Stromme MARI-CLEAN MS 501/30 User manual

Manual

www.stromme.com

stromme marine products

-

MS 501/30

440 V / 60 Hz or 400 V / 50 Hz

2Man Mari-Clean MS501-30 12-2015 Rev.01

Before start up.

High pressure pump water inlet.

•

BeforeconnectingtheWatersupplyhosetothepumpinletush

the pipeline to ensure that it is clean inside.

• Minimuminletwaterowis1,5timestheratedwatercapacity.

• Thewaterpressureatthepumpinletshallbe0,5to4bar.

NOTE !

Checkandcleantheinletlteronadailybase,changethelterwhen

needed.Ifthewaterqualityispoorchecktheltermorefrequently.This

is to prevent wear and damages to the pump.

Dimensions for low pressure water supply pipe / hose.

0 - 3 m 3 - 25 m 25 - 150 m

Ratedcapacity45l/min. ¾" 1½" 2"

Electrical connection.

•

Make sure all electrical extension cables used meets the

requirements(seetablebelow),toavoidhighamperage,burnt

contactors and/or other potentially hazardous situations.

Dimensions for electrical extension cables for MS 501/30.

Rated 36 kW recommend minimum.

0 - 50 m 50 - 150 m 150 - 200 m

25 mm² 35 mm² 50 mm²

Nozzle size to be used: 055.

Description Part No.

Drainnozzle055forpipeØ40toØ100mm,¼"femalethread. 3111-49380

HPnozzle¼"15°055. 3111-41055

HPnozzle¼"round055. 3111-45055

Roto nozzle 055 TN500. 3111-48055

GUIDELINES

3x440V/60Hzor3x400V/50Hz

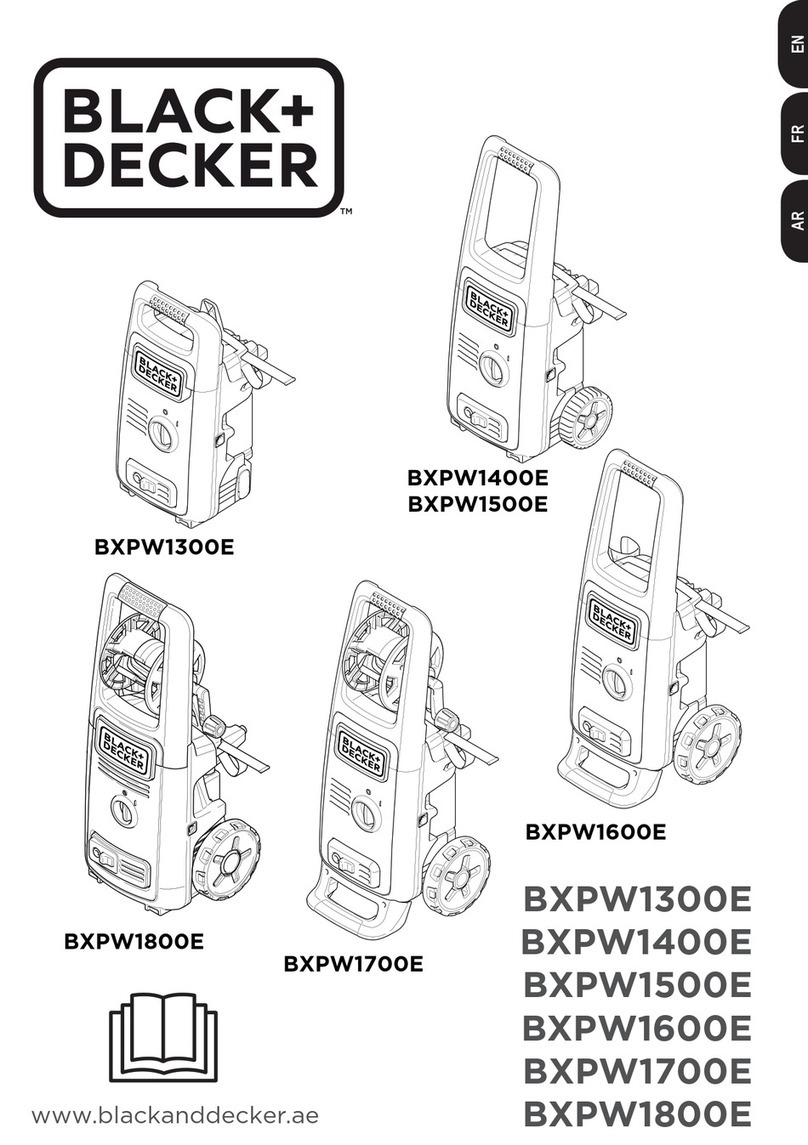

Mari-Clean MS 501/30

NOTE !Unroll the full length of cable when in use.

In case of pressure drop never adjust the unloader / pressure

regulatingvalve.Checkandchangenozzle,lter,watersupply

rstandiftheproblempersists-consultthemanual.

Man Mari-Clean MS501-30 12-2015 Rev.01

The acceptance of any tender from us includes the acceptance of the following warranty terms.

Thewarrantyperiodistwelve(12)monthsfromdeliverydate,unlessitisagreeddifferentlyin

writing.

Warranty will be granted only if:

-Originalorrecommendedspareparts,articlesofconsumptionandservicepartsareused.

- Service is done by trained technicians/personnel.

-Service and maintenanceintervalsare respectedandfollowed asrecommendedby themanufacturer.

- Serial number and running hours stated.

The manufacturer warrants the products to be free of defective material and workmanship.

The warranties concerning components manufactured by subcontractors, such as motors,

transmission,etc.arehandledfollowingtheconditionsgivenbythemanufacturerofthecomponent.

Thewarrantydoesnotcoverpartsthataresubjecttonormalwearandtearsuchashoses,

couplings,valves,sleevesandnozzles.

The responsibility of the manufacturer in its sole discretion is limited only to those defects which

occurwithincircumstancesveriesashavingdefectsinoriginalmaterialsorworkmanshipand

notify with a written report immediately of any defects after receipt of the machine and also

providedthatthemachinehasbeenusedinaccordancewiththeoperatinginstructions,andby

peoplewithknowledgeofinstallation,operationandmaintenance.

Manufacturer shall not be held liable from warranty responsibility if particular defect found arises

fromimproperuse,ignoringwarnings,incorrectpositioningorinstallationorsizingofpipesand

exiblehoses,insufcientfeedwaterowrates,pumpdevelopedcavitations,notfollowing

recommendedserviceandmaintenanceintervals,usednon-genuineandnotrecommended

spareparts,notapproveddesignchangesandunauthorizedremedyofdefectsbytheclientor

third parties.

Allwarrantyclaimsmustbeledinwritingwithinthirtydaysofthedefectbeingidentiedfrom

the date of receipt of the machine.

Afterreceiptofawrittenclaimanditisacceptedbythemanufacturer,themanufacturerwilldeliver,

ex-works,thecorrespondingpartsfreeofcharge.

Defective parts or components replaced under warranty must be placed at manufacturers disposal

and become his property. The manufacturer shall have the option of requiring the return of the

defective part/parts to establish the claim.

The claimant will be responsible for the transportation cost of both the defective and repaired

parts and also for the risk of damage during such transportation.

Themanufacturershallnotbeheldliableforanycompensationwhatsoever,foranydamageto

products,personalinjury,deathorforanydamagedmaterials,lossofworkinghoursandprots

that arise indirectly by a faulty machine throughout the process of replacing or repairing defective

components.

The manufacturer is not to be responsible for any defects occurring after the termination of the

warranty period.

Warranty terms

Man Mari-Clean MS501-30 12-2015 Rev.01

© Copyright STROMME

This publication or any part thereof may not be reproduced or transmitted

by any process or means without prior written permission of STROMME.

Please feel free to contact us about the content in this document.

Equipment type: ........................................................................................

..................................................................................................................

Unit serial number: ..................................................................................

Ship name: ..............................................................................................

Yard: ........................................................................................................

IMO number: ...........................................................................................

Date of commissioning: ...........................................................................

Other: ........................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

NOTE ! Please always state the and running hours

when

contactingus,fororderingsparepartsandinothercorrespondence.

Order your spare parts at spares@stromme.com

5

Man Mari-Clean MS501-30 12-2015 Rev.01

DECLarat IoN

www.stromme.com

www.stromme.com

No asbestos materials are utilized in any assembly or sub-assembly component of any

product listed below and spare parts for these products distributed by STROMME worldwide.

This is based upon information provided by suppliers of the raw materials used to manufacture

these products. As such, STROMME makes no independent representations or warranties,

expressed or implied, and assume no liability in connection with the use of this information.

Name of STROMME Authorized Signatory: Dipl.-Dipl.-Ing. Steffen Kruss

and its spares.

STROMME accepts responsibility only for products supplied directly by us. No responsibility is accepted for errors, which

may have arisen during sampling, resale or transportation by external parties.

No asbestos materials are utilized in any assembly or sub-assembly component of any

product listed below and spare parts for these products distributed by STROMME worldwide.

This is based upon information provided by suppliers of the raw materials used to manufacture

these products. As such, STROMME makes no independent representations or warranties,

expressed or implied, and assume no liability in connection with the use of this information.

Name of STROMME Authorized Signatory: Dipl.-Dipl.-Ing. Steffen Kruss

Signature of Authorizwd Signatory:

Position/Title: Product Manager

Mari-Air, Mari-Clean and Mari-Dry

Date: 13 December 2015

Place (where signed): Friesenweg 1, 22763 Hamburg, Germany

T: +49 40 30 97 880

Germany@stromme.com

Screw Air Compressors and

Breathing Air Compressors

High Pressure Cleaner

Air Drier

STROMME accepts responsibility only for products supplied directly by us. No responsibility is accepted for errors, which

may have arisen during sampling, resale or transportation by external parties.

This includes, but is not necessarily limited to:

Mari-Air

Mari-Clean

Mari-Dry

DECLARATION AND CONFIRMATION

OF ASBESTOS FREE PRODUCTS

6

CoNt ENt

Man Mari-Clean MS501-30 12-2015 Rev.01

GUIDELINES 2

Mari-CleanMS501/30 3x440V/60Hzor3x400V/50Hz 2

Before start up 2

High pressure pump water inlet 2

Dimensions for low pressure water supply pipe / hose 2

Electrical connection 2

Dimensions for electrical extension cables 2

Nozzle size to be used: 055 2

Warra Nty t Er MS 3

FILL IN EqUIPMENt INF or Mat IoN 4

DECLarat IoN 5

CoNt ENt 6

GENEra L INFor Mat IoN 9

t ransportation 9

Storage 9

Waste 10

Design 10

10

SaFEty 11

Safety conscious work 11

Before work 13

Working area 13

During operation 13

SySt EM DESCr IPt IoN 14

Waterlines 14

Feedwaterline 14

Precautionsagainstfreezing 14

Filtering of feeding water 15

Filter 15

7

CoNt ENt

Man Mari-Clean MS501-30 12-2015 Rev.01

oPErat IoN 16

15°forstrippingandthoughcleaning 16

25°forgeneralcleaning 16

40°forlightcleaning 16

Before start up 17

Water inlet 17

Dimensions for low pressure water supply pipe / hose 17

Electricalconnection 18

Dimensionsforelectricalextensioncables 18

Pump 18

Stopandstartpowerswitch. 19

Start 19

Operation 19

Stop 19

Emergencystop 19

MaINt ENaNCE 21

Filter 22

Inletlter 22

t ro UbLE SHoot ING 23

Pro DUCt INF or Mat IoN 26

Main components MS 501/30 3 x 400 V / 50 Hz 29

FLoW DIaGra M 30

GENEra L DIMENSIoNS 31

8

CoNt ENt

Man Mari-Clean MS501-30 12-2015 Rev.01

SPar E Part S 32

Electrical motor 36 kW 35

aCCESSor IES 45

HPhose½",600bar 45

Quickcouplings 45

Lancesandsprayguns 45

Nozzles 45

SEr VICE LoG 52

MaINt ENaNCE LoG 53

PEr SoNaL Prot ECt IVE EqUIPMENt 54

ELECtr ICaL Dra WINGS 55

9

Man Mari-Clean MS501-30 12-2015 Rev.01

GENEraL INF or Mat IoN

transportation.

The equipment must be handled with care and according to

labels and markings on the package during transportation and

storage.

When lifting the equipment always use suitable and safe lifting

devices.

Whentheequipmentshallbereplaced,alwaysconnectlifting

devises to all four lifting eyes.

Beforelifting,ensurethattheequipmentisnotconnectedto

electricity or other units etc.

Storage.

Theequipmentmustbestoreddry,dustfree,protectedfrom

shock,vibrations,temperaturebelow0°Corabove50°Cand

avoid humidity more than 70%.

Whenstored,theequipmentshallbeinitspackingorrepackit

to keep it from dust and damages.

Before the equipment is taken into use after a long period of

storage,theequipmentmustbecheckedbeforeinstallation.Filter

and other items of disposable consumption should be replaced

if needed.

This manual contains information and instructions required to

install,operateandmaintaintheequipmentinasafeandeffective

way. Always follow the instructions given in this manual.

Only use the equipment as stated in the instructions.

Not following the instructions given in this manual can result in

equipmentnotfunctioningproperlyand/ordamagetoperson,

equipment and/or environment.

Ensure that all personnel working with the equipment are

competent and have sufcient knowledge of installation,

operation and maintenance.

The manual must be accessible to all persons who come into

contact with the equipment.

This equipment was developed, manufactured, tested and

documented considering all current safety standards.

CAUTION

Always comply with general and local rules and regulations

when moving and lifting equipment.

Noncompliance could result in injuries to person and

damage to equipment or the environment.

10 Man Mari-Clean MS501-30 12-2015 Rev.01

GENEraL INF or Mat IoN

Waste.

Any waste from the machine, such as used lters, grease,

lubricating oil etc. must be disposed according to the local

regulations and through an authorized disposal company.

Design.

The Mari-Clean high pressure cleaners are designed and built

to obtain the highest quality and to withstand the rough and

corrosive environment at sea.

The Mari-Clean high pressure cleaners are the most labour

saving and effective tool for demanding cleaning tasks on board.

TheMari-Cleanhighpressurecleanersoffermaximumexibility

andefciencywhenitcomestocleaningofdisparatesurfaces

found aboard a ship.

The Mari-Clean high pressure cleaners are designed to be easy

to handle and maintain.

The operating company must ensure that the personnel who is

working on or with the equipment have all the appropriate

qualicationsforthetask.

The personnel must fully understand and follow the contents of

this manual.

The equipment is manufactured in Denmark by Clena High

Pressure Systems AS.

The equipment is distributed and sold by STROMME. For further

information please contact stromme@stromme.com or visit our

web site www.stromme.com

Allkindsofconversionormodicationoftheequipmentareto

be made by the manufacturer.

The uses of addition parts that are not approved by the

manufacturer or their representatives are not allowed.

The manufacturer or their representatives cannot be held

responsible for any resultant damages.

11

Man Mari-Clean MS501-30 12-2015 Rev.01

SaFEty

CAUTION Thistypeofsafetyinstructionindicatesasituationwhich,

ifnotavoided,couldresultininjuriestopersonand/or

damage to equipment and/or environment.

Thistypeofsafetyinstructionindicatesasituationwhich,

ifnotavoided,couldresultinseriousinjuriestoperson

and/or damage to equipment and/or environment.

NOTE !

This type of safety instruction is generally connected to

certain activities or conditions.

It is important to follow the instruction.

If the recommendation is not followed, it can result in

damage to equipment and/or environment.

WARNING

DANGER

Safety conscious work.

•

Alwaysfollowrulesandinstructionsgiveninthismanual,bythe

operator and/or by law.

• Always follow the shut down procedures described before any

kind of work are done on the equipment.

•

Always follow the start-up procedures when the equipment is

to be taken into use or shall be restarted after standstill.

12 Man Mari-Clean MS501-30 12-2015 Rev.01

SaFEty

Damage and accidents are often caused by postponed or badly

accomplished maintenance or repair. The following basic rules

and recommendations shall be followed at all times.

•

Followthehandling,maintenanceandotherinformationin

this manual.

•

Checkandreplace(ifnecessary)essentialparts,suchas

hoses and safety devices.

•

Only use proper hoses and accessories that are correctly

sized for the unit's maximum operating pressure.

•

Maintenance and repairs shall be done by qualied

personnel and only with the use of original spare parts.

•

Never leave the high pressure cleaner unattended when it

is working.

•

Before doing any maintenance or repair on the high pressure

cleaner,themotormustbeturnedoff.Waituntiltheunithas

cooleddown,thenreleasethepressure.

If the safety precautions and operating instructions are not

followed properly, it could result in serious injuries to

person and/or damage to equipment and/or environment.

WARNING

•

The high pressure cleaner is equipped with a safety valve

that shall be checked regularly to ensure proper function.

•

The high pressure pipes and hoses must be checked

regularly and never put in use if damaged or worn.

•

High pressure system components, particularly if the

machineisusedoutside,mustbeprotectedadequately

againstrain,frostandheat.

•

The electric parts of the system must be protected

adequately from water spray and must in all aspects comply

with the norms in force.

•

Highpressurepipes,hosesandaccessoriesmustbesized

correctly for the systems' maximum pressure.

•

The full length of these high pressure pipes must be well

fastenedtoasturdystructure,thisistoavoidseriousinjury

if accidentally the connections break when pressurized.

• Safety guards for moving parts must not be removed when

the equipment is in use.

13

Man Mari-Clean MS501-30 12-2015 Rev.01

SaFEty

Standard personal protective equipment does not give a

person enough protection against injuries if hit by the

water jet.

WARNING

Accidents and damage are often caused by neglecting signs on

the machine and/or safety information in this manual.

Before work.

High pressure pipes and hoses must be checked before work.

They must not show any apparent signs of abrasion and all

ttingsmustbeinperfectshape.Anydamagemustbecorrected

before the equipment is taken into work.

Working area.

The working area of a high pressure system must be clearly

bounded with the warning sign. Access to the working area that

is within the water jet’s range must be absolutely forbidden.

During operation.

• The water jet must always be directed towards the working

areaonly,beitfortestingorinspections.

•

Theoperatormustalwaysplacehisownsafety,andother

workers / persons' safety before any other interest.

•

The operator's actions must always be governed by good

sense and responsibility.

• Ifanykindofproblemarisesduringoperation,theoperator

must immediately release the trigger on the gun to stop the

high pressure spraying water and stop the high pressure

cleaner.

• The operator must pay attention to how debris is moved by

the water jet.

•

Personnel that needs to gain access to the working area

must wait until the operator gives permission to enter the

area.

•

Personnel authorized to gain access to this area must be

previously trained and informed about the risks that may

arise from failures or malfunctions of the high pressure unit.

• The operators and coworkers must always wear a suitable

helmetwithprotectivevisor,protectiveclothingandboots

that give a good grip on slippery / wet surfaces.

More information about personal protective equipment can be

found in this manual (see the content list).

14 Man Mari-Clean MS501-30 12-2015 Rev.01

SySt EM DESCr IPt IoN

It is important to avoid any obstruction that can hinder the feed

waterowthatcausedpressuredropalongthelinethiscan

cause cavitations that will damage the pump.

Toavoidvibrationandnoisefromthepumps,motors,pipesand

other parts of the system we recommend.

•

For stationary equipment: installation of appropriately sized

pulsation dampener.

•

The pipes connected to the system must have exible

sections at the connection point.

This is to avoid transferring vibrations from one part of the system

to another.

Feed water line.

•

We recommend installing a low pressure gauge for checking

the feed water pressure close to the water inlet.

Water lines.

Precautions against freezing.

If the pump is used in areas and/or during periods of the

yearwherethereisanyriskoftemperaturesbelowfreezing,

thepumpandxedpipingshallbelledwithanti-corrosion

and anti-freezing solution.

NOTE !

To ensure safety and correct operation it is of utmost

importance to comply with the above instructions.

WARNING

15

Man Mari-Clean MS501-30 12-2015 Rev.01

SySt EM DESCr IPt IoN

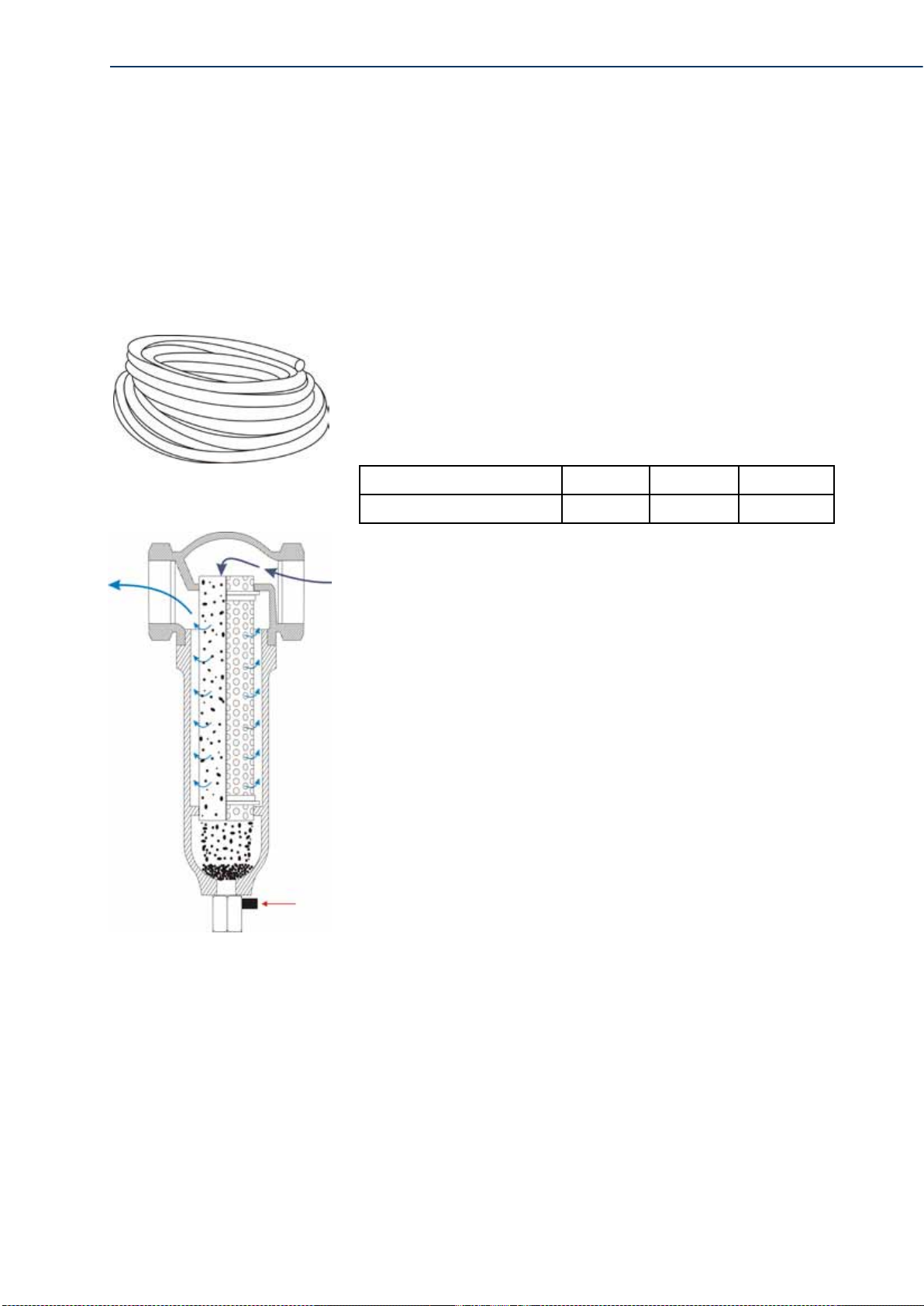

Filtering of feeding water.

Filter.

Thehighpressurecleanerisprotectedbya100µmlteronthe

feedingwaterline(describedonpage42).

Theunlteredwaterentersfromtherightside.Thewaterpasses

throughthelterunitandexitsoutthroughtheleftside.

Particlesinthewaterthatislteredoutaccumulatesinthelter.

See also the Maintenance chapter.

To maintain and ensure the high pressure cleaner operation

andtoavoiddamagetothehighpressurepump,check

andcleanthelterregularlyandreplaceitwhennecessary.

See also Maintenance.

NOTE !

16 Man Mari-Clean MS501-30 12-2015 Rev.01

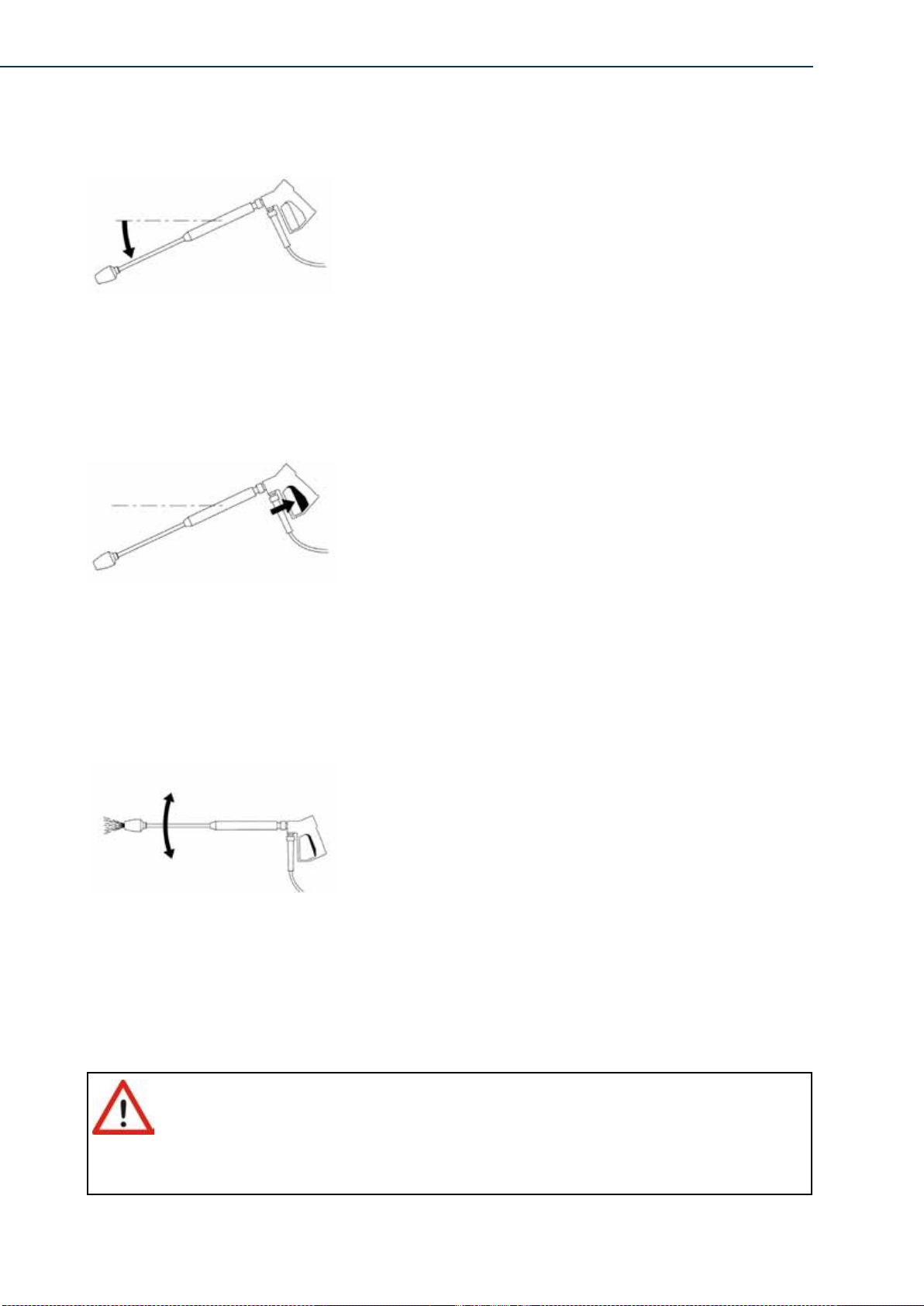

oPErat IoN

The impact of the high pressure cleaning is related to the water

pressure,thechoiceofthenozzleandthedistancebetween

nozzle tip to the cleaning surface. A nozzle with wider spread

angle gives a milder impact on the surface than a nozzle with

anarrowerangle,seebelow.

Therearenoxedrulesonthecombinationofwaterpressure,

spread angle and cleaning task. The guidelines below shall be

taken as guidance.

15°forstrippingandthoughcleaning.

•

Removingpaint,greaseand/ordirtfromwood,

stone or metal.

•

Removing marine growth from boats and other

marine equipment.

•

Removing rust from steel and oxidation from

aluminium.

• Removing heavy mildew stains.

25°forgeneralcleaning.

•

Cleaning roofs, gutters and other surfaces

fromdirt,mud,sootandgrime.

•

Removing algae and bacteria build-up from

pools and basins.

•

Removing light mildew stains on buildings etc.

• Rinsing of surfaces before painting.

40°forlightcleaning.

•

General light cleaning and rinsing of cars,

boats,patios,poolsandbasinsandsimilar.

17

Man Mari-Clean MS501-30 12-2015 Rev.01

oPErat IoN

Before start up.

NOTE !

The procedures described above shall be accomplished

before every start up.

It is especially important to do the checks carefully if the

equipment has not run for sometime and after any physical

disconnection of the water supply.

Water inlet.

Beforeconnectingthewatersupplyhosetothepumpinlet,ush

the hose to ensure that it is clean inside.

Dimensions for low pressure water supply pipe / hose.

0 - 3 m 3 - 25 m 25 - 150 m

Ratedcapacity45l/min. 1" 1½" 2"

Check the water supply. It shall be as follows:

•

All valves between the pump and the feeding sources are

completely open.

• Allttingsandconnectionsmustbeproperlytightenedand

no leakage anywhere.

•

Thefeedlineisconnectedanduptopressure,thepumps

must never run dry.

• Allltersinthesuctionlinemustbeclean.

• Clean/ushtheltersbylettingwaterrunthroughfor10sec

until the water is clean.

•

Checkandclean/ushtheinletlteronadailybase,change

thelterwhenneeded.

• Ifthewaterqualityispoor,checktheltermorefrequently

to avoid damage to the high pressure pump.

NOTE !

Minimum inlet water flow is 1.5 times the rated water capacity.

Maximuminletwatertemperature 30°C/86°F

Maximuminletwaterpressure 4bar

Minimum inlet water pressure 0.5 bar

18 Man Mari-Clean MS501-30 12-2015 Rev.01

oPErat IoN

Electrical connection.

Toavoidhighamperage,burntcontactorsand/orotherpotential

hazardoussituations,makesureallelectricalextensioncables

used,meettherequirements(seetablebelow).

NOTE !

Attherststart-uporafteralongperiodofnotusingthe

machine,waterleakmayoccurattheplungerseals,this

may happen if during the standstill period the seals got

hardened.

Allow the machine to run and let the hardened seal be

relined again during operation and check again for any

leakages after one or two hours.

Dimensions for electrical extension cables.

0 - 50 m 50 - 150 m 150 - 200 m

25 mm² 35 mm² 50 mm²

Oil drain plug

Oil level

Oil sight glass

Pump.

Check the oil level of the pump (oil dipstick or sight glass).

Using the oil dipstick to check the oil level is more accurate.

Theoillevelmustbebetweenthemarkingsonthedipstick,or

not drop below the red dot on the sight glass. Top up or drain off

if needed.

UseonlySAE15/40gearoil.

NOTE !Never use hydraulic oil for the pump.

19

Man Mari-Clean MS501-30 12-2015 Rev.01

oPErat IoN

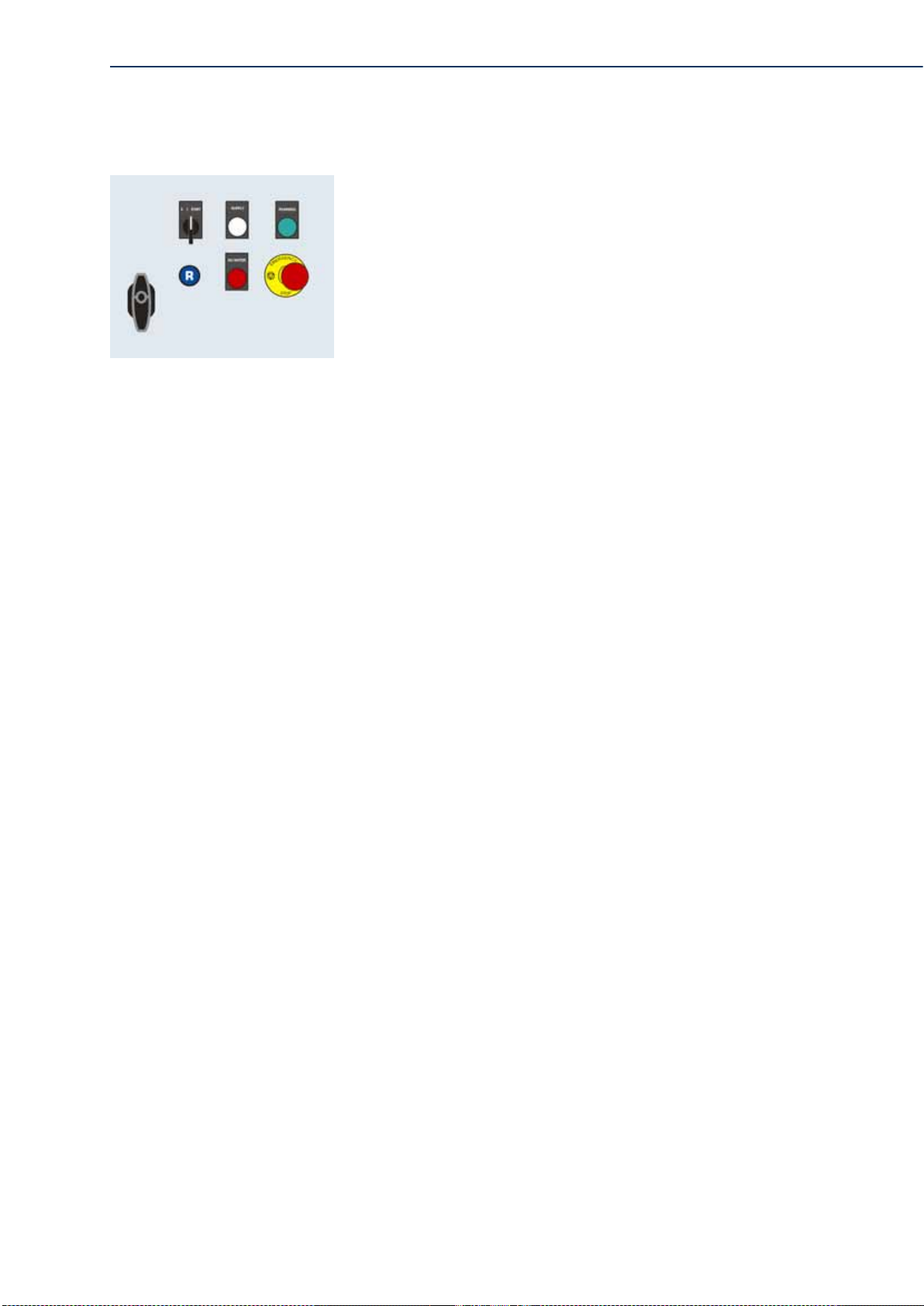

Stop and start power switch.

Start.

•

To start always point the spray gun nozzle downwards

before pulling the trigger.

• Takeatightgriponthespraygun,pullthetriggerandstart

working.

•

Assoonasthesprayguntriggerisreleasedthewaterow

stopped and the pump will stop operating after the maximum

cut-off set pressure is reached.

• If the high pressure cleaner will be idle for a period of time

we recommend turning the stop/start switch to 0

•

Release the spray gun trigger the machine will stop after the

maximum cut-off set pressure is reached.

• Turn the high pressure cleaner stop/start switch to 0.

• Start the unit by turning on the feed water supply.

•

Pullthesprayguntriggertoletthewaterowthroughthe

high pressure hose and the spray gun before connecting

the lance and nozzle to the spray gun.

• Turn on the high pressure cleaner stop/start switch to 1.

•

Release the emergency switch if needed by turning its

clockwise.

Operation.

Stop.

• Press down the red button.

Emergency stop.

• 0-1-START - High pressure cleaner stop/start switch.

•

POWER ON - White lamp lit when there is power to the

cabinet/unit,poweroffwhentheemergencystopswitchis

activated.

• RUNNING - Green lamp lit when motor is running.

•

R(Reset)-Toresetthethermalrelay,checkfaultbefore

re-starting machine.

•

NOWATER-Checkinletwatercapacityforsufcientsupply

before re-starting machine.

• EMERGENCY STOP.

20 Man Mari-Clean MS501-30 12-2015 Rev.01

oPErat IoN

To start always point the Roto nozzle downwards before

pulling the trigger.

Takeatightgriponthespraygun,pullthetriggerandstart

working.

When started it can be move in all positions.

To ensure safety and prevent accident never point a high

pressure spray gun towards people or any other living

creatures since this will result in serious injuries.

WARNING

Table of contents

Popular Pressure Washer manuals by other brands

Power Stroke

Power Stroke PS141912 Operator's manual

Good Way

Good Way HPW-1500G Operating and maintenance instructions

blueclean

blueclean 5640 Original instructions

Power Stroke

Power Stroke PS80979 quick start guide

BE Power Equipment

BE Power Equipment HW152EMD user manual

Excell

Excell VR2300 Operation manual