18

Optional features

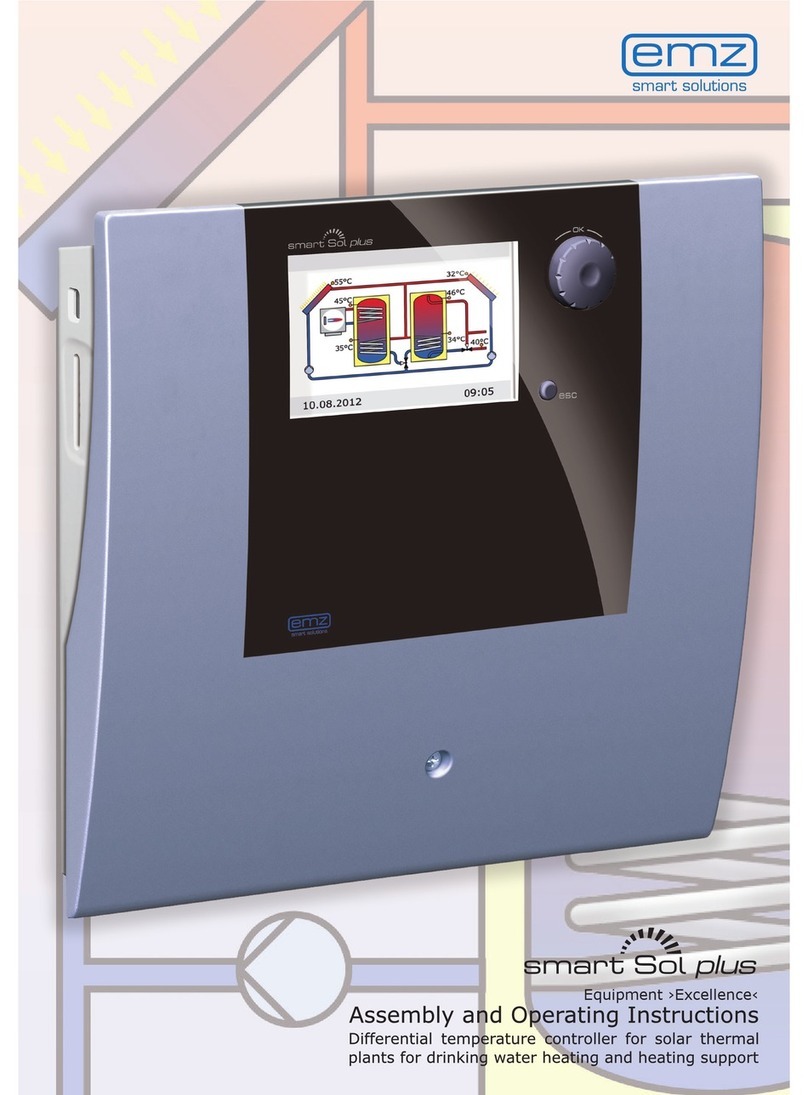

Optional volumetric ow sensor:

Measurement of solar radiation (heat quantity):

The solar yield is calculated from the ow rate and the differential temperature.

The differential temperature is the difference in the temperature of the collector

sensor and the solar circuit return line sensor. There are various technical options:

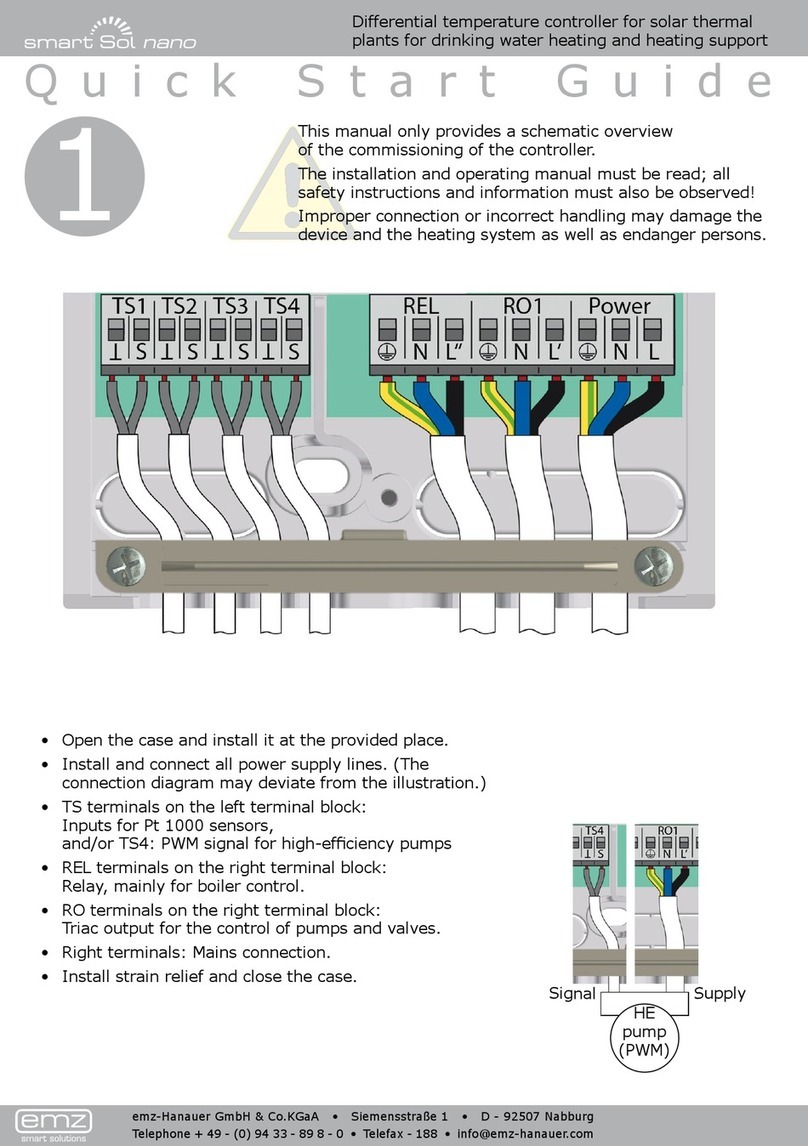

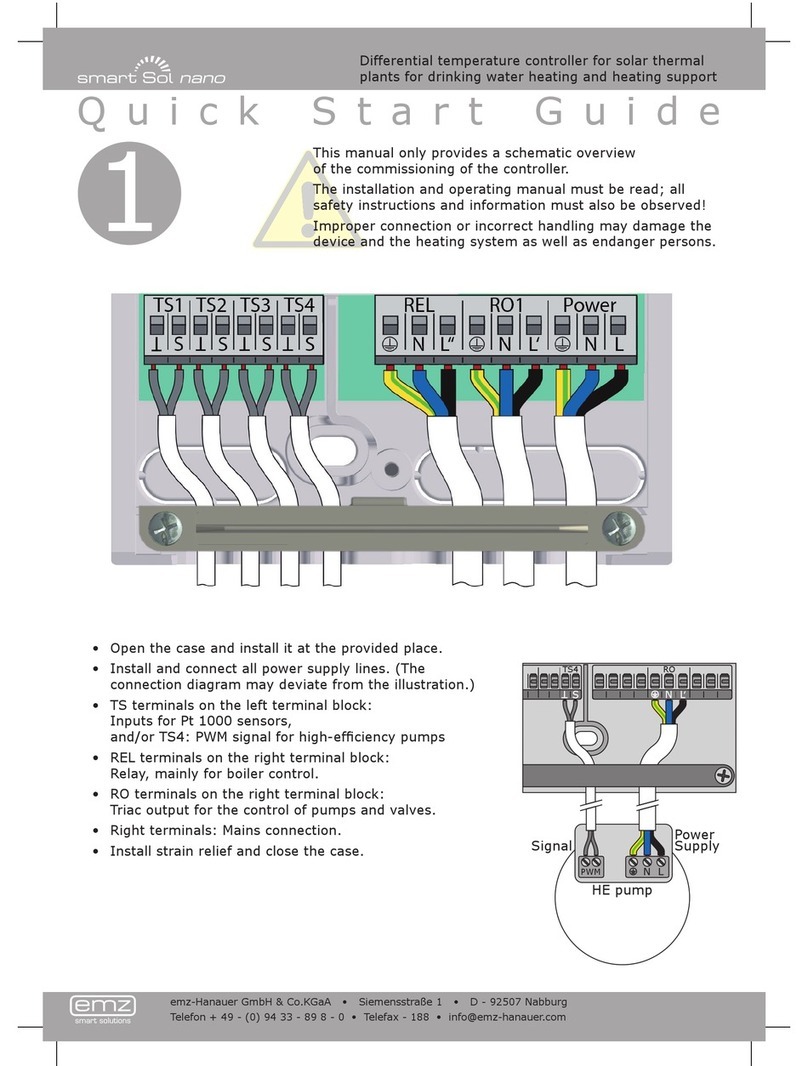

a) Use of a vortex volumetric ow sensor with 2 analog signals for ow rate and

temperature. The vortex sensor can be inserted directly at the plug connector provided

behind the TS3/4 terminals. All plant layouts permit solar radiation. When a vortex

sensor is connected to plug UI1/UI2, the cover plate at the housing must be broken out.

Plug connector for vortex

sensor behind the

terminals

TS3/TS4.

Pin assignment

Plug connector for vortex sensor:

1 = UI1 = Temperature sensor

2 = UI2 = Flow rate sensor

4 3 2 1

+5V GND UI2 UI1

b) Impeller sensor (incrementation input)

An impeller sensor can be connected to TS3 or TS4 and must be adjusted during

installation. The temperature sensor for the solar return line is connected to TS3 or TS4

and must then be set in the menu 1.1.4 Heat quantities. Solar radiation measurement

using an impeller sensor is possible for plant layouts 1, 2, 3, 4, 5, 7, 10, 12 and 14.

Optional micro SD card:

The solar controller features the following data interfaces:

The recesses in the left-hand side of the

housing base accommodate an USB connector

and a slot for a data medium (micro SD card).

These interfaces can be used e. g. to read error messages or

saved data or to transfer software updates to the controller.

Access to the data on the micro SD card

is possible via the USB connector.

Only the SD cards authorized by emz may be used.

The micro SD card is detected by the controller automatically.

Before removing the micro SD card from the controller, the item

›Remove SD card safely‹ must be selected under ›1.2 Settings‹.