StreetStrider 8s User manual

1

Copyright © 2019 StreetStrider International, LLC

8s OWNER’S MANUAL

1-800-348-0998 | www.StreetStrider.com

Copyright © 2019 StreetStrider International, LLC

2Copyright © 2019 StreetStrider International, LLC

Owner’s Manual Contents

About This Manual............................................

Parts Identication............................................

Assembling the StreetStrider 8s........................

Unpacking and Prep..................................

Front Wheels............................................

Rear Wheel...............................................

Poles and Skis................................... ........

Brakes.......................................................

Rear Hub Shifter................................ ........

Frame Strut..............................................

Front Wheel Alignment.............................

Advanced Lean-to-Steer Technology..........

Folding.....................................................

Simple Steps to Learn to Stride.........................

Safety Equipment..............................................

Mechanical Safety Check...................................

Return Policy.....................................................

Limited Warranty...............................................

3

4

8

8

8

9

10

13

14

15

16

17

19

20

22

24

25

26

1

2

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

4

5

6

7

8

3

Copyright © 2019 StreetStrider International, LLC

Records

About This Manual

1

Record your StreetStrider model, serial number (on the frame just behind

the underside of the bottom bracket; see photo) and other information

below. Retain your sales receipt as proof of purchase.

This StreetStrider 8s Owner’s Manual contains important assembly, maintenance, safety and performance information. It was

written to help you get the most performance, comfort, enjoyment and safety out of your new StreetStrider. Keep this manual

handy for future reference.

IMPORTANT: If your StreetStrider was purchased unassembled, read this manual before you assemble it. The Limited Warranty

found in this manual on page 26 applies only to StreetStriders that comply with the assembly instructions in this Owner’s

Manual.

IMPORTANT: You should read this manual before you go out on your rst ride.

Riding a StreetStrider can be a hazardous activity even under the best of circumstances. It is highly recommended that your

rst stride on your new StreetStrider be taken in a controlled environment, away from cars, obstacles and other cyclists, and

wearing your helmet.

Proper maintenance of your StreetStrider is your responsibility as it reduces the risk of injury. This manual contains many

IMPORTANT, CAUTION and WARNING statements concerning the consequences of failure to maintain or inspect your

StreetStrider. When inspecting your StreetStrider, be certain to secure all parts properly as described in Table 2-1. Under-

tightening or over-tightening can result in component damage. StreetStrider parts have metric hardware - always use the

correct tools.

IMPORTANT: It is impossible to predict every condition that will occur while striding. StreetStrider (the Company) has made

no representation about the safe use of the StreetStrider under all conditions. There are risks associated with the use of any

StreetStrider that cannot be predicted or avoided, and the Company recommends safe and cautious striding.

WARNING Failure to read and comply with all assembly, safety, performance and maintenance

requirements and warnings, and unsafe or improper use of the StreetStrider could result in serious

injury or death.

Register your StreetStrider online at www.StreetStrider.com so we can notify you about new models, care and maintenance

issues, and record your serial number. You may also want to register your serial number with your local police department in

the event that your StreetStrider is lost or stolen.

MODEL COLOR SERIAL NUMBER

DATE OF PURCHASE PLACE OF PURCHASE

4Copyright © 2019 StreetStrider International, LLC

Parts Identication

2

Figure 2.1 StreetStrider 8s Parts. Refer to Table 2-1 for part numbers and descriptions.

5

Copyright © 2019 StreetStrider International, LLC

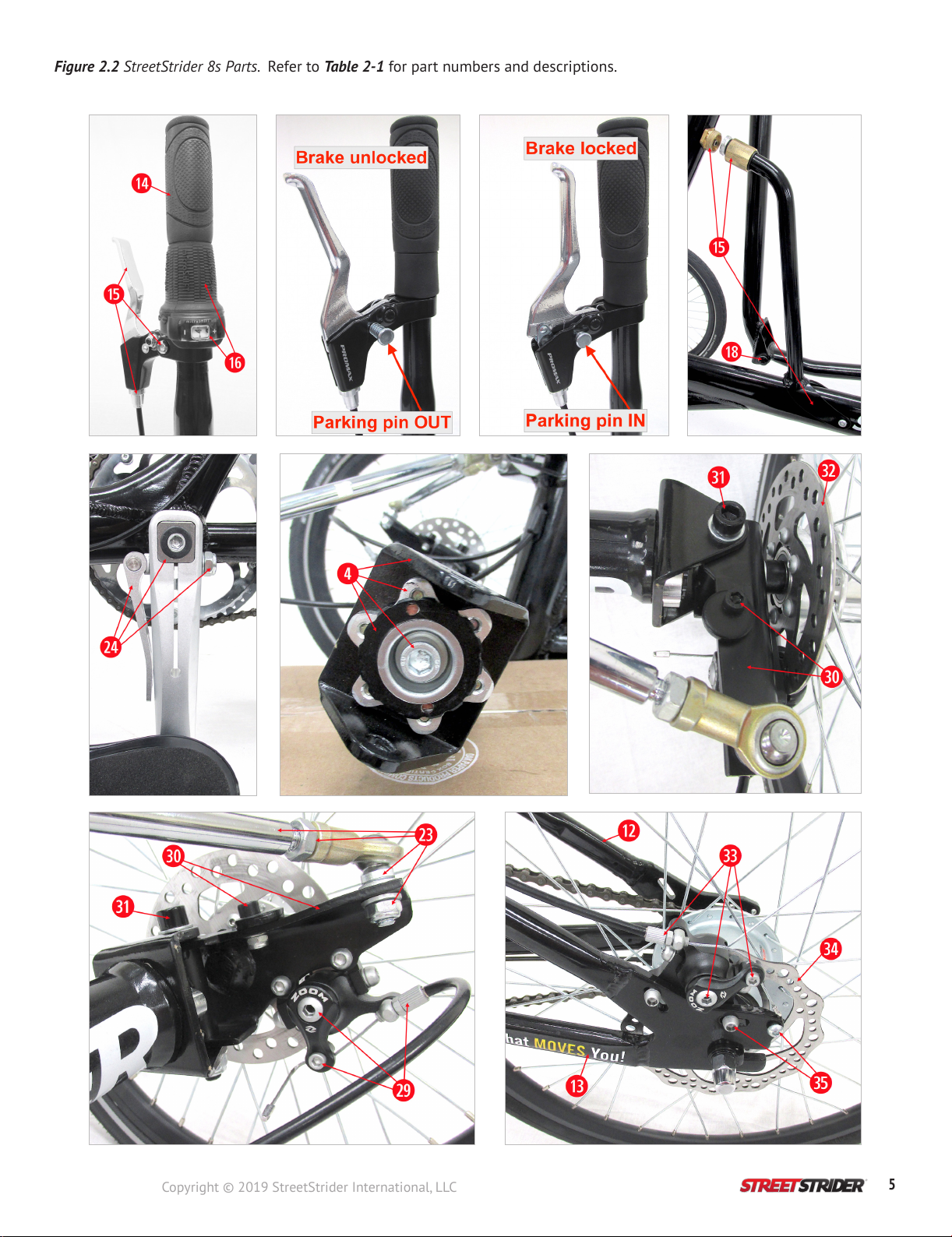

Figure 2.2 StreetStrider 8s Parts. Refer to Table 2-1 for part numbers and descriptions.

6Copyright © 2019 StreetStrider International, LLC

#DESCRIPTION HARDWARE SPECIFICATIONS QTY STATE

1Main frame bone AL 6061 T6 1

2Head tube Bottle cage bosses

Strut coupling boss M5 x P0.8 threads, 2 front side, 1 rear side 2 Tighten to secure

cage and coupling

3Crossbar 1

4Front beam Clevis bracket with

adjustable caster angle

Male and female 52 tooth spline

M31 x P1.0 lock ring

M10 x P1.5 x L20 x W8, center screw

2

Tighten after

adjusting caster

angle

5Fold joint Quick Release clamp stem

nylon lock nut M6 x P1.0 x L20 x H10 x W10 1 Snug to secure

6Stride pole upper Left and right side 2

7Strider pole lower 2

8Frame strut Coupling at top end

Saddle at bottom end

¾” x 11.5 TPI GHT, M5 x P0.8 inner face

M5 x P0.8 binding screw w/ nylon washers

1

1

Tighten

Snug

9Strider ski Composite bushings

Roller bearings

OD12 x ID10 x L15 x 17 mm ange, at Joint #2

OD 26 x ID 18 x L 20, at Joint #3

4

4

Grease

Grease

10 Foot platform 4 mm hex screw,

Grip tape on surface M5 x P0.8 x L12 x H12 x W4, 12 Tighten

11 Rear fender frame 4 mm hex screw, M5 x P0.8 threaded hole for luggage rack 1 Tighten

12 Fender stay 2

13 Chain stay 2

14 Hand grip Left and right side, rubber 2

15 Twist grip shifter 3 mm hex screw M4 x P0.7 x L16 x W3, clamp 1 Tighten

16 Brake lever

5 mm hex screw

Parking pin

Cable housing adjuster

Cable doubler

M5 x P0.8 x L20 x H10 x W5, clamp

OD 10, spring loaded

M10 x P2.0 barrel adjuster with lock ring

Front brake, with adjuster and lock ring

2

2

2

1

Tighten

Adjust-lock

Adjust-lock

17 Joint #1, cross bar-pole

pivot clamp assembly

4 mm hex screw

3 mm hex set screw

4 mm hex pan head

Roller bearings

4 mm at head screw

M5 x P0.8 x L30 x H8 x W4, clamp cap

M6 x P1.0 x L5 x W3, with cup end, cross bar

M6 x P1.0 x L10 x W4, lock screw

OD26 x ID18 x L20, in cross bar

M6 x P1.0 x L20 x W4, inner shaft end

8

8

2

4

2

Tighten evenly to

secure pole

Tighten

Tighten

Grease

Tighten

18 Joint #2, pole-ski pivot

8 mm hex screw,

washer,

17 mm nut

M10 x P1.5 x L75 x H15 x W8

OD16 x ID10 x T1

M10 x P1.5 x L10 x W17, nylon lock

2

2

2

Snug but allow joint

movement

19 Joint #3, ski-pedal pivot 6 mm hex spindle OD18 X L60 x W6, 9/16” x 20 TPI

Right threads right, Left threads left, C clip 2 Tighten

20 Front beam pivot

8 mm hex screw

3 mm hex set screw

Tapered roller bearing

M10 x P1.5 x L20 x W8, front cap

M6 x P1.0 x L5 x W3, rear end

OD 47 x ID 20 X T15

1

1

2

Tighten

Tighten

Grease

Figure 2-1 StreetStrider 8s Parts List with Hardware Specications.

7

Copyright © 2019 StreetStrider International, LLC

#DESCRIPTION HARDWARE SPECIFICATIONS QTY STATE

21 Front wheel rim and tire Rim 36H, Tire 16” x 1 3/8”, ISO 37 x 349 2 80-85 psi

22 Front wheel hub 19 mm hex axle nut M12 x P1.75 x L10 x W19, nylon lock 2 Tighten

23 Steering linkage

Inboard and outboard

rod ends

Threaded linkage rod

M8 x P1.25 x L20 x W14 ats on stud

M8 x P1.25 x L10 x W13 nylon lock nut

M8 x P1.25 x L20 rod, right and left thread ends

M8 x P1.25 x L5 x W14, right and left jam nuts

4

2

4

Lubricate balls

Tighten

Tighten

Tighten

24

Crank arm set with quick

release left side

Bottom bracket

8 mm hex screw

QR stem

Square taper

M8 x P1.0 x L15 x H12 x W8, 18 mm ange

M10 x P1.5 x L10 x W17, nylon lock

68 x 122 mm

2

1

1

Tighten

Snug

Tighten

25 Chain ring with guard 52 T 1

26 Chain 1/2” x 1/8” x 93 links 1 Lubricate

27 Rear wheel rim and tire Rim 36 H, Tire 20” x 1 3/8”, ISO 37 x 451 1 80-85 psi

28 Internal gear hub 15 mm axle nuts 8 speed, 3/8” x 26 TPI x W15 axle nuts 2 Tighten

29 Front disc brake

5 mm hex mount screw

5 mm hex caliper screw

5 mm hex outer pad

3 mm hex inner pad

Cable housing adjuster

4 mm hex cable clamp

M6 x P1.0 x L15 x H10 x W5, through knuckle

M6 x P1.0 x L15 x H10 x W5, through bracket

W5 outer pad adjuster with 2 mm lock set screw

W3 inner pad adjuster, through center screw hole

M6 x P1.0 x L15 knurled for ngers with lock ring

M5 x P0.8 x L12 x H10 x W4, socket and nut

4

4

2

2

2

2

Tighten

Adjust-tighten

Adjust-tighten

Adjust

Adjust-lock

Adjust-tighten

30 Steering knuckle w/

lean stop

5 mm hex screw

Lean stop disc

Composite bushing

M6 x P1.0 x L15 x H10 x W5, socket screw

W10 nylon lock nut

OD24 x T4 with 6 mm offset hole

OD12 x ID10 x L15 x 17 mm ange

2

4

Adjust-tighten

Grease

31 King pin bolt in front beam

clevis

8 mm hex bolt

washer

17 mm nut

M10 x P1.5 x L75 x H15 x W8, socket

OD16 x ID10 x T1

M10 x P1.5 x L10 x W17, nylon lock

2

4

2

Snug but allow

knuckle swivel

32 Front disc rotor 4 mm hex screw M5 x P0.8 x L10 x H10 x W4, Rotor 120 mm 12 Tighten

33 Rear disc brake

5 mm hex mount screw

5 mm hex caliper screw

5 mm hex outer pad

3 mm hex inner pad

Cable housing adjuster

4 mm hex cable clamp

M6 x P1.0 x L15 x H10 x W5, through drop out

M6 x P1.0 x L15 x H10 x W5, through bracket

W5 outer pad adjuster with 2 mm lock set screw

W3 inner pad adjuster, through center screw hole

M6 x P1.0 x L15 knurled for ngers with lock ring

M5 x P0.8 x L12 x H10 x W4, socket and nut

2

2

1

1

1

1

Tighten

Adjust-tighten

Adjust-tighten

Adjust

Adjust-lock

Adjust-tighten

34 Rear disc rotor 4 mm hex screw M5 x P0.8 x L10 x H10 x W4, Rotor 140 mm 6 Tighten

35 Rear drop out

Dropout slot for rear hub axle

Holes for rear brake mounting bracket

M5 x P0.8 hole for rear luggage rack screw

2

4

2

Specication

Key

M=OD of threads, mm L=length W=wrench t, mm

P=pitch, threads/mm H=OD of head T=washer thickness, mm

TERMINOLOGY: The right and left sides of the StreetStrider refer to sides when one is striding.

IMPORTANT: Save the box and packing material as they must be used to repack the StreetStrider for any returns.

8Copyright © 2019 StreetStrider International, LLC

Assembling the

StreetStrider 8s

Unpacking and Prep (see video)

3

3.1

To assemble your StreetStrider 8s, rst follow the steps and photos in this manual and view the StreetStrider 8s assembly videos where

indicated. Included in the shipping box are the StreetStrider 8s in parts, an Owner’s Manual [1] and a small bundle in the top tray inside the

box containing a tool kit [2] which includes, four open end wrenches 17 x 14, 15 x 13, 14 x 12, and 13 x 10 mm [3], seven hex wrenches 8,

6, 5, 4, 3, 2.5, 2 [4], two tire levers [5], a 19 mm front hub socket [6], and a front wheel caster spanner wrench [7]. The parts bags contain the

front beam shaft assembly [8], a right crank arm screw [9], the shifter cassette parts [10], three wheel reectors [11], two front brake cable

tips [12], zip ties [13], touch up paint [14], and two spare inner tubes [15], Figure 3.1.2.

Figure 3.1.1 The StreetStrider box shows which

side is up. You will need a blade or scissors,

pliers, tape measure, grease and a rag.

Figure 3.1.4 The main frame assembly,

padded and secured with zip ties, is on the

bottom cardboard panel which has corner

cut-outs.

Figure 3.1.2 The top tray in the box holds

the parts bundle and the support layers

underneath protect the StreetStrider.

Figure 3.1.5 Grip the corner cut-outs and

lift that panel and the folded StreetStrider

out of the box, set the unit on a table, and

remove the remaining zip ties.

Figure 3.1.3 The front wheel assembly and

rear wheel are the next 2 layers. Remove the

wheels and set aside.

Figure 3.1.6 Once all the packing is removed

set the foot platform assemblies (lower pole,

ski, foot platform, crank arm) aside.

Front Wheels (see video)

3.2

Figure 3.2.1 Lay the frame on it’s left side.

Retrieve the front beam shaft assembly,

take the cap, tapered bearings and back

plate off the shaft, and get the 8 and 3 mm

hex wrenches.

Figure 3.2.2 Loosen the set screw under

the front beam shaft tube with a 3 mm hex

wrench. Slide the shaft into the tube so that

the at section on the rear end of the shaft

ts just above the 3 mm.

Figure 3.2.3 With the shaft inserted all the way

forward, secure the shaft by tightening the set

screw with the 3 mm hex wrench.

9

Copyright © 2019 StreetStrider International, LLC

Figure 3.2.4 With the frame

upright, slide the back plate and

one of the tapered bearings,

with taper facing forward, onto

the shaft. Grease the bearings.

Figure 3.2.8 Lower the left

steering linkage so the outboard

rod end can be attached to the

left steering knuckle.

Figure 3.2.5 Unfold the front

wheels on the front beam and

set the front wheel assembly in

front of the shaft.

Figure 3.2.9 Unscrew the 13 mm nylon lock nut from the rod end

stud, insert the threaded stud through the hole at the forward end of

the steering knuckle, secure the stud with the nylon nut having one

washer above and one washer below the knuckle and then hold the

stud and tighten the nut using two 13 mm wrenches.

Figure 3.2.6 Grease the front

bearing race in the front beam.

Figure 3.2.7 Insert the other

bearing onto the shaft with the

taper facing rearward. Put the

cap over the front of the beam

shaft, insert the 10 mm screw, and

tighten with the 8 mm hex wrench.

Figure 3.2.10 Repeat steps

to attach the right steering

linkage.

IMPORTANT: We recommend adding a liquid thread locker to the threads of the 10 mm screw.

Figure 3.2.11 Route the front brake cables

from the head tube, under the steering

linkage and over the front beam. If the cable

housing is off of the cables slide it back on.

Insert the left and right cable and housing

into the barrel adjuster on the left and right

brakes, respectively.

Rear Wheel (see video)

3.3

Figure 3.3.1 Remove the silver

acorn nut and gray (or yellow)

non-turn washer from the right

axle end.

Figure 3.3.2 From the parts bag retrieve the shifter cassette parts,

the cassette pulley, the driver cap ring (often in the rear side of the

pulley), and the lock ring. Press the driver cap over the hub driver

until it snaps down.

Figure 3.3.3 Place the cassette

pulley over the axle so that the

red dots on the washer and the

cassette pulley are in line.

10 Copyright © 2019 StreetStrider International, LLC

Poles and Skis (see video)

3.4

Figure 3.3.4 Put the lock ring onto the

cassette pulley so that the 2 yellow dots are

adjacent.

Figure 3.3.5 Rotate the lock ring 45°

clockwise to lock the cassette pulley onto

the hub.

Figure 3.3.6 Replace the non-turn washer with

tongue pointing rearward, and screw the acorn

nut back onto the axle a few turns.

Figure 3.3.7 Remove the plastic brace in the

rear drop and loop the chain over the rear

drop out and the bottom bracket, BB.

Figure 3.3.8 Unscrew acorn nuts on each end

of the axle so there is an exposed section of

axle under the non-turn washers that can

slide into the dropouts. On the left side, align

the brake rotor with the brake caliper gap.

Figure 3.3.9 Slide axle into dropouts all

the way forward, align the tongue of the

non-turn washers with dropout slots, nger

tighten the acorn nuts on both ends, and

loop chain around hub sprocket.

IMPORTANT: Inate tires to 80-85 psi.

Figure 3.4.1 While the head tube is

folded onto the main frame, use the

4 mm hex wrench to remove the 4

screws and caps from the both pole

clamps at Joint #1.

Figure 3.4.2 Apply a little

grease to the screw heads

and threads then set the

caps with screws on the

table.

Figure 3.4.3 Raise the head tube while sliding the quick release, QR,

clamp pin to the right. With the head tube in the full upright position

allow the clamp pin to insert into the hole.

11

Copyright © 2019 StreetStrider International, LLC

Figure 3.4.4 Rotate the QR stem to the

vertical position so that the lever is

against the head tube then close the

lever downward.

Figure 3.4.5 Retrieve the right foot platform assembly

(lower pole, ski, foot platform, and crank arm with chain

ring) and position next to right side of the frame. Make

sure the chain is looped over the BB spindle.

Figure 3.4.6 Rotate the BB spindle

so that the upper surface of the left

rectangular end piece on the spindle has

the shallow channel and is horizontal.

Figure 3.4.7 Lift the right crank arm so it is in the 6 o’clock

position and insert it onto the BB square spindle. Using the

8 mm hex wrench, screw the crank bolt into the spindle and

tighten to 30 ft lb, then wrap the chain around the chain ring.

Figure 3.4.8 Lift the right lower pole and t it into the right Joint #1 clamp

base. Place the Joint #1 cap with greased screws over the pole and using the 4

mm hex wrench, screw each the 4 caps screws in about 5-10 turns. Add a little

grease to the inner surface of the lower pole.

IMPORTANT: Make sure there is a little grease on the spindle so the crank arm slides on rmly.

Figure 3.4.9 Apply a little grease to the lower section of the right upper

pole, which has a brake lever and shifter, then slide it into the lower

pole to a level that ts the height of the user. The upper pole can also

be rotated toward the side to provide a comfortable width for the user.

Figure 3.4.10 The pole height lines

are used to set the approximate pole

height for the height of the user, from

< 5’ to approximately 7’.

Figure 3.4.11 With the 4

mm hex wrench, carefully

tighten the Joint #1

clamp in an X pattern so

that all the screws are

tightened evenly and the

space between the clamp

base and cap on the front

side of the pole is equal

to the space on the rear

side.

IMPORTANT: A good starting pole height will position the user’s arm to have a 90°

elbow bend, with forearm parallel to the ground when standing on the platforms and

holding the grips of both poles in vertical position.

12 Copyright © 2019 StreetStrider International, LLC

Figure 3.4.12 Place the left ski assembly on

the left of the frame, rotate the right crank

to the 12 o’clock position and rest the left

upper pole on the right foot platform.

Figure 3.4.13 Lift the left crank arm to to

the 6 o’clock position and open the QR lever.

Note that the QR stem, visible in the crank

arm opening, will t into the channel of the

BB end piece and lock the crank onto the BB.

Figure 3.4.14 SRotate the QR lever 180° so

the at face of the QR stem is visible in the

crank arm opening, which will allow the

opening to slide over the BB end piece.

Figure 3.4.15 Slide the crank arm

opening over the BB end piece

as far as possible.

Figure 3.4.19 Attach the lower and upper pole on the left

side following the procedure used on the right side. Make

sure the left and right poles are set to the same height,

rotate the poles to approximately shoulder width of the

user and also parallel from the side view.

Figure 3.4.16 Rotate the QR lever

180° so that the QR stem ts

into the BB end piece channel.

Figure 3.4.17 Close the QR lever

against the crank arm.

Figure 3.4.20 Rotate the brake levers to a forward position, rotate the

shifter so the gear indicator window is seen by the user, tighten the

brake lever clamps with the 5 mm hex wrench and the shifter clamp

with the 3 mm hex wrench. Use 2 of the zip ties to orderly hold the

cables to the poles.

Figure 3.4.18 If the QR lever

closes without any resistance

open the lever, pull the crank

arm off the BB ¼ inch (6 mm),

tighten the 17 mm stem nut ¼

turn, push the crank arm back

on, and close the QR lever. If

needed, repeat until QR closes

with some resistance.

IMPORTANT: A good starting pole height will position the user’s arm to have a 90° elbow bend, with forearm parallel to the

ground when standing on the platforms and holding the grips of both poles in vertical position.

13

Copyright © 2019 StreetStrider International, LLC

Brakes (see video)

3.5

Figure 3.5.2 Fold the head tube down and push the cable housing from the left brake lever into the opening at the top of the crossbar so

that the base of the cable doubler is visible through the hole in the fold joint. While pulling the cable down at the caliper make sure there

is no exposed cable visible at the brake lever by inserting the cable housing ferrules into the brake lever barrel adjuster. Also, insert the

cable housing ferrules into the base of the cable doubler using the pliers if needed.

Figure 3.5.1 Make sure the brake rotor is centered in the caliper gap between the pads and the wheel spins freely. If adjustment is needed,

loosen the caliper positioning screws with a 5 mm hex wrench, tighten the inner pad with the 3 mm hex wrench, inserted through the

caliper lever, and the outer pad with the 5 mm hex wrench to center the rotor in the gap, then tighten the positioning screws. If the rotor is

already centered in the caliper gap tighten the pads against the rotor in order to attach the brake cable in the next steps.

Front Brakes

Figure 3.5.3 Loosen the clamping screw with the 4 mm hex wrench so there is space to route the brake cable under the nut. Grip the brake

cable end with pliers, rotate the pliers to make the cable taut, then tighten the cable clamping screw. Unscrew the inner and outer brake

pads so that a sliver of light can be seen between the rotor and pads and so the wheel spins freely. Bend the cable away from rotor and

squeeze a cable tip onto the end of each cable. Repeat on the other brake.

To make sure both front brakes stop equally, stand in front of the StreetStrider, squeeze the left brake lever and pull the StreetStrider

forward while slowly easing the brake pressure. If one wheel starts rotating before the other, which begins to turn the StreetStrider, adjust

the brake pads and/or the barrel adjuster at the caliper until that wheel begins to rotate with the other wheel.

IMPORTANT: Properly adjusted brakes will clamp the wheels when the brake lever is squeezed

and about 1 inch (25 mm) from the rubber grip.

14 Copyright © 2019 StreetStrider International, LLC

Rear Hub Shifter (see video)

3.6

Rear Brake

Figure 3.5.4 With the chain wrapped around

both the right crank arm chainring and

the rear hub sprocket, pull the rear wheel

backwards to make the chain taut, center

the front of the wheel in the frame chain

stays, and tighten the acorn nuts with the 15

mm wrench, rst right side then left. A taut

chain should only move about ½” if lifted at

a point midway between the chain ring and

hub sprocket.

Figure 3.5.5 The rear brake

caliper is adjusted exactly as

described for a front brake

caliper.

Figure 3.5.6 Both

brake levers have a

parking brake pin

to hold the brake

lever in a squeezed

position. If the

parking brake does

not hold, unscrew

the brake lever

barrel adjuster.

Figure 3.5.7 To install the 3 wheel

reectors onto the spokes, position

the reector between spokes and

rotate so the reector ends snap

around the spokes.

Figure 3.6.1 At the grip on the right pole, twist the

shifter to gear 1. At the rear hub, pull the shifter

cable taut and make sure the length of cable from the

ferrule to the center of the clamping screw is 101 mm

(4 in). If not, loosen the nut with the 10 mm wrench,

adjust to 101 mm and tighten.

Figure 3.6.2 Slide the ats of the clamping screw with nut facing outward into the

oblong slot at the 10 o’clock position of the cassette pulley. Ease the shifter cable

housing forward through the frame so the shifter cable lies in the pulley groove

from the 10 to 6 o’clock position. Insert the 2 mm hex wrench into the tab with a

hole at the 9 o’clock position of the pulley and rotate the spring-loaded cassette

pulley ¼ turn counter clockwise.

Figure 3.6.3 While holding the wrench at the 6

o’clock position pull the shifter cable housing

forward until the cable can be slid into the slot

of the arm of the cassette pulley, push the black

plastic ferrule on the end of the cable housing

into the socket, then return the wrench to the

9 o’clock position making sure the cable lies in

the groove under the cassette pulley.

15

Copyright © 2019 StreetStrider International, LLC

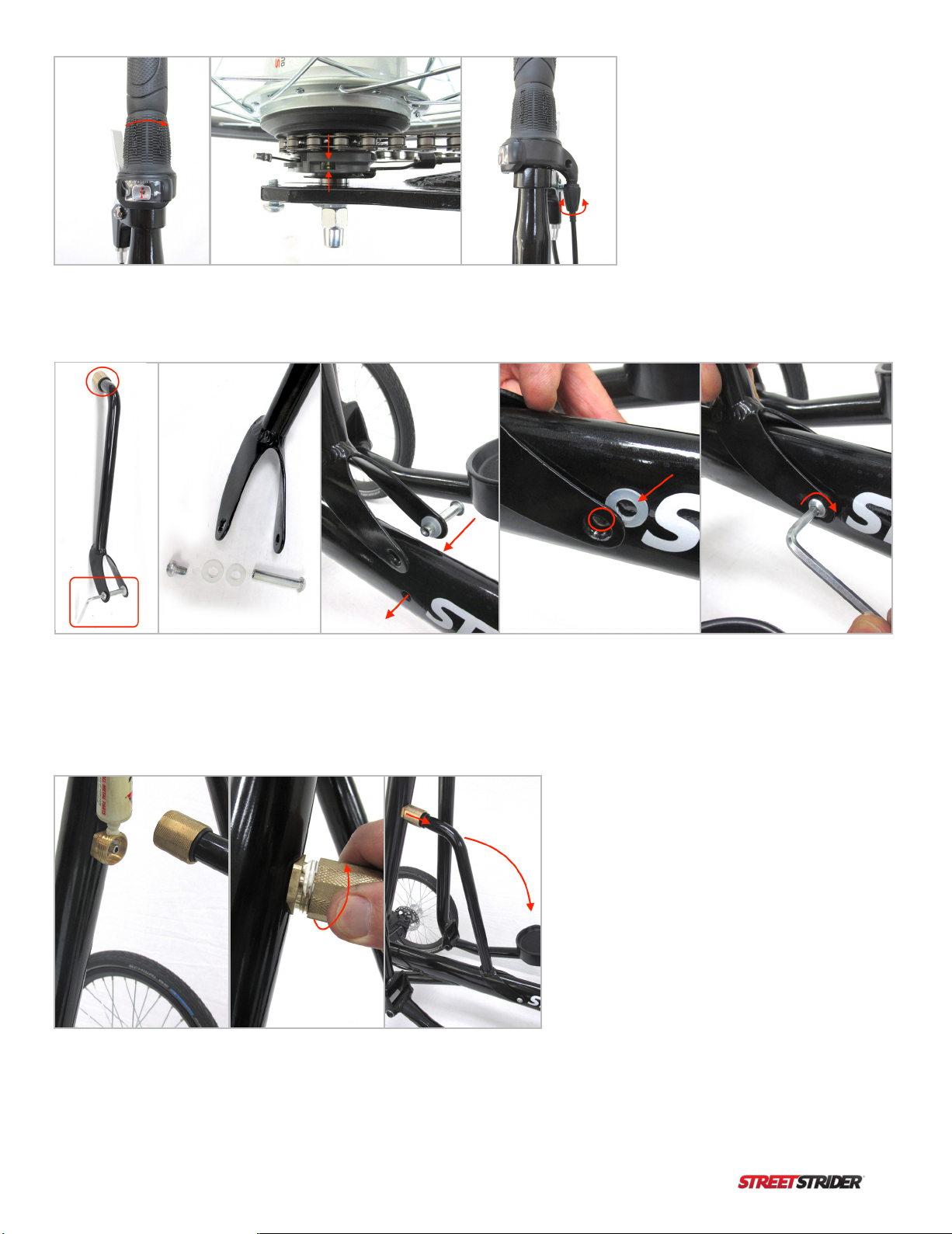

Frame Strut (see video)

3.7

Figure 3.6.4 To check gear alignment,

twist the shifter to gear 4 and make

sure the 2 yellow lines in the cassette

pulley window are in line. If the lines

are offset use the barrel adjuster nut at

the shifter to move the lines into the

correct position.

Figure 3.7.2 Add some grease to the threads of the

brass receiver attached to the rear side of the head

tube, press the brass collar over the receiver and

tighten. To fold the head tube down the brass collar

is disconnected from the receiver and the strut folded

backwards pivoting at the saddle screw.

Figure 3.7.1 Retrieve the frame strut, which has a brass threaded collar at the top and frame saddle at the bottom. Using the 5 mm hex

wrench, unscrew and separate the binding screw and the 2 nylon washers. Insert the longer female end of the screw through the hole at the

end of the right side of the saddle and add a nylon washer on the inner side of the saddle. Align the saddle and screw with the frame hole

and push the screw through the hole until it appears in the frame hole on the left side. Slide the second nylon washer between the saddle

and the frame and over the screw end. Insert the male screw and tighten the screw with the 5 mm hex wrench. the receiver and tighten.

16 Copyright © 2019 StreetStrider International, LLC

Front Wheel Alignment (see video)

3.8

Figure 3.8.1 The front wheels should be aligned/parallel so

they do not point in (toe in) or point out (toe out). Alignment

is important for performance so take the time to do it

correctly. Inate the tires, 80-85 psi, set the StreetStrider

upright, not leaning, on a level surface. Making the crossbar

parallel to a horizontal line behind the StreetStrider, such

as a shelf or window will ensure it is not leaning. Parallel

lines on the surface such as a table edge will help to see if

wheels are parallel. Measure the distance from the center

rib of one tire to the center rib of the other tire on both

the front or leading edge and the rear or trailing edge. The

distances should be near 26 inches and should be equal to

each other within 1/8” or 3 mm.

Figure 3.8.3 When the wheels are parallel to within 1/8” or 3 mm,

tighten the jam nuts against the rod ends. To tighten the jam nuts,

rst rotate both rod ends as far as possible in the direction that

the jam nuts will tighten, then use the 14 mm wrench to tighten

the jam nut against the rod end. Check to make sure that each

steering linkage rod is free to rotate as the StreetStrider is leaned

to each side.

Figure 3.8.2 If the distances are not equal to each other,

use the 14 mm open end wrench to loosen the jam

nuts that are tightened against the base of each rod

end. On each steering linkage, one rod end has right

hand threads and the other has left hand threads, so

make sure to turn the jam nuts in the correct direction

to loosen. Rotate the linkage rod one way or the other-

note how the tire angle changes - until the distance

between the tire center ribs in the front is equal to that

in the rear and the wheels are parallel while making

sure that the cross bar stays horizontal. Any adjustment

to the right linkage rod should be duplicated on the left

linkage rod to maintain symmetry.

Figure 3.8.4 To increase resistance to

leaning, the King Pin bolt (red line) can

be tightened with the 8 mm hex and 17

mm open end wrenches. To change the

lean angle degree, adjust the position of

the lean stop disc (circle) on the steering

knuckle with the 5 mm hex and 10 mm

open end wrenches. The left lean stop disc

regulates the right lean angle and the right

stop disc regulates the left lean angle.

When adjusting the lean angle make sure

the tire clears the pole by 1 inch, 25 mm.

IMPORTANT: Do not over tighten and strip the thin jam nut

17

Copyright © 2019 StreetStrider International, LLC

Advanced

Lean-to-Steer

Technology (see video)

3.9

To steer vehicles with 2 front wheels, the wheel hub connected to the steering knuckle turns or pivots on a mostly vertical axis/component

called the King Pin. The upper end of the King Pin axis can be angled backward and that angle is called the caster angle. At the angle

limits, a vertical King Pin would have a caster angle of 0° and a horizontal King Pin would have a caster angle of 90°. The caster angle

controls the way a wheel can steer. At 0° caster angle, the wheel pivots on a vertical axis to steer right or left and this type of steering is

called toe. At 90° caster angle, the wheel pivots on a horizontal axis and can only lean left or right and this is called camber. As the caster

angle is increased the front wheels will steer with less toe and more camber.

In most vehicles with a low center of gravity, such as automobiles and recumbent tricycles, the caster angle is typically about 3-6°,

which increases steering stability compared to 0° caster. Large camber lean is not necessary because the center of gravity is low and

the probability of tipping over in a turn at speed is low. However, when the center of gravity is higher, as when standing upright on a

StreetStrider, being able to lean into a turn at speed is necessary so the StreetStrider lean-to-steer system is designed to combine both toe

steering and camber.

The StreetStrider 8s is the rst model with a user-adjustable caster angle of the King Pin providing more stability for the novice at low

caster angles or more performance at speed for the professional at higher caster angles. At the end of the front beam the King Pin bolt

passes through the clevis bracket and steering knuckle. On the 8s the ends of the front beam have a 52 tooth male spline and the clevis

bracket ts onto the end of front beam with a 52 tooth female spline. Accordingly, each spline tooth rotation of the clevis bracket is

approximately a 7° change in caster angle. A low caster angle, 10 – 20° allows the wheels to mostly toe steer, which provides increased

stability at low speed. A higher caster angle, 30-50° allows much more camber, which increases leaning and performance at higher speeds

although the trade off is a bit less stability at low speed. The illustrated instructions below show how the StreetStrider 8s caster angle can

be adjusted to suit the desire and ability of the user.

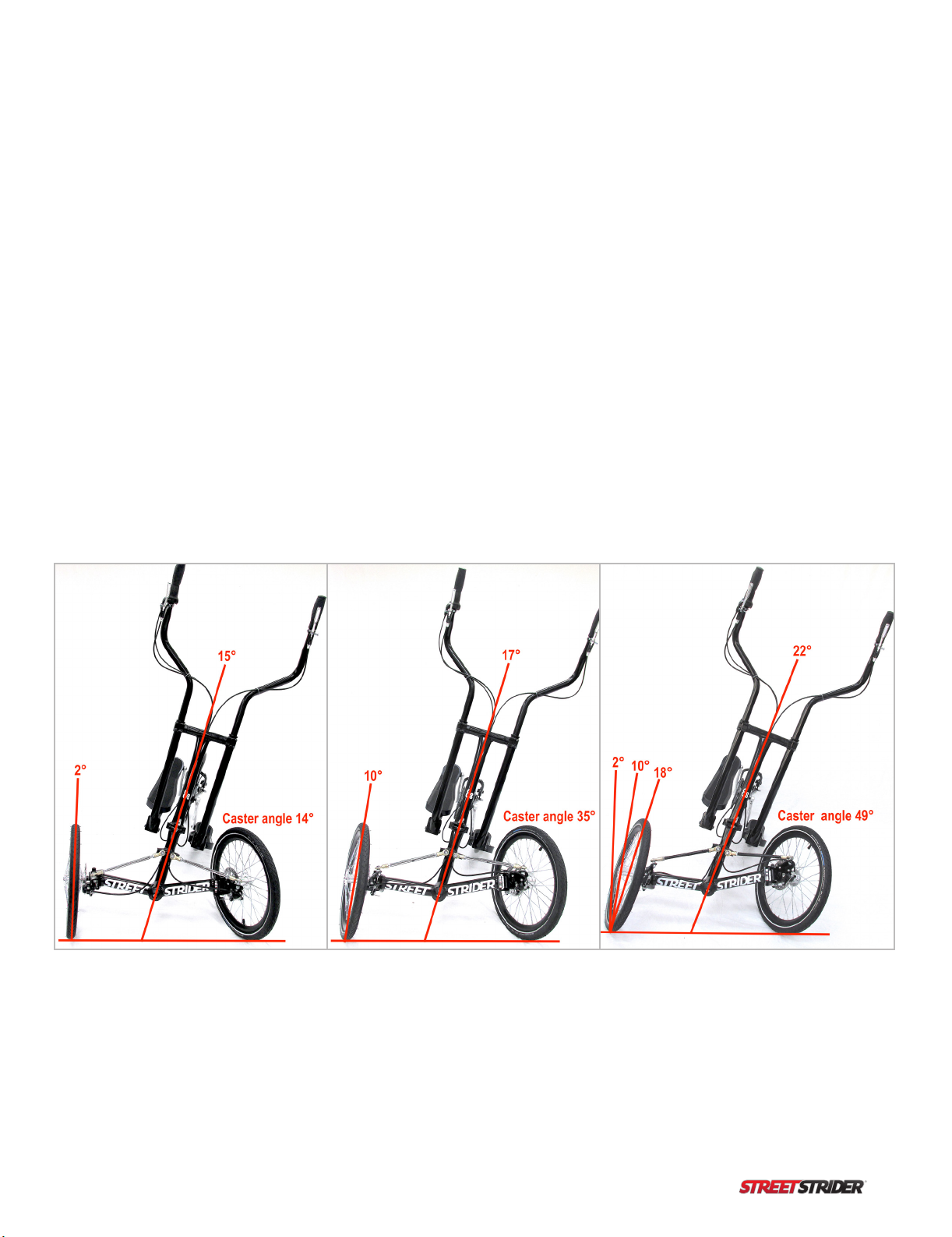

Caster Angle and Wheel Camber

Figure 3.9.1 By setting the caster angle at 14° the StreetStrider frame can lean about 15° but the outer front wheel will only camber about

2°. Most of the steering results form a change in toe angle. At 35° caster angle the frame leans about 17° and the outer wheel has more

camber to about 10°. At 49° caster angle the lean increases to 22° and the outer front wheel cambers to 18°. In a turn, the inner wheel toe

angle and camber lean is a bit more than the outer wheel.

18 Copyright © 2019 StreetStrider International, LLC

Figure 3.9.2 The caster angle of

the King Pin can be set at lower

or higher values.

Figure 3.9.6 Use the clevis

spanner wrench with the 8 mm

hex wrench as lever to unscrew

the lock ring.

Figure 3.9.3 Lift one side of the

front beam so the wheel is off

the table. Unscrew the King Pin

bolt with the 8 mm hex wrench

and the 17 wrench.

Figure 3.9.7 Slide the clevis

bracket female spline off the

male spline.

Figure 3.9.4 Slide the steering

knuckle out of the clevis bracket

and move the front wheel

assembly forward.

Figure 3.9.8 On the left side both the male and female

splines have a yellow dot at top center. Right side has red

dots. If those 2 dots are aligned, the clevis caster angle will

equal 0°. Each spline tooth is also a 7° angle change. The

small indentations in the female spline are every 2 teeth or

14°. Any adjustment to caster angle on one clevis must be

duplicated at the other clevis so they remain parallel.

Figure 3.9.5 Unscrew the center

bolt with the 8 mm hex wrench.

Note that the surface of the

clevis bracket on each end of

the front beam are parallel.

IMPORTANT: After caster angle adjustment the front wheels MUST be realigned

19

Copyright © 2019 StreetStrider International, LLC

Folding (see video)

3.10

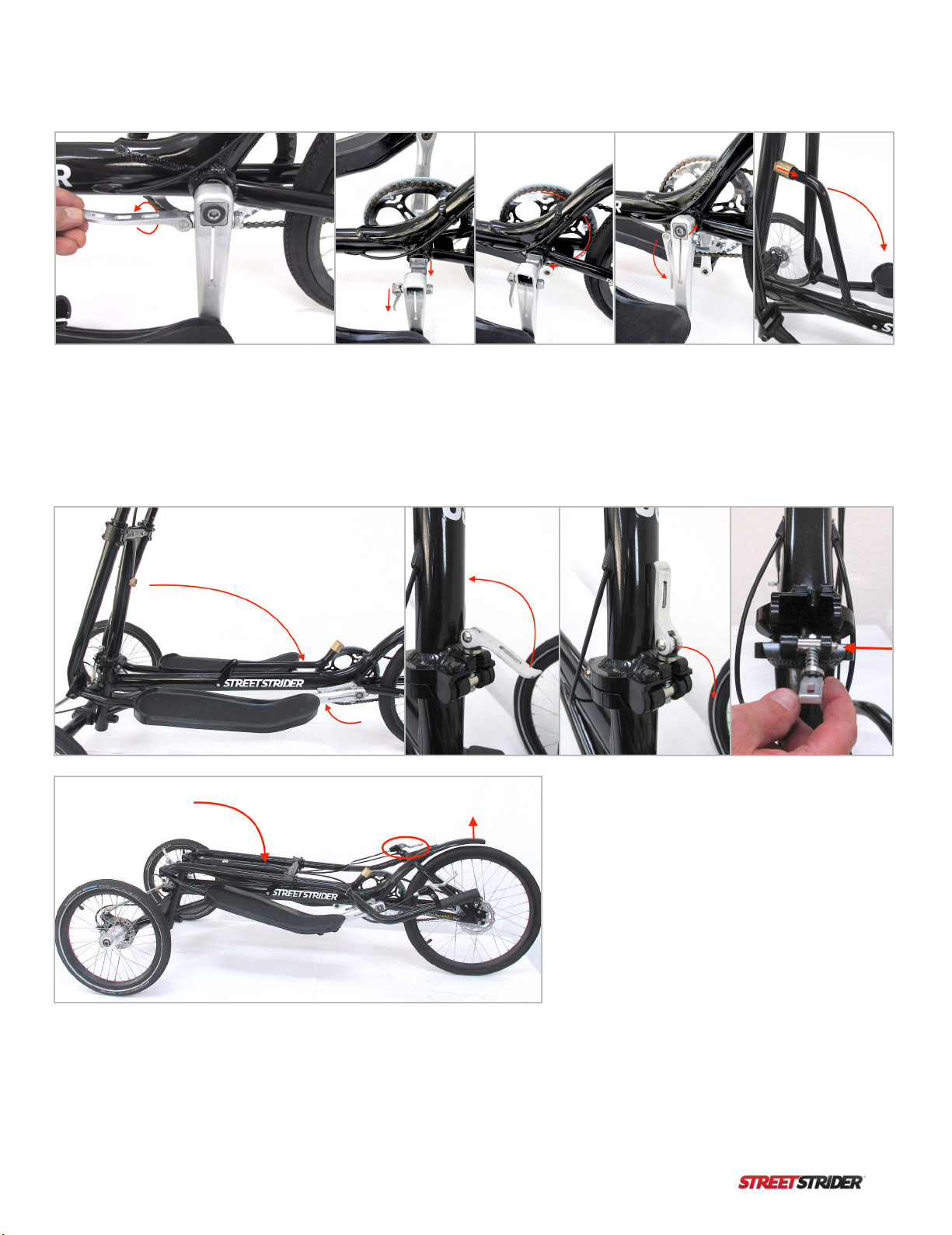

Figure 3.10.1 Stabilize the StreetStrider

by engaging the right parking brake pin

to lock the rear brake. From the left side

of the StreetStrider, rotate the left crank

arm to the 6 o’clock position, lift the quick

release lever, rotate the lever 180° and

lower it to the left side of the crank arm.

Figure 3.10.2 Pull the crank arm off the BB spindle just to where

the BB end piece can be rotated 180° so the right crank can also be

rotated to the 6 o’clock position. Insert the crank arm over the end

piece, lift the QR lever and rotate 180° then push the lever back down

the side of the crank arm.

Figure 3.10.3

Unscrew the brass

coupling at the top

of the strut and fold

it back ward to the

main frame.

Figure 3.10.4 Rotate the crank arms forward so the foot

platforms are horizontal. Lift the QR lever of the head

tube fold joint up and rotate the stem forward. With

one hand supporting the head tube, pull the QR stem

to the right side so the pin disengages from the hole

and lower the head tube down. With the rear brake

locked the strider can be lifted by the rear fender and

rolled or stood up against a wall for storage.

20 Copyright © 2019 StreetStrider International, LLC

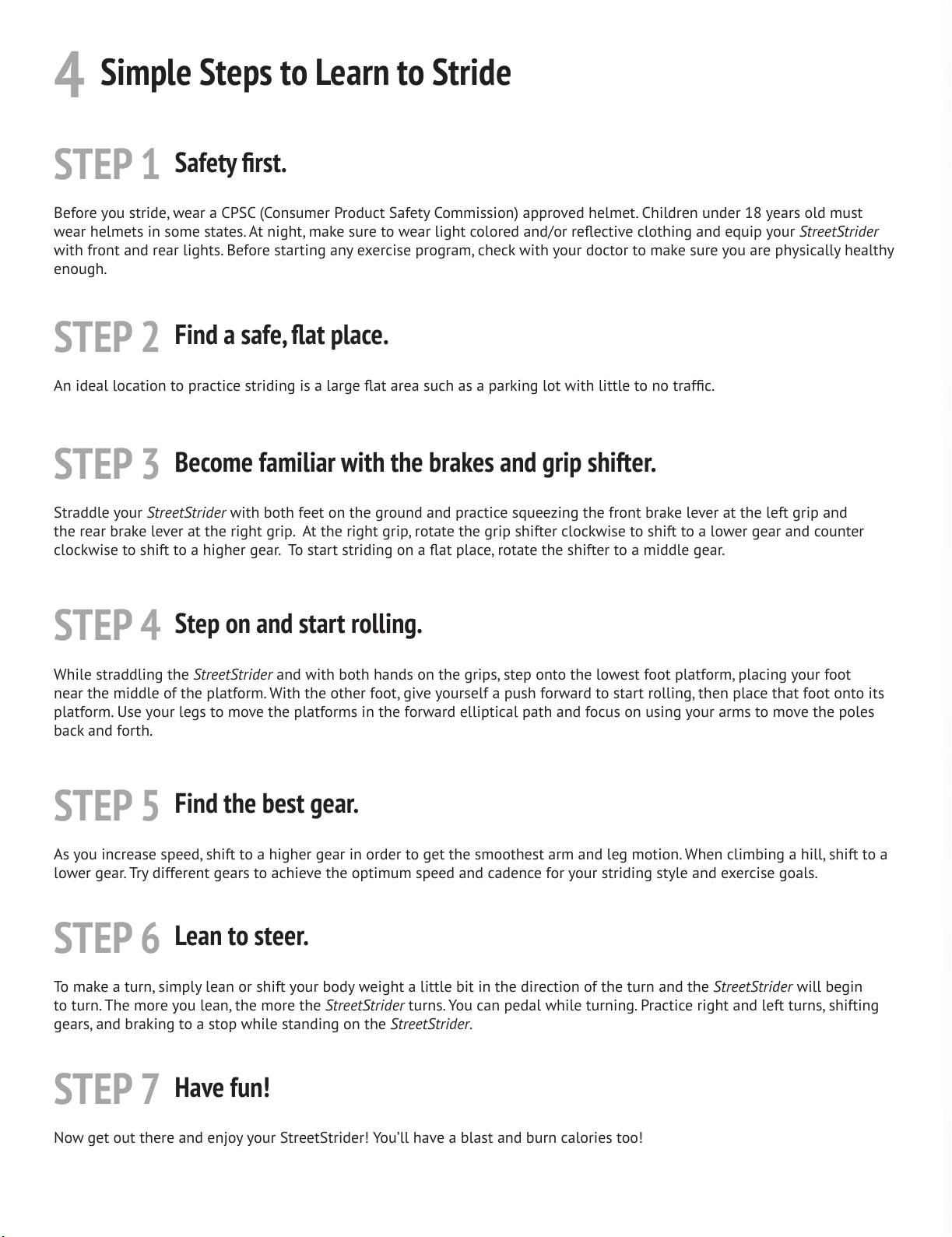

Safety rst.

Find a safe, at place.

Become familiar with the brakes and grip shifter.

Step on and start rolling.

Find the best gear.

Lean to steer.

Have fun!

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

Simple Steps to Learn to Stride

4

Before you stride, wear a CPSC (Consumer Product Safety Commission) approved helmet. Children under 18 years old must

wear helmets in some states. At night, make sure to wear light colored and/or reective clothing and equip your StreetStrider

with front and rear lights. Before starting any exercise program, check with your doctor to make sure you are physically healthy

enough.

An ideal location to practice striding is a large at area such as a parking lot with little to no trafc.

Straddle your StreetStrider with both feet on the ground and practice squeezing the front brake lever at the left grip and

the rear brake lever at the right grip. At the right grip, rotate the grip shifter clockwise to shift to a lower gear and counter

clockwise to shift to a higher gear. To start striding on a at place, rotate the shifter to a middle gear.

While straddling the StreetStrider and with both hands on the grips, step onto the lowest foot platform, placing your foot

near the middle of the platform. With the other foot, give yourself a push forward to start rolling, then place that foot onto its

platform. Use your legs to move the platforms in the forward elliptical path and focus on using your arms to move the poles

back and forth.

As you increase speed, shift to a higher gear in order to get the smoothest arm and leg motion. When climbing a hill, shift to a

lower gear. Try different gears to achieve the optimum speed and cadence for your striding style and exercise goals.

To make a turn, simply lean or shift your body weight a little bit in the direction of the turn and the StreetStrider will begin

to turn. The more you lean, the more the StreetStrider turns. You can pedal while turning. Practice right and left turns, shifting

gears, and braking to a stop while standing on the StreetStrider.

Now get out there and enjoy your StreetStrider! You’ll have a blast and burn calories too!

Table of contents

Other StreetStrider Elliptical Trainer manuals

Popular Elliptical Trainer manuals by other brands

Horizon Fitness

Horizon Fitness Elliptical LS 635E user guide

Christopeit Sport

Christopeit Sport 1721L Assembly and exercise instructions

JLL

JLL CT100 owner's manual

Core Health & Fitness

Core Health & Fitness Star Trac 4-CT Assembly manual

U.N.O

U.N.O MOTIVE FITNESS CTX 1000 manual

Core Health & Fitness

Core Health & Fitness Stairmaster 10G Install manual