Strong Flow AG Series Manual

OPERATING AND MAINTENANCE

INSTRUCTIONS

28.9.2018

StrongFlow Oy

Domicile: Kaarina

Ahokylänkatu 3

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

StrongFlow Oy

Ahokylänkatu 3

20780 Kaarina

Y-Tunnus 2024125-8

www.strongflow.fi

+358 20 730 1820

AG-250/330

Water softeners

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 2/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

1. GENERAL INFORMATION........................................................................................................ 3

2. INSTALLATION ........................................................................................................................ 4

2.1 Location selection.................................................................................................. 4

2.2 Filling resin to pressure vessel............................................................................... 5

2.3 Water line connections.......................................................................................... 5

2.4 Brine tank and tube connection ............................................................................ 6

3GENERAL CONTROLLER INSTRUCTION .................................................................................... 7

3.1 Controller display................................................................................................... 7

3.2 Controller buttons ................................................................................................. 8

4. PROGRAMMING CONTROLLER............................................................................................... 9

4.1 Initial power-up/ Re-initialization (reset) .............................................................. 9

4.2 Default settings.................................................................................................... 10

4.3 Additional settings (P9-P19) ................................................................................ 14

4.4 Cycle time programming...................................................................................... 15

4.4.1 Regeneration modes.................................................................................... 15

4.4.2 Manual regeneration ................................................................................... 15

5. START-UP OF THE FILTER AND VALVE................................................................................... 16

6. MAINTENANCE AND TROUBLESHOOTING ........................................................................... 17

6.1 Cleaning the automatic valve filter screen/net ................................................... 17

6.2 Changing the resin ............................................................................................... 17

6.3 Possible problems and causes ............................................................................. 18

7. ATTACHMENTS..................................................................................................................... 19

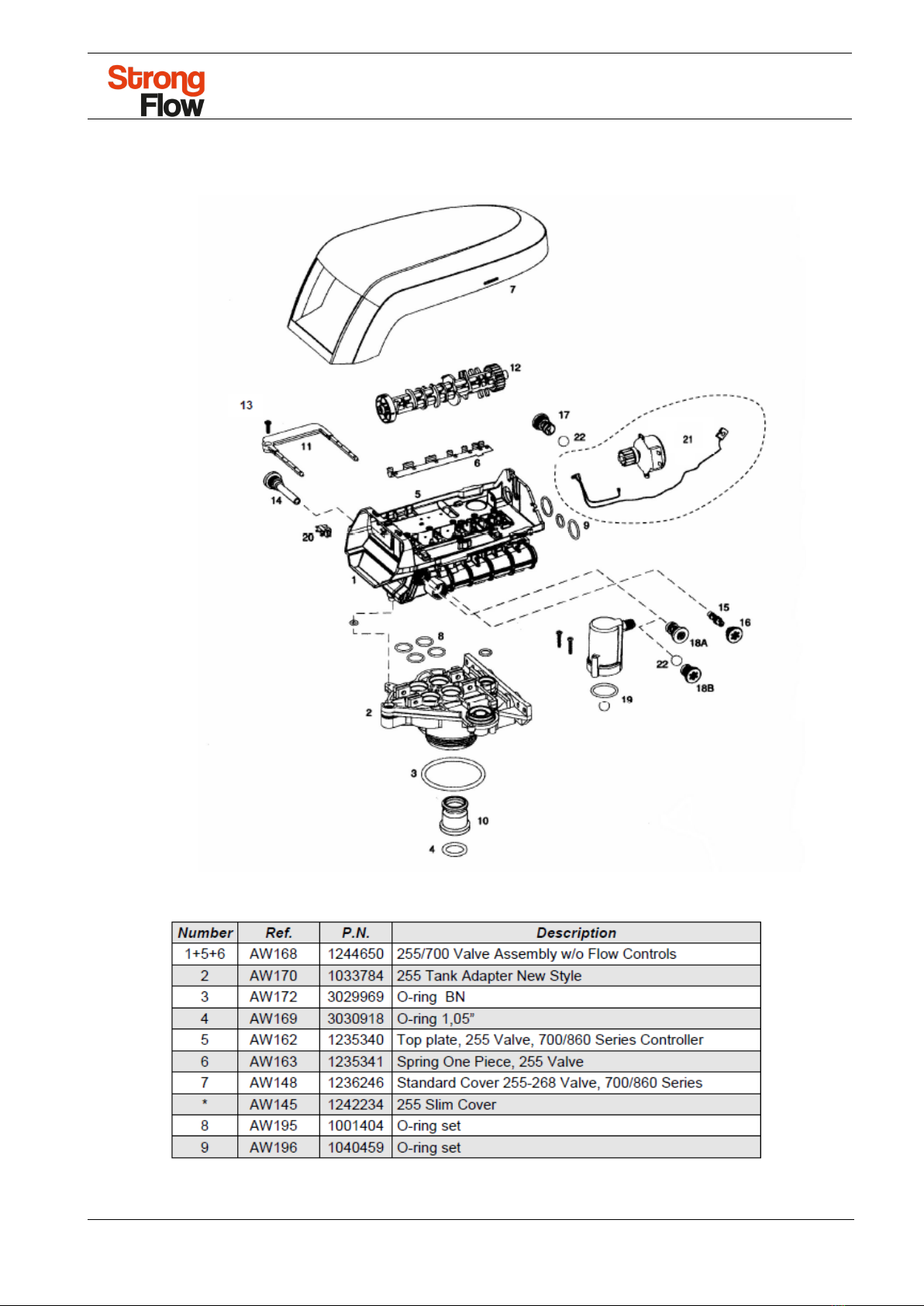

Attachment 1: Automatic valve configuration .......................................................... 19

Attachment 2: Exploded view and spare part list...................................................... 19

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 3/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

1. GENERAL INFORMATION

AG-CAB filter can be used for water softening and filtration of iron and manganese. Filters have fully

automatic operation principle and only regular refill of salt is needed. More detailed technical

information can be found from table 1.

Table 1. Technical information

The content of the delivery:

•Pressure vessel, diffusor with tube, automatic valve, drain tube, resin

•Brine tank, salt suction pipe, salt suction hose, regeneration salt

•Manual

250 330

Connections (filter)

DN

Flow rate l/min 32,7 57

Capacity

m3/°dH 120 200

Resin l 38 65

Rinse water l/rinse 350 470

Pressure index

bar

Working pressure, min/max.

bar

Water temperature, min/max.

°C

Ambient temperature, min/max.

°C

Electrical connections

V/Hz

Need for electric power

W

Height / diameter (filter)

mm 257 x 1385 334 x 1370

Widht / depth / height (brine tank)

mm

Brine tank volume

l85 85

AG

n. 4,8

380 x 380 x 790

20 / 10 (drain line)

10

2 / 6

2 / 38

5 / 40

230 / 50

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 4/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

2. INSTALLATION

2.1 Location selection

1. Install the filter to even surface and dry place that is equipped with large enough

drainage to handle the backwash water. Please note that the filter creates 700-

1300 litres of backwash water each time it regenerates.

2. For electrical connections there must be grounded power outlet 230V / 50Hz. Use

only the power AC adapter that is supplied.

3. Make sure there is enough room around the filter for possible maintenance.

4. Do not use filter or piping at temperatures above 40 °C. Filter should be protected

from freezing.

5. Please note that it’s on customers duty to install non-return valve to line of filtrated

water.

6. Filter may not be exposed to direct spray of water.

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 5/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

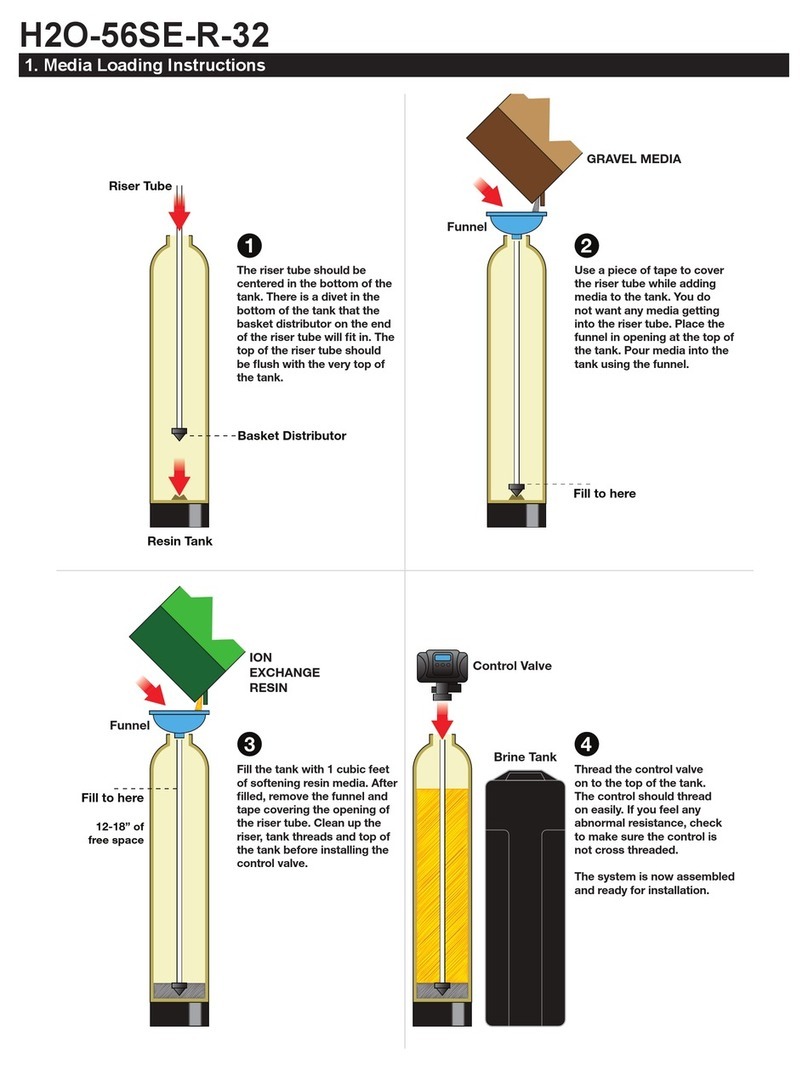

2.2 Filling resin to pressure vessel

Pressure vessel is filled with resin so that the threaded automatic valve is turned open. Diffusor tube

is detached from valve and left in its place inside the vessel. Upper end of diffusor tube is sealed

with suitable cap or tape and after that resin can be poured into the vessel. Seal from diffusor tube

is removed and automatic valve is turned in place. All pipe connections need to be checked before

filter is started.

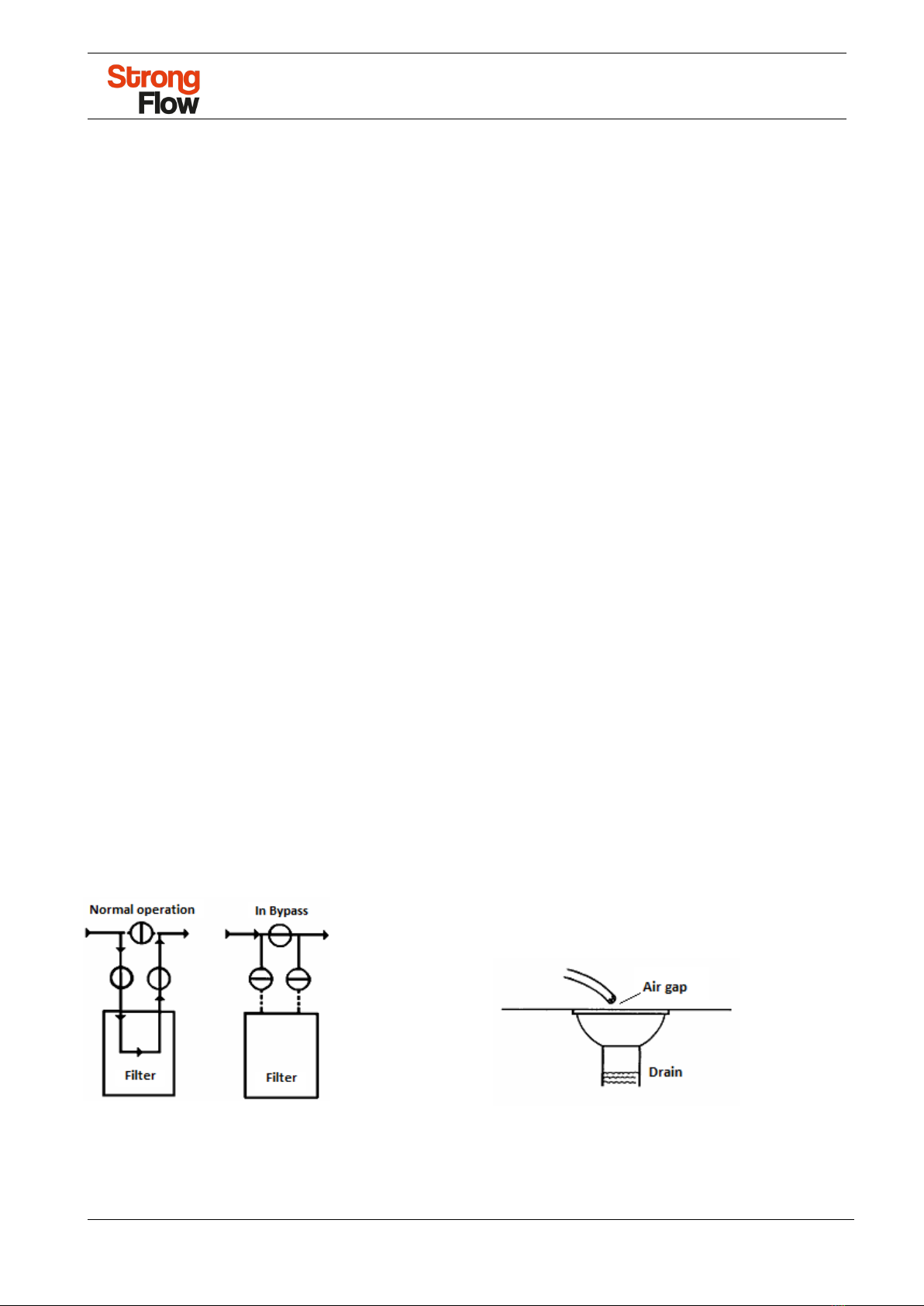

2.3 Water line connections

Filters inlet and outlet fittings are ¾” internal thread. Outlet fitting is marked with arrow. Drain line

fitting for 12,7 mm tube is pre-installed to valves drain line connection by supplier.

Its recommended that bypass line is installed between inlet and outlet lines to allow detaching of

filter for maintenance without interruptions in water supply (picture 1.).

Attach drain tube to fitting and run to drain so that siphon is avoided (picture 2). In ideal installation

the drain tube sets all the way to drain. If this is not possible, drain tube can be lifted to maximum

height of 1,8 meters if the tube length doesn’t exceed 4,6 meters. In this case the inlet water

pressure to filter needs to be over 2,8 bars.

Picture 1. Valve Bypass System Picture 2. Drain line connection

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 6/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

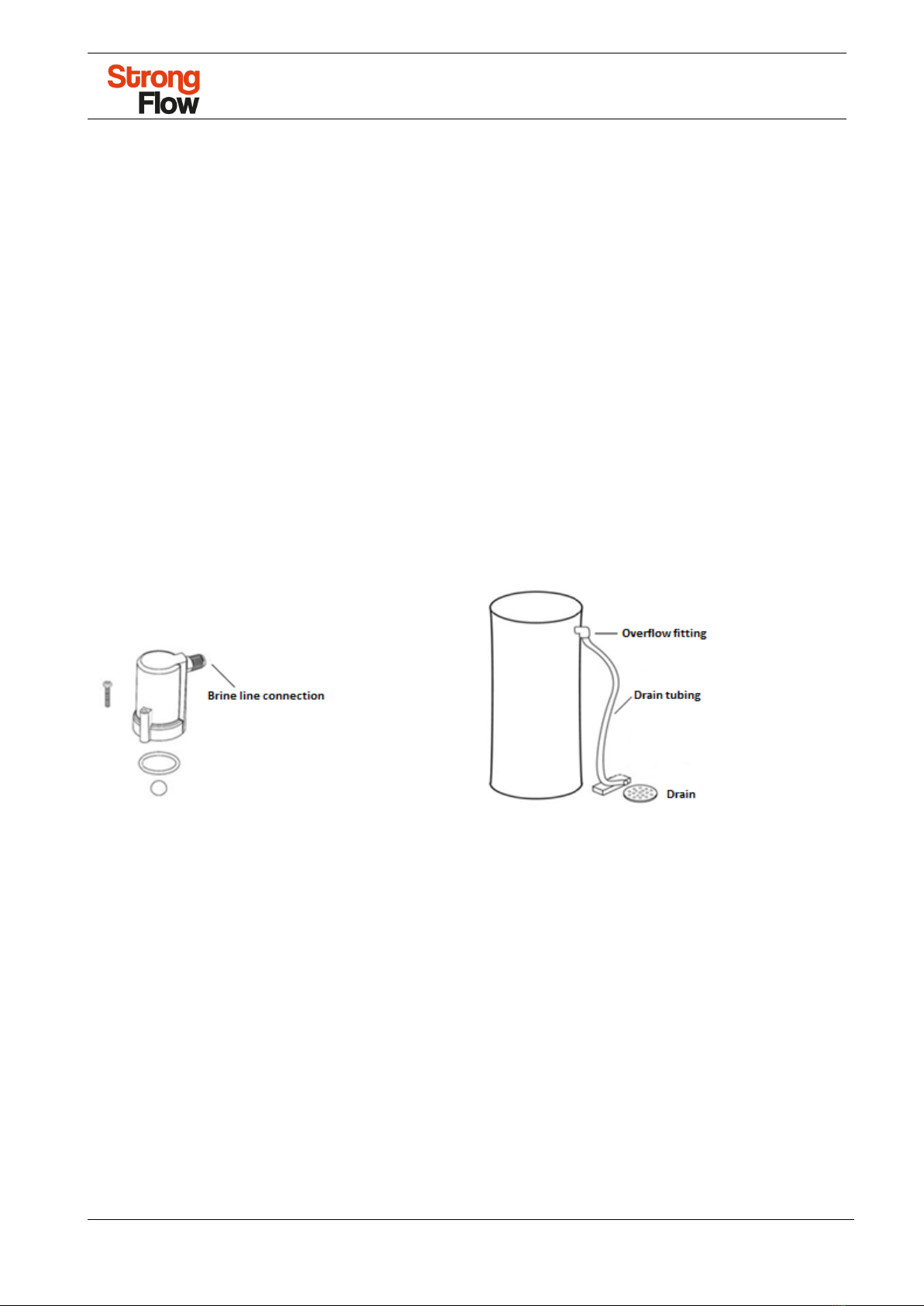

2.4 Brine tank and tube connection

Brine tank should be installed to even platform. Connect brine tanks suction tube (picture 3) to air checks

regenerant line connection. Before starting the filter that all connections are well prepared, and tubes /

piping have no places for leakage. Possible leakage in brine suction line can cause premature closure of

floating ball valve and excess brine left to bottom of brine tank.

Drain tube must be installed between brine tank and drain to further damages in possible overflow

situation of brine tank. Attach tube to overflow fitting and run to drain (picture 4).

Picture 3. Air check Picture 4. Overflow line connection

Operating and maintenance manual

AG-CAB1035 Water softner

Sivu 7/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

3 GENERAL CONTROLLER INSTRUCTION

3.1 Controller display

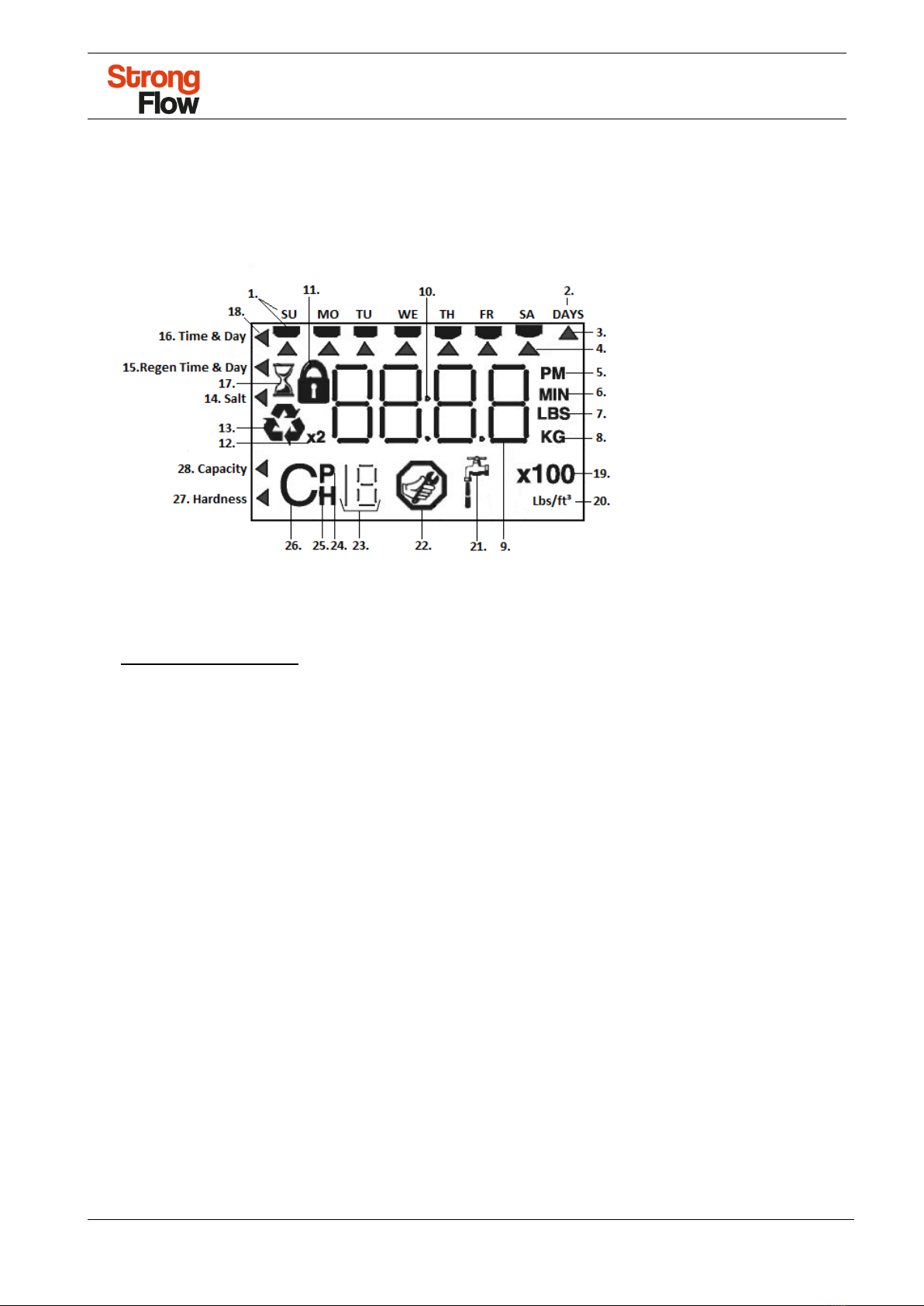

Picture 5. Display icons

Description of Symbols

1. Day of week when regeneration takes place

2. Check (see chapter 3.2).

3. Shows interval for regeneration in days

4. Shows the days for regeneration

5. Not in use

6. Not in use

7. Shows how many grams of salt is used for each litre

of brine.

8. Not is use.

9. Shows the set values (e.g. current time, time for

regeneration etc.)

10. Separator for hours and minutes.

11. Shows if value is locked. When shown its not possible

to change the value in case.

12. Filter makes two regenerations in a row.

13. Regeneration process is running.

14. Not in use.

15. Time and date for regeneration when controller is in

normal mode and under programming.

16. Current time and date when controller is in normal

mode and under programming.

17. Shown when cam-axel is turning into new position

and new stage begins.

18. Status of the screen

19. Not in use.

20. Not in use.

21. Not in use.

22. Not in use.

23. Regeneration stage status

24. Not in use

25. Programming mode on.

26. Regeneration stage (together with 23.)

27. Not in use.

28. Capasity.

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 8/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

3.2 Controller buttons

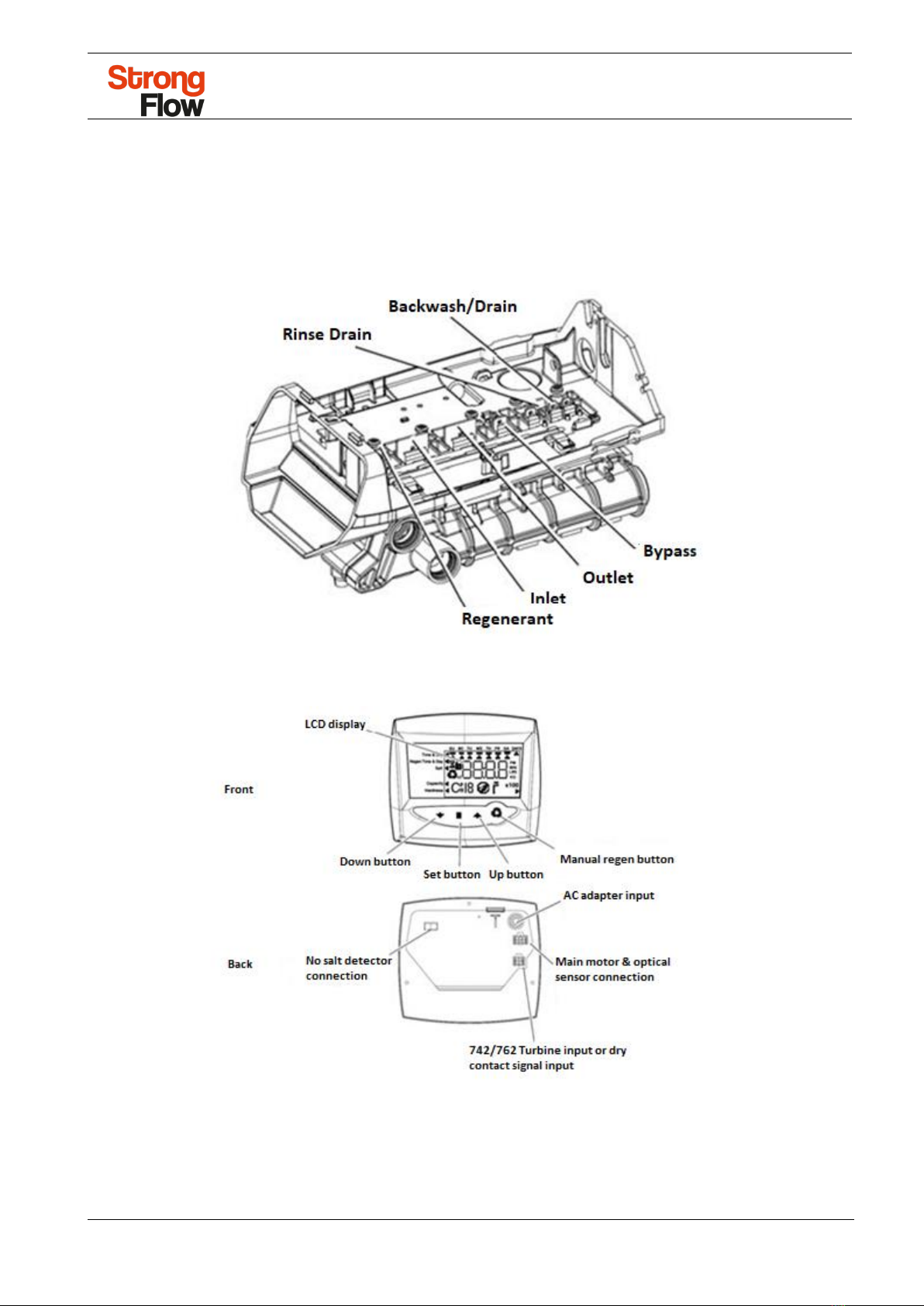

Controller is operated with following buttons (picture 6).

Picture 6. Controller buttons

1. DOWN arrow. Generally used to scroll down or increment through a group of choices.

2. SET. Used to accept a setting that normally becomes stored in memory. Also used together with

the arrow buttons.

3. UP arrow. Generally used to scroll up or increment through a group of choices.

4. REGENERATE. Used to command the controller to regenerate. Also used to change the lock

mode.

Controller will return to initial/home mode in 30 seconds if none of the buttons are pushed.

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 9/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

4. PROGRAMMING CONTROLLER

4.1 Initial power-up/ Re-initialization (reset)

When filter is installed to water supply the start-up can begin. However, do not open the inlet water

valve yet.

1) Connect AC adapter to power source (picture 7). Make sure that the electric cord doesn’t tangle

around the camshaft.

Picture 7. Controller identification

2) Select right valve type from table 2.

•Select your valve type using UP and DOWN buttons. Accept selected valve type with SET

button.

3) Select system size (resin volume in tank) from table 2.

•Select the nearest volume to your actual system size by using UP and DOWN buttons.

Accepted selected resin volume with SET button.

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 10/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

Table 2. Filters valve types and resin volumes

4.2 Default settings

Use UP ( ) and DOWN ( ) buttons to increment through the available selections. Press

SET ( ) button to accept selected value or type.

1) Set time of day

•Press DOWN

•Set the correct time of day and press SET

2) Set Day of week

•Press DOWN

•Set the correct day of week. (1=Sunday, 2=Monday, 3=Tuesday etc.)

•Press SET

Filter Valve type Resin volume

AG-250 255 40

AG-330 255 65

AG-370 278 90

AG-410 278 105

AG-470 278 160

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 11/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

3) Set time of regeneration

•Press DOWN

•Choose time of regeneration

•Press SET

4) Set days to regenerate

OPTION 1

•Press DOWN

•Set number of days between time-clock regeneration (regen frequency)

•Default value is “3”

•Press SET

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 12/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

OPTION 2:

Specific day of week regeneration:

•Press DOWN

•To change the controller to regenerate on specific days, set the number of days between

regeneration to zero “0”.

•Press the SET button and the display will show a flashing cursor at the top under Sunday. The

day of week can be selected when the cursor is below it.

•To toggle the day on/off, the triangular cursor must be below that day and flashing.

•Press SET

5) Set salt amount

•Press DOWN

•Recommended salt amount is 110-150 mg/l

•Set salt amount and press SET

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 13/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

6) Set capacity

•Press DOWN

•Automatic valve will count filter capacity automatically by systems resin volume and salt

amount. Don´t chance settings

•Press SET

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 14/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

4.3 Additional settings (P9-P19)

Additional settings (see table 3) are accessible by pressing and holding the UP and DOWN buttons until the

control displays a “P” value.

Table 3. Additional settings

Use UP ( ) and DOWN ( ) buttons to increment through the available selections. Press

SET ( ) button to accept selected value or type.

Recommended settings:

P9 1

P10 1

P13 0

P16 Not used

P17 Not used

P18 Not used

P-value Parameter descriptopm Units Notes

P9 Unit of measure - 0=english, 1 =metric

0 = 12h

1 = 24h

P11 Service interval months

P12 Remote regen sw. Delay s -

0 = none

1 = salt check only

2 = generate chlorine and check salt

P14 Refill rate gpmx100 -

P15 Brine type gpmx100 -

0 = variable reserve, delay regen

1 = fixed reserve, delay regen

2 = variable reserve, immediate regeneration

3 = fixed reserve, immediate regeneration

P17 Reserve percentage for fixed reserves %

0 = internal turbine, Magnum IT NHWB

1 = 1" autotrol turbine

2 = 2" autotrol turbine

3 = user defined K factor

4 = user defined pulse equivalent

5 = MagnumIT HWB

pulses/liter (P18 = 3 ja P9 = 1)

liters/pulse (P18 = 4 ja P9 = 1)

K factor or pulse equivalent

-

-

P16

P19

Flow sensor select

P18

-

-

Reserve type

-

P13

Chlorine generator

Clock mode

P10

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 15/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

4.4 Cycle time programming

Automatic valve will select right regeneration cycle times automatically based on filters system

size. Do not chance any settings.

4.4.1 Regeneration modes

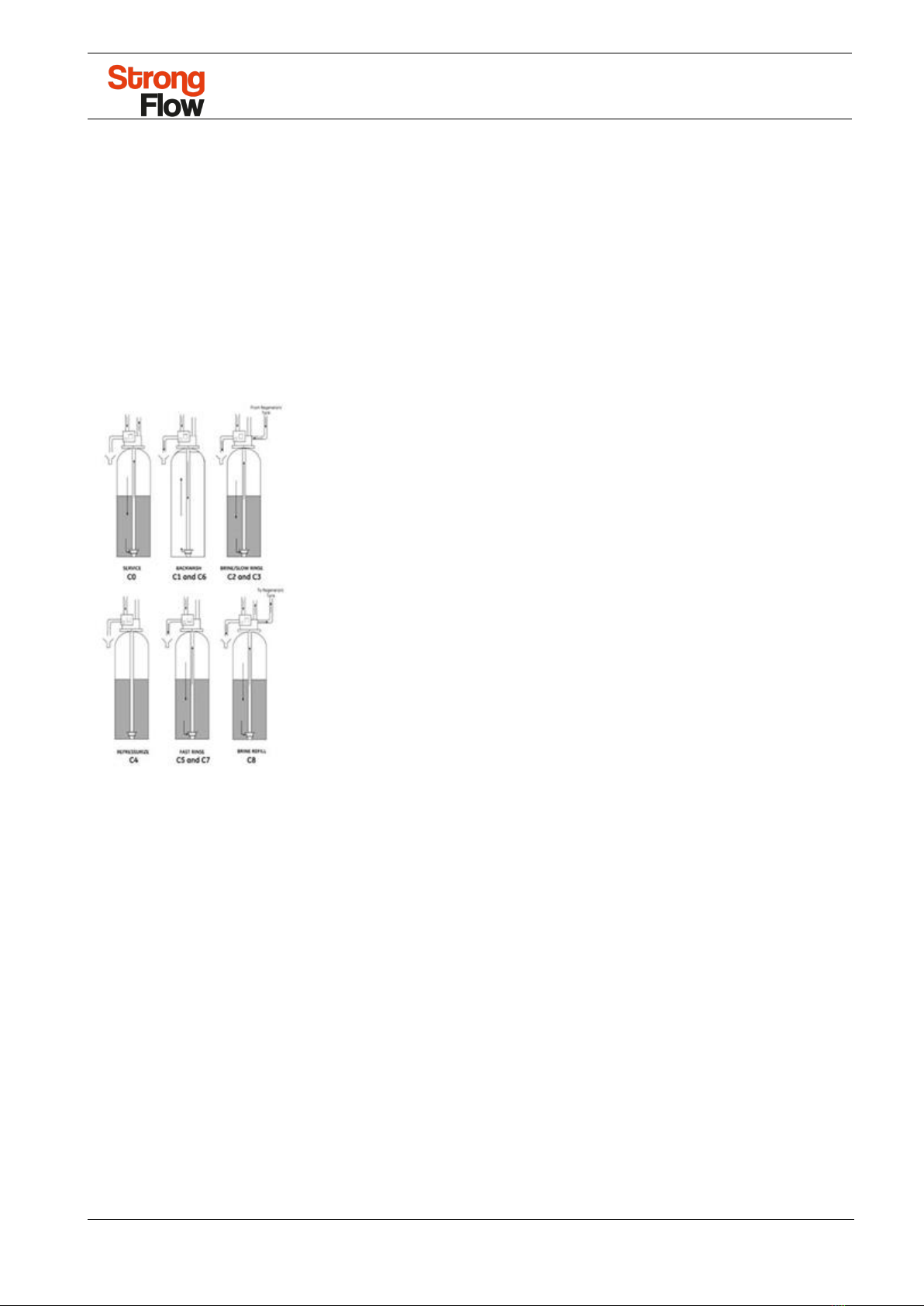

Below is described the regeneration cycles of automatic valve that is used in AG-CAB filters.

C0 = Normal filtering stage (not shown)

C1 = Regeneration back wash

C2 = Suction of the brine

C3 = Slow flushing

C4 = Pressurizing / prepared

C5 = Quick flushing

C6 = Backwash 2 (only in valve 255)

C7= Quick flush 2 (only in valve 255)

C8= Fill of brine tank with water

Picture 8. regeneration cycles

4.4.2 Manual regeneration

Manual regeneration can be done with two ways:

Option 1. Press the REGENERATE button shortly. Regeneration symbol starts blinking on the

screen. Valve executes additional regeneration cycle on the pre-set time (2:00 as standard).

Option 2. Press the REGENERATE button for five seconds and the regeneration cycle starts

immediately.

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 16/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

5. START-UP OF THE FILTER AND VALVE

The actual start-up of filter can be made after filter is in place and controller is programmed. Please

see the following instructions.

1. Remove the cover of valve.

2. Make sure that water inlet and outlet valves (and by-pass valve if exists) are closed

3. Press the Regenerate-button for five seconds to start the regeneration manually –camshaft

now turns to regeneration position C1.

4. Remove the air from filter. When filter is in stage C1 open the inlet valve partially. Do not

open the inlet valve fully to prevent that filtering resin goes to automatic valve.

5. When the filter is full of water the water starts to flow slowly to drain. Inlet valve can now

be fully opened. Let the water flow to drain until it becomes clear.

6. Fill the brine tank (start-up fill). First the brine tank is filled with water about 10 cm from the

bottom of the brine tank. Then insert about 50-75 kg of clean regeneration salt to brine tank.

There needs to be enough salt that the brine becomes saturated (salt is filled at least 30 cm

from bottom of the tank). Then fill some 15 l of additional water to brine tank.

7. Make sure that the water inlet valve is now fully open.

8. Press the SET and arrow UP buttons at the same time to set the valve to next stage C2. Press

the SET and arrow UP buttons again at the same time to set the valve to next stage C3.

Repeat this until valve is in stage C8.

9. Let the water to flow to brine tank.

10. Press once more SET and UP arrow buttons at the same time to set the system to C0 stage

(C0 not shown in the controller screen).

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 17/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

6. MAINTENANCE AND TROUBLESHOOTING

6.1 Cleaning the automatic valve filter screen/net

Within normal use it is enough if automatic valves filter screen/net is cleaned once or twice a year.

Screen/net is located on the left side of the valve.

6.2 Changing the resin

Please see following instruction for changing the filtering resin.

1. Close the inlet and outlet valves.

2. Start the regeneration cycle manually (see chapter 4.4.2, page 15) and wait until valve is in

backwash stage C1 - the filter is now unpressurized.

3. Remover the electric power plug from valve and open/remove the filters water line

connections.

4. Remove the automatic valve (twist the valve - right handed thread) and plug the diffusor

upper end of tube.

5. Hose water inside the tank so the resin starts to flow out together with water. Remove the

diffusor tube and continue until all resin is removed from the tank. Take care of the

disposal of used resin according to your local instructions (e.g. polymer-based can be

treated like other plastic waste).

6. Fill the tank with new resin as instructed in chapter 2.2 (page 5).

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 18/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

6.3 Possible problems and causes

Problem Possible cause Solution

a. Uncontrolled brine refill flow rate a. Remove brine control to clean ball and seat

b. Air leak in brine to air check b. Check al connections in brine line for leaks.

Refer to instructions.

c. Drain controlclogged with resin or other debris c. Clean drain control

Flowing or dripping water at a. Valve stem return spring weak a. Replace spring. (Contact dealer)

drain or brine line after regeneration b. Debris preventing valve disc from closing b. Remove debris

a. Low water pressure a. Make correct setting according to instructions.

b. Restricted drain line b. Remove restriction.

c. Injector plugged c. Clean injector and screen.

d. Injector defective d. Replace injector and cap. (Contact dealer)

e. Valve disc 2 and/or 3 not closed. e. Remove foreign matter from disc and check

disc for closing by pushing in on stem.

Replace if needed. (Contact dealer)

f. Air check valve prematurely closed f. Put control momentarily into brine refill, C8.

Replace or repair air check if needed

a. AC adapter or motor not connected a. Connect power

b. Defective adapter or motor b. Replace adapter/motor. (Connect dealer.)

Brine tank overflow

Control will not draw brine

Control will not regenerate automatically

a. Improper regeneration a. Repeat regeneration after making certain

correct salt dosage was set.

b. No salt in regenerant tank b. Add salt

No conditioned water after c. Injector or screen plugged c. Clean injector and screen.

regeneration d. Air check valve closes prematurely d. Put control momentarily in brine/slow rinse, C2

Replace or repair air check if needed

(Contact dealer.)

Water taste salty Regeneration does not work normally Check brine draw and time of regeneration.

Control power has been connected and the

controlis not sure of the estate of the operation.

Disconnect and reconnect the power. If problem

persists, obtain the appropriate controller or AC

adapter for either 50 or 60 Hz power.

a. Controller does not know the position of the a. Wait for two minutes fot the controller to return to

camshaft. Camshaft should be rotating to find home position. The hourglass should be flashing on

home position. the display indicating the motor is running.

b. Check that motor and optical sensor is connected.

Verify that motor wire harness is connected to motor

and controller module. Verify that motor gear has

engaged can gear. If everything is connected try

replacing in this order:

wire harness, motor, optical sensot, controller.

c. Camshaft is turning for more than five c. Verify that optical sensor is in place and connected

minutes to find position to wire. Verify that camshaft is connected appropriately.

Verify that no dirt or rubbish is clogging any of the cam

slots. If motor continues to rotate indefinitely, replace

the following components in this order:

wire harness, motor, optical sensot, controller.

ERR 2 is displayed

b. Camshaft is not turning during ERR3 display.

ERR 3 is displayed

Control power does not match 50 or 60 Hz

Press the UP arrow and the control should reset.

ERR 1 is displayed

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 19/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

7. ATTACHMENTS

Attachment 1: Automatic valve configuration

Operating and maintenance

instructions

AG-250/330 water softeners

Sivu 20/22

StrongFlow Oy

Tel. +358 20 730 1820

Domicile: Kaarina

Ahokylänkatu 3

www.strongflow.fi

Business ID: 2024125-8

FI-20780 Kaarina

VAT no: FI25511181

Attachment 2: Exploded view and spare part list

This manual suits for next models

2

Table of contents

Popular Water Dispenser manuals by other brands

Whirlpool

Whirlpool WHES48 Installation and operation manual

Asset

Asset ATLANTIS 60 Installation, user and maintenance manual

Pentair

Pentair FLECK 5600SXT Service manual

Rain Tree

Rain Tree BioSand Filter user manual

Oster

Oster Chill & Filter Powered Water Dispenser instruction manual

Puretec

Puretec SOL-2CI Series user guide

Hague

Hague MAXIMIZER 7180 Owner's manual and installation guide

H2O

H2O H2O-56SE-R-32 quick start guide

Water Depot

Water Depot ECONO Series owner's manual

Canature WaterGroup

Canature WaterGroup 85HE owner's manual

Bradley

Bradley Terreon TDB3108 Installation

Follett

Follett Symphony Plus installation instructions