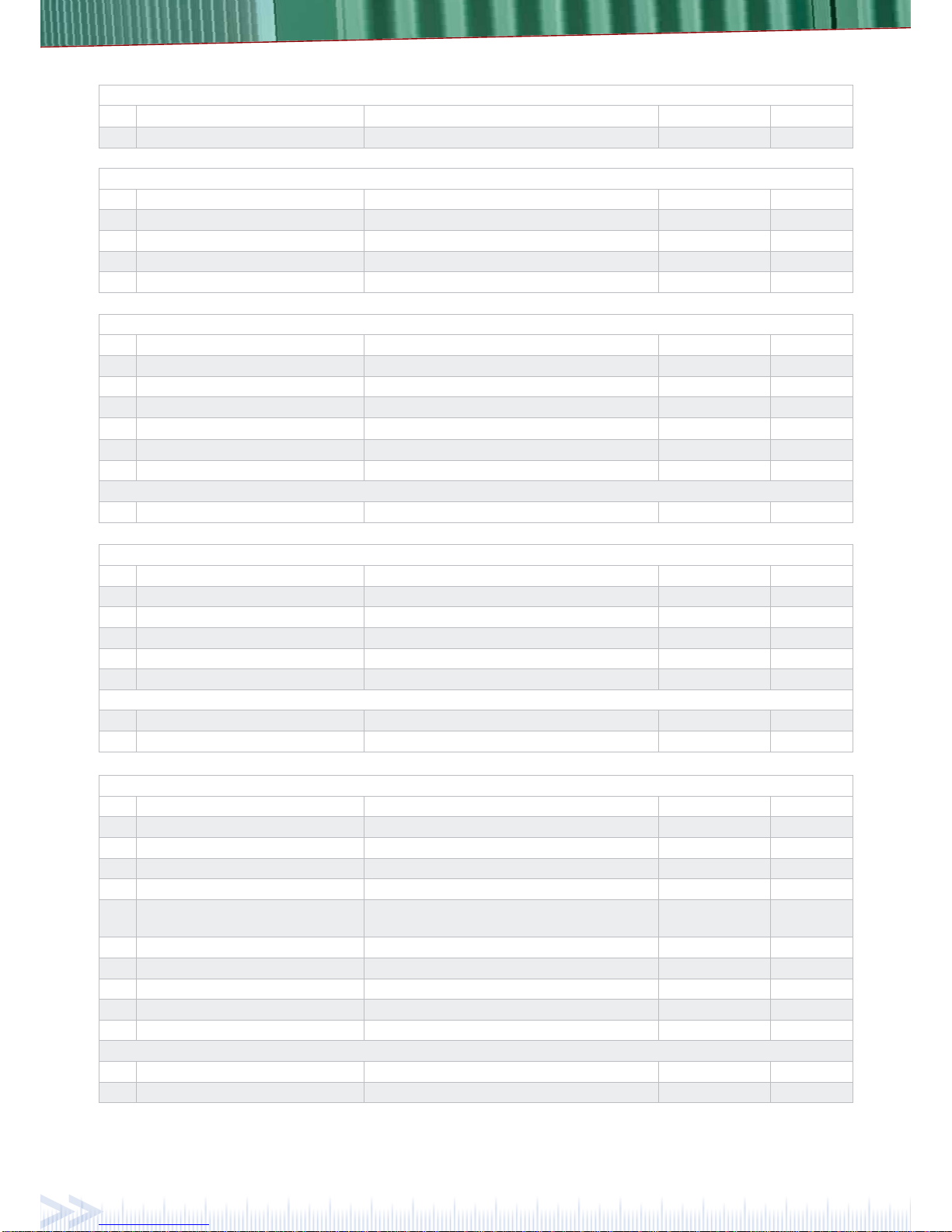

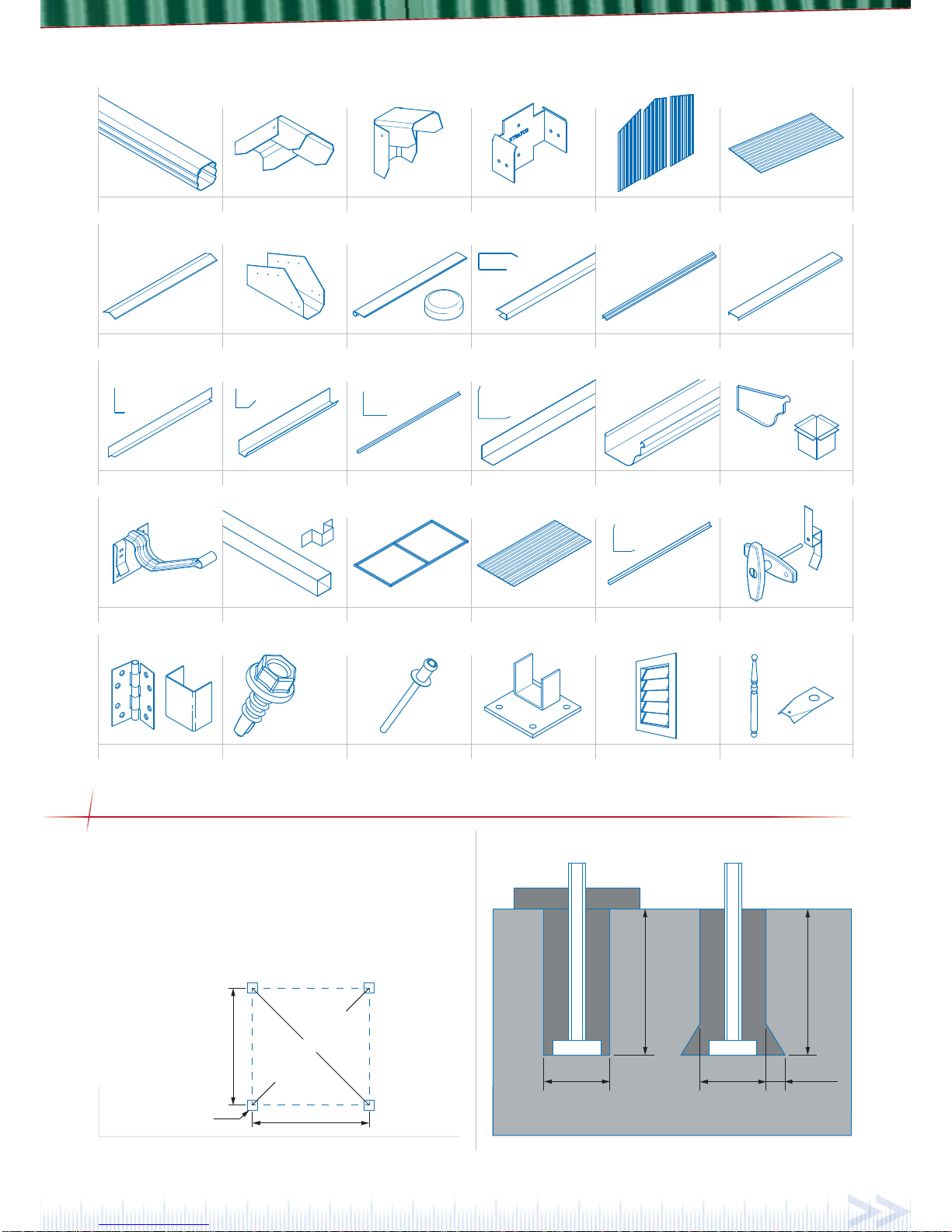

H1 HERITAGE GARDEN SHED COMPONENT LIST

NO. COMPONENT CARTNOTE DESCRIPTION CODE QTY.

10 ROOF SHEETS CGI HER G/SHED .35 D/SIDE COLOUR CGIHGS35D## 6/1.355

11 DOOR LINTEL HER G/SHED DOOR LINTEL 1.2 GALV HDL12GA 1/0.930

12 DOOR JAMBS HER G/SHED DOOR JAMB 1.2 GALV HJA12GA 2/2.300

13 CORNER FLASHINGS HER G/SHED CORNER FLASHING COLOUR HCF## 4/2.025

14 DOOR LINTEL FLASHING HER G/SHED DOOR LINTEL FLASH COLOUR HLF## 1/0.950

15 DOOR TRIM FLASHING HER G/SHED DOOR TRIM FLASH COLOUR HTF## 2/1.890

16 SHEETING CAPPING HER G/SHED CAPPING COLOUR HSC## 2/2.500

17 BARGE ROLL BARGE ROLL 100 .55 COLOUR BRO10055## 4/1.400

18 PAINTED POST CAP PAINT POST CAP ROUND 50MM GALV FH-1032 4

19 RIDGE CAPPING ROLL TYPE RIDGE 355 .55 COLOUR RTR35555## 1/2.550

20 10X16 SELF-DRILLING SCREW TEK SCREW NO WASH 10 X 16MM TEKNNW1016 265

21 10X16 SELF-DRILLING SCREW COLOUR TEK SCREW NO NEO 10 X 16MM COLOUR TEKNNW1016## 125

22 12X35 SELF-DRILLING SCREW COLOUR TEK SCREW NEO 12 X 35MM COLOUR TEK1235## 95

23 POP RIVET RIVET 3.2X3.2 GRIP (4-2) ALUM RIV4-2 77

24 INSTRUCTIONS INSTRUCTION AND COMPONENT LIST INCLHGSH01 1

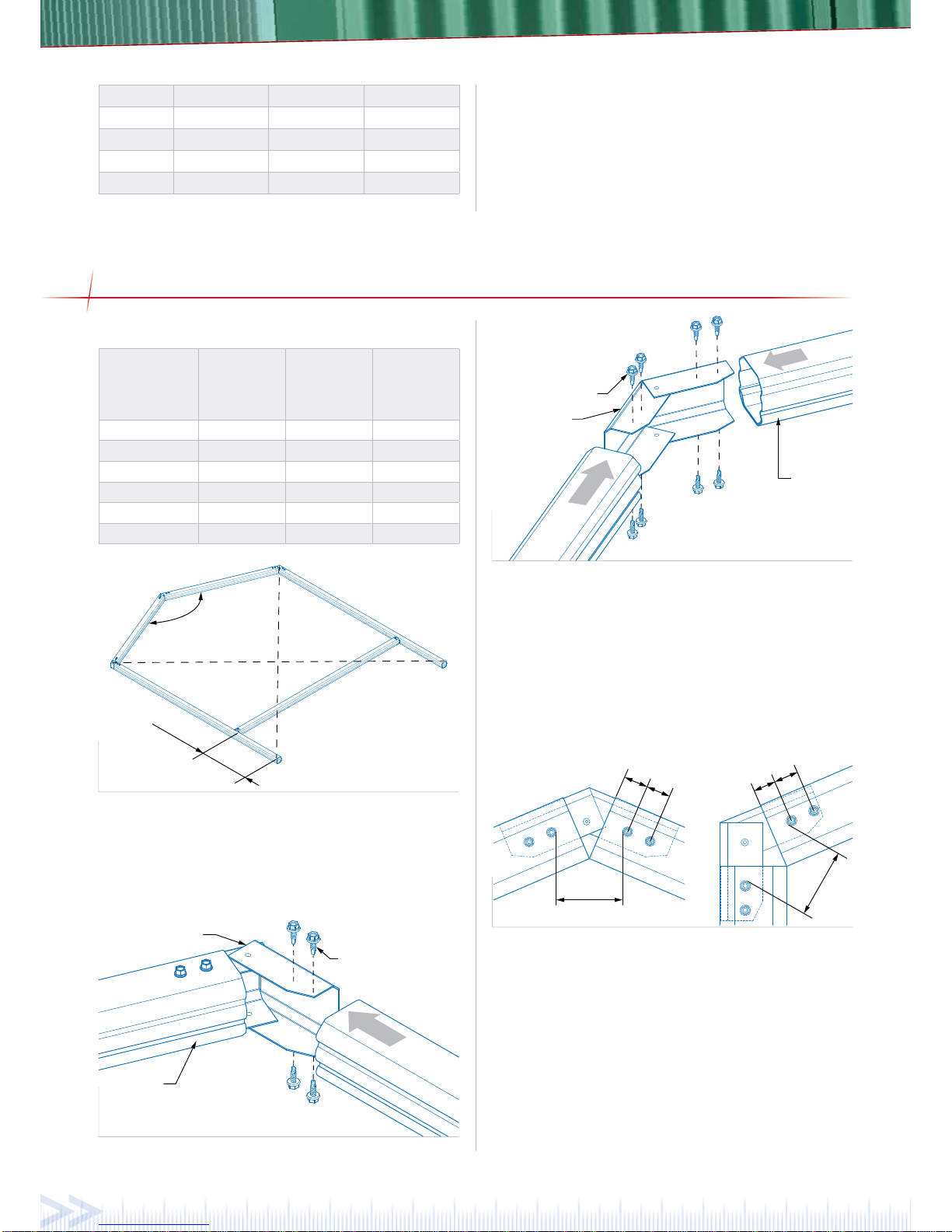

HERITAGE SHED PA DOOR KIT COMPONENT LIST

NO. COMPONENT CARTNOTE DESCRIPTION CODE QTY.

25 DOOR SHEET CGI HER G/SHED .35 D/SIDE COLOUR CGIHGS35D## 1/1.840

26 PA DOOR FRAME HERITAGE GARDEN SHED DOOR FRAME HGDF 1

27 DOOR FLASHINGS HER G/SHED DOOR FLASHING COLOUR HDF## 2/1.840

28 PA BUTT HINGE 100x75 HINGE BUTT 100X75MM F/P ZINC PLATED FH-1122 2

29 PA “T” BAR HANDLE HANDLE T SHAPE CHROME F/FIX CODE: FH-1104 1

30 PA DOOR TONGUE STRIKER TONGUE LATCH TO SUIT GARAGE HANDLE FH-1102 1

31 10x16 WAFER HEAD SCREWS WAFER HEAD TEK 10 X 16MM WTK1016 16

23 POP RIVET RIVET 3.2X3.2 GRIP (4-2) ALUM RIV4-2 8

21 10x16 SELF-DRILLING SCREW COLOUR TEK SCREW NO NEO COLOUR 10 X 16MM TEKNNW1016## 20

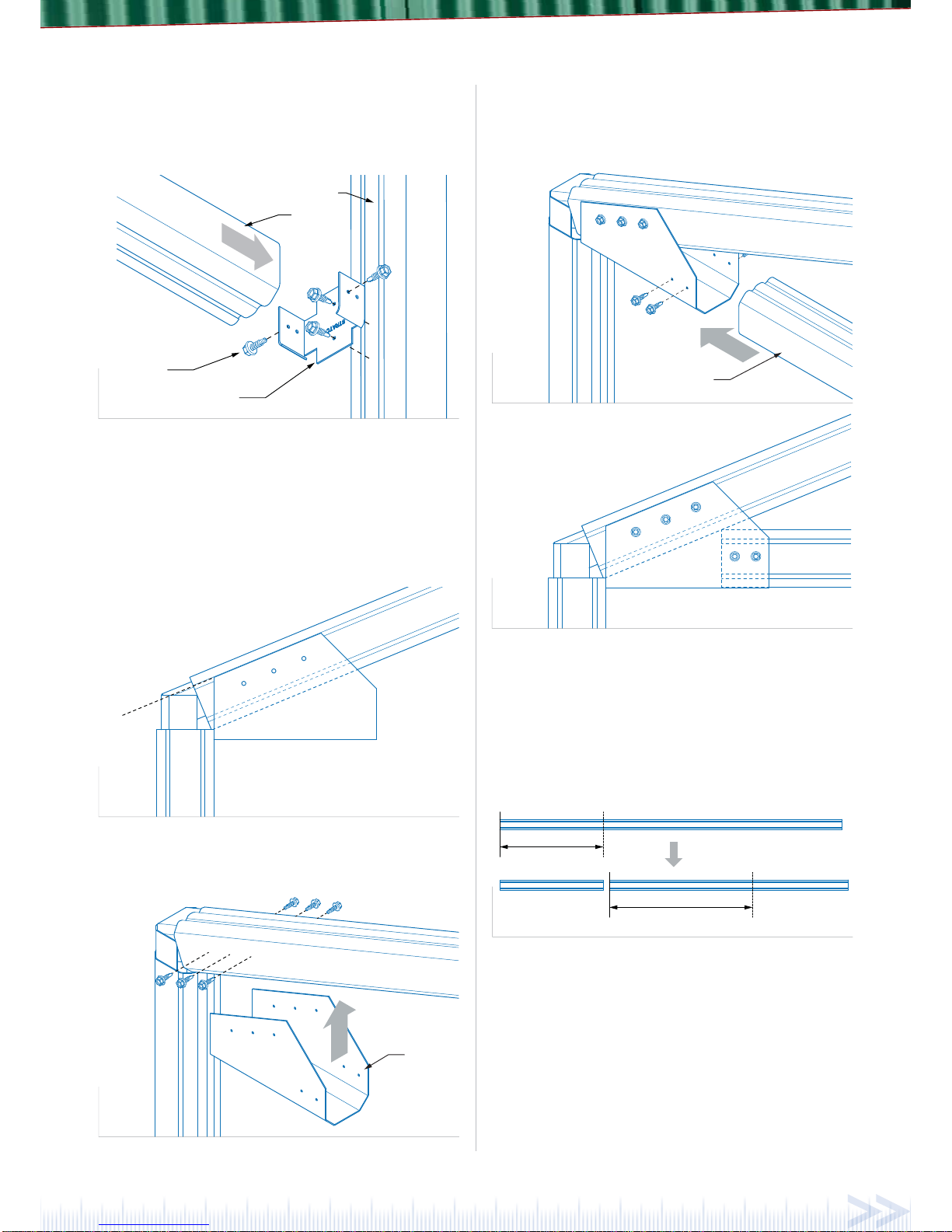

HERITAGE SHED GUTTER & DOWNPIPE KIT

NO. COMPONENT CARTNOTE DESCRIPTION CODE QTY.

32 DOWNPIPE STRAP D/PIPE STRAP 50X50 COLOUR DPST5050## 2

33 DOWNPIPE OUTLET D/PIPE OUTLET 50X50 COLOUR DPOL5050## 2

34 DOWNPIPE D/PIPE SQ .55 50X50 COLOUR 1800 DPSQ555050##18 2

35 GUTTER BRACKETS OG GUTTER 125 TIMBER FIX BRACKET OGG125TFX 8

36 STOP END LH OG GUTTER 125 S/END LH COLOUR OGG125STENL## 2

37 STOP END RH OG GUTTER 125 S/END RH COLOUR OGG125STENR## 2

38 GUTTER OG GUTTER 125 COLOUR OGG125## 2/2.460

LESS:

16 SHEET CAPPING HER G/SHED CAPPING COLOUR HSC## 2/2.500

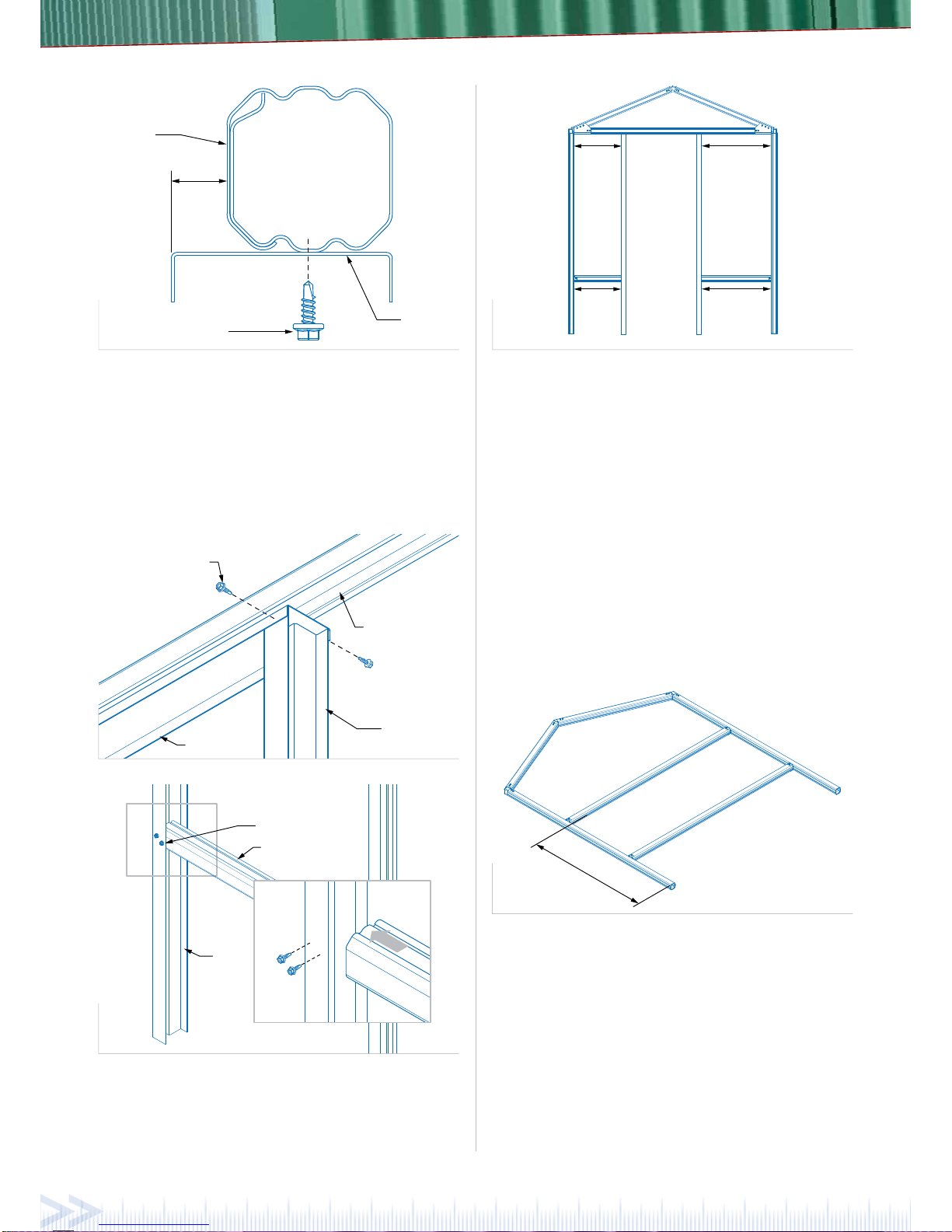

OPTIONAL EXTRAS

NO. COMPONENT CARTNOTE DESCRIPTION CODE QTY.

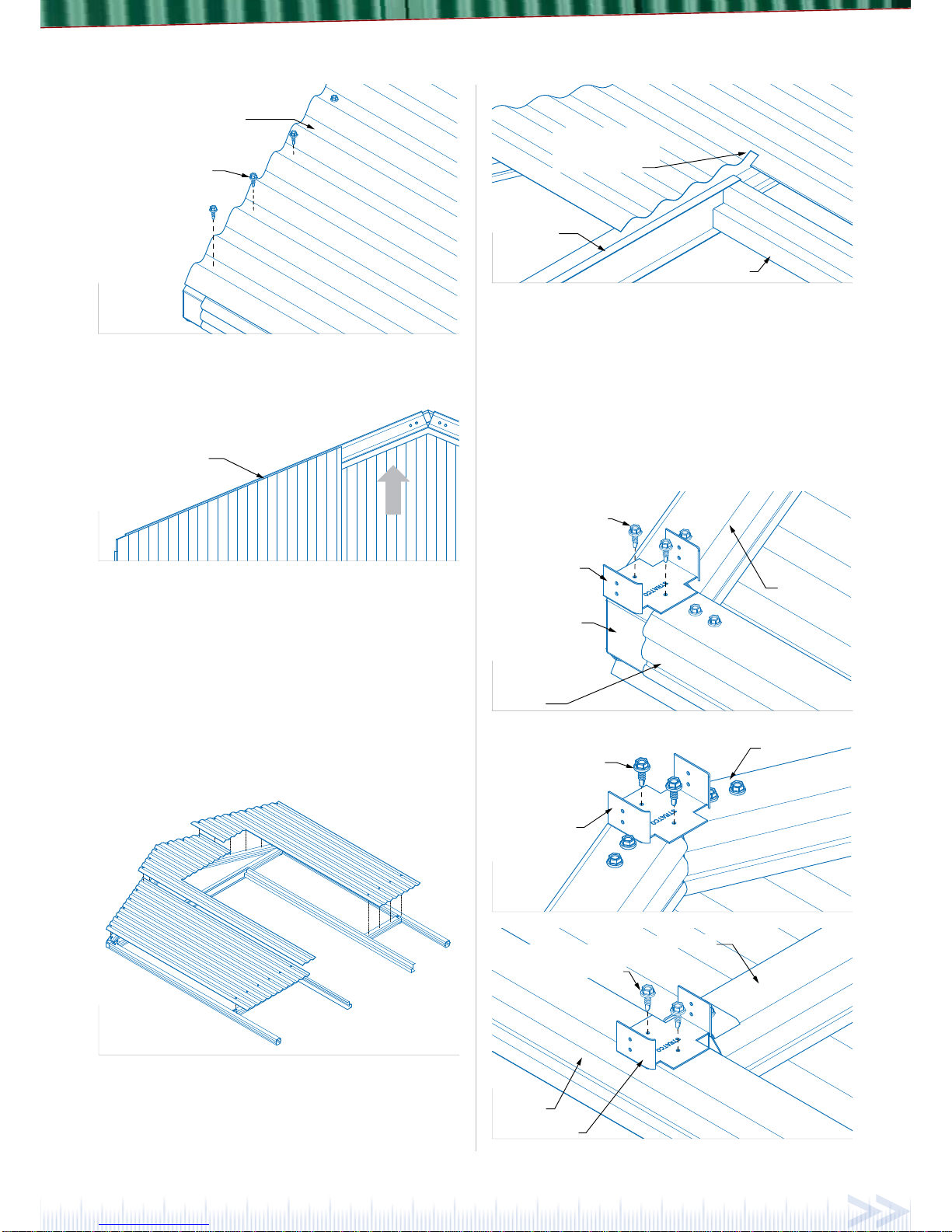

39 LH FOOTING PLATE HERITAGE G/SHED FOOTING PLATE LH HGFPL 2

40 RH FOOTING PLATE HERITAGE G/SHED FOOTING PLATE RH HGFPR 2

41 12X20 SELF DRILLING SCREW 12-14X20 HEX TEK SCREW NO WASHER TEKNNW1220 16

42 MASONRY ANCHORS DYNABOLT HEX 8X40MM HW-4781 14

43 BOLT/NUT HEX HEAD BOLT & NUT ZP M10X20 4.6N/S HBM1020ZP 2

44 ANGLE BRACKETS 2 HOLE BENT BRACKET HW-5797 2

45 GABLE SPIRE H/SHED SPIRE 700 COLOUR HGSP700## 2