Eurotherm 2116 User manual

Other Eurotherm Temperature Controllers manuals

Eurotherm

Eurotherm 216 User manual

Eurotherm

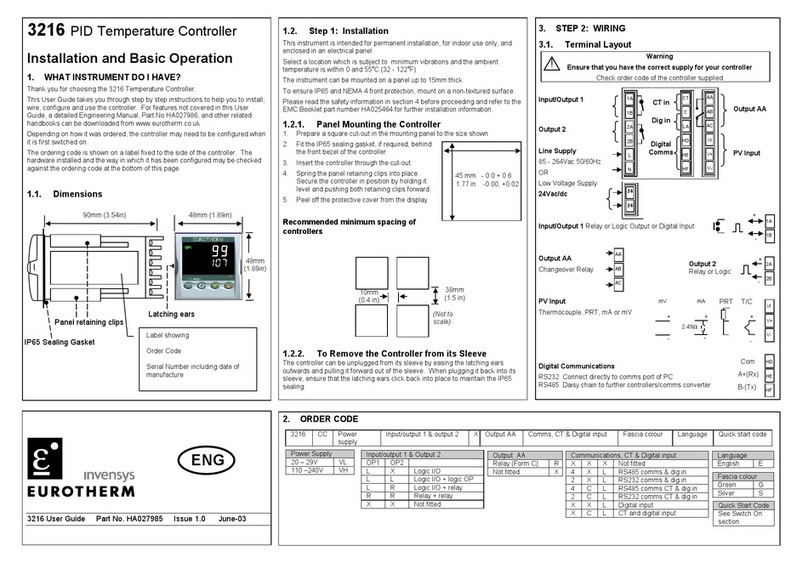

Eurotherm Invensys 3216 User manual

Eurotherm

Eurotherm 3116 User manual

Eurotherm

Eurotherm Invensys 3216 User manual

Eurotherm

Eurotherm 2208e Owner's manual

Eurotherm

Eurotherm 3100 Installation and operation manual

Eurotherm

Eurotherm 2208L User manual

Eurotherm

Eurotherm Invensys 3216 User manual

Eurotherm

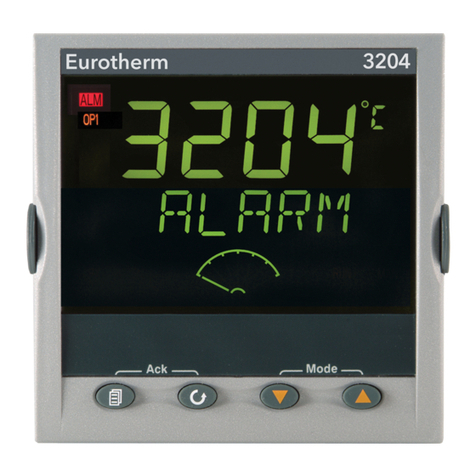

Eurotherm 3200 User manual

Eurotherm

Eurotherm 2108i Wiring diagram

Popular Temperature Controllers manuals by other brands

P.W. KEY

P.W. KEY rt-208gt operating manual

BH Thermal

BH Thermal BriskONE owner's manual

West Control Solutions

West Control Solutions KS 45 Operation Notes

MCS

MCS RITC-15B Operator's manual

SMC Networks

SMC Networks Thermo-con INR-244-639 Operation manual

eltherm

eltherm Ex-TC It Series operating instructions

Omron

Omron C200H-TV Series Operation manual

industrie technik

industrie technik CA1 instructions

KRAL

KRAL EET 32 operating instructions

dixell

dixell XR420C Installing and operating instructions

Opt Lasers

Opt Lasers TEC-8A-24V-PID-HC operating manual

Vaillant

Vaillant VR 92/3 Operating and installation instructions