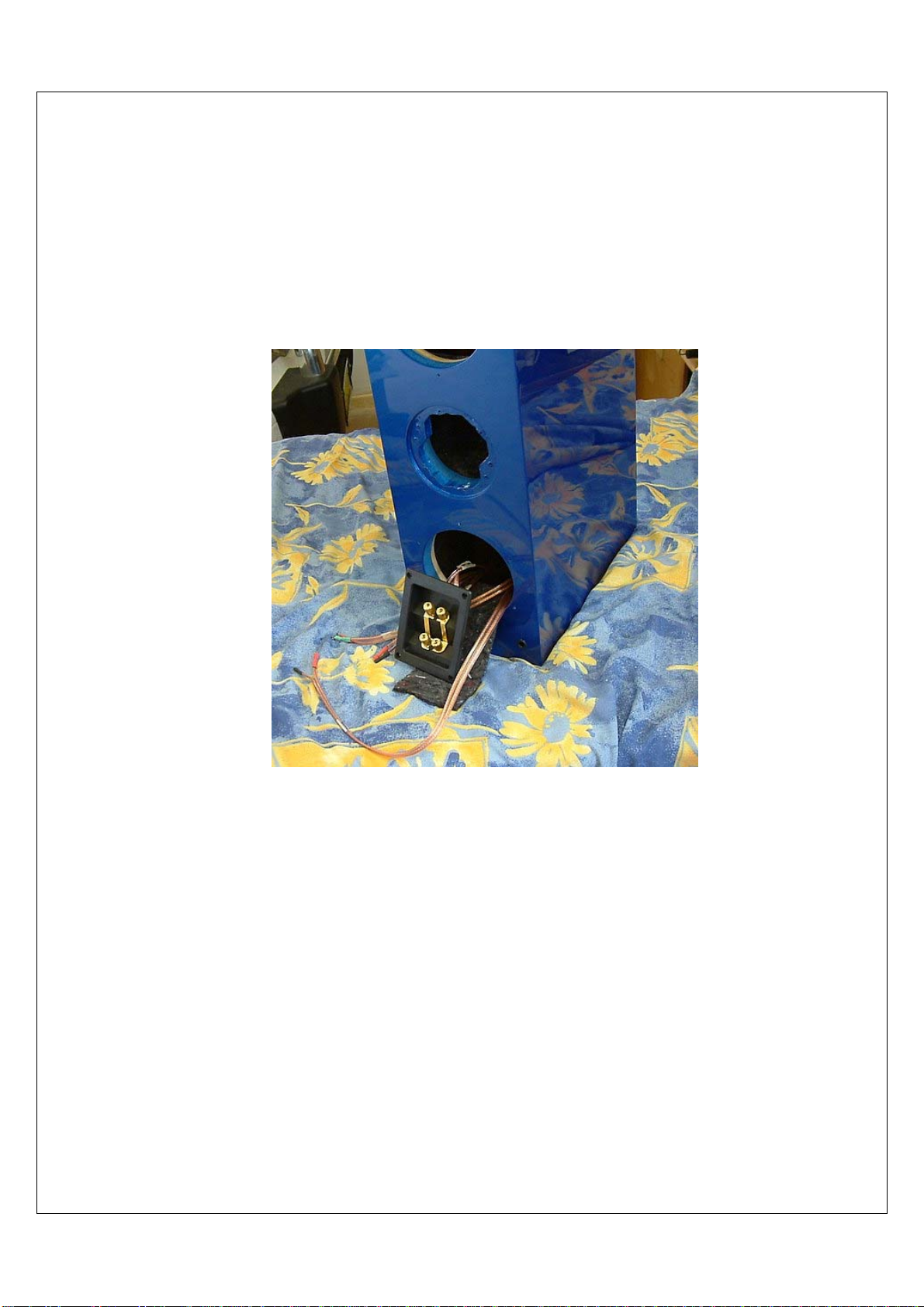

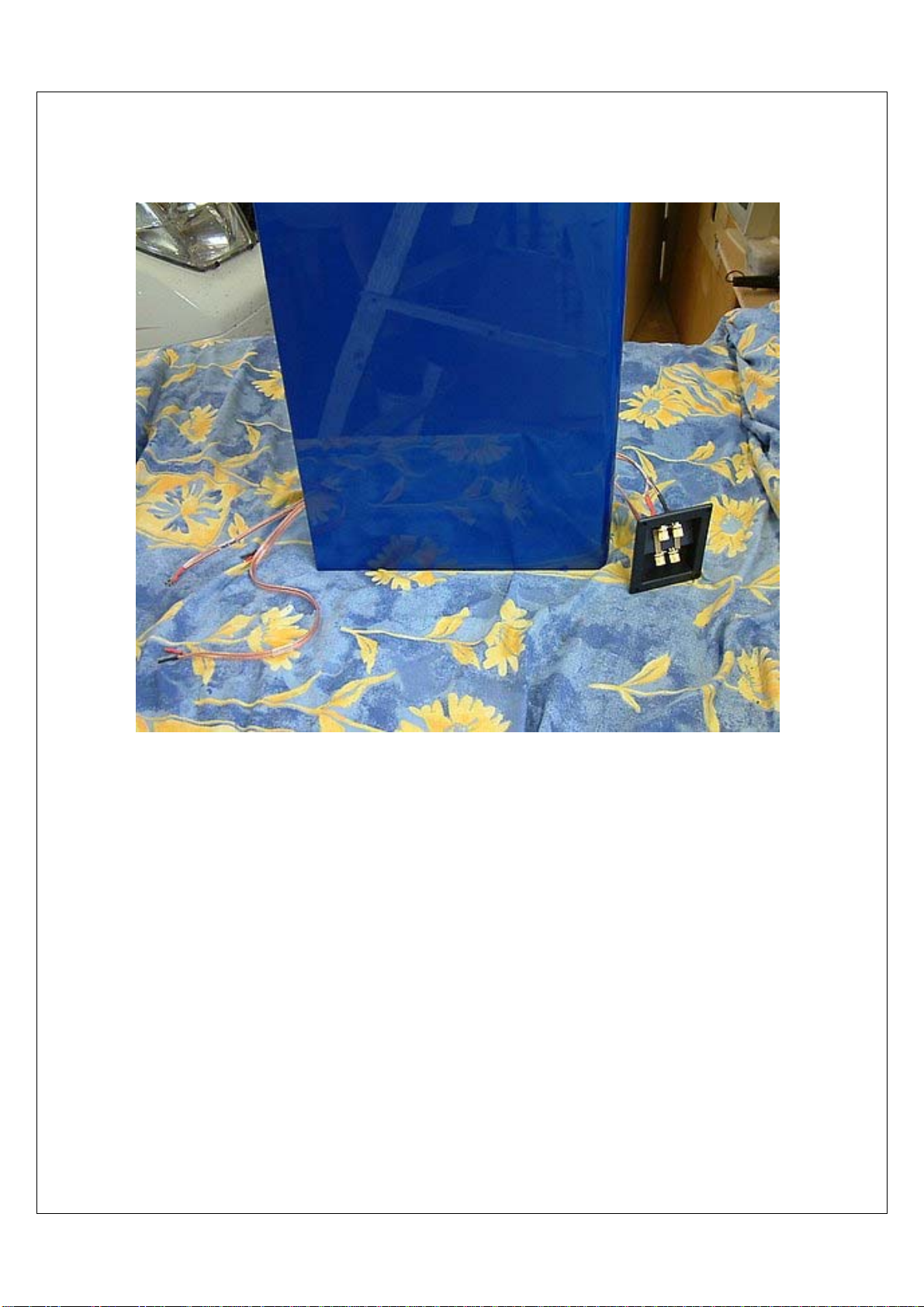

Fit speaker 4 terminal cup through felt and rear panel mounting hole then secure with 4 MDF countersunk wood screw

20

Note: Fit speaker 4 terminal cup so terminal post faces toward the top of the box

This manual suits for next models

2

Table of contents