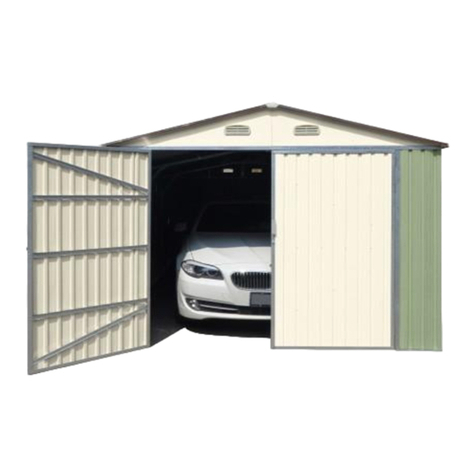

SLIDING DOOR HANDI-MATE™ INSTALLATION GUIDE

HANDI-MATE™SHED

INSTALL GUIDE

PRIOR TO INSTALLATION

It is important that you contact your local government authority to determine if building approval is required.

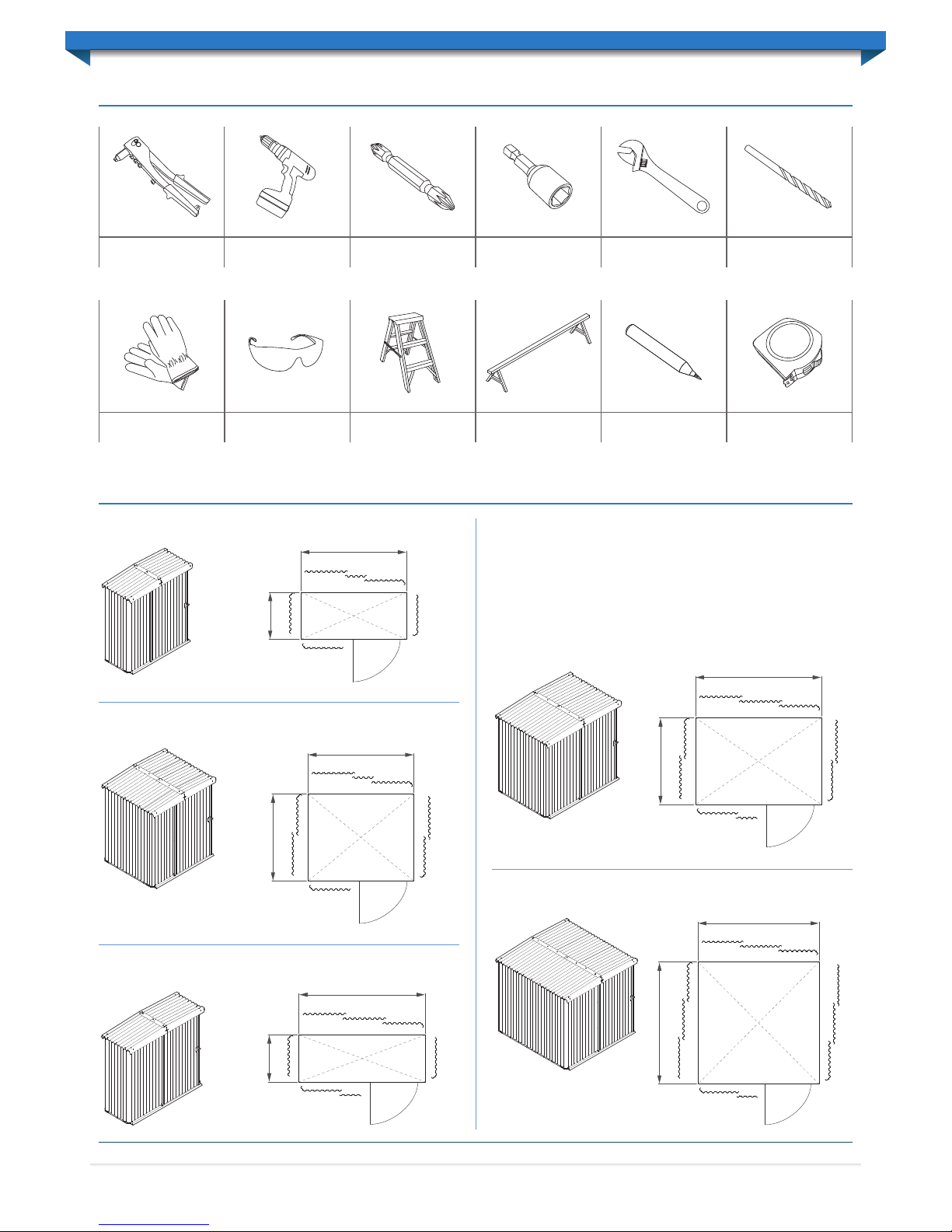

To ensure that the installation and erection of your Stratco Handi-Mate™ Shed proceeds smoothly you should confirm that all the components and

materials listed on the delivery documentation and in this installation guide have been supplied. Details for ordering individual components can be found in

the “Component Index” section at the end of this document.

Carefully read this installation guide to familiarise yourself with all the steps involved and ensure that you have the correct tools and equipment for the job.

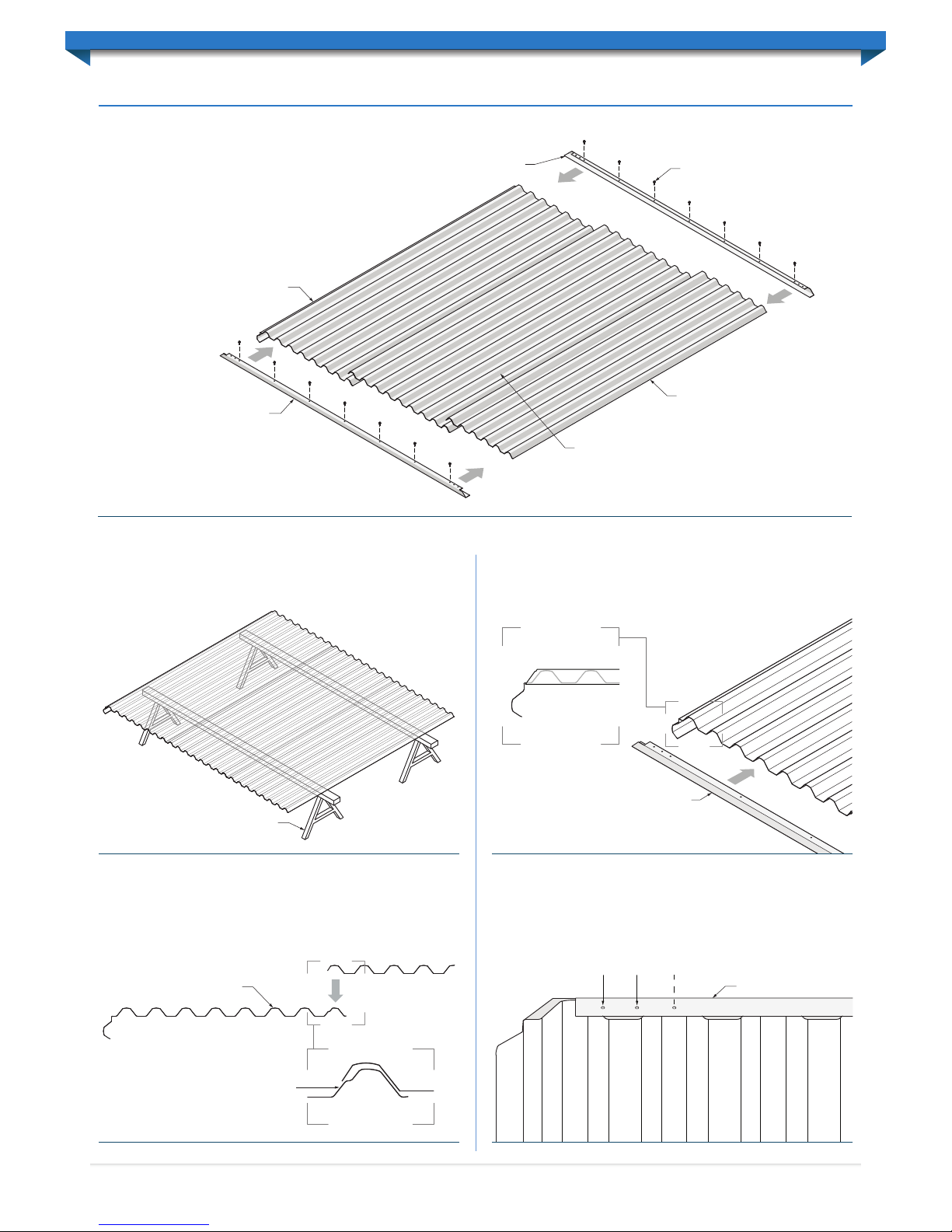

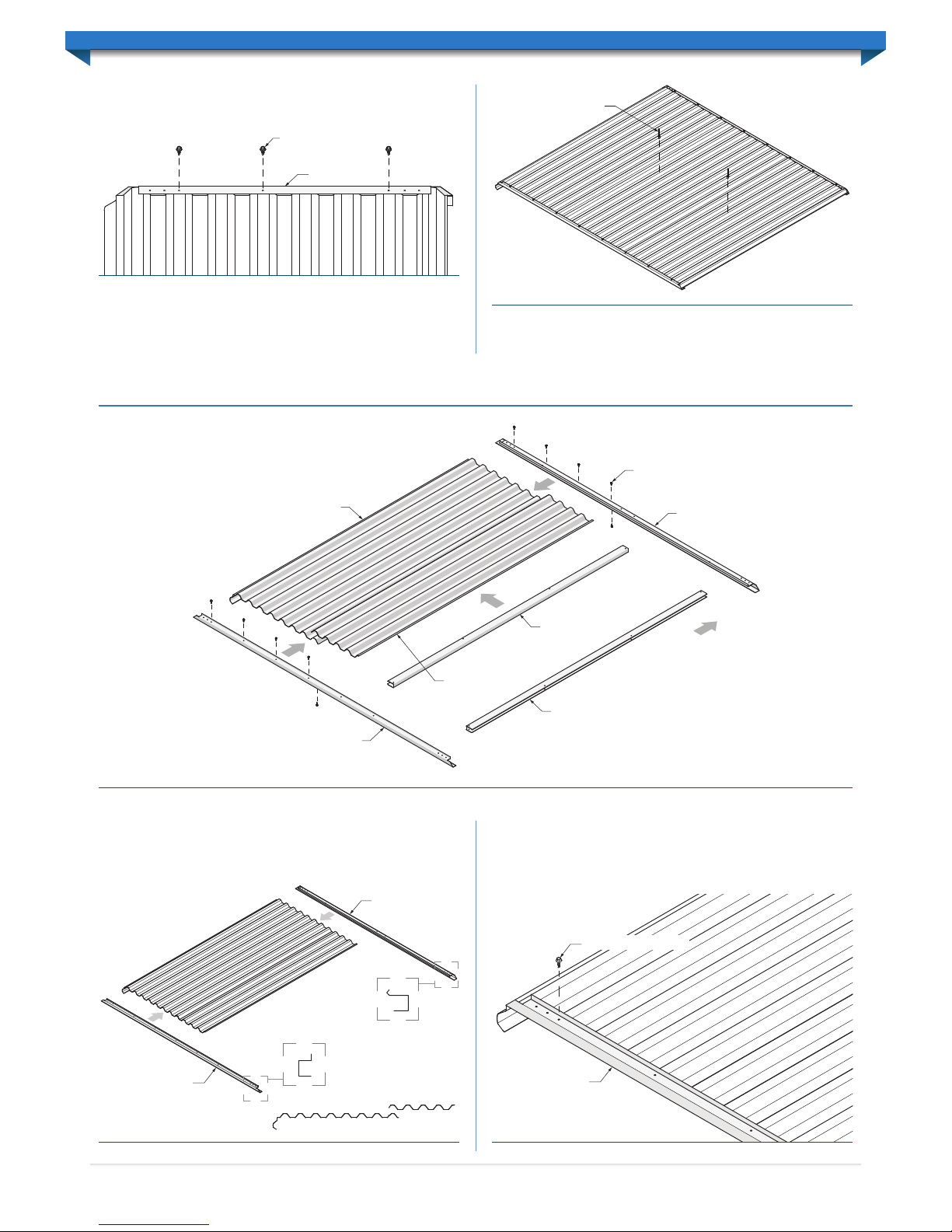

All Stratco Handi-Mate™ Sheds must be securely bolted to a permanent concrete base with sufficient masonry anchors securing all four corners of the

Handi-Mate™ shed to prevent wind uplift.

SHED WINDOWS (OPTIONAL)

Stratco Shed Windows are avaliable as an optional add-on, avaliable in both Louvre and Sliding variations. Refer to the “Window Installation” section if

installing a Stratco Window, or visit your local Stratco store for more information.

FLOORING PREPARATION

The installer is responsible for ensuring the slab or concrete pads are sufficient to support the shed and sustain wind loading.

Do not directly anchor your shed to pavers.

Option 1 - Before building the shed, pour a base that is larger than the area by at least 200mm in each direction. The base should be poured so the concrete

outside the shed floor area slopes away from the shed to help prevent water from entering the shed.

Option 2 - Substantial concrete pads may be used at each anchor location as an alternative to a complete concrete floor. It is recommended pads are

minimum Ø250mm x 400mm deep, embedded into a firm natural soil base.

IMPORTANT NOTES:

1. It is essential to clear and level the site prior to assembling your Stratco Handi-Mate™ Shed.

2. Note there are different types and colours of screws. Ensure that the right type and colour screw is being used at each location.

3. Stability and performance of the shed relies on the door being closed during high wind events.

4. Do not traverse the roof of the Handi-Mate™.

5. Use heavy gloves when handling steel sheeting and flashings and never attempt to install a shed in windy conditions.

BEFORE YOU START