STRATOS 15 Installation manual

Household

Water Softener STRATOS Series

INSTALLATION, START-UP

AND MAINTENANCE MANUAL

MAIN FEATURES OF THE STRATOS SERIES

Meter delayed or immediate

Metered regenerations can be programmed.

Mixing valve

Allows the adjustment of the residual hardness degree.

Built-in By-pass

The system can be isolated from the installation.

Transformer

External transformer.

Multilingual programmer

The user can select the following languages: English, French and Spanish .

Certified product

Ocial certicates.

Easy salt refilling

Easy water softener salt relling.

ESP

FRA

ENG

Optimized regeneration

The regeneration process has been adjusted in order

to reduce salt and water consumption (up to 50% of

salt and a 40% of water).

Functional and smart design

It will t in your home like any other electrical

appliance.

Holiday Mode

It allows the user to program low consumption

periods in which the system will carry out small

washes.

Adjustable regenerating degree

Several regeneration degrees can be adjusted according to the

hardness of water to be treated and the desired eciency.

State-of-the-art display

Interactive display with multicolour icons.

PLEASE KEEP THIS MANUAL, SINCE IT INCLUDES THE SERVICE BOOK AND THE

WARRANTY, IN ORDER TO BE ABLE TO OFFER YOU A BETTER AFTER-SALES SERVICE.

1. Presentation

5

01. PRESENTATION

01.1 Water Softener Safety

01.2 What To Do Before

02. INTRODUCTION

02.1 What Is Hardness?

02.2 How Does Your System Work?

02.3 Regeneration of the System

02.4 Regeneration Degree and Capacity

02.5 Working flows

02.6 Hardness Leakage

02.7 Residual hardness

02.8 Sodium Increase

03. TECHNICAL SPECIFICATIONS

04. UNPACKING AND VERIFICATION OF THE CONTENTS

05. PREVIOUS WARNINGS

05.1 Conditions for the proper operation of the system

05.2 Installation of the system

05.3 Start-up and maintenance

06. INSTALLATION OF THE SYSTEM

06.1 Required Tools and Pieces

06.2 Step-by-Step Installation

06.3 STRATOS Programmer

06.4 How to Program the System

07. START-UP

07.1 Hydraulic Start-up

07.2 Residual Hardness Regulation

07.3 How to check for Hardness

08. MAINTENANCE / HYGIENISATION

09. GUIDE FOR THE IDENTIFICATION AND SOLUTION OF PROBLEMS

10. MAINTENANCE SERVICE BOOK

11. NOTES

12. EC DECLARATION

13. GUARANTEE

Page

6

6

6

7

7

7

8

9

9

9

9

10

11

12

12

12

13

14

14

14

14

16

17

19

19

20

21

21

23

24

26

27

27

Content

1. Presentation

6

1. PRESENTATION

The system you have just bought is a state-of-the-art equip-

ment, able to deliver softened water to your home.

Developed and designed by IONFILTER, a leading company

from the industry with more than 20 years of experience; this

equipment will deliver softened water without scaling salts,

thus protecting your water supplies, avoiding the obstruction

of all pipes and allowing you to enjoy the benefits of softened

water.

The quality of the water in our environment is getting worse

every day, leading to an increase in water hardness, which

causes problems in pipes and affects the proper operation of

appliances using water, by increasing the maintenance and

reducing their service life.

The reality of this is what has driven us to design this series of

domestic water softeners, in order to provide you with a water

of the highest quality.

Your STRATOS H.E. water softener will provide you and your

family the benefits and advantages outlined below:

- ENERGY SAVING

- Greater wellness feeling.

- Soft and smooth skin.

- Increases the service life of electrical appliances and

heaters.

- ECONOMIC SAVING: it reduces the consumption of

soap, fabric softeners and chemical products.

- Low maintenance cost.

- Operation is completely automatic.

It is very important that you read and keep this manual before

installation and start-up of the system. If you have any questions

regarding the use or maintenance of this system, please contact the

Technical Assistance Service (TAS) of your distributor.

1.1 Safety of the Water Softener

Your safety and that of others is very important. We have inclu-

ded some safety messages in this manual.

This is the symbol for a safety alert. This symbol will

warn you about possible situations in which you or

those around you could be at risk.

All safety messages will have the alert symbol or the words

‘DANGER’ or ‘WARNING’.

USE WITHIN THIS MANUAL

‘DANGER’

Serious or life-threatening risk if the following instructions are not im-

mediately followed.

‘WARNING’

All safety messages will inform about the possible danger, how to re-

duce the injury risk and what might happen if the instructions are not

followed.

1.2 What To Do Before

See section ‘Previous warnings’ before installing the water

softener.

Carefully follow the instructions for the installation.

(Warranty may be considered void, should the installation be

faulty).

Please read the entire manual before undertaking installation.

Then, collect all necessary materials and tools for the insta-

llation.

Check the plumbing installations and the electric connectors.

All installations must be done according to the law in force in

each region or country.

Please be careful when handling the water softener. Do not

knock it over, let go of it or place it onto sharp objects.

Under no circumstances should the softener be installed on

the outside, since it must be protected against sunlight and

bad weather conditions.

1. Presentation

7

2. INTRODUCTION

These systems come with a residual hardness regulator as

standard, which allows selecting the appropriate hardness for

your home.

Its friendly-use electronic programmer will allow you to put the

system into operation in an easy and fast manner.

2.1 What Is Hardness?

Hardness is the quantity of scaling salts present in water,

which are mainly composed of low solubility salts of calcium

and magnesium. The main salts causing hardness are listed

below:

Calcium bicarbonate:

Calcium chloride:

Calcium sulphate:

Magnesium bicarbonate:

Magnesium chloride:

Magnesium sulphate:

Ca(CO3H)2

CaCl2

CaSO4

Mg(CO3H)2

MgCl2

MgSO4

These salts, due to its chemical properties, have a tenden-

cy to precipitate, producing scale on pipes and obstructing

them as they accumulate. In the same way, hardness has a

high tendency to scale on electrical resistors from heaters

and to precipitate into heaters when temperature increases.

The combination of hard minerals and soap produces a soap

curdling. This soap curdling reduces the cleansing properties

of soap. Hard minerals precipitation builds a layer on cooking

utensils, connections and plumbing fixtures. It may even alter

the taste of food.

MAIN PROBLEMS

Precipitation on pipes, fixtures and appliances.

Precipitation on electrical resistors, increase on energy

consumption due to the generated isolation.

Higher consumption of soap and chemical products.

Reduction of the electrical appliances’ service life and

greater maintenance.

All these problems are solved when using a water softener,

since water obtained after being treated by the system is

completely free of scaling salts.

For the most part of Europe, hardness is indicated in French

hydrometric degrees, but there are also other measuring

units, according to each region.

Below are the most usual equivalences.

UNITS

1 ppm of Calcium

1 ppm of Magnesium

1 ppm of CaCO3

1º French (ºHF)

1º German (ºd)

1º English (ºe)

1 mmol/L

1 mval/L=meq/L

ppm of CaCO3

2,5

4,13

1

10

17,8

14,3

100

50

º French

0.25

0.413

0.1

1

1.78

1.43

10

5

2.2 How Does Your System Work?

Water softening is carried out by means of an ion exchange

process. On this purpose, the system uses resins with the

chemical capacity of capturing Calcium (Ca) and Magne-

sium (Mg) ions and removing them from water.

When Calcium and Magnesium ions are captured by the

resin, two Sodium (Na) ions are released which, due to its

chemical properties, produce salts with a higher solubility

avoiding all hardness-related problems.

Therefore, when water gets softened, its sodium level in-

creases.

Further information on this procedure can be found in ‘Sec-

tion 2.8’.

ION EXCHANGE RESINS:

They are synthetic compounds, usually with an spherical

shape, able to capture certain chemical substances pre-

sent in water, which then exchanges for other substances.

Water softening uses strong cation resins, which are com-

posed of styrene copolymers and divinylbenzene with a

sulphur base.

2. Introduction

8

The exchange resin charge is inside the column of the water

softener and takes up a significant part of the total volume

(between 60 and 75%, according to each model). A part of

the column must remain empty, in order to allow for a proper

regeneration of the resin bed.

During the treatment process, water goes into the multi-way

valve through the inlet connection, flows towards the upper

part of the tank through the top nozzle and goes downwards

through the bed resin, thus producing the ion exchange.

Treated water is collected by the bottom nozzle and led to

the multi-way valve through the inner tube of the tank. Treated

water is sent for consumption using the outlet connection. At

this point, the system has a treated water meter in order to

measure the water volume.

2.3 Regeneration of the System

The quantity of calcium and magnesium ions that the resin

may retain is limited; therefore, the water volume a water sof-

tener can treat is limited as well.

The system must periodically carry out a process known as

regeneration, which allows the resin to recharge with sodium

ions, so it can continue softening water.

In STRATOS systems, the regeneration process starts auto-

matically when the configured water volume is achieved. The

programmer allows the user to set several regeneration start

modes (see ‘Section 6.3’ to obtain further information how to

operate the programmer).

The regeneration of a softener system is composed of several

stages, which are described below:

BACKWASH:

Water comes into the column through the lower manifold,

washing the suspended mater and fluffing the resin bed up,

thus facilitating the subsequent regeneration process.

Water

outlet to

service

Inlet from

supply network

Water

outlet

to drain

BRINE ASPIRATION:

By means of an aspiration process relying on a Venturi effect,

the system sucks the brine solution, which has previously

been prepared in the regenerating tank. This brine solution is

introduced downwards in the softening column, gets in con-

tact with the ion exchange resin and regenerates it.

Salida

de agua a

servicio

Salida

de la solución de

salmuera hacia

desagüe

Entrada

de agua de red

Succión

de salmuera por

efecto venturi

SLOW WASH:

In this stage the brine solution, which has been previously

sucked up, goes through the resin bed. Throughout this pro-

cess, the contact between the brine and the resin is complete,

which optimizes the regeneration.

Water

outlet to

service

Brine

solution outlet

towards drain

Inlet from

supply network

Brine

suction by a

Venturi effect

QUICK WASH:

Washing water goes downwards through the resin bed, get-

ting it settled and ensuring the complete removal of the brine,

which might remain inside the bottle.

Tap water inlet

Water outlet to

service

Brine removal,

quick wash

2. Introduction

8

9

TANK FILLING:

The necessary water volume is sent to the brine tank in order

to prepare the same amount of consumed brine for the next

regeneration process. This process is fully automatic, thus it

is not necessary to add any water to the brine tank (except

during the start-up, as indicated in ‘Section 7’).

NOTE: During the regeneration process, the systems may allow

untreated water to go through, in order to guarantee the water

supply.

2.4 Regeneration Degree and Capacity

The exchange capacity is the quantity of hardness that a cer-

tain resin volume can retain before getting exhausted. This va-

lue is usually expressed as ºHFxm3/litre.

The higher the resin volume of the system is, the higher will be

the quantity of hardness that can be retained before the resin

gets exhausted. It is very important to choose the appropriate

system for each type of installation.

Depending on the quantity of sodium chloride used to rege-

nerate each litre of resin, the exchange capacity of the resin

may change.

STRATOS softeners have six different regeneration degrees,

depending on the conditions in which the system must work

(for further information, please read ‘Section 3’).

Systems are supplied as a standard with a regenerating de-

gree of 80g NaCl/litre of resin, which is appropriate to work up

to the maximum hardness indicated below:

MODEL

STRATOS 15

STRATOS 25

Salt consumption

1.2 Kg (80g/lt)

2 Kg (80g/lt)

Maximum hardness

45ºHF

70ºHF

2.5 Working Flows

Water softeners working by means of an ion exchange must

respect certain contact periods between water to be treated

and resin, in order to ensure that the softening process is ca-

rried out properly. For STRATOS softeners the working ranges

indicated below must be respected:

Minimum flow (litres/hour): Resin volume x 4

Maximum flow (litres/hour): Resin volume x 40

Should working ranges be outside the recommended ranges,

the proper operation of the system could be affected (exces-

sive loss of charge, hardness leakage, etc.)

For further information on the minimum and maximum flows for

each softener, please check the general specifications table.

2.6 Hardness Leakage

The ion exchange process on which water softening is based

may be affected by different factors, which can reduce its effi-

ciency, thus causing a certain level of hardness leakage.

ELEVADA CONCENTRACIÓN DE SODIO EN EL AGUA A TRATAR

It may interfere in the exchange process.

OVERFLOW

Since there is not enough contact time, some of the hardness

may not be retained by the resin.

REGENERATION DEGREE

The higher the regeneration level is, the lower is the risk of a

hardness leakage.

2.7 Residual Hardness

Depending on the final use of treated water, it may be neces-

sary to obtain fully softened water or, on the contrary, it may be

desirable to leave some residual hardness.

These systems have been designed to supply fully softened

water, but the control valve integrates a residual hardness

mixer, which allows for the regulation of the desired hardness

degree in treated water (see ‘Section 7’).

Note: In water for human consumption it is recommended

to have a residual hardness between 5 and 8 ºHF if pipes

are made of copper, and between 8 and 10 ºHF if they

are made of iron (for the latter, it is also recommended to

install a silicopolyphosphates filter afterwards).

10

2. Introduction

10

2.8 Sodium Increase

Most of the sodium we consume on a daily basis comes from

food, specially processed food, since salt is an excellent pre-

servative and is used as an additive in prepared products.

Sodium consumption through the water we drink is rather low

when compared with that obtained from food.

In spite of this, it is very important to bear in mind, as mentio-

ned above, that water softeners increase the sodium concen-

tration present in treated water when compared to the con-

centration measured on the inlet.

WARNING: The maximum recommended sodium level in water for

human consumption is of 200 ppm. Depending on the sodium concen-

tration and the hardness of water to be treated, it is possible that softe-

ned water contains a higher concentration of sodium than recommended.

Should this be the case, or if water is to be consumed by persons who

must follow a low sodium diet, it is recommended to install a household

reverse osmosis system in order to be able to drink the water.

The table below can be used as a guideline to know the

increase on sodium concentration in treated water depending

on the inlet hardness:

INITIAL HARDNESS

IN WATER ºHF)

10

15

25

30

35

40

45

50

60

SODIUM ADDED BY THE SOFTE-

NER (mgNa/litre)

43

65

108

130

152

173

195

217

260

3. Technical Specifications

10

11

10

Model

STRATOS 15 STRATOS 25

Code

795113 795224

Resin volume

15 Litres 25 Litres

Working flow

1,2 1.8

Maximum flow

1,0 1.6

Regeneration 80 g/L

Salt/regeneration 1.2 Kg 2.0 Kg

Exchange capacity 61ºHFxm3102ºHFxm3

Backwash 3 min 6 min

Counterflow 3.3 min 2.7 min

Quick rinsing 3 min 6 min

Brine Aspiration 40 min 49 min

Regeneration 120 g/L

Salt/regeneration 1.8 Kg 3.0 Kg

Exchange capacity 75ºHFxm3122ºHFxm3

Backwash 3 min 6 min

Counterflow 5 min 4.2 min

Quick rinsing 3 min 6 min

Brine Aspiration 43 min 52 min

Regeneration*

Salt/regeneration *200g/L: 3,0 Kg *250g/L: 6,25 Kg

Exchange capacity 90ºHFxm3175ºHFxm3

Backwash 3 min 6 min

Counterflow 8,3 min 8,7 min

Quick rinsing 3 min 6 min

Brine Aspiration 49 min 64 min

Dimensions

Height: A900 1130

Width: B335 335

Depth: C570 570

3. TECHNICAL DATA FOR THE STRATOS MODEL

Inlet

hardness

15ºHF

20ºHF

25ºHF

30ºHF

35ºHF

40ºHF

45ºHF

50ºHF

55ºHF

60ºHF

(61ºHFxm³)

4.06 m³

3.05 m³

2.44 m³

2.03 m³

1.74 m³

1.53 m³

1.36 m³

1.22 m³

1.11 m³

1.02 m³

STRATOS 25 (795224)

(122ºHFxm³)

8.13 m³

6.10 m³

4.88 m³

4.06 m³

3.49 m³

3.05 m³

2.71 m³

2.44 m³

2.22 m³

2.03 m³

(175ºHFxm³)

11.66 m³

8.75 m³

7.00 m³

5.83 m³

5.00 m³

4.38 m³

3.89 m³

3.50 m³

3.18 m³

2.92 m³

(102ºHFxm³)

6.80 m³

5.10 m³

4.08 m³

3.40 m³

2.91 m³

2.55 m³

2.27 m³

2.04 m³

1.85 m³

1.70 m³

(75ºHFxm³)

5.00 m³

3.55 m³

3.00 m³

2.50 m³

2.14 m³

1.88 m³

1.67 m³

1.50 m³

1.36 m³

1.25 m³

(90ºHFxm³)

6.00 m³

4.50 m³

3.60 m³

3.00 m³

2.57 m³

2.25 m³

2.00 m³

1.80 m³

1.64 m³

1.50 m³

VOLUME OF TREATED WATER ACCORDING TO INLET HARDNESS

STRATOS 15 (795113)

Inlet

hardness

15ºHF

20ºHF

25ºHF

30ºHF

35ºHF

40ºHF

45ºHF

50ºHF

55ºHF

60ºHF

12

4. Unpacking and verification of the contents

12

4. UNPACKING AND VERIFICATION OF THE

CONTENTS

It is important that prior to installing and starting the system

you check the received materials, with the aim of guarantee-

ing that it has not been damaged during transport.

Any claims for damages during transport must be presen-

ted together with the delivery note or invoice to the distri-

butor, including the name of the carrier, within a period of

24 hours following the reception of goods.

All systems are supplied fully assembled and are composed

of the elements below:

• Metered STRATOS H.E. valve. It is fully automatic and made

of Noryl. It has a built-in isolation by-pass and a mixing valve

for residual hardness.

• Bottle containing resin made of reinforced polyethylene with

glass fibre.

• The strong cation ion exchange resin, specially made for

softening, is supplied inside the bottle.

• Compact STRATOS cabinet, made of plastic, which can

contain enough salt for several regenerations.

• Brine suction system.

• Packaging and protections, including a pressurised air ba-

lloon to prevent the bottle from moving.

Before starting the installation of the system, please read this

manual carefully.

The air balloon must be removed before starting the installation.

The packaging materials can be recycled and must be thrown

away in the appropriate selective recycling bins or the specific

centre for the Collection of waste material.

The machine that you have acquired has been designed and

manufactured with high quality materials and components

that can be recycled and reused. This product must not be

thrown away into the usual urban rubbish bins. When you

want to throw the machine away, it must be taken to a specific

local centre for the collection of materials, stating that it has

circuits, and electric and electronic components, as well as

ion exchange resin.

In order to obtain more information about how to dispose of

your electrical and electronic machine once they have fulfilled

their use, contact the management of urban waste service or

the establishment in which you acquired the system.

The proper collection and treatment of the machines that can

no longer be used contributes to the preservation of natural

resources and also to avoiding potential public health risks.

5. PREVIOUS WARNINGS

STRATOS water treatment systems ARE NOT POTABLE WATER

SYSTEMS.

Should the water to be treated not come from a public water su-

pply, that is, from an unknown source, a physical-chemical and

bacterial analysis of the water shall be necessary, with the aim of ensu-

ring its proper purification applying the proper techniques and systems

appropriate to each case, PRIOR TO THE INSTALLATION of the system.

Contact your distributor in order to obtain advice about the most

appropriate treatment for you.

5.1 Conditions for the proper

operation of the system

• Do not use hot water in the system (T<36ºC).

• The room temperature must be between 4ºC and 45ºC.

• The system should be installed in a dry environment, free of

acid vapours. Otherwise, please ensure a proper ventilation.

• A minimum pressure of 2.5 bars must be ensured. Should

this minimum pressure not be available, a pressure system

shall be installed.

5. Previous warnings

12

13

12

• If inlet pressure is higher than 5.5 bars, a pressure regulator

must be installed.

• Water to be treated must be properly filtered, therefore, it is

recommended to install a pre-filter to guarantee the removal

of suspended particles, which may be swept along by inlet

water. It is recommended to use FILTERMAX self-cleaning

filters. Please contact your distributor for further information.

Failure to install an appropriate filter would result in particles obs-

tructing the inner holes or injectors of the system, thus affecting its

proper operation. .

5.2 Installation of the system

•If the water softener must treat all the water supply of your

home, connect it to the general supply pipe before connec-

ting the rest of pipes, except for pipes supplying the outside.

Taps located outside the house must supply hard water. Due

to the sodium increase in softened water, it is not recommen-

ded to use it for watering, since it can negatively affect the

growth of plants and vegetables.

• Should it be necessary to condition the installation of the

home in order to install the system in the foreseen location,

it must be carried out in accordance with the national regula-

tions in force, concerning internal electric and hydraulic ins-

tallations.

• The planned location for the installation must have enough

space for the system itself, its accessories, connections, and

to carry out a proper maintenance.

• The system should not be installed next to a heat source or

where it receives a direct flow of hot air.

• The drain connection, where water from regeneration will be

driven, must be underneath the installation if possible. Drain

connection must always have a free outlet. The diameter of

this connection must have a minimum size of 1”. The maxi-

mum distance between the water softener and the drain in-

take cannot be placed higher than 6 m.

Drain hose Drain hose Drain hose

Underground drain Supply pipe Sink outlet

4 cm for

aeration

4 cm for

aeration

• The surroundings and the environment where the system

and faucet are to be installed must meet the appropriate hy-

gienic and sanitary conditions.

• Avoid external drips from pipes, drains, etc. onto the system.

• Under no circumstances must the system be installed on

the outside.

• Should softened water be supplied to a hot water or vapour

generator, it will be necessary to install a dependable check

valve between the water softener and the generator, in order to

prevent hot water from returning to the system and damaging

it.

• It is recommended to install some valves for sample taking

both for treated and untreated water, as close as possible to

the water softener.

• If there are quick-closing valves, it is recommended to install

a device to prevent water hammers.

• The water softener only works with a power supply of 12

volts – 50 herz, which comes from the transformer included

in the system. Please make sure that the transformer is used

and that it is connected to a power supply of 220 – 240 V,

50Hz. Also, it must be ensured that the electrical installation of

the house is properly protected by a circuit breaker or a fuse.

• If daytime pressure is higher than 5.5 bars, night-time pres-

sure may exceed the maximum. Please use the pressure-

reducing valve if necessary. (a pressure-reducing valve may

reduce the flow).

• It is recommended to install a silicopolyphosphates filter in

the system’s outlet to protect the pipes from the corrosion of

softened water.

6. Installation of the system

14

5.3 Start-up and maintenance

• The system must be hygienised periodically. See ‘Section 8’

for further information.

• Maintenance must be carried out by qualified technical

personnel, under the proper hygienic conditions. (For further

information contact the technical service of your distributor.)

6. INSTALLATION OF THE SYSTEM

The installation of the water softener must be carried out by

skilled technical personnel. Follow the recommendations in

‘Section 5’ Previous warnings of this manual.

Given that the system that you are going to install impro-

ves the quality of the water you consume and is conside-

red a food, all of the tools that you are going to use for

the assembly and installation must be clean and, under no

circumstances, contaminated or impregnated with grea-

se, oils or rust. Please be extremely careful when handling

the materials that are going to be in contact with treated

or untreated water. (For further information contact your

distributor.)

6.1 Required Tools and Pieces

Before starting the installation, please take all the necessary

tools and follow the instructions included in ‘Section 6.2’.

IF WELDED COPPER PIPES ARE USED

Tube-cutter

Blowtorch

Clamps

Tin-Silver

Sandpaper or steel wool

IF THREADED PIPES ARE USED

Pipe-cutter or steel saw

Thread rolling machine

Sealing paste for pipes

Clamps

IF CPVC PLASTIC IS USED

Pipe-cutter

Steel saw

Adjustable wrench

Glue for PVC

Clamps

IF ANY OTHER MATERIAL IS USED

Other appropriate pipes and fasteners for drinking water su-

pply, according to the requirements from the manufacturer

and the local regulations.

6.2 Step-by-Step Installation

1. The system must always be installed with the supplied by-

pass valve. Additionally, a three-valve by-pass can be installed.

The by-pass of the STRATOS systems has several positions.

By-pass

Service

Inlet

Outlet

6. Installation of the system

14

15

6. The system is supplied with a set of inlet and outlet con-

nections. Please make sure that fastening clips are tightened

on the connectors.

7. The tubes and accessories used to connect the main su-

pply pipe to the inlet and outlet of the water softener valve

must be loosely measured, cut and assembled.

Please keep all fastenings, joints and tubes centred and

straight. Check that water flows from the pipe towards the

inlet of the water softener.

NOTE: The inlet and outlet are indicated in the valve. Draw

the sense of the flow to be sure.

IMPORTANT: Check that the pipes are fixed, aligned and leaned

on something in order to avoid any pressures on the inlet and

outlet of the water softener. A wrong pressure coming from a misaligned

pipe, or which has not enough place to lean on, could damage the valve.

WELDED COPPER

1. Carefully clean and apply welding paste on all joints.

2. Carry out all the welding.

NOTE: Do not weld to the installation the pipes of the by-

pass valve. The heat from the welding could damage the

valve.

IMPORTANT: In order to install the copper pipes and assemble

the earth-grounding clamp, this must be already fastened. It is

necessary to screw on this piece.

RECOMMENDED INSTALLATION

Service

Valve

Valve

Pressure gauge

Sample taking

point

Sample

taking point

Valve for by-pass Supply network inlet

Water Softener Drain

Optional

sediment

filter

2. Close the general water supply valve, which should be next

to the main pump or the water-meter.

3. Open all taps in order to empty the pipes from all water.

NOTE: Make sure that the heater is not emptied, in order

to prevent any damages on it.

‘DANGER’ There is a danger of injury due to an excess of

weight. It is necessary that at least two persons move and install

the system, as well as move and rise the salt bags. There is a danger of

suffering back injuries and other body injuries.

4. Move the water softener towards the installation place. Pla-

ce it on an even surface. If necessary, place it on a plywood

platform at least 2 cm thick. Then, level the platform using a

wedge.

Plywood

Wedge used to level the platform

Installation ground

Minimum 2 cm

thickness

IMPORTANT: Do not place the wedges directly underneath the

salt tank. The weight of the tank filled with water and salt may

cause the tank to break against the wedge.

5. First make a visual check and clean the inlet and outlet

connections of the softener to remove any residues.

6. Installation of the system

16

This programmers will provide you with information concerning

the operation of the system, as well as allowing you to set up

all parameters.

MAIN FEATURES:

User-friendly and intuitive programming.

Multicolour interactive digital display.

Holiday Mode

Here the desired regeneration can be chosen by time, de-

layed, immediate or mixed.

MULTICOLOUR LCD DISPLAY: It shows the information concer-

ning the state of the system. Depending on each moment, the

display will show different types of messages:

Service: It offers information concerning the operation of the system.

15:57

Last Regen. : jul. 01, 2012

Mode: Meter Override

Capacity

Remaining

Flow

Rate

Regeneration: It shows the regeneration stage of the system and

the remaining time. It shows as well the current time.

21:02

Advancing to

Backwash

Programming: It shows the internal parameters and allows its

modification.

Time Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

THREADED PIPE

1. Apply a sealing paste for pipes or Teflon tape on all male

threaded pipes.

2. Tighten all threaded connections.

CPVC PLASTIC PIPE

1. Clean, prepare and glue all joints according to the

manufacturer’s instructions.

OTHER

Please follow the instructions from the pipes’ manufacturer

when using other types of pipes and fixtures approved for

drinking water.

INSTALLATION OF THE DRAIN

Measure and cut the necessary length, and then connect the

drain line of ½” to the accessory for the drain connection of

the water softener. Fasten the hose with a clamp.

NOTE: Hook the hose of the drain to the underground dra-

in. Tighten the drain hose. This will prevent any pipe whip

during regenerations.

HOW TO INSTALL THE ELBOW OF THE OVERFLOW

DRAIN OF THE SALT TANK

Connect the overflow drain elbow from the system to a near

drain. This drain intake must be at a lower height than the

overflow drain.

NOTE: The overflow hose must be installed in such way

that water cannot return from the drain hose.

6.3 STRATOS Programmer

DESCRIPTION OF THE PROGRAMMER

All systems have a built-in state-of-the-art electronic program-

mer with a multicolour interactive display. This advanced con-

troller allows to fully monitor the operation of the system. The

display is installed on the upper part of the compact cabinet.

6. Installation of the system

16

17

Time Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Date and Time

15:57

jul. 22 , 2013

‘MENU’ BUTTON: Press this button to go to the menus and sub-

menus. Once inside, you can go back through the program-

ming process.

‘SET/REGEN’ BUTTON: Press this button to trigger immediate or

delayed regenerations. When programming, it allows to select

the parameter as well as to confirm it.

‘+ and -’ BUTTON: Press this button to select and modify the

parameter.

HOW TO LOCK THE PROGRAMMER: : If no button is pressed during

certain time, the programmer gets locked for security reasons,

and shows the message below when any button is pressed.

15:57

Last Regen. : jul. 01, 2012

Mode: Meter Override

Capacity

Remaining

Flow

Rate

Key Locked, Press and

Hold “MENU” Key for 3

Seconds to Unlock

To unlock the programmer, press the ‘MENU’ button during

3 seconds.

6.4 How to Program the System

STRATOS systems are configured to carry out delayed rege-

nerations at 2 a.m.

USER PROGRAMMING:

1. Connect the supplied transformer with the electrical con-

nector located on the rear part of the system. The program-

mer must be in service and show a message similar to that in

the previous section.

IMPORTANT: When connecting the system the fo-

llowing message may appear:

15:57

Last Regen. : jul. 01, 2012

Mode: Meter Override

Capacity

Remaining

Flow

Rate

Advancing to Service

Wait Please

This means that the system is entering the service mode.

If two minutes have gone by, and this message is still

showing, please contact your distributor.

2. Press the ‘MENU’ button for 3 seconds to get into the inter-

nal program of the system. At this point you may have access

to the following parameters:

Time Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Time: The current date and time can be configured.

Time Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Date and Time

15:57

jul. 22 , 2013

18

6. Installation of the system

18

Miscellany: Here the following parameters can be

selected:

1.Units of measure, in the metric or American system. It is

supplied by default in the metric system.

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Region & Language

Region

Language

Tiempo Miscelanea Datos De

Entrada

Modo

vacaciones

Conguración

avanzada

Información

del sistema

Region

Metric

US Gallon

2.Language: There are three languages available: Spanish,

English, French, German. It is supplied by default in Spanish.

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Language

English Français

Español Deutsch

Input data: It must be programmed.

1. Hardness: Inlet water hardness in ppm of CaCO3 (ºHFx10).

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Hardness & People

Water Hardness

People Number

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Water Hardness

0 1 7 0 PPM

2. Inhabitants: Number of persons who usually live in the home.

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

People Number

0 1 Person

Holiday Mode: Here the user can set when there will

be nobody at home for a long period of time.

During this period, the system will carry out small washes

without consuming salt, in order to prevent water from stagna-

ting inside the system.

Time

Region &

Language

Hardness &

People

Holiday

Mode

Advanced

Settings

System

Information

Holiday Mode

ON OFF

End Date of Holiday

July 24 , 2013

7. Start-Up

18

19

18

System information: This feature delivers informa-

tion on the water softener:

• Total number of regenerations.

• Total volume of treated water.

• Regeneration hour.

• Volume of treated water between each

regeneration.

• Safety regeneration frequency.

• Length of the regeneration stages.

• Current ow.

• Maximum registered peak ow.

• Software version.

ADVANCED PROGRAMMING (ONLY FOR PROFESSIONAL USE):

This internal level is only intended for the Technical Service and

is password protected. Under no circumstances should the

programmed parameters be modified without checking pre-

viously with the Technical Service of the dealer.

HOW TO START A REGENERATION:

STRATOS water softeners allow you to program both delayed

or immediate regenerations. On this purpose, press the ‘RE-

GEN’ button for 3 seconds to get into the menu below:

15:57

Last Regen. : jul. 01, 2012

Mode: Meter Override

Capacity

Remaining

Flow

Rate

Manual Regen.

DELAY

IMMEDIAT

By pressing the ‘SET/REGEN’ button, the user can select the

type of regeneration and with the ‘MENU’ button, the user

can trigger the regeneration.

HOW TO MOVE THE REGENERATION FORWARD:

Once the regeneration has started, the user can move

forward to the next stage by cancelling the current one. On

this purpose, just press any of the buttons on the program-

mer. This function will be disabled during the time in which

the motor is moving forward to the next stage.

7. START-UP

7.1 Hydraulic Start-up

Before starting the system up, please check that all steps pre-

vious to installation, assembly and programming have been

properly followed, according to this instructions’ manual, as

well as the regulations in force. To start the system up, please

follow the instructions below:

Do not charge the system with salt until the end of the start-up. In

order to prevent any air pressure on the water softener and the

pipes, please follow these instructions in order.

1. Place the by-pass valve on the ‘service’ mode.

2. Fully open two or more cold and treated water faucets loca-

ted near the water softener.

3. Plug the programmer to the power supply using the trans-

former included in the system.

4. The program must be in ‘service’, otherwise please check

‘Section 6.3’.

5. Press the ‘REGEN’ button for 3 seconds to start a regene-

ration. Now you are inside the regeneration menu. Select the

immediate regeneration. After some minutes, the system will

move to the Backwash stage.

6. Slowly open the water inlet valve to allow the entrance of

water inside the system. At this point, the inlet flow must be

rather low, since in this position water will come in from the

bottom of the bottle and flow upwards to the drain.

7. When water starts flowing continuously through the drain,

fully open the water inlet of the system. At this point, the bottle

will be full of water and so a higher flow will not produce any

damage. Water going out to the drain may be a bit yellowish

or brown. This is completely normal, since it is due to the pre-

servatives of the resin.

8. Let the water flow through the drain until it runs clear.

9. Close the water supply to the system for five minutes, so

the resin can settle down the bottom of the bottle, and the air

that might be left inside can flow towards the upper part of the

bottle.

10. Open the inlet valve of the system and wait for some mi-

20

7. Start-Up

20

Then measure the water hardness present on the outlet of

the system and check that it fits within the desired values.

Otherwise, adjust the regulator and check again.

WARNING: The hardness regulator is supplied in the closed

position, therefore, if the system is not adjusted, it will supply fully

softened water.

nutes in order to make sure that the remaining air has been

purged.

11. Cancel the current regeneration stage and move forward

to the filling stage of the tank. Now the brine tank will auto-

matically start to fill up with water. Let this stage run the full

process. At the end of the stage, the system will finish the

regeneration which was started in point 6.

12. Start another regeneration according to point 6 and wait

until the system reaches the Backwash stage. Press any button

to mover forward to the Brine suction stage.

13. The system should suck water from the brine tank. Let

the suction work for some minutes just to make sure that it is

working properly.

14. Cancel all the remaining stages of the regeneration.

15. Put the by-pass in the service mode and check that trea-

ted water is properly softened (see ‘Section 7.3’).

16. Charge the brine tank with salt.

17. The system is ready to operate.

’DANGER’ There is a danger of injury due to an excess of weight.

It is necessary that at least two persons move and rise the salt

bags. There is a danger of suffering back injuries and other body injuries.

7.2 Residual Hardness Regulation

As mentioned in ‘Section 2.7’, it is not recommended to su-

pply completely softened water to household supplies.

In order to modify the residual hardness, lightly open the regu-

lating valve, as indicated in the image below.

This manual suits for next models

3

Table of contents

Popular Water Dispenser manuals by other brands

Water Care

Water Care TotalCare Series Installation instructions & owner's manual

WaterLogic

WaterLogic WL7 Technical manual

Everpure

Everpure ESO7 Replacement Cartridge EV9607-25 Specification sheet

Honeywell

Honeywell HWB1083S owner's manual

vita

vita SP-A6D-CS user manual

Galaxy

Galaxy VDR 14/100 owner's manual

Elkay

Elkay ezH2O Liv LBWD00 C Series INSTALLATION, CARE & USER MANUAL

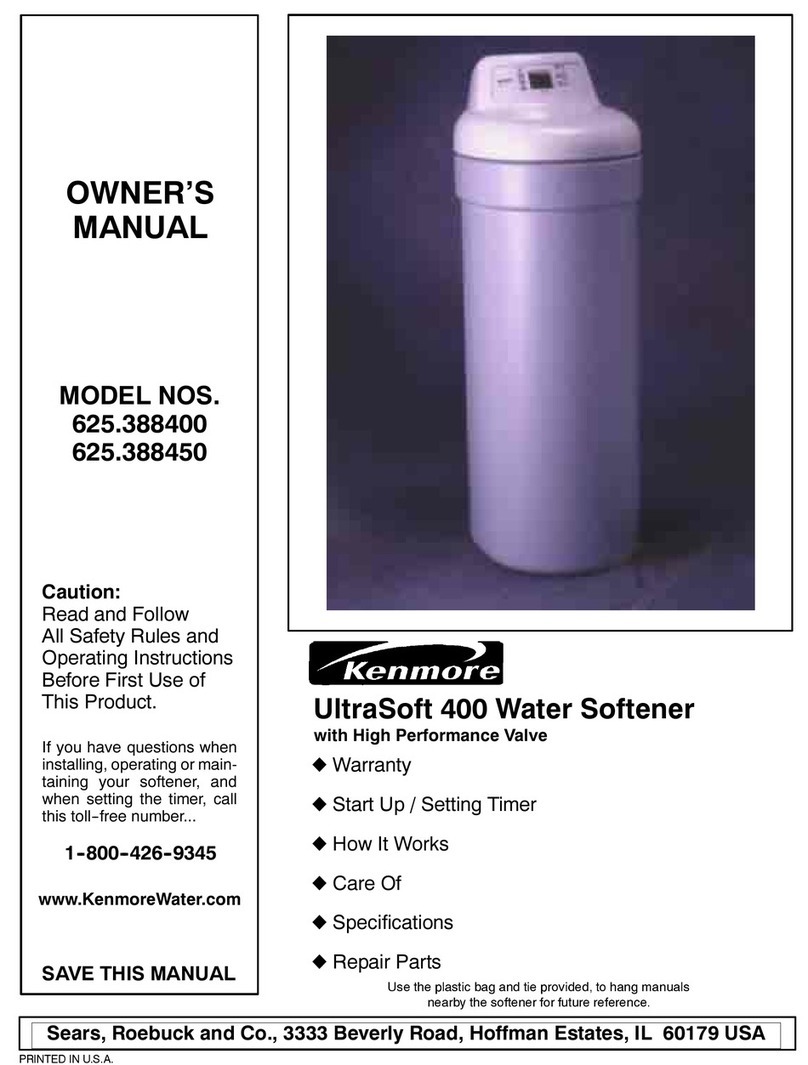

Kenmore

Kenmore ULTRASOFT 400 625.3884 owner's manual

Follett

Follett Symphony 01089580 instructions

socorex

socorex CALIBREX solutae 530 Operating instruction

Borg & Overstrom

Borg & Overstrom T2 user guide

Follett

Follett Symphony Plus 25 series Operation and service manual