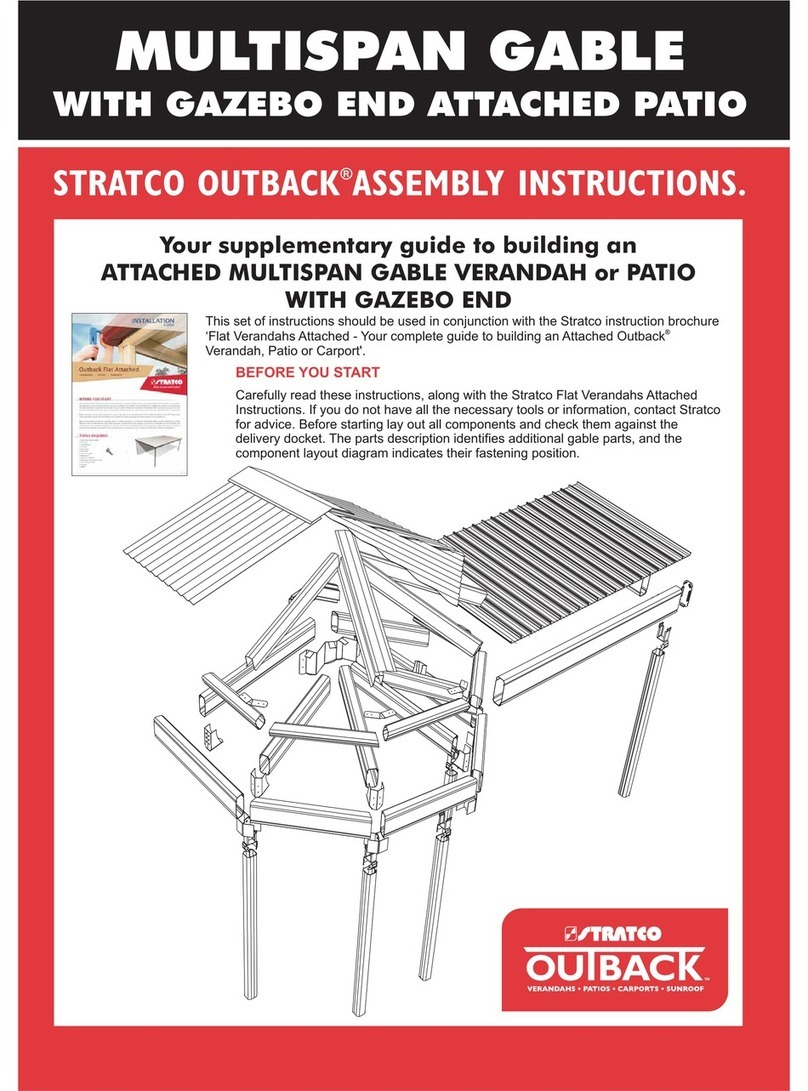

COLLAR TIE

END PURLIN SUPPORTS

The collar tie spans horizontally across the outside of the

internal gable portal frames. It aligns with the top of the hip

rafters, so that the front roof sheets can run continuously

over the rectangular end rafter, front purlin and the collar tie.

Again pre-drill first through the double flange material with

one large 14 x 95 hex head self drilling screw at each end,

and fasten to side of gable rafters.

End purlin supports (68mm purlins) are only required if

indicated in the drawings supplied. End purlin supports

span between the collar tie and the end frame and are to

be fastened in place using the 68mm purlin bracket

before front purlin/s are screwed in place.

If only one end purlin support is required fasten one

purlin bracket mid-span of collar tie and a second mid-

span of the end frame (inline with the top of 120 end

rafter) using two 10 x 16 hex head self drilling screws per

bracket (Figure 16). If two end purlin supports are

required fasten brackets at third points along both collar

tie and end rafter (ie, 2 along collar tie and 2 along end

rafter, Figure 17).

Measure, cut and mitre end purlin supports to fit flush

between collar tie and end frame ensuring double flange

is on top. When two end purlin supports are required legs

on purlin brackets may need to be bent inward or outward

slightly to accommodate angle between end purlin

supports and frame.

Fasten end purlin supports in place using two 10 x 16 hex

head self drilling screws per bracket per side of end

purlin support. Cut (and mitre if necessary) front purlin/s

to span between end purlin supports. 68mm purlin

brackets are to be fastened to end purlin supports where

they meet front purlin/s and front purlin/s are screwed in

place.

This procedure applies to both ends of the Dutch

Gable unit.

Note :

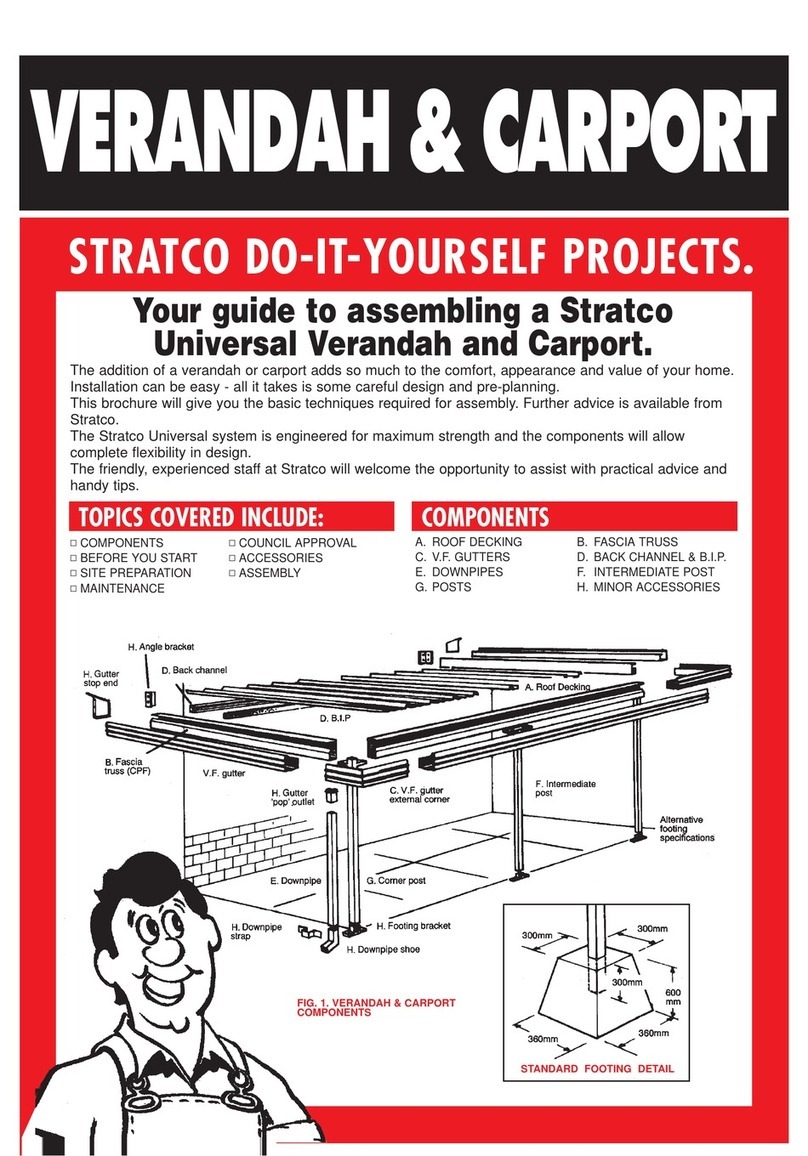

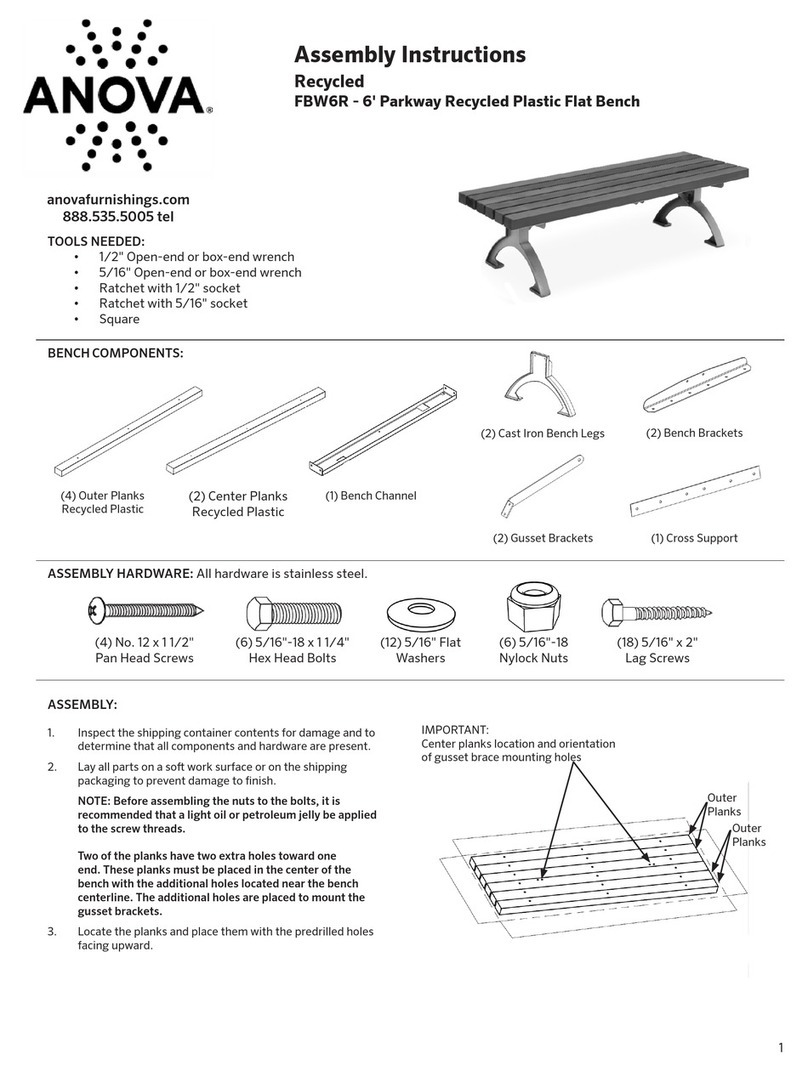

CONCRETE REMAINING FOOTINGS (IN

CONCRETE FOOTING)

GUTTER ASSEMBLY

Once the carport frame is complete concrete the remaining

footings. Only concrete the galvanised tube footing stumps.

The concrete should be finished slightly raised

towards the column, ensuring water runs away from the

column, see figure 11.

If concrete or soil is in permanent contact

with the colorbond columns, corrosion will result in the base

of the colored column. Refer to the "Selection, Use and

Maintenance of Stratco Steel Products" brochure for

complete details of maintenance requirements.

(a) Measure and cut gutters to the appropriate length ( ie

back length of gutter should equal outside frame

dimensions + 30mm). Rivet and silicone seal.

(b) Notch hole in gutter and insert downpipe pop so that

downpipe is in line with a portal column.

If your column footings are in ground you would have

installed your portal frames with a slight fall towards

downpipe end. Ensure that the gutter is notched at the right

end.

However if you are bolting the footings on to existing

concrete slab, and there is a slight fall in the slab ensure

that the downpipe is at the lower end of the slab to help the

water run off). Fasten the pop in place using rivets and

silicone seal.

(c) Cut 70 mm long metal strips from band supplied. Pop

rivet these tags to the top of the eaves purlins and end

frame rafters at 1200 mm centres. Rivet the back lip of the

gutter to these tags, ensuring the back face of the gutter is

held vertical as shown in Figure 18. Rivet and silicone seal.

Note:

Note:

Important Note:

16

COLLAR TIE ONE END PURLIN SUPPORT

COLLAR TIE

END PURLIN

SUPPORT

END PURLIN

SUPPORT

FRONT

PURLIN

END FRAME

68mm PURLIN BRACKET

2 (10 X 16 HEX HEAD SELF

DRILLING SCREWS)

THROUGH BOTH SIDES

17

COLLAR TIE TWO END PURLIN SUPPORTS

COLLAR TIE

END PURLIN

SUPPORT

END PURLIN

SUPPORTS

FRONT

PURLIN

END FRAME

68mm PURLIN BRACKET

2 (10 X 16 HEX HEAD SELF

DRILLING SCREWS)

THROUGH BOTH SIDES