Strongman Tools Telford User manual

Version 1

1

INSTALLATION MANUAL& OPERATION

INSTRUCTIONS

SINGLE POST CAR PARKING LIFT

Version 1

2

Date: 5/06/2018

TABLE OF CONTENTS

CHAPTER 1: USER’S RECORD 3

CHAPTER 2: INTRODUCTION 4

CHAPTER 3: SAFETY INSTRUCTIONS 5

CHAPTER 4: DESCRIPTION AND TECHNICAL DATA 9

CHAPTER 5: INSTALLATION INSTRUCTIONS 12

CHAPTER 6: INSTALLATION STEPS 17

CHAPTER 7: OPERATION INSTRUCTIONS 30

CHAPTER 8: MAINTENANCE 34

CHAPTER 9: ELECTRIC & HYDRAULIC DIAGRAMS 36

CHAPTER 10: TROUBLE SHOOTING 41

CHAPTER 11: LIMITED WARRANTY 43

NOTES 44

Version 1

3

CHAPTER 1: USER’S RECORD

RECORD BELOW INFORMATION WHICH LOCATED ON THE NAME PLATE

MODEL NO ____________________________

SERIAL NO ____________________________

CUSTOMER ____________________________

DATE OF INSTALLATION _________________

WE HEREBY DECLARED THAT THE ABOVE MENTIONED MACHINE HAS BEEN INSTALLED

CORRECTLY. ALL FUNCTIONS HAVE BEEN CHECKED AS WELL AS CORRECT OPERATING

OF ALL SAFETY DEVICES. WE CONSIDER THEREFORE THE MACHINE WORK IN GOOD

CONDITION.

Date of Installation The authorized technician

---------------------------- ------------------------------------

The customer

---------------------------------

(READ THIS MANUAL COMPLETELY AND PAY MORE ATTENTION TO THE INSTRUCTIONS BEFORE INSTALLING)

Version 1

4

CHAPTER

2:

INTRODUCTION

This

Manual

has

been

made

to

supply

the

owner

as

well

the

user

with

the

basic

instructions

for

installation

and

a

correct

use

of

the

Single

post

car

parking

lift

.

Read this guide carefully before using the lift and follow the instructions given by this guide to grant

it a correct function, efficiency and a long service life.

Single

post

car

parking

lift is

dependant

parking

type

where

it

requires

valet

to

remove

lower

car

away

before

lowering

the

platform.

This lift is suitable for residential parking purposes. The platform moves only vertically, so that the

users have to clear the ground level to get the higher level car down. It is hydraulic driven Type that

lifted directly by cylinder with chain connected to carriage.

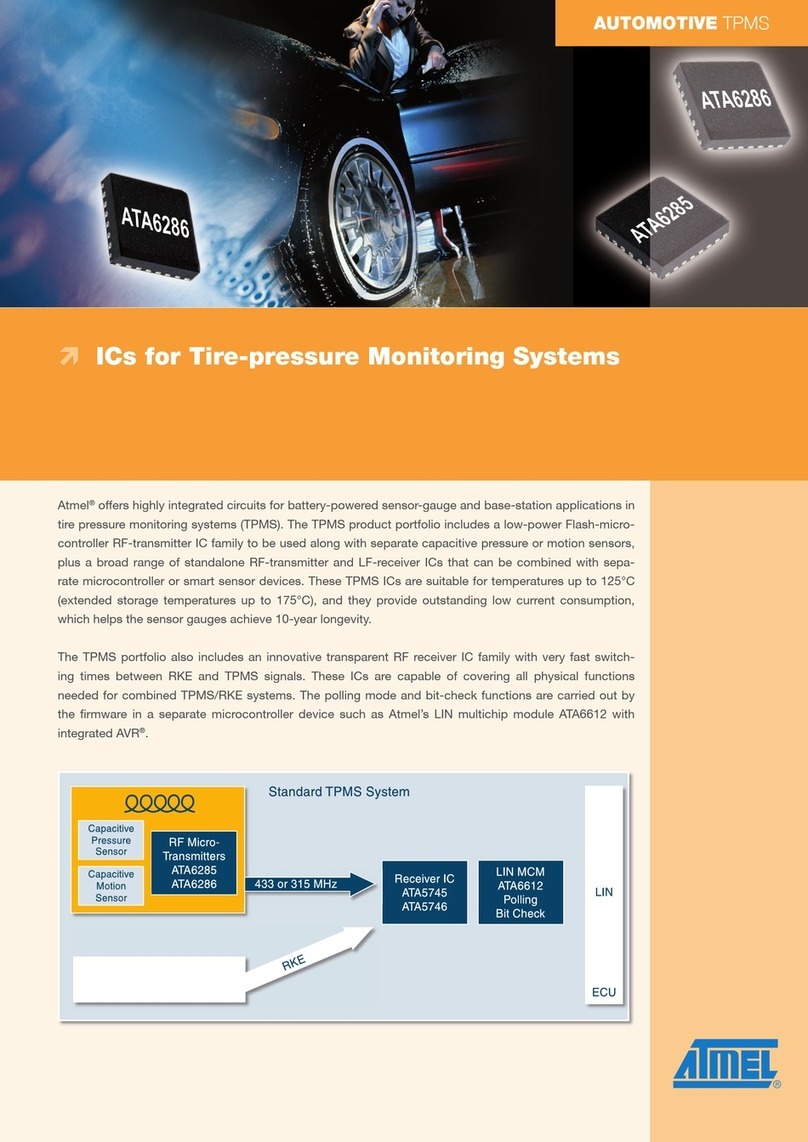

This is electro-hydraulic lift used ONLY for motor vehicle parking.

The product designed according to the EN 1493:2010 and EN 14010:2003+A1:2009.

Reference of Directive Machine: 2006/42/EC.

Working Principle:

1. When operating the unit and pushing UP Button, the hydraulic power unit will be electrically

activated to pump hydraulic oil from tank to hydraulic oil cylinder.

2. The hydraulic cylinder will pull upwards the steel chain which is connected to the carriage.

3. The carriage will lift the platform as both of them are connected with bolts.

4. Once reaching pr-determined lifting height, the carriage will touch the limit switch and stop

the hydraulic motor.

5. The ground floor under the platform is free for parking lower car.

Version 1

5

CHAPTER 3: SAFETY INSTRUCTIONS

1. Read and understand all safety warning procedures before operating the parking lift.

2. Do not install the parking lift on any asphalt surface.

3. This parking lift is designed for parking motor vehicles that weighs within its max lifting

capacity.

4. Exceeding the maximum lifting weight will cause grave damage to the lift and DANGEROUS

INJURIES for the persons.

5. This parking lift, in its standard version, is not designed for outdoor use.

6. This parking lift is not designed to be used as car service lift to do any maintenance for the

car on platform.

7. The manufacturer doesn’t bear any responsibility for any accidents or damage might

happen to the cars or/and persons due to misuse of the lift.

8. Keep hands and feet away from any moving parts. Keep feet clear of parking lift when

lowering.

9. The parking lift MUST only be used by qualified staff, properly trained for such work.

10.During installation, do not wear unfit clothes, large cloves, ties, etc, which could get caught

by moving parts of the machine.

11. The parking lift surrounding area must be free from people or objects which could be a

danger for lifting operations.

12.Use suitable handling and lifting tools/equipment such as crane, forklift, and pallet lift during

off-loading of the packages and during installation of different parts.

13.Always insure the safety devices are engaged before any attempt to work on or near

vehicle.

Version 1

6

14.The parking lift is only designed to park the entire body of vehicle, having maximum weight

not more than the lift capacity.

15.The vehicle must be centered and positioned in a stable correct way with respect to the

platform and following the instructions given by manufacturer.

16.Make sure that the lift and its devices are working correctly, according to the specific

instructions for maintenance.

17.Do not modify the parking lift without manufacturer’s written approval.

18.If the parking lift will not be used for a long period, proceed as follows:

a. Disconnect the energy source.

b. Empty the oil from the Hydraulic unit tank.

c. Grease the moving parts which might be damaged by dust or drying out.

19.Only Authorized personnel are allowed to operate the control box. Only person with

qualification for repairing electrical appliances could open control box.

20.Control box is allowed to open only after power is cut off.

21.Installation technicians should be healthy, well trained and qualified to carry on the

installation with experience for both mechanical &electrical work.

22.The car must be parked at the right direction.(See below Fig.1)

Version 1

7

WARNING SIGNS

Version 1

8

Fig.2

Fig.3

Version 1

9

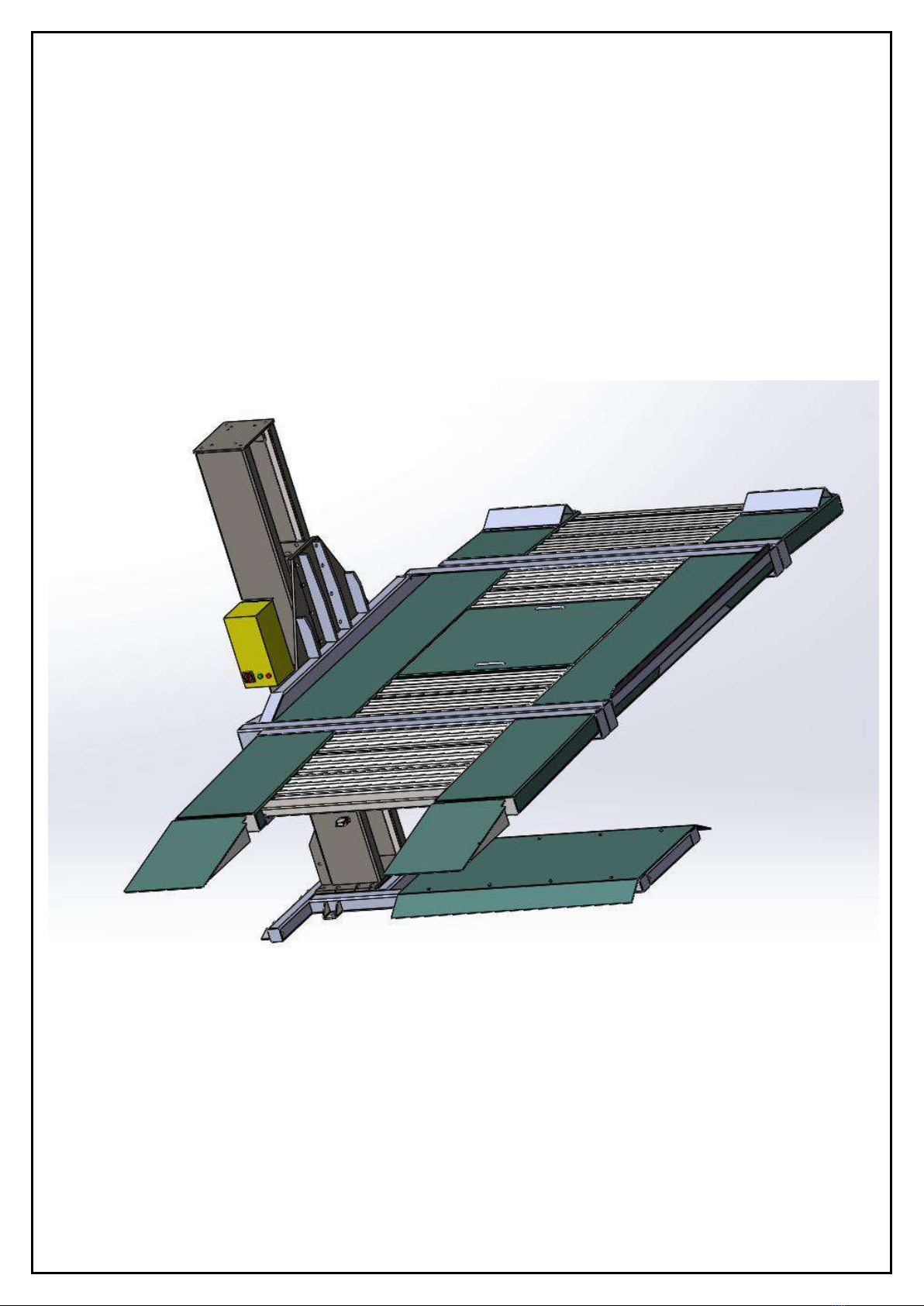

CHAPTER 4: DESCRIPTION AND TECHNICAL DATA

4.1 OVERALL DESCRIPTION

1

. Unit Base

2. Cover of base

3. Carriage

4. Post

5. Support beam

6. Platform (3 pcs)

7. Ramp

8. Wave plate

9. Stopper

10. Hydraulic power unit

motor

11. Oil Tank

12. Stand of control

box

13. Control

box(could be

fixed on the post)

Version 1

10

4.2 TECHNICAL DATA

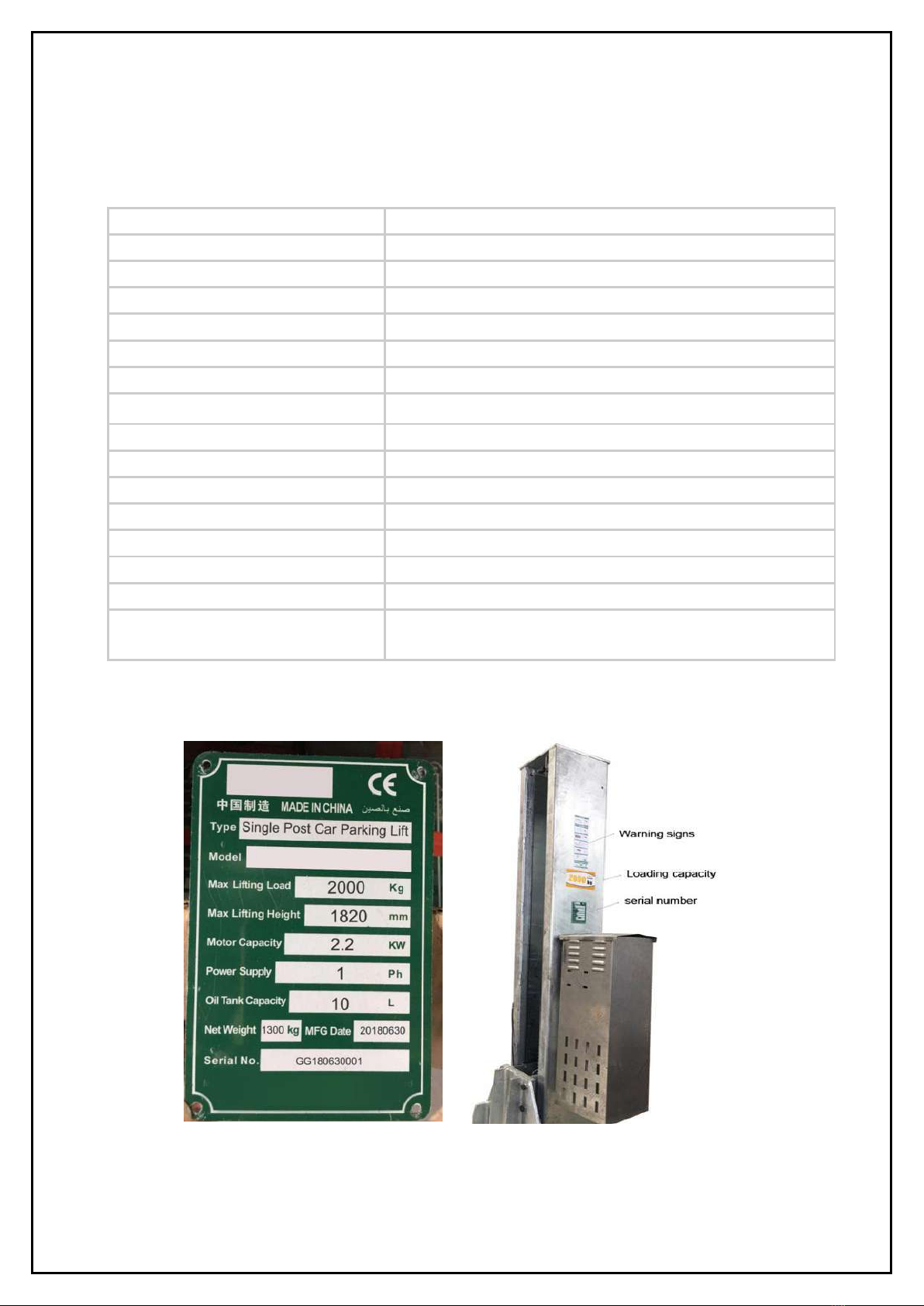

4.3 Identification Plate with Serial Number:

Fig.4 Fig.5

Manufacturer Strongman Tools Ltd

Machine Type Single Post Car Parking Lift – Hydraulic driven

Model NO. Telford - Single Post

Max Lifting Capacity 2000 Kg

Max Lifting Height 1820mm

Max dimension of vehicle 5000*1850*1550mm

Max weight of vehicle 2000 Kg

Lock Release Type Electric lock release

Outline Dimension 3945x 2631x 2479 mm

Unit Weight 1300 Kg

Parking Width 2000mm

Rise/Drop Time 60 S/50 S

Power Supply/Motor Capacity 220V/ 1Ph/ 50Hz. - 2.2 KW

Run Way & Ramps Diamond Steel Plates

Noise Level ≤85dB

Platform – Middle Diamond Steel Plates and removable Corrugated

Galvanized Steel Plates

Version 1

11

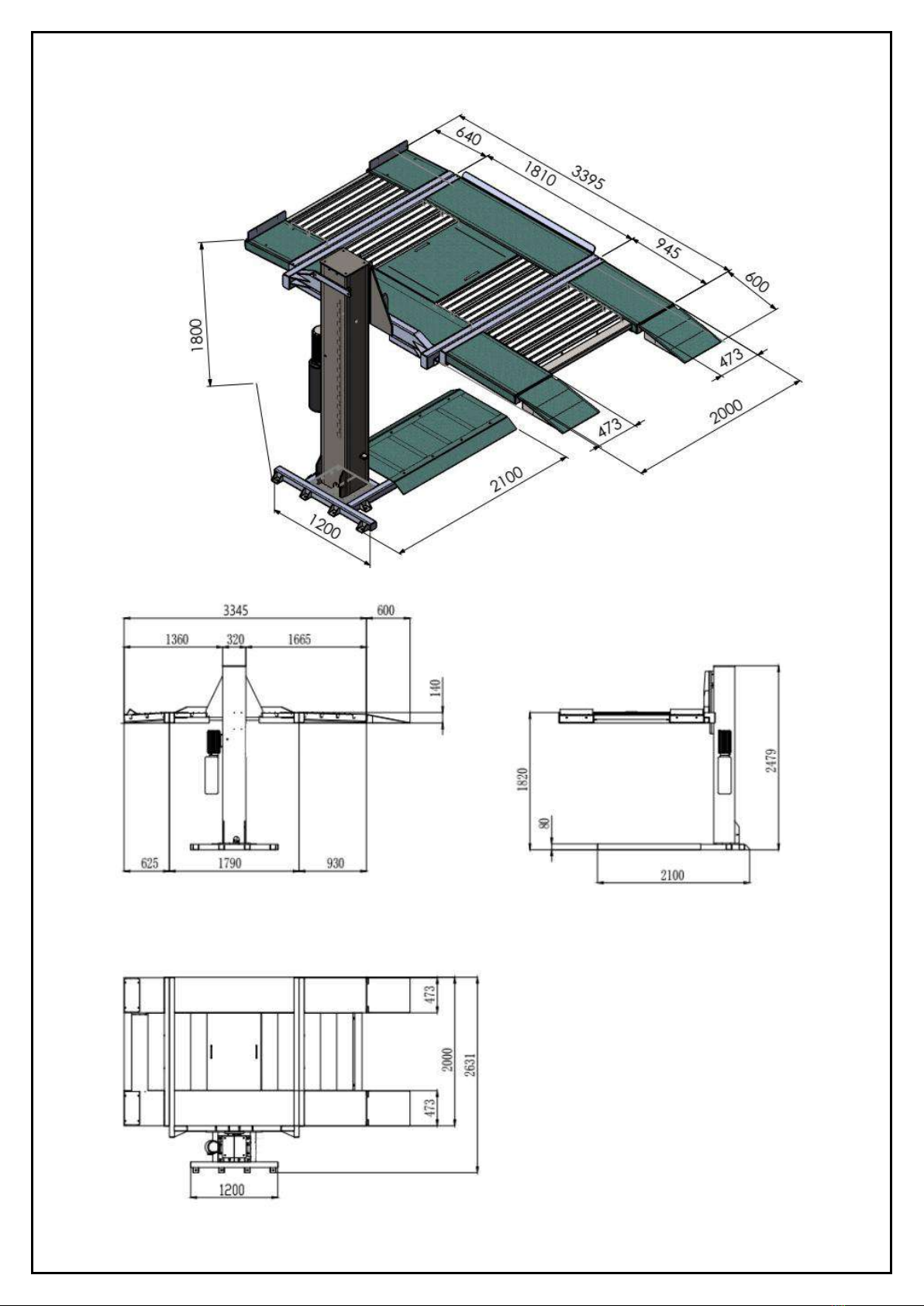

4.4 LiftDimensions

12

Version

1

CHAPTER

5:

INSTALLATION

INSTRUCTIONS

Strongman Tools Ltd Equipment,

ensuring

our

customers’

safety

is

our

primary

concern. Our

car

parking

lift

was

designed

and

built

with

safety.

However,

safety

relies

on

proper

installation

and

training.

Prepare

for

a

successful

installation

by

making

sure

your

floor

meets

specific

requirements.

Installation

technicians

should

be

healthy,

well

trained

and

qualified

to

carry

on

the

installation

with

experience

for

both

mechanical

&electrical

work.

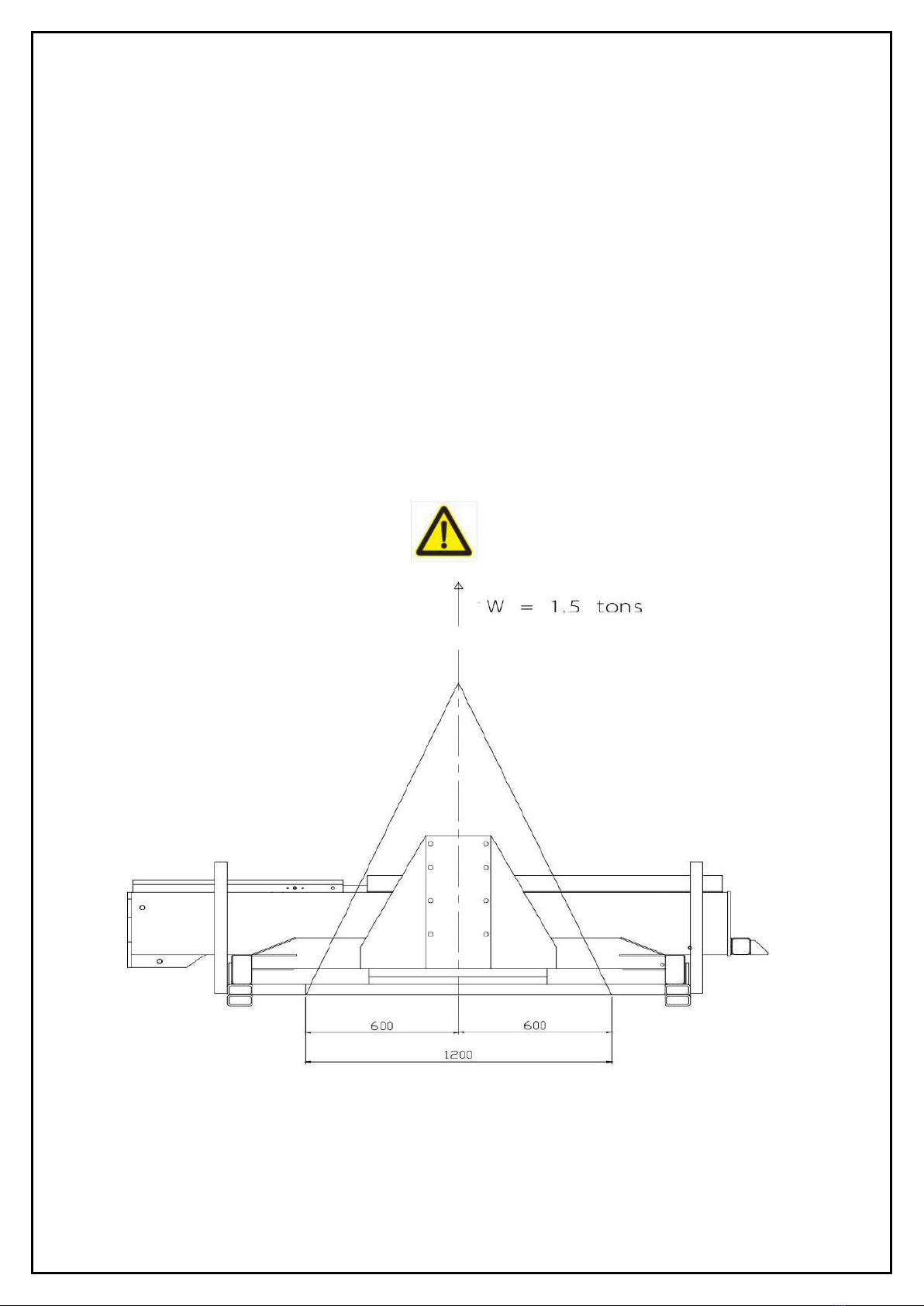

Use

hoist

/

crane

with

suitable

steel

chain

or

woven

belt

to

lift

he

package

to

the

place

you

need

to

install.

The

lifting

capacity

of

the

hoist

must

be

more

than

1.5

Ton.

Fig.6

Version 1

13

5.1 Unpacking the package

Check the package and off-load the contents near the installation place.

Fig. 7

The hydraulic power unit box and standard parts & chains box are light, could be carried by hand.

Then take out steel parts one by one using suitable lifting hoist (Fig. 9 is an example of hoist).

Fig. 8 Fig. 9

Version 1

14

Parts need crane or hoist to carry during off-loading the package for installing the lift

Description Weight (kg) Carrying Method

1 Runway platform (at stopper side) 85

By Crane or hoist

2 Runway platform (at ramp side) 105

3 Cover of base 48

4 Post and Carriage 325

5 Base 103

6 Mid platform 364

7 Steel plate for packaging 128

Parts with weight less than 20kg

8 ramps

Human handling

9 Power unit

10 chains

11 Standard parts

5.2 SITE SELECTION:

Before installing your car parking lift, check the following:

Lift Location: Always use architect’s plans when available.

Check layout dimension against floor plan requirements making sure adequate space is

available. Your lift requires a 220v, 30amp, single phase, grounded electrical source. There

should be room enough to operate the lift in a safe manner and without restrictions.

Space Required: Please refer to the drawing for detailed installation size.

Overhead Area: The area where the lift will be located should be free of overhead obstructions

such as heaters, building supports, electrical lines, doors, lights, etc.

Floor Area: Visually inspect the site where the lift is to be installed and check for cracked or

defective concrete.

Version 1

15

5.3 FLOOR REQUIREMENTS:

A leveled floor is strongly suggested for proper installation and balance lifting. Small differences

in floor slopes may be compensated by proper shims. If a floor is of questionable slope,

consider the possibility of pouring a new level concrete slab.

DO NOT install car lift on any asphalt surface or any surface other than concrete.

DO NOT install car lift on expansion seams or on cracked or defective concrete.

DO NOT install car lift on a second/elevated floor without consulting building architect first.

DO NOT install car lift outdoor as it’s not designed for outdoor conditions.

New concrete must be adequately cured for at least 30 days.

All models MUST be installed on 3,000 PSI reinforced concrete slab only.

New Poured Concrete slab Specifications: Minimum 200 mm thickness.

Old ,unleveled or damaged Concrete slab Specifications:

In this case you can cut out a 1m x 1m square form the old slab, and pour new concrete to a depth

of about 300mm. You can then tie this new section of slab back into the existing slab with Rotary

Hammer Drill drilled in. Do it under all car lift posts.

Specifications of concrete must be adhered to. Failure to do so could cause car lift failure resulting

in personal injury or death. The floor strength should be suitable to carry the weight of the car lift

plus 2 cars, one on the ground floor and one on the platform.

5.4 Other environment requirements

Temperature required: -30 ºC to 45 ºC

Air humidity:≤80%

Altitude: ≤2000 m

5.5 TOOLS AND EQUIPMENT NEEDED:

Appropriate lifting equipment such as forklift or Hoist.

Rando HD 46 or other good quality garage hydraulic oil.

Chalk line and measure tape.

Rotary Hammer Drill with 3/4’’ drill bit.

Sockets and Open wrench set.

Vise Grips.

Lithium lubricating grease

Version 1

16

5.6 PARTS LIST:

Main Parts list

Item Size (mm) Qty Item Size Qty

Stop plate 470*100*40 2 Oil Tank 10 L 1

Base cover 1420*830 1 Steel wire rope 1

Post 230*290*320 1 Chain Lh12461 1

Ramp 600*470 2 Base plate 1

Gusset plate 1040*745 1 Hydraulic Cylinder 1

Wave plate 1040*224 8 Steel wire rope 1

Middle platform

runway

1650*473 2 carriage 1

Platform Runway (At

Stop plate side)

555*473 2 Hydraulic Power

Unit

1

Platform Runway (At

Ramp side)

860*473 2 Operation Panel 1

Oil Hose 1

Standard Parts List

Item Size Qty Item Size Qty

Hex bolt, flat washer ,

spring washer

M8*30 4 Nut M12 1

Hex bolt, flat washer,

spring washer

M18*45 18 Chain wheel Φ110 1

Bolt M5*15 4 Roller on carriage 4

Bolt M6*20 1 Oil bearing 42*38*50 5

Hex bolt, flat washer,

spring washer

M12*35 4 Limit switch 1

Bolt M6*25 1 Limit switch cable 2*0.5 1.5 m

Countersunk bolt M6*15 1 Flat washer 16 2

Countersunk bolt M10*10 1 Split cotter 2.5 4

Hex bolt ,flat washer ,

spring washer

M14*30 4 Elastic cylindrical

pin

φ3*20 2

Hex bolt M5*30 4 Flat washer 12 1

Countersunk bolt M10*15 6 Sliding block 8

Anchor Bolt M18*220 12 Electromagnetic 1

Bolt M4*20 4 Cable 1

Expansion Anchor

Bolt

M20*180 8 Hose 2-JIC1/2 1

Elbow ZG1/4-JIC1/2 1

Version 1

17

5.7

BEFORE

INSTALLATION

1.Identify

the

packaging

components

and

check

for

missing

parts.

Contact

Strongman

if

shortage

discovered.

2.Installation,

adjusting

and

testing

operations

are

to

be

performed

by

qualified

staff

only.

3.The

lift

must

be

installed

on

a

leveled

concrete

floor,

having

minimum

thickness

of

150

mm

and

an

extension

of

at

least

1500

mm

from

anchoring

points.

4.The

lift

installation

concrete

surface

must

be

relatively

smooth,

leveled

in

all

directions

5.After

unloading

the

package,

place

it

near

the

intended

installation

location.

6.Dismantle

the

steel

parts

of

the

lift

from

the

package.

7.Remove

the

packing

materials

(steel

brackets,

cartoons,

etc)

from

the

installation

site.

CHAPTER 6: INSTALLATION STEPS

6.1 : DETERMINE LOCATION AND MARK WITH CHALK ON THE FLOOR

1.Determine the location for installing the parking unit considering all safety instructions.

2.Place the base on the floor and confirm its location before fixing to the floor.

3.Mark base outline with chalk on floor to ensure no displacement occurs during installation.

Fig 10

Version 1

18

6.2 INSTALL THE BASE ON THE FLOOR.

Before this step, carry the base by crane or hoist to installation site as it is heavy.

1. Drill each anchor hole in the concrete using a rotary hammer drill. To assure full holding power, do

not oversize the hole or allow drill to wobble. (Fig.11)

3. After drilling, remove dust thoroughly from each hole and make certain that the base remains

aligned with the chalk line during this process.

4. If shimming is required, insert the shims with selected thickness as necessary under the base plate

anchor bolts so that when the anchor bolts are tightened, the base will be horizontal. (Fig12).

5. With the shims and anchor bolts in place, tighten by securing the nut to the base then turning2-3 full

turns clockwise. DO NOT use an impact wrench for this procedure.

Version 1

19

Fig.11

Fig.12

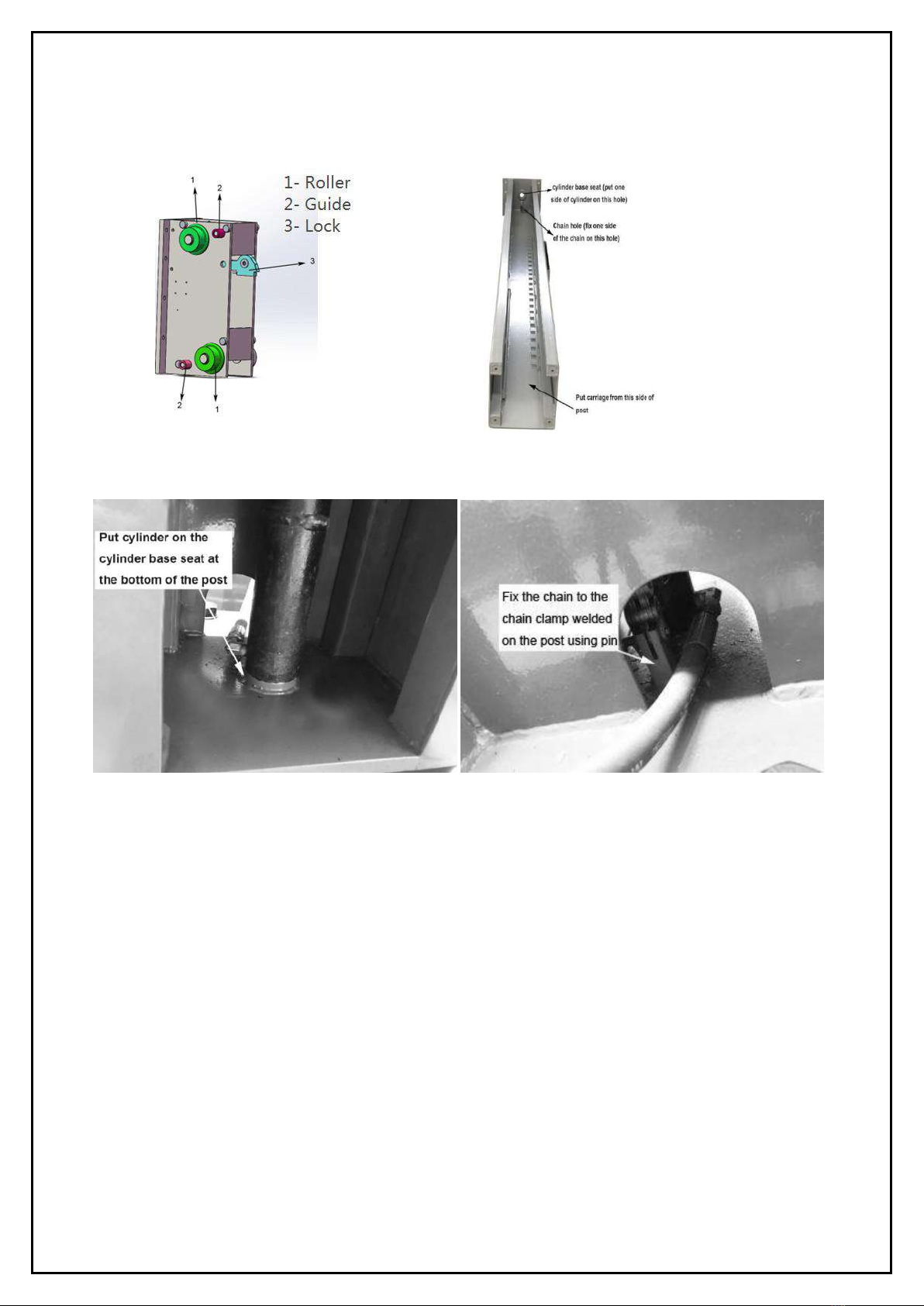

6.3: INSTALLATION OF CARRIAGE, CYLINDER & CHAIN INSIDE THE COLUMN (POST):

Carry carriage and post by

1. Insert the carriage (Fig 13) into the post from the top of the post (Fig 14).

2. Insert the chain pulley hole to the head of the cylinder.

3. Put the cylinder on the cylinder base seat at the bottom of the post (Fig 15).

4. Insert the chain inside the chain pulley and fix one side of the chain on the clamp behind the

cylinder base at the bottom of the post (Fig 16).

5. Fix the other side of the chain to the carriage using threaded connection rod M20 (Fig 17 & Fig 18).

6. Fix the cover on the top of the post using bolts M18 x 45.

Version 1

20

Fig.13 Fig.14

Fig15 Fig16

Table of contents