Strack Z7510 User manual

MULTIZONE TEMPERATUR CONTROLLER

Z7510

OPERATING INSTRUCTION

ITemperatur controller

2STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Dear customer,

thank you for having chosen a STRACK temperature controller.

This high quality device has been produced in our ISO 90010 certified

factory and was shipped to you after a thourough quality test

Unpack Check the device for eventual shipping damage.

Don‘t connect damaged equipment!

Claim the damage with your shipping agent.

Read Please read carefully this operating manual before bringing

the device into service!

Connect Wiring the device should be done by your qualified

electrician following the instructions given in this

manual.

Warranty period is 1 year and includes all malfunctions clearly

caused by material, production or design failures.

Repair or replacement in this case are free of charge,

you only pay the shipping cost to our factory.

No further claims or requirements can be accepted,

especially for consequential losses or damages.

Service We help you quickly and at resonable costs.

Just send us the device with repair order and precise

description of the malfunction.

Carefull packaging is essential for a safe shipment!

Small repairs up to 80,- EUR are done immediately

without formal offer. In any other case, we contact you

as soon as possible to determine the next steps.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

3

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR5000-v.3

NOLDEN Regelsysteme GmbH 3

Carefull packaging is essential for a safe shipment !

Small repairs up to 80,- EUR are done immediately without

formal offer. In any other case, we contact you as soon as

possible to determine the next steps.

To facilitate your orientation in this manual, you find the

following symbols :

Safety advice

General information

Wiring- and installing advice

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

4STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

4

Table of content

Chapter Page

1 Features 5

2 Safety advice 6

3 Specification 8

4 Installation and wiring 10

5 Operation : 14

5.1 Operating elements and keys 14

5.2 Master switch 15

5.3 Display and operation modes 16

6 Settings : 27

6.1 Configuration level - device 27

6.2 Configuration level - zones 37

6.3 Operation level - Control parameters 47

6.4 Error messages 53

6.5 Factory default settings 55

7 Key word index 58

8 Appendix : 61

8.1 Custom pin assignment

8.2 Interface parameters (optional) 63

9 CE-Conformity declaration 69

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

5

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 5

1. 1. Features

Ready to use compact multizone temperature

controller for all 230V hotrunner systems

- Compact unit for 4, 6 or 8 zones

- Automatic self-tuning for every zone, also

during current operation („Hot autotuning“)

- LCD grafic display with plain language

operation

- Intelligent, programmable soft start routine

- Stand-by operation for production stops -

also to be activated via external switch

- Boosting to free „frozen“ nozzles

- Programmable alarm settings for every zone

- Integrated heater current monitoring

- Data interface as an option (e.g. Arburg)

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

6STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

6

2 Safety advice

1. Please read this advice carefully.

2. Keep this operations manual for use near the

machine.

3. This is an electral device driven with high

voltage, please respect the usual VDE- and

safety regulations.

Mains voltage and every voltage greater than 42

volts is dangerous !

4. Connect to a power source following the

identification plate on the device.

5. Avoid contamination of the interior with debris,

liquids or sprays.

Risk of short-circuit, fire or electric shock !

6. Before cleaning the device, disconnect from the

power source.

7. Place the device in a stable manner and prevent

it from slipping away. Take care of the tension

load created by the wiring, fix the cables separa-

tely from the controller.

8. Don‘t place the device on hot machine surfaces

or near radiation sources of hot parts.

9. Keep the power connection cable clear of hot

parts or sharp edges.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

7

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 7

10. Disconnect the power cable immediately, if

- it was damaged,

- liquid or parts penetrated the device,

- the device was damaged by falling down or

other mechanical impacts,

- you have the suspicion of any malfunction.

11. The operator must be thoroughly instructed by

a qualified person for the work to be carried out.

12. Intervention at the device must only be carried

out by qualified staff members.

For repair, the device should be send back to

our factory. Attempted self-repair causes

immediate termination of the warranty period !

If spare parts are required, only parts recom-

mended by the supplier must be used. The use

of other parts may cause damage and/or

hazard for operation personnel.

13. Please respect further recommandations and

warnings described in this operations manual.

.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

8STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

8

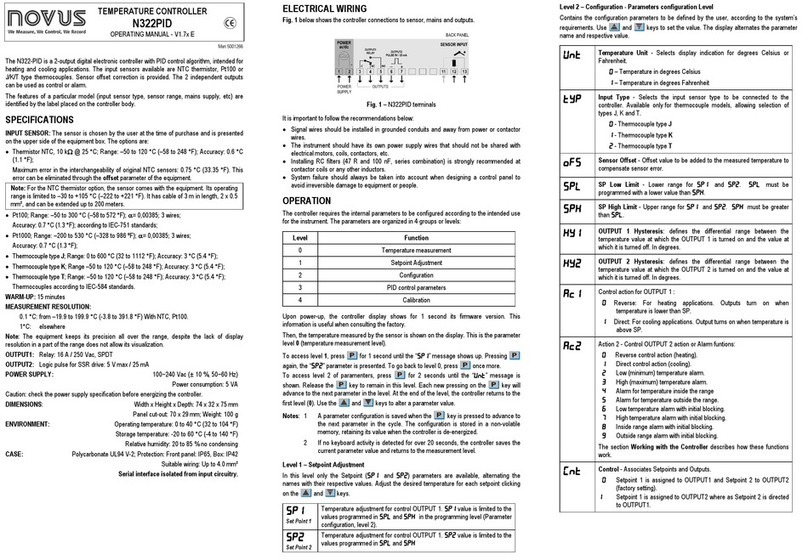

3. Specification

Mains voltage :

230V 3~, +/- 10%, 50/60Hz

Nominal rating/nominal current :

Max. load per zone 3.600W / 16A

Total load of the device max. 17,25kW, 3x25A

Fuses

Heater : 16A FF, 6,3x32mm per zone

Alarms:

2 alarms programmable per zone, each as

temperature– or current alarm

Sensor inputs :

Thermocouple Fe-CuNi, type J, 0...800°C

Internal zero point correction

Thermocouple is monitored for cable breakage,

short-circuit and polarity errors.

Power control :

0...100% proportional, zero-voltage switching

Triac rated up to 35A

Display :

Shows actual values en setpoints, load current,

alarms, configuration parameters, control deviations

and temperature curves

Language settings English / German, plain text for

control– and configuration-parameters

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

9

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 9

Automatic soft-start :

(factory defaults)

Powersetting 50% / temperature 80°C / time 5 min

Sensor-/load-connectors :

16 or 24-pole standard-industry female plug 16A/400V

Pin assignment NR-Norm, other norms available (see

appendix)

Standby / alarm-exit :

7-pin plug :

2 floating contacts (230VAC, max. 3A) for alarms.

One floating input to activate the 2

nd

(standby-)

temperature-setpoint for all zones simultaneously,

wired in parallel with the internal “stand-by” switch.

Accuracy :

0,25% FS

Insulation voltage :

2,5kV mains/sensor circuit

Dimensions

324 x 380 x 167mm (WxDxH, 4 to 8 zones)

Colour

Structured

RAL3000 Casing

Weight

11,4 kg (NR4008)

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

10 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

10

4. Installation and wiring :

4.1 Installation :

The installation site must provide easy access for

the operator without hazard. Sufficient mechanical

stability must be guaranteed, also secure the device

from slipping on the installation surface.

Protect from heat, radiation and allow free air circu-

lation. Protect power cable from heat and mechani-

cal stress. Do not place the device on hot surfaces.

Take care of the tension load created by the wiring,

fix the cables separately from the controller.

4.2 Connection of the power supply :

This device must only be operated at the voltage

indicated on the name plate. Please check for a

sufficient fuse protection of the power outlet fore-

seen for the device.

Protective earth conductor must be provided !

4.3 Connection of heater and thermocouples :

Please compare the connecting diagram on the

temperature controller (backside, near the outlet)

with the diagram of the mould. Inappropriate con

nection can destroy controller, heater and TC !

Available mould connecting cables contain heater–

and FeCu-Ni compensation wires for TC. Never use

compensation wires to connect a heater.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

11

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 11

Maximum load capacity for the heater when using

mould connector VK24 (24-pol. + PE) or VK16 (16-pol.

+ PE)

The maximum load capacity of the heater wires

(1,5sqmm Cu) depends on the operating conditions (see

also DIN VDE 0298 Part 2 and 4).

@ op. condition : Continuous

@ wire location : Individually, free installation on wall

or floor

@ ambiant

Temperature : 30°C, free air circulation, no heat

radiation

VK 24 : VK 16 :

1 heater 12,5 A 1 heater 12,5 A

2 heaters 12,5 A 2 heaters 12,5 A

3 heaters 11,5 A 3 heaters 11,5 A

4 heaters 10,5 A 4 heaters 10,5 A

5 heaters 10,0 A

6 heaters 9,5 A

Load and TC-

connection NR24 :

Load and TC-

connection NR16 :

Other pin assignment

(see appendix chapter 8.1 of this manual)

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

12 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

12

4.4 Alarm-/ Stand-by connection :

For every zone, two alarm functions can be pro-

grammed individually. These alarms operate 2

common floating contacts as cumulative exits for all

zones together, they are wired on a 7-pin connector

on the back side. Default settings are one process-

high temperature alarm (A1, pin 4 and 5) as well as

one load-breakage alarm (A2, pin 2 and 3).

To activate the 2nd temperature set-point (stand-by

function), another floating contact is wired to pin 6

and 7. This function can also be activated manually

with a button on the front panel .

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

13

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 13

1 2

3

4

Fig. : Back side NR 4008-v2

1 Heating– and TC-connection

2 Data-interface (optional)

3 Alarm ouput / external Stand-By

4 Power cord

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

14 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

14

5. Operation

5.1 Keys and operation elements

4 3

1 5

6

2 7

Fig.: Front view NR 4008-v2

1 Display

2 Keys

3 Switch for stand-by operation

4 Boost-key

5 Phase control lights (one for every phase)

6 Master switch

7 Load fuses for every heating zone

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

15

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 15

5.2 Master switch

Before wiring the device, make sure that the main

switch is in position OFF „0“. Herewith, all poles are

disconnected from the mains voltage. The main

switch can be locked following EN81-80. Before

working on the device itself or on a tool connected

to it, the switch must be locked to prevent the device

against unintentional restart.

This can be done by retracting the power cable and

securing it against re-connecting or by locking the

main switch with a personal lock.

After having finished the wiring completely, switch

the device on with main switch in position ON „1“.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

16 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

16

5.3 Display and keys

Display :

The device is equipped with a bright, sharp LCD-

screen. After switching the unit on and internal test,

the actual temperatures of all zones are being

shown.

Zone: 1

Actual tempera-

ture : 200 °C

In the case of a 4 zones unit , the actual values

and temperatures of all zones are shown at the

same time .

Left column : Actual value

Right column : Setpoint

Parameters and settings are mostly being displayed

in plain text.

The display can be set to other languages (see

chapter 6.1 configuration level - device).

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

17

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 17

Keys :

Zone selection

Actual value and setpoint of the choosen zone

Parameter selection in one choosen zone.

Parameter setting (e.g. setpoint or control

parameter) to higher or lower values.

(altered, but not yet acknowledged values are

being marked with a flashing „E“

Enter - Acknowledges the pre-set values and

saves them into power-independant memory

Menu - Configuration menu for the whole

device or for one zone, depending on the

actual screen beeing displayed

„HOME“ - Back to home menu with display of

actual temperature of all connected zones

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

18 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

18

Tracing function. Shows the actual tempera-

ture curve of one zone (to be choosen first with

the zone key) To turn off the tracing function,

press the key again.

Tendency display - shows the temperature

deviation vs. setpoint in all zones simultane-

ously, also display of eventual alarms per zone

Contrast adjustment of the LCD-screen :

Press „Enter “ and at the same time the „▲“ or „▼“

keys

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

19

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

NOLDEN Regelsysteme GmbH 19

Switch for stand-by operation

Toggles all zones simultaneously from

normal temperature setpoint SP1 to

stand-by setpoint SP2, e.g. to lower the temperature

during process interuptions to prevent the mass

from „cooking“.

Wired internally in parallel with the “stand-by” plug

on the back side of the device. This permits the

switching to stand-by mode also by an external

contact, e.g. in the injection moulding press.

If a higher setpoint SP2 is programmed, the control-

ler can also be used to follow a triggered

temperature curve in the process.

Manual Boost - temporary temperature

increase for all zones by a pre-set value

(boost addiation SP3), e.g. to free

„frozen“ nozzles. The activated boost-setpoint is

hold for a given time (boost holding time), then the

temperature is lowered again to the normal

operation setpoint SP1.

Operating instruction Z7510 Multizone temperatur controller

ITemperatur controller

20 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

Operations manual NR4000-v.2

20

Phase controll lights

for all 3 phases of the mains power

source. Is one of the controll lights

not lit, the according phase of the power source is

not functioning, several heaters and/or the main

control unit are not working properly. Before

looking for malfunctions in the control device,

check the correct power supply first.

Master switch (see chapter 5.2)

Table of contents

Other Strack Temperature Controllers manuals