Watnext WatHome20 Series User manual

Overcounter and undercounter water coolers

WatHome20

Instruction manual

WatHome20Up, WatHome20In

Product models

WatHome20Up // Overcounter sparkling water cooler

WatHome20In // Undercounter sparkling water cooler

IMPORTANT: Read carefully the instruction manual and safety

procedures before carrying out the installation of the dispenser

Always leave this document ready for use close to the dispenser

All rights reserved.

No part of this document can be printed, copied or published in any way

before obtaining written approval from the producer. The same is valid for

numbers and figures.

The information given into this document are based on general data

known by the producer at the time of the publishing of the document,

concerning construction, materials characteristics and working methods,

therefore this document can be adapted at any time. This is why, these

instructions are only to be considered as general guidelines for the

installation, the use and the maintenance of the dispenser.

This document is only valid for the standard version of the dispenser,

therefore the producer is not responsible for damages due to devices sold

with different technical specifications from standard version.

The instruction manual has been edited with care and attention; however,

the producer cannot be considered responsible for any error or oversight

that could be contained in the document or for any consequence

originated by these oversights.

Watnext Industries srl

Via Malta 2/8 - 16121 Genova (ITALY)

+39 010 776 6296

info@watnext.it

watnext.it

General

instructions ... 02

Use of the following instruction

manuale ... 02

Pictograms and symbols ... 02

Customer service and technical

support ... 03

Law regulations ... 03

Safety information ... 04

Safety warnings ... 04

Safety precautions ... 04

Technical data ... 05

Technical data ... 05

Description of components ... 05

Producer data ... 06

Warranty ... 06

Warranty exclusions ... 06

Builder responsibilities ... 07

Unpacking ... 09

Firsy check of supplied

material ... 09

Unpacking of supplied

material ... 09

Visual examination ... 10

Installation ... 11

Installation location ... 11

Dispenser cleaning ... 11

Dispenser placing ... 11

Connection and duty

start ... 13

Connection to water supply ... 13

Connection with power

supply ... 14

Connection with CO₂ cylinder ... 14

Regulation of CO₂ and

temperature ... 15

Management procedures for the

dispenser ... 16

Maintenance ... 18

Regular maintenance ... 18

Malfunctioning, causes, seek-out,

interventions ... 20

Law regulations for

disposal ... 22

Dismantling dispenser ... 22

Disposal of expired material ... 22

Disposal of electric material waste

WEEE ... 22

Electrical system ... 24

Form I

Dispenser duty start form ... 25

Form III

Regular maintenance form ... 26

Form III

Extraordinary maintenance

form ... 27

Index

02

1. General instructions

Use of the following instruction manual

Please read the safety rules before using the dispenser

Pictograms and symbols

This manual includes following symbols and pictograms:

Suggestion Suggestion and advices to complete procedures in a

simple way

Read Read safety instructions

Beware Procedures that can lead to harm for the dispenser or

surroundings if not followed with due attention

Danger Procedures that can lead to harm for the dispenser or

people if not followed with due attention

Danger Electrical power

Crossed bin Do not dispose electric material in generic trash. Please

ask about the disposal of electric material to authorities in charge in

your country

Danger In case of use of this dispenser by children or persons with

physical or mental reduced capacity, or without experience or

knowledge of the dispenser, the supervision of a specialist is

mandatory. Children should not play with the dispenser

Beware Operations and fixing on electrical system and refrigerating

system are to be permitted only to specialized and authorized staff

Introduction Before using the dispenser, please read carefully the

instruction manual!

03

Customer service and technical support

Get in touch with the reseller for any information concerning specific

settings, maintenance or necessary fixing that are not included in

following manual. The reseller is always the most appropriate contact to

get the assistance you need.

Please be sure to have following data available:

• Dispenser model name

• Dispenser serial number

You can find these information on label afflixed on the dispenser.

Law regulations

Laws concerning potable water treatment systems in Italy are: ministerial

decree 06.04.2004, n.174 art. 9 – legislative decree n.31 of 2011 and

ministerial decree of 07.02.2012 n.25.

This user manual that comes along with the dispenser is divided in many

sections that analyze and explain all the correct procedures that must be

carried out to maintain a good performance level of the dispenser. It also

explains possible health and safety risks for technicians and final user if

the procedures given are not adopted.

This user manual is addressed to all the “downstream” subject who use

the water dispenser:

• Professionals that take care of transport, stocking, sale, installation,

use and maintenance (preventive, ordinary, extraordinary) from the

entrance into the market to its final dismantlement.

• Direct users

This user guide for installation, assembling, use and maintenance of

dispensers must follow with each device that enters into the market

(ministerial decree 07.02.2012 n.25 art. 6 comma b).

04

2. Safety informations

Safety warnings

• Do not place the dispenser on inclined surface, pillows, carpets,

raised floor or shelf

• Only use potable water from water network. Do not use with water

coming from wells, rain deposit, rivers and sea water.

• Do not use hot water

• Use the dispenser in clean locations.

• Do not use the dispenser with temperatures below 4°C

• Do not use tubing longer than 3 meters

• Do not pull on tubing to move the dispenser

• Avoid exposing the dispenser to sun rays or high temperatures

• Properly clean the dispenser periodically (see concerning chapter)

• Avoid leaving heating systems or flammable substances near the

dispenser

• Do not open or alter the dispenser

• In case of water leakage, close the main valve and call for

maintenance

• The dispenser should not be used by children

Safety precautions

• Keep top parts closed during the use of the dispenser

• If filters have been placed, replace them periodically following

producer recommendations.

• Flow water for at least 5 minutes after long periods of inactivity of

the dispenser, and after every change of filter

• Only use suggested materials for internal cleaning (see chapter

concerning periodic maintenance)

• Do not move the dispenser if water is flowing

• Only use on potable water

• Avoid storing water in bottles for too long

05

1

2345

3. Technical data

Technical data

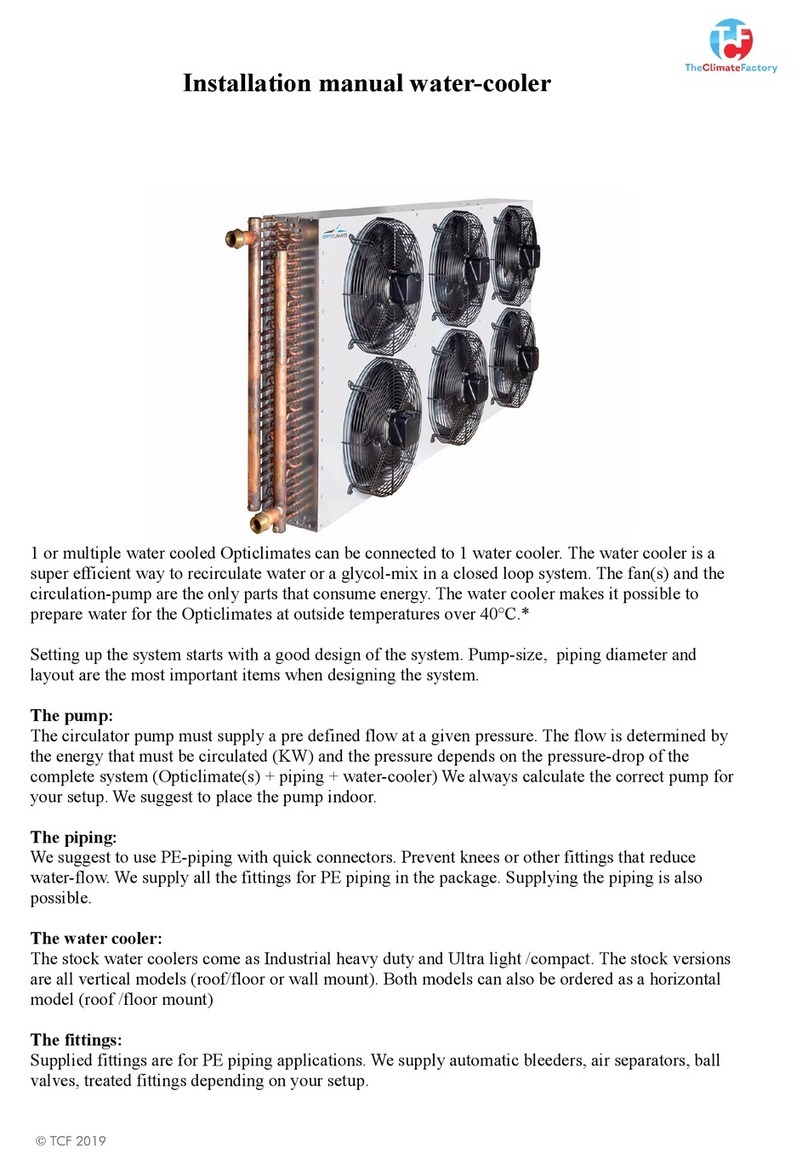

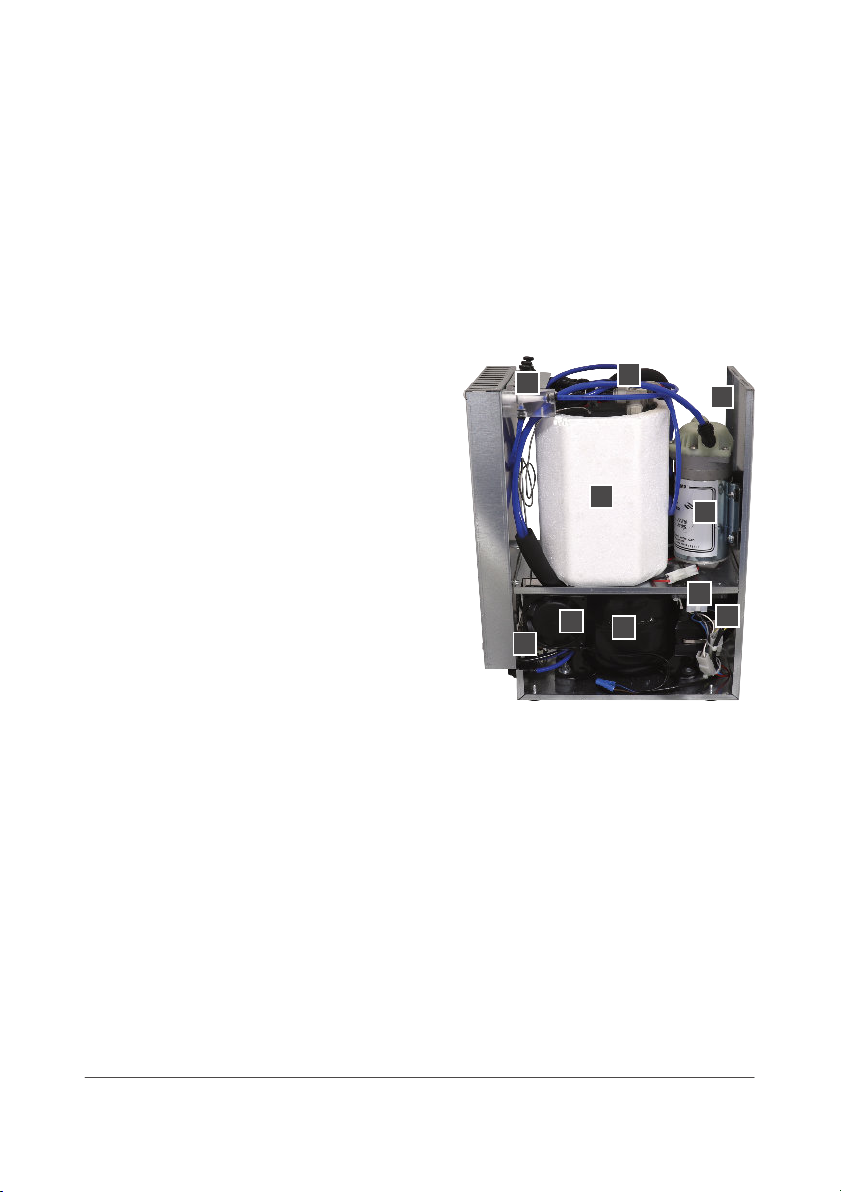

Description of components

The dispenser is formed by following main components (see picture

below)

1. Condensator

2. CO₂ inlet 6 mm tubing

3. H₂O inlet 8 mm tubing

4. Thermostat

5. IEC power plug On-Off

6. Ambient water

7. Cold water

8. Sparkling water

9. Drain grid

10. Ambient Water outlet

8 mm

11. Cold water outlet 8 mm

12. Sparkling water outlet

8 mm

Size 18x47x42 cm

Weight 12 Kg

Power supply 230 V AC

Total power absorption 220 W

Thermal power 15 l/h

Compressor 156 Watt (ΔT = 10°C)

Coil Stainless steel AISI 304

Water pump 65 W

Fittings Metric 8-6 mm

Hermetic saturator With internal cooling 1,5 l

9

6

7

8

1

12

2

11

3

10

45

06

Producer data

The main data of the dispenser are displayed in the label affixed on the

back or on one side of the dispenser, but also on the back cover of this

user manual.

Data available on the label:

• Producer

• Dispenser model

Important in case of alteration or loss of producer label the warranty

is no longer valid

Warranty

Watnext industries srl covers in warranty the dispenser for 12 (twelve)

months from the day of invoice issue to the authorized reseller, that will

grant in its turn a legal warranty to end user.

Warranty covers any deficiency of manufacture and construction.

Watnext industries srl commits with replacing or repairing free of charge

at its headquarters in Genova (ITALY) any component that, following also

customer judgement, could be defective. Malfunctions due to usury are

not included in the warranty. In the event that a technical support was

needed from Watnext industries srl specialized personnel for an on-site

maintenance service, the cost for stay will be charged to end user. Free of

charge supply of spare parts covered by warranty is always consequent to

defective parts oversight from producer (or authorized third parties)

Warranty do not cover components subject to usury (filters, pumps,

faucets and mixer taps, pressure regulators, water meters, co2

bottles,ecc..). It also cannot cover defect caused by normal usury or

inappropriate use of the dispenser.

N.B. a technical support for repair will only postpone the warranty on

replaced or repaired component

Warranty exclusions

Warranty will not cover damages coming from negligence or different

use of the dispenser, for example:

07

• Transport

• Negligence

• Inappropriate or unadapted use of the dispenser

• Different use from the one specified in this user manual

• Wrong power connection or electric shock due to atmospheric

agents

• Uncorrect installation, carried out by unauthorized personnel

• Natural events, calamities

• Maintenance support (ordinary or extraordinary)

• Repairs carried out by unauthorized or unqualified technical

personnel

• Each alteration that hasn’t been previously approved by Watnext

industries srl

• Use of spare parts or equipment not directly supplied or approved

by Watnext industries srl

• Alteration or loss of producer label

• Disrespect of instructions given for the installation or unauthorized

alteration

Builder responsibilities

In order to be covered by warranty given by the producer, the end user

must comply with precautions given in this user manual.

Some basic rules that must be followed:

• The installation must be carried out by specialized and authorized

professionals following the instructions given in the user manual

• For ordinary maintenance the specialized professional must only

use authorized spare parts

Watnext industries srl refuses any responsibility in case unauthorized

spare parts have been used.

Only with authorized spare parts Watnext industries srl can guarantee the

conservation of best water features to final user:

• Avoid overloading the dispenser (check working limits)

• Do not unplug the dispenser from power supply while water is

flowing

08

• The installation should be done in adequate location (avoiding hot

sources, far from children reach, not exposed to sun rays and with

good flow of air to permit aeration)

Builder declines any direct or indirect responsibility that could be due to:

• Installation done by non professionals

• Maintenance done by non professionals

• Use of inadequate or unauthorized components

• Disrespect of instructions given in this user manual

• Installations uncompliant with specific law regulations that have to

be applied in country of destination

• Modifications (substantial or non substantial) carried out on the

dispenser, on software, on hardware and operations logics, unless

previously authorized

• Unauthorized repairs, carried out by non specialized professionals

4. Unpacking

Warning always check first shipping data (delivery address,

destination, package quantity, order number, dispenser model and

code, ecc..)

Firsy check of supplied material

The dispenser must always travel in vertical position. If

the dispenser is delivered lying down or upside down,

or on its side, the dispenser should be returned, as

there is a high chance that the ice-bank will be

irreparably compromised. It should be left in upside

position at least 2 hours, then put it on test bench to

check if it can work.

The packed dispenser must look intact. It should not

show impact signs, breakage signs, crumpled

cardboard, rips..

It should not show alteration signs.

Is should not show traces for having remained under rain, snow, cold, low

temperatures ecc..

Any sign on the box could cause problems with the regular functioning of

the dispenser.

Danger the dispenser, like every other dispenser with ice bank, must

compulsorily travel and be stocked in vertical position. Laying down

or turning upside down the dispenser can lead to irreversible

damages to cooling circuit

At the moment of delivery, check that the dispenser traveled in vertical

position – that is to say if it traveled on a pallet.

Unpacking of supplied material

After the preliminary check has been carried out, you can proceed with

the unpacking of the dispenser. Please respect the arrow sign placed on

the cardboard. This is the procedure to remove the dispenser from its box:

• Cut the safety plastic strapping (if any)

09

• Open the upper part of the box (be careful using cutter)

• Remove Styrofoam, bubble wrap or paper used to protect the

dispenser

Carefully examine the dispenser looking for possible damages. If any,

please inform immediately the courier and the supplier.

Important leave packing material far from children’s reach

Suggestion store packing material and boxes. They can be useful for

future shipping of the dispenser to service center

Visual examination

The body of the dispenser (chassis) must result intact visually and in

perfect conditions.

Important Watnext industries srl follows rigid and detailed control

procedures before the shipping

10

5. Installation

Installation location

The location where the dispenser is placed should have following

features:

• Temperature between +4°c and +35°C

• The aeration must be sufficient to allow good performances of

cooling systems

• Max Humidity 80%

• Following ministerial decree 25, the dispenser should be placed in

healthy ambient

The dispenser must not be placed in open places, exposed to weather, or

placed into ambient where it could be subject to smoke, vapor, abrasive

powders, abrasive agents or where there is a risk of fire or explosions

(where anti-explosion devices have to be used).

Dispenser cleaning

Do not use dirty cloths, used for other purpose, or dump as they could

contaminate the supply nozzle.

Only use absorbent paper (for food use) that can be damp with neutral

detergents, non-aggressive and diluted with water.

Do not use alcohol. Do not use solvent, corrosive or degreasing products.

Do not touch supply nozzles if not wearing for example disposable

gloves.

Dispenser placing

Ensure a suitable location for the installation, it must bear the weigh of

the dispenser and if must be flat (maximum inclination 5°). Also ensure a

good ventilation.

Place the dispenser in order to guarantee a minimum of 5 cm between

the dispenser and the walls – cooling circuit must “breathe” as easily as

possible. A rise of temperature inside the dispenser brings to

malfunctioning, but also to an anticipated compressor failure. Do not

install the dispenser in closed ambient. We suggest to add some

11

aeration openings/ grids to the storage compartment chosen for the

dispenser, in order to clear out the heat produced by cooling system.

The dispenser should not be placed near direct or undirect heat sources.

Warning the power supply cable and the water supply must

absolutely be kept separated. Be careful while moving the dispenser

before the installation, avoiding shocks, falls or accidental hit that

could damage internal circuits.

The undercounter dispenser WatHome20 is connected to draft

column with 8mm diameter tubing. The maximum distance

suggested to preserve good performances is 2 meters between the

column and the dispenser.

In order to avoid condensation, it is important to insulate outlet

tubing headed for the draft column

12

6. Connection and duty start

Warning installation must be carried out to the letter by qualified and

licensed professional following ministerial decree 37/08. We decline

any liability for installation provided by unqualified staff. Avoid

temporary connections

Connection to water supply

Warning always check water supply pressure and place a h2o

pressure regulator calibrated to 3 bar upstream of the dispenser. This

precaution will avoid some possible damages due to pressure peak

and water hammer originated in the water supply itself. Also, a

pressure lower than 2 bar could cause problems

Operations of installation and maintenance must be carried out in good

hygienic conditions, concerning hands and equipment used. In the event

of a second installation, do not use the same tubing but replace it entirely.

Connect the tubing of water supply

We suggest to place an interruption valve upstream of the dispenser. The

interruption faucet will be useful to section the water supply when

needed (maintenance, moving the dispenser, replacing of cartridge, ecc..)

Connect the tubing to rear outlet of the dispenser indicated as H₂O IN

The connection with water supply is carried out with 8 mm tubing

connected to the dispenser in the inlet “H₂O IN”

Eventually, a filtrations system or microfitration can be connected to this

same water supply line. If any, it should be placed between the main

water supply valve and the dispenser water inlet (H₂O IN).

N.B. Water supply features in order to guarantee the good functioning of

dispenser:

• Absence of overpressures

• Maximum pressure 3.5 bar

• Minimum pressure 2 bar

In the event that water supply pressure was higher than suggested (>3.5

bar or 350 KPa), a pressure regulator will be necessary upstream of the

13

dispenser with maximum calibration to 3 bar.

Danger a filtration system placed upstream of the dispenser requires

a different procedure of work start. The water entering into the

dispenser should be particulate-free and clear (no suspended

elements).

Light waters (like the ones coming from osmosis) can alter CO₂

effervescence.

Before opening the main water valve, follow the indications given in

section "Connection and duty start".

Connection with power supply

The connection with power supply is provided connected the IEC cable

with a power socket. This power socket must be connected to ground and

suitable for dispenser requirements (see technical sheet).

Check that line voltage meets the technical features it should respect.

Connect the female plug IEC 320 in the specific socket of the dispenser.

Connect the male plug of the cable to power supply socket.

Warning replace immediately the power cable if damaged

Before turning the dispenser ON, follow the indications given in section

"Connection and duty start".

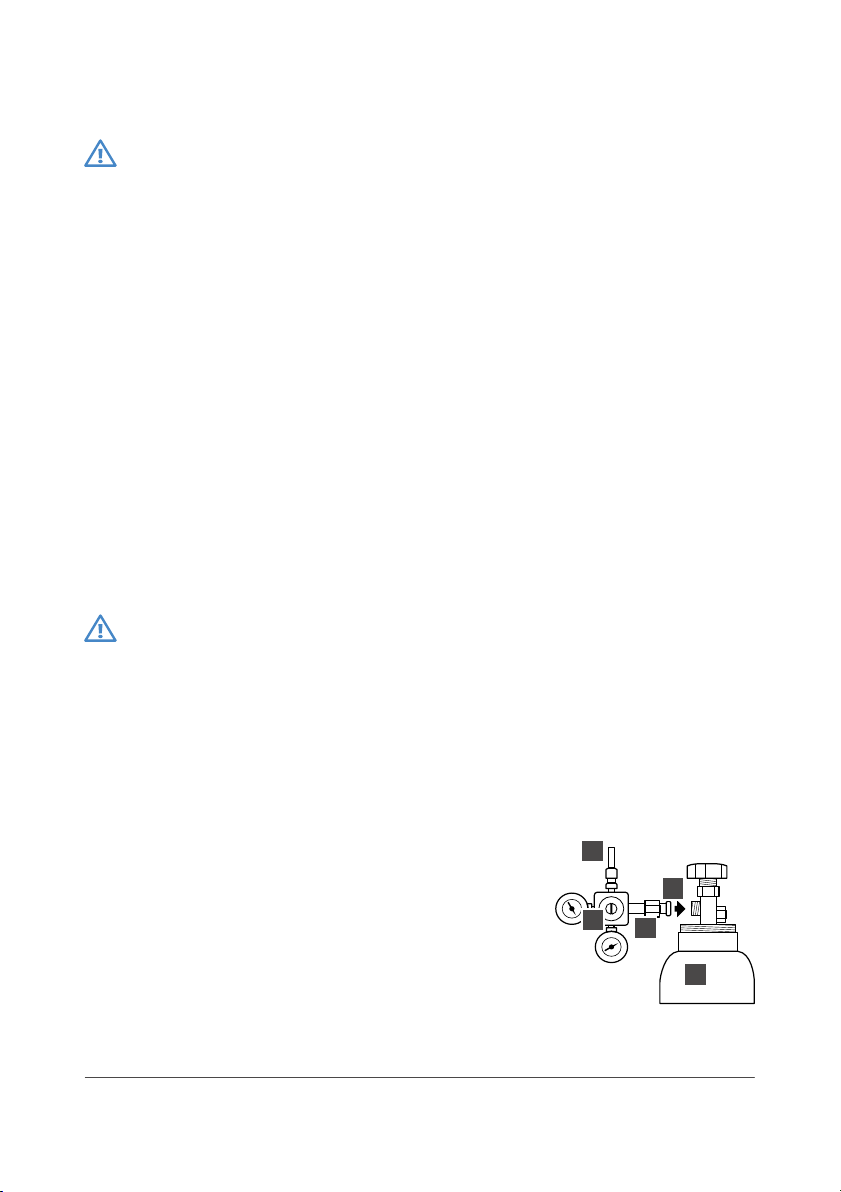

Connection with CO₂ cylinder

1. Connect the pressure regulator R with CO₂

cylinder B checking the correct position of

Teflon gasket.

2. Tighten the nut N and check that tubing T

(outlet) is connected properly

3. CO₂ cylinder must be kept in upright

position

4. CO₂ cylinder must be secured with a chain or

similar to avoid falling

14

T

RN

B

G

Before opening the CO₂ cylinder, follow the indications given in section

"Connection and duty start".

Regulation of CO₂ and temperature

Once the dispenser is on duty, it is necessary to regulate the level of

carbonation and the temperature.

CO₂ regulation

Sparkling water has two parameters for quality : the level of saturation

and the effervescence. The first is regulated with the pressure of co2, the

second depends on the type of watering entering into the dispenser and

the process of saturation. Regulation of co2 pressure must be set

between water supply pressure +0.5 bar with a maximum of 4 bar.

Important: the carbonation also depends on temperature. The

dissolution of co2, that is to say the level of carbonation, rises with the

lowering of water temperature. The final regulations has to be carried out

once the optimal working temperature has been reached (40/60

minutes from first start).

Warning air in the hydraulic system will hinder a good carbonation.

The presence of air bubbles can happen during first use.

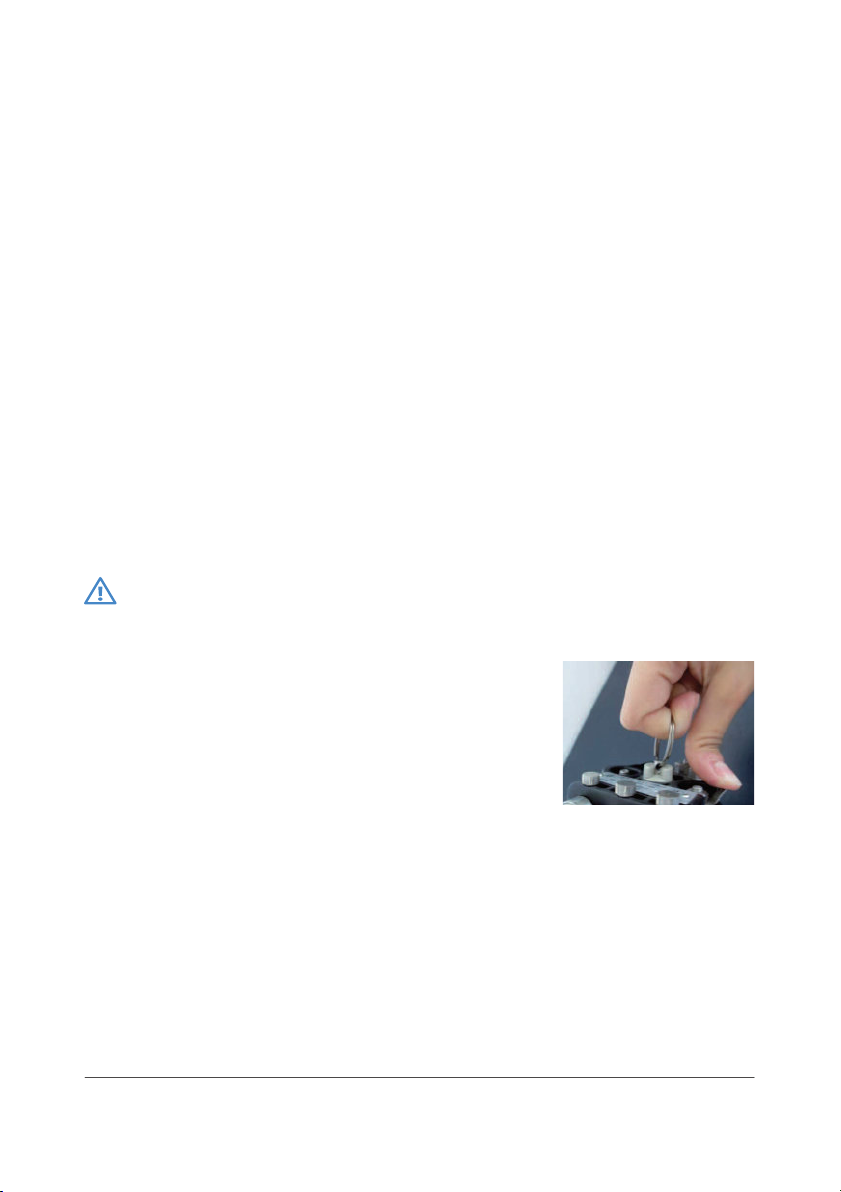

These are the solutions:

1. Remove the upper part of the case and

discharge the carbonator: open the safety

valve pulling the specific ring.

2.Dispense a good quantity of sparkling water

at once until the dispenser will “blow”- the

pump cannot keep up with required

quantity of sparkling water and CO₂ will be

blown by aerator, expelling also air bubbles

Temperature regulation

The temperature of water supplied depends on inlet water temperature

and internal temperature of ice bank. The thermostat regulates the ice

bank and the temperature is already set. Regulating the thermostat to

higher temperatures we would have no ice, so the temperature can be

regulated while losing the thermal flywheel, that is to say lowering the

cool water supply capacity. The regulation of temperature can be done

15

through the thermostat placed inside the dispenser: the upper part of the

case has to be removed, then it is possible to set the specific black knob

“cooler” from 0 to 7- higher values mean cooler water.

Flow regulation

With a screwdriver the flow regulator placed at the rear of the dispenser

can be set as follows:

• Closing: lower flow and better carbonation

• Opening: higher flow and lower level of carbonation

1. Hermetic carbonator

2. Pump

3. Flow regulator

4. Condensator

5. Electronic board

6. Compressor

7. Vent

8. Evaporator

T. Thermostat

V. Solenoid valve

Management procedures for the dispenser

The dispenser could be equipped with 2 or 3 mechanical faucet,

depending on the type of water supplied. For water supply, simply full the

lever of the faucet towards you. The faucet for sparkling water is equipped

with a compensator to regulate the water flor and guarantee a good level

of carbonation.

In order to prevent malfunctioning of the pump, it is mandatory that the

dispenser runs water in its circuits. Is water supply is missing, a protection

system will stop the pump. The pump stops working after 4 minutes of

continuous work. To recover the functioning of the dispenser, please

unplug the dispenser from power supply and try again when water supply

is back.

12

5

4

6

8

7

T

V

3

16

Cleaning of draft faucet is essential to prevent water from bacteria

contamination. We suggest a daily cleaning with a non-toxic product

(hydrogen peroxide).

17

18

7. Maintenance

Regular maintenance

Cleaning of hydraulic system

End user can only carry out regular maintenance operations described in

following user guide, with the help of specialist if needed. The constructor

declines any liability if the procedures given are not being followed and

reserve it’s right to suspend the warranty.

Periodic cleaning is important to avoid bacteria growth. Especially when

the water supply is not covered by chlorine treatment, periodic

throughout cleaning is mandatory (at leat every 6 month)- or according to

water treatment systems installed before the dispenser.

Sanitization of hydraulic system must be carried out with a good oxidant

and solvent product, that efficiently removes silt and bacteria.

We suggest the use of hydrogen peroxide with a solution at 24 volumes,

and a maximum application time of 15 minutes. The use of other

disinfectant products, with strong oxidant power like peracetic acid or

ozone could lead to corrosions, vapors or noxious smell.

After the application of hydrogen peroxide, a good rinsing of hydraulic

circuits is necessary – at leat 5 liters for each circuit: ambient water, cold

water, sparkling water. The sparkling water systems, with its stock of

water, could need a longer rinsing. Litmus paper test can be used to check

if there is any hydrogen peroxide left..

Cooling system cleaning

The winglet of condenser for ventilation must be throughout cleaned by

aspiration or with a brush. Dust deposit will strongly reduce the

effectiveness of cooling system and irreparably damages the compressor

in the long term.

Warning any regular maintenance that need the intervention of

qualified professionals must be reported and described in the form at

the end of this manual “form II”.

Regular maintenance described is to be evaluated for a normal use of

the dispenser. In case of burdensome work amount of the machine,

the maintenance needs to be carried out more frequently

This manual suits for next models

2

Table of contents

Popular Water Dispenser manuals by other brands

BRIO

BRIO CLPOU320UVF4 Setup manual

Lancaster

Lancaster PLATINUM LINE LES X Factor Series Installation, operating and service manual

Osmio

Osmio Duo Hydrogen instruction manual

clage

clage Zip HydroTap G4 B 160 operating instructions

DOCRILUC

DOCRILUC ENFRIADOR-AGUA USER AND MANTINANCE MANUAL

Culligan

Culligan HD-202 Brochure & specs