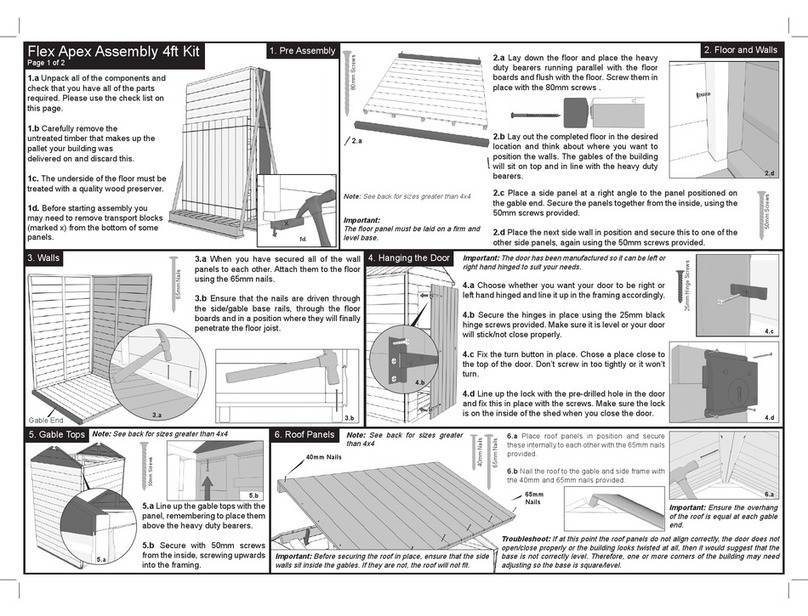

Flex Apex Assembly 6ft Kit

Page 1 of 2

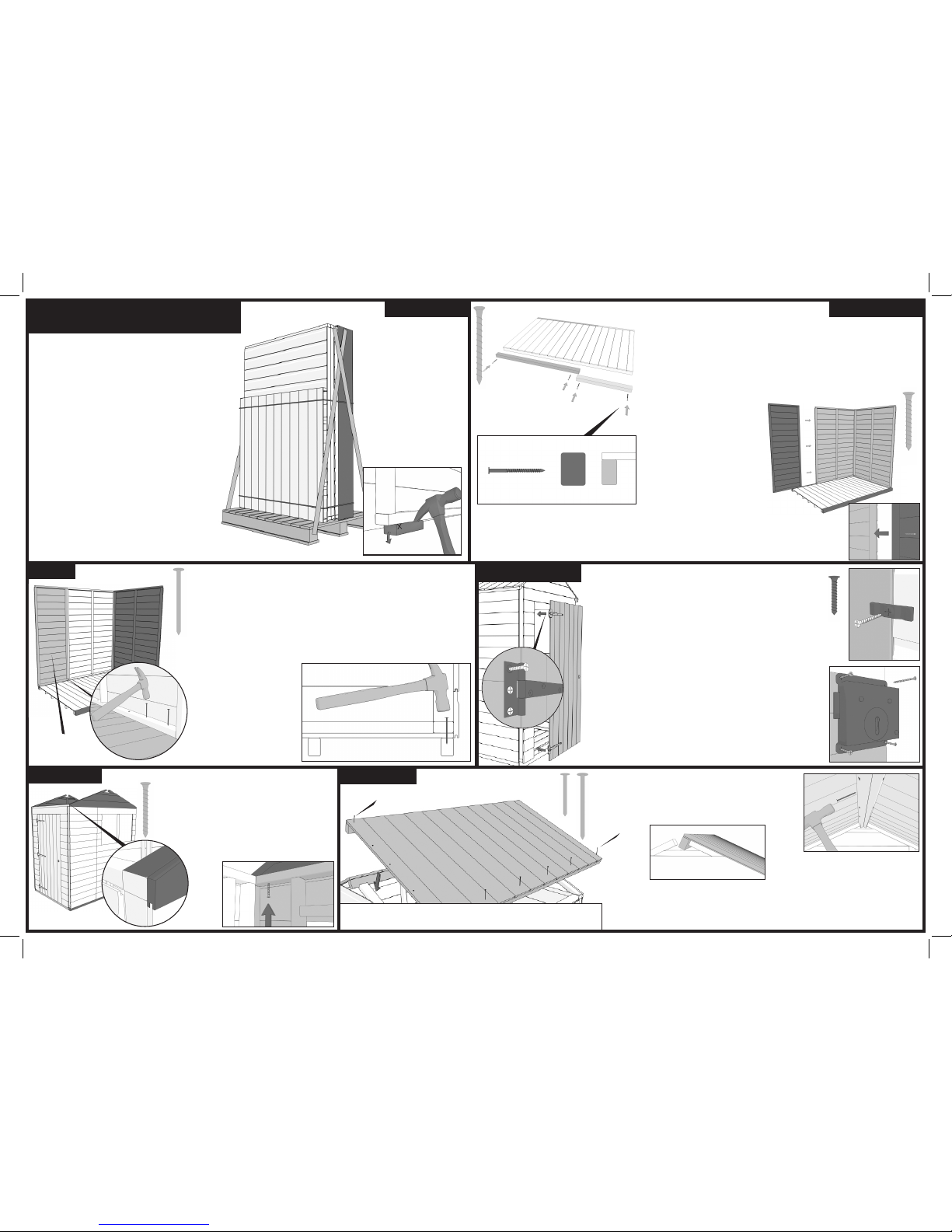

1. Pre Assembly

80mm Screws

Important:

The oor panel must be laid on a rm

and level base.

Note: See back for sizes greater than 4x6

2.b Lay out the completed oor in the desired location and think

about where you want to position the walls. The gables of the

building will sit on top and in line with the heavy duty bearers.

2.a

2. Floor and Walls

2.c Choose a 4ft panel that

will be part of your gable,

position this on top of one of

the heavy duty bearers and

line it up so that it is ush

with the side of the oor.

2.d To make up the 6ft gable

you need to position one of

the smaller panels alongside

the larger one. Secure these

panels together from the in-

side using the 50mm screws

provided.

2.a Lay down the oor and place the heavy

duty bearers running parallel with the bearers along the 6ft edge.

They must sit ush with the oorboards. Screw them in place with

the 80mm screws.

50mm Screws

3. Walls

65mm Nails

3.a Place a 4ft panel at a right angle to the panels positioned on

the gable end. Secure together using the 50mm screws.

3.b Place the remaining panels in position by repeating the last

three steps

3.c When you have secured all of the wall panels to each other.

Attach them to the oor using the 65mm nails.

2.d

3.d Ensure that the nails

are driven through the

side/gable base rails,

through the oor boards

and in a position where

they will nally pene-

trate the oor joists.

3.c

3.d

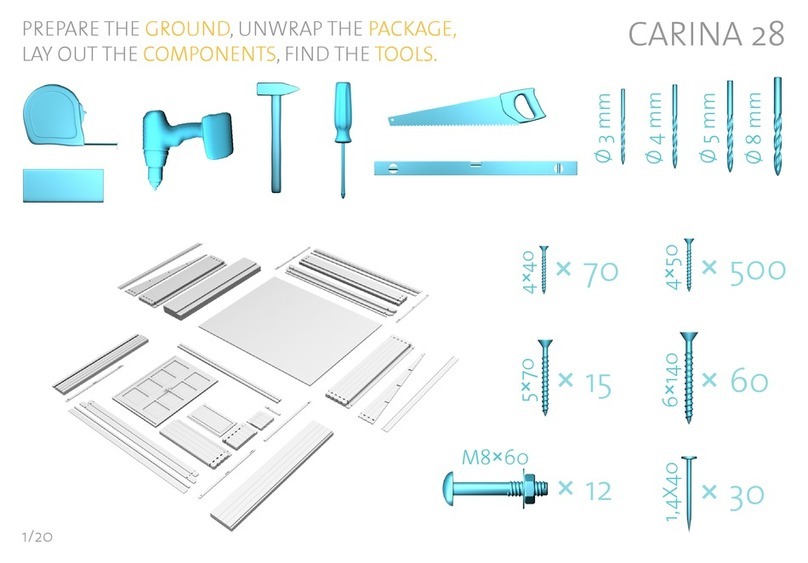

4. Hanging the Door

4.b

25mm Hinge Screws

4.c

4.d

Important: The door has been manufactured so it can be left or

right hand hinged to suit your needs.

4.a Choose whether you want your door to be right or

left hand hinged and line it up in the framing accordingly.

4.b Secure the hinges in place using the 25mm black

hinge screws provided. Make sure it is level or your door

will stick/not close properly.

4.c Fix the turn button in place. Choose a place close to

the top of the door. Don’t screw in too tightly or it won’t

turn.

4.d Line up the lock with the pre-drilled hole in the door

and x this in place with the screws. Make sure the lock

is on the inside of the shed when you close the door.

5. Gable Tops

Note: See back for sizes greater than 4x6

50mm Screws

5.a Line up the gable tops with the pan-

els on the 6ft side, remembering to place

them above the heavy duty bearers.

5.b Secure with 50mm screws from

the inside, screwing upwards into

the framing.

5.a 5.b

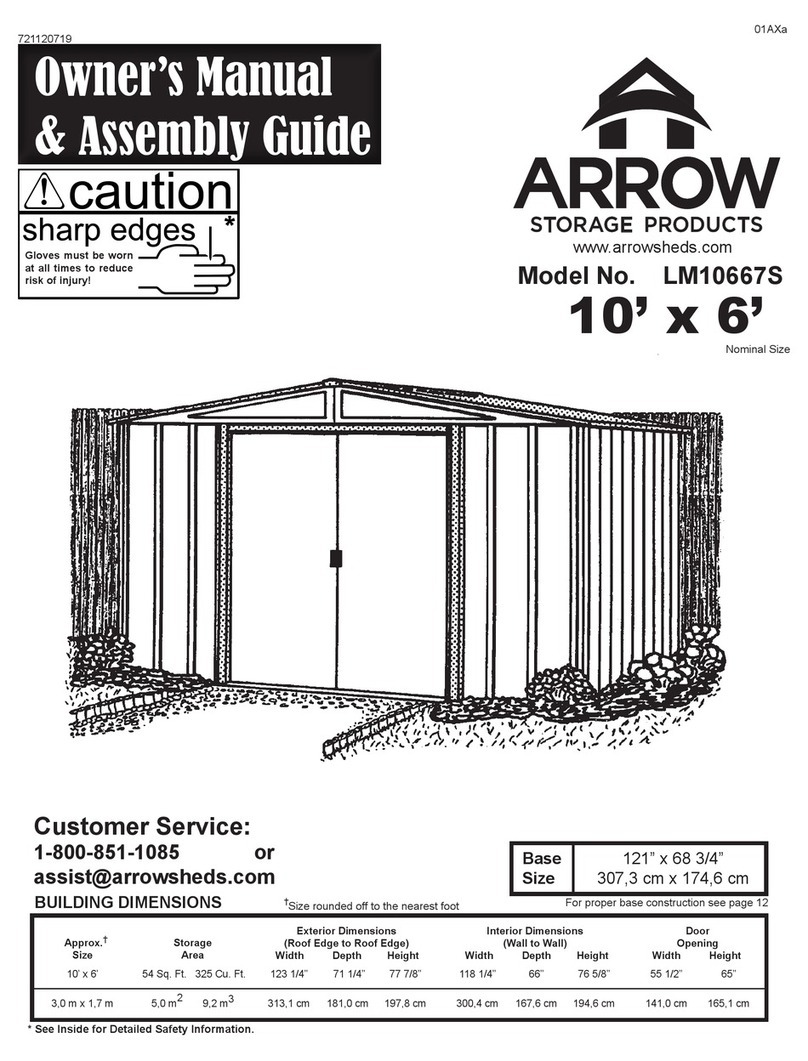

6. Roof Panels

40mm Nails

Note: See back for sizes greater

than 4x6

65mm

Nails

6.a Place roof panels in position and secure these

internally to each other with the 65mm nails provided.

6.b Nail the roof to the gable and side frame with the

40mm and 65mm nails provided.

65mm Nails

40mm Nails

Important: Ensure the overhang of the

roof is equal at each gable end.

Troubleshoot: If at this point the roof panels do not align correctly, the door

does not open/close properly or the building looks twisted at all, then it would

suggest that the base is not correctly level. Therefore, one or more corners of

the building may need adjusting so the base is square/level.

Gable End

6.a

Important: Before securing the roof in place, ensure that the side

walls sit inside the gables. If they are not, the roof will not t.

1.a Unpack all of the components and

check that you have all of the parts

required. Please use the check list on

this page.

1.b Carefully remove the

untreated timber that makes up the pal-

let your building was

delivered on and discard this.

1c. The underside of the oor must be

treated with a quality wood preserver.

1d. Before starting assembly you

may need to remove transport blocks

(marked x) from the bottom of some

panels.

1d.