If you choose to vary from these instructions

your warranty will be impaired.

5

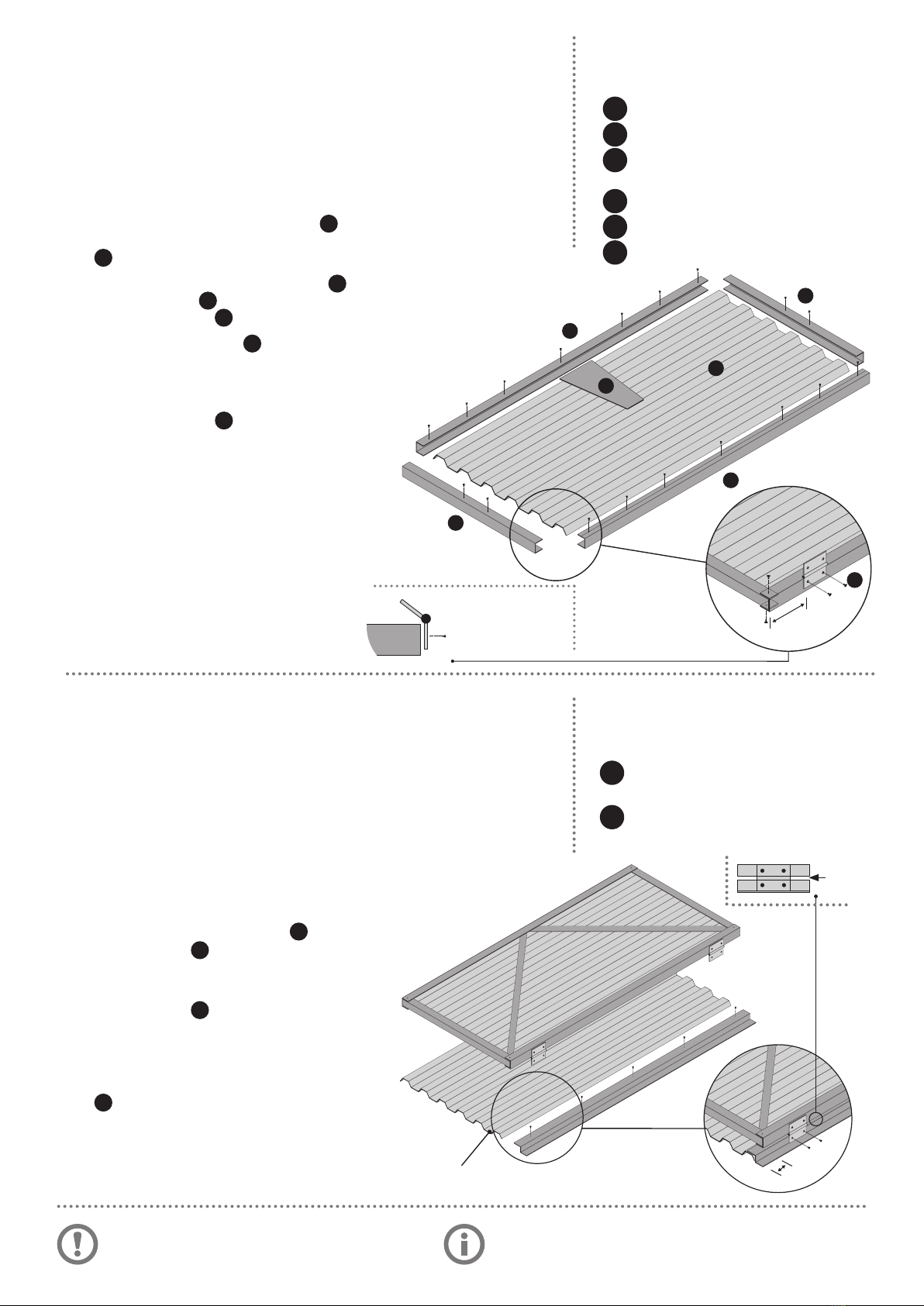

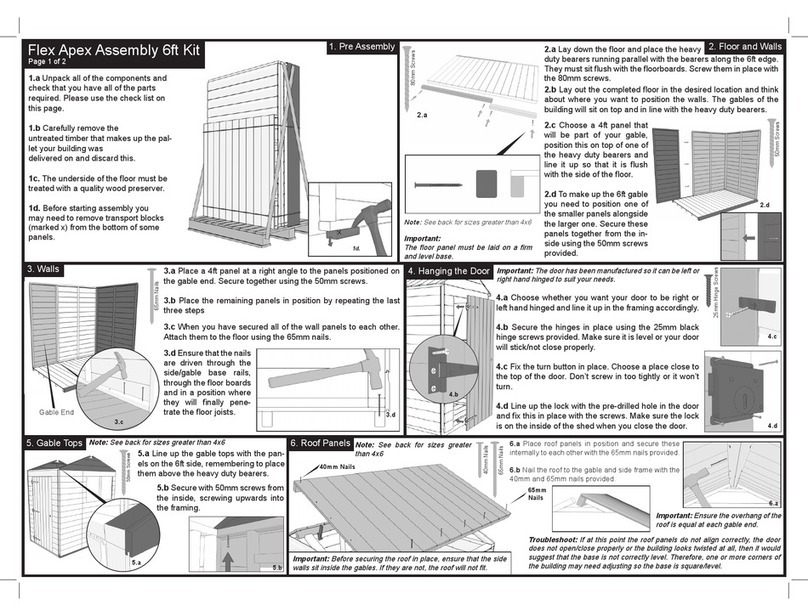

Side wall assembly

1. Stand up the back wall and as your helping hand is holding

it up, bring the left end wall in to meet it at the left corner

(diagram 1) overlapping the corners (diagram 2). Drill and x

at approximately 100mm down from the top and up from the

bottom, drilling and xing from the outside.

2. Bring the right end wall into the right back corner and perform

the same again, checking to make sure the walls are sitting at

at the bottom.

3. Bring the front wall into place and join the front corners to

the end walls, same as the back (diagram 3).

4. Finish joining the corners by xing at approximately

200-300mm apart. You will nd it easier to drill these

corners if they are supported on the inside (see tip).

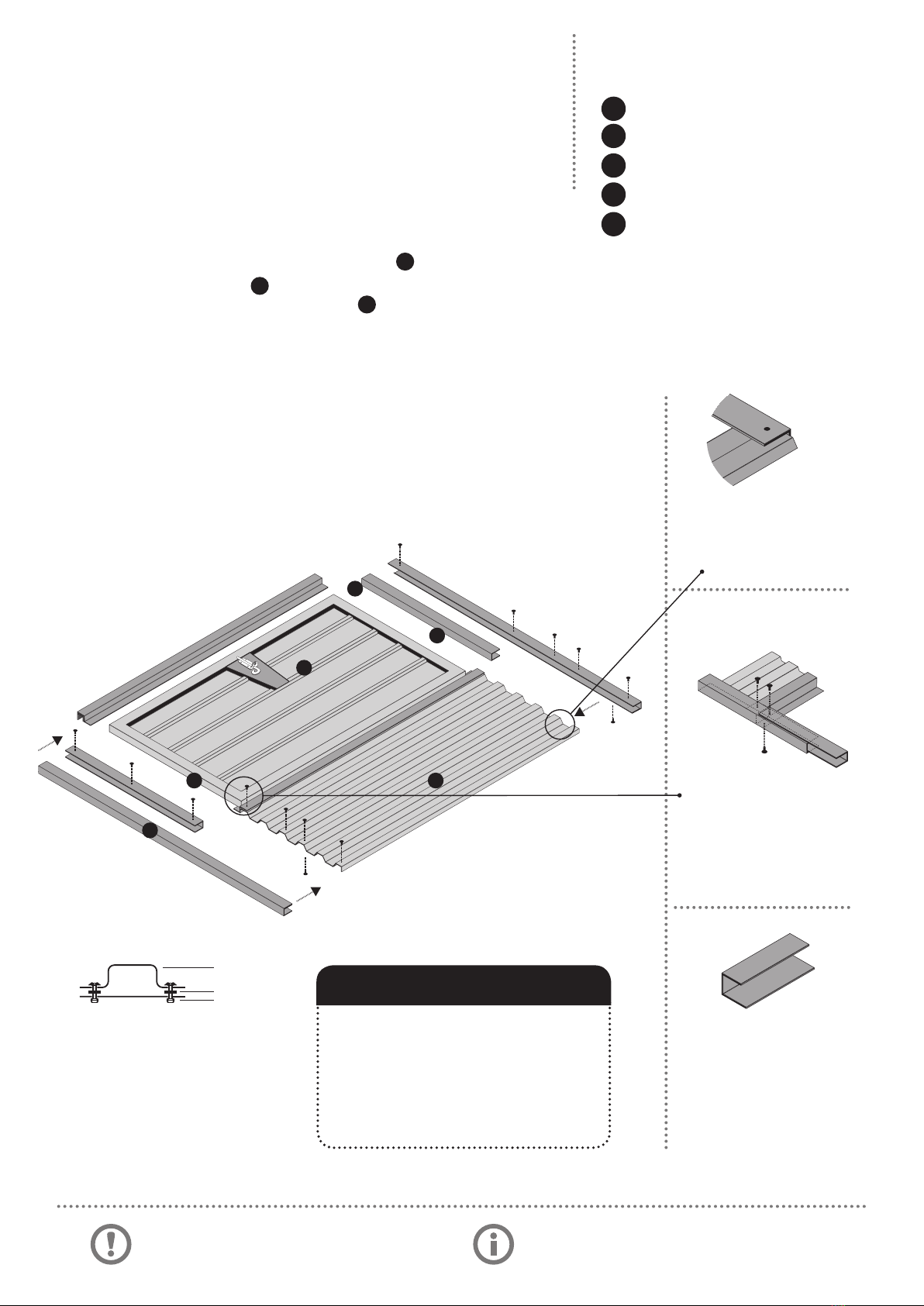

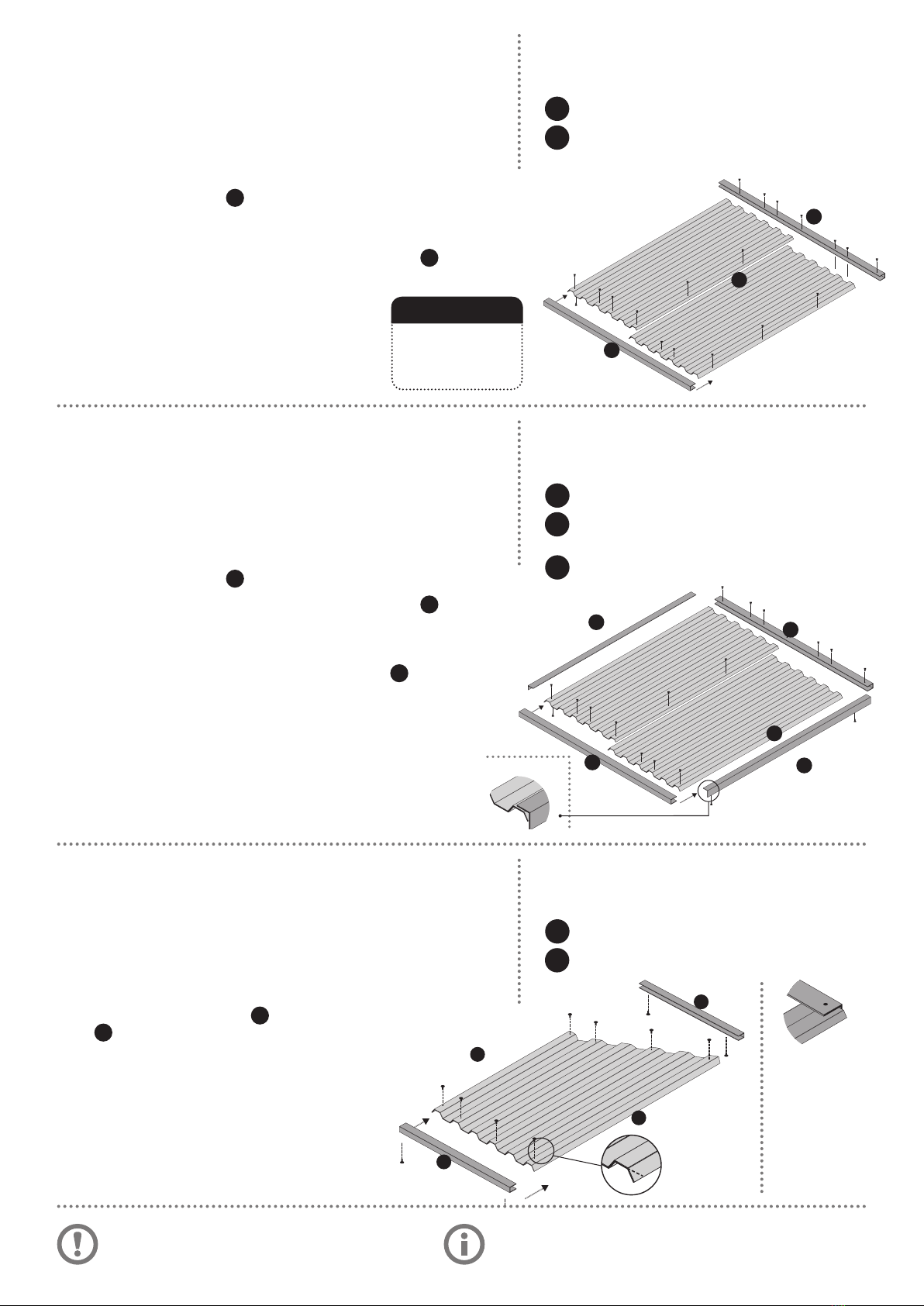

Fixing the roof

5. With a person at each end of the roof, lift it over the top of your

upright walls and lower down on top with an overhang that

looks best to you (diagram 4). At the left end x through the 'L'

ashing into the top channel of the left end wall. Measure the

overhang at the back and x the right end 'L' to the right end

wall with the same overhang as the left end. If it is difcult to

get the same overhang at each end, this will be caused by an

unlevel site or walls that are not square. Adjust accordingly. Fix

the 'L's at 300mm apart.

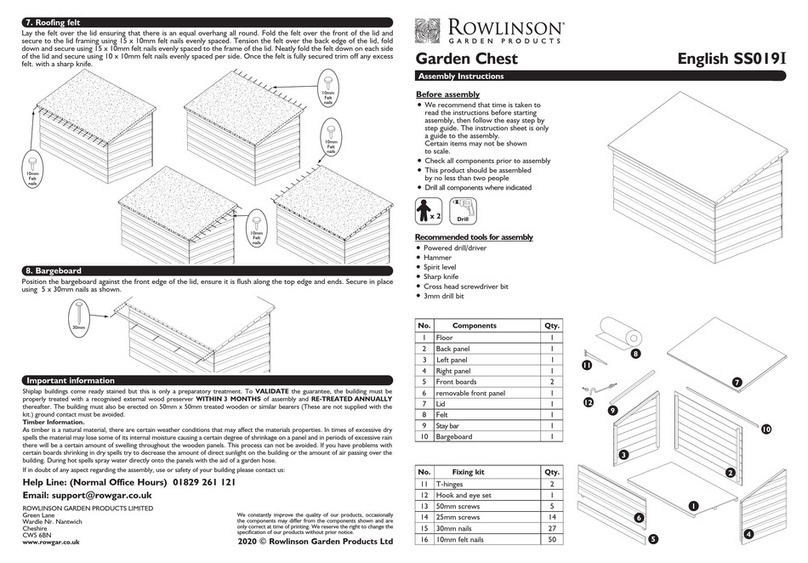

6. Using the ladder and the tape measure, x down through the

top of the roof, through the pan into the top channel of the front

and the back walls (10mm more than the overhang). Fix beside

every second rib. You will not need to worry about these xings

leaking as any water seeping through these xings will end up

on the outside of the walls.

Fit the door braces and install shed

7. Fit the door braces, if not already done so. Check that all

lings/swarf is removed.

8. Important: Fix your shed down to its foundations. If your

foundations are unlevel or bowed, you will have problems with

your padbolt and door levels. This can be xed by slipping a

spade under either door jamb and lifting. You will soon get a

feel for which side needs propping up.

Step 7:

Installation

Tip

Use the handle end of a hammer in

the inside of the corner, but beware

of drilling holes on the end of your

hammer.

Important

• Do not attempt to assemble panels

in rain or windy conditions.

• Make sure your foundations are

squared and level before erecting

panels.

• It is easier to remove all swarf

(lings) before you stand your

walls up.

• Complete all panels before

erecting your shed.

• Keep a rm grip on panels when

handling. If they slip they will

cause damage.

• Always wear non-slip gloves,

protective footwear and eyewear.

Important

It is essential that every shed has a oor, but the only way to make

sure your shed is there to stay on windy sites is with a recessed

concrete oor. Phone 0800 80 SHED for free advice. See page 6

for more details.

diagram 1

diagram 2

diagram 3

diagram 4

If you need advice, call us FREE on 0800 807 433