STS Instruments Siloxane User manual

STS Instruments Ltd,

Service & Maintenance

Manual

201

8

SILOXANE MONITOR MAN AL

STS INSTR MENTS COPYRIGHT 2018

STS INSTR MENTS LTD

|

www.siloxanemonitoring.com

1

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

TABLE OF CONTENTS

2.0 Manual Guide ..................................................................................................... 2

2.1 Document Version ............................................................................................ 2

2.2 Symbols sed .................................................................................................. 2

3.0 Safety Information ............................................................................................... 3

3.1 Environmental parameters .................................................................................. 3

3.2 Instrumentation Safety Symbols ............................................................................ 4

4.0 Service Schedule ................................................................................................. 5

5.0 Maintenance -Weekly .......................................................................................... 10

5.1 Fittings & cables ............................................................................................. 10

5.2 Automated Water Trap ..................................................................................... 10

5.3 Coalescing Filter ............................................................................................. 10

5.4 Instrument Air intake fan ................................................................................... 10

5.5 Instrument Exhaust Fan ..................................................................................... 10

5.6 Kiosk Exhaust Fan ............................................................................................ 10

6.0 Maintenance –Annually ........................................................................................ 10

6.1 Coalescing Filter ............................................................................................. 10

6.2 Flame Arrestor ............................................................................................... 10

6.3 Biogas regulator pressure set .............................................................................. 10

6.4 Heated line .................................................................................................... 11

7.0 Maintenance Menu .............................................................................................. 11

7.1 Access to menu ............................................................................................... 11

8.0 Fault Identification ............................................................................................. 14

8.1 Instrument Error codes ..................................................................................... 14

8.2

4-20mA Remote Data Error codes ................................................................... 14

9.0 Flow Diagrams ................................................................................................... 15

2

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

2.0 MAN AL G IDE

2.1 DOC MENT VERSION

Issued by

Author

Issue Date

Revision Number

STS

Jim Ward

18/10

/2016

1.0

STS

Jim Ward

20/10/2016

1.1 Final

STS

Jim Ward

06/02/2017

1.2

Amends P6.

STS

Jim Ward

26/05/2017

1.3 4

-

20mA error codes P14

STS

Jim Ward

16/08/2017

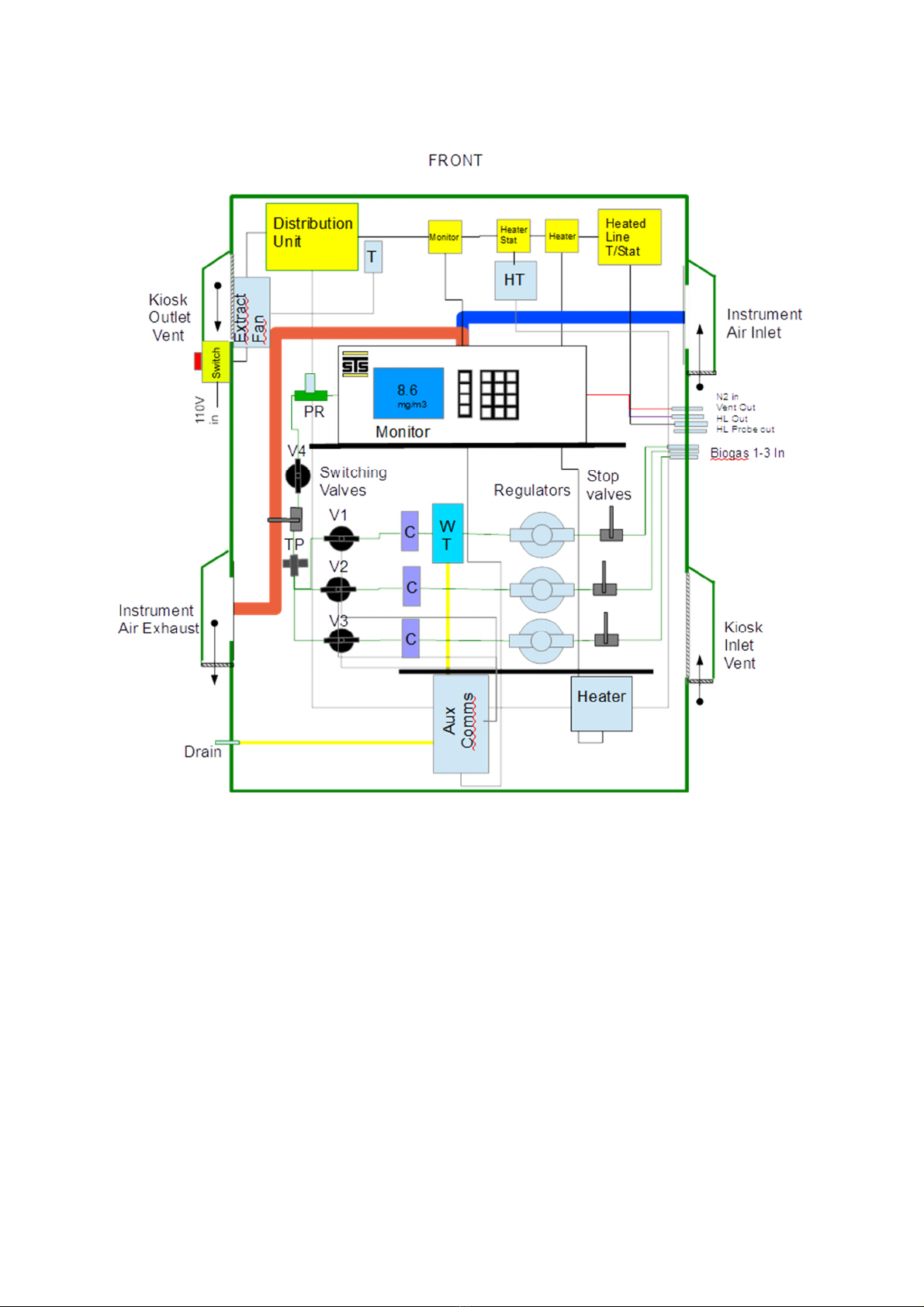

1.4 Added kiosk schematic and gas flow through kiosk P18

2.2 SYMBOLS SED

Safety Warning

Identifies potential

hazards to either

the user or the

installation.

Failure to follow this

information may result in

physical injury that in some

cases could be fatal, cause

irrevocable damage to the

instrument or damage to the

envi

ronment.

Electrical Hazard

Identifies specific

electrical hazards

to the user.

Failure to follow this

information may result in

physical injury that in some

cases could be fatal or may

cause irrevocable damage to

the instrument.

Notes

Identifies

areas

where clarification

may be required.

Should at any point you require additional help or information on the use or installation

of the system please contact STS directly at: sales@safetrainingsystems.com or +44 (0) 1344

483563

3

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

3.0 SAFETY INFORMATION

3.1 ENVIRONMENTAL PARAMETERS

•The Siloxane Monitor is not weatherproof and must be housed in a suitable kiosk or cabinet

if sited outside of a building

•If siting inside a building consideration should be given to the local conditions as regards to

dust, moisture and ventilation the Monitor is available supplied in a 19” rack case suitable

for indoor use with inbuilt thermostatically controlled extraction fans.

The STS Siloxane Monitor operates from a 110V mains supply, the instrument case

should not therefore be opened without having first isolated the power supply and disconnected

the kettle lead form the rear of the instrument. The high voltage section of the instrument is

protected by clear cover – this should not be removed unless necessary- having followed the above

instructions. FAIL RE TO ISOLATE THE S PPLY MAY RES LT IN ELECTRIC SHOCK.

It is the responsibility of the owner of the instrument to complete a risk assessment on its

installation, operation and servicing before being commissioned for use.

Inhalation of gases may be harmful to health, it is the responsibility of the operator to ensure they

have adequate training in the safety aspects of handling biogas/landfill gas and that they follow

appropriate procedures at all times. The vent/exhaust form the instrument must be piped to an

area designated safe to discharge to atmosphere- a flame arrestor may be required to be fitted.

Installation and Maintenance of the unit should only be carried out by suitably trained personnel

according to the applicable code of practice.

Maintenance should be carried out only using STS approved replacement parts and components –

use of substitutes will invalidate the warranty and may be hazardous to both operator and

instrument.

No alterations should be made to the instrument or its ancillary components.

Failure to comply with the instructions in this manual could result in injury to the user.

The instrument captures fuel gas any work associated with the instrument must be carried out by a

class of person competent and certified to do so.

Should at any point you require additional help or information on the safe installation or

use of the system please contact STS immediately at: sales@safetrainingsystems.com or +44

(0) 1344 483563

4

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

•The monitor is suitable for use between 5C and 45C without additional cooling/heating

required.

•Gas supply to the instrument should be at a minimum of 200mbar

•Adequate ventilation/air passage around the instrument should be provided.

3.2 INSTR MENTATION SAFETY SYMBOLS

Caution

Electrical Hazard

Earth Point

Hot Surface

5

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

4.0 SERVICE SCHED LE

External

Area Instructions

Nitrogen Cylinder

and Piping

Make sure Nitrogen Cylinder is secured safely. Record cylinder size/type. Check

for leaks at Regulator using Snoop, redo connection if leaks present. Record

cylinder and regulator pressure. Make sure regulator is set to 1Bar. Piping to

instru ent should be fastened with no da age or degradation. If da age is

present, replace the whole Nitrogen line.

Sa ple Line Piping

Check there are no leaks at sa ple supply, redo connection if a leak is present.

Pipe work to the instru ent should be fastened securely,

insulated/weatherproofed with the heated line installed. Check the visible

piping for da age or degradation. If da age is present, atte pt to replace the

da aged section.

Heated Line and

Weatherproofing

Check whether the heated line has been installed correctly. Record the set

te perature and easure the te perature inside the insulation using a

te perate probe. Check the insulation for da age and degradation. If da age

is present, atte pt to repair that section.

6

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

Vent and Drain

Piping

Check that the Vent and Drain Piping are fastened securely and have no

da age or degradation. If da age is present, replace the whole line. Visibly

check the vent/drain line for any blockages. If a blockage is suspected, confir

this by connection the Nitrogen to the vent/drain line and pressuring the line.

These lines are open to at osphere and should not retain any pressure.

Confir that the vent/drain line is venting into a suitable location. If the vent

has a fla e arrestor installed, re ove the arrestor and purge it with Nitrogen at

1Bar.

Leak Check

Run a leak check on the Nitrogen lines. The leak check shall be perfor ed with

the nitrogen cylinders connected but closed. The service engineer shall verify

no discernible pressure drop over 30 inutes.

Any checks on the biogas syste shall be perfor ed in accordance with the

Installation Manual.

Kiosk

Area Instructions

General Kiosk

Clear any debris, check weatherproofing. Fasten any loose cables

and piping. Record the general state of kiosk and any da aged

parts.

Fla e Arrestor

Disconnect then purge the Fla e arrestor with 1Bar Nitrogen,

venting onto a sheet of white paper. Record any residue found. If

excessive residue is found replace fla e arrestor.

Coalescing Filter Note any Discolouration and Moisture. Replace with New Filter.

7

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

Water Trap

Record any visible water or oisture inside the water trap.

Record any visible corrosion to the fittings, if so replace Water

Trap.

Fans

Record the previously set ther ostat te perature. Ther ostat

should be set to 25degC. Clear any debris around the fans, filters

and cowls. Check the kiosk fans operate when ther ostat is

triggered by changing the threshold te perature. If they don't,

check the with a ulti- eter to confir the ther ostat is

powering the fan. If it is, replace the Fan, else replace the

ther ostat and repeat to confir the fan is working.

Instru ent Intake and Exhaust Clear any debris. Record any da age to the join/seal to the

instru ent and to the kiosk.

Mains and Electrical Visually inspect and record any da age and degradation. If any

da age, disconnect the supply and speak to the anufacture.

Instrument

Area Instructions

General Instru ent

Record the general condition of Instru ent casing, bulkhead gas

fittings and ains cable. Clear any internal debris.

Particle Filters

Re ove two particle filters and blow through with 1Bar Nitrogen

venting onto a sheet of white paper. Record any residue found. If

excessive residue is found replace particle filter.

Fans

Check whether instru ent intake and exhaust fans start up upon

powering the instru ent. If they do not, using a ulti- eter,

easure the voltage to the fans. If they aren't getting power,

return instru ent to the anufacturer.

8

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

PCB, LCD and keypad.

Check LCD and keypad are fully operational by navigating the

enus of the instru ent. Record any da age and degradation.

Check LCD and keypad are fully operational.

Pipe work

Check the internal piping is fastened, and there is no da age or

degradation. Replace any da aged sections.

Leak Check

Via View Stats in the Maintenance enu. Pressurise with N2 in

Phase 0, close N2 supply, allow 10 ins for stabilisation. Then

start recoding the te perature and if after 5 ins there has been

a 20% drop, check all the connections and repeat. If there is still

a leak, this line will need detailed inspection with the potential

for so e or all of the piping to need replacing. Then pressurise

with N2 in Phase 6 with the vent closed, close N2 supply, likewise

repeat the above step recording the pressure drop.

Pu p and Relief Valve

Via View Stats in the Maintenance enu, set to phase 2 and

record the pu p pressure. If the pressure is less than

approxi ate 15PSI, adjust relief valve and repeat. If the pressure

does not change, check for leaks.

Nitrogen Regulator

Via View Stats in the Maintenance enu, set to phase 0. Record

the nitrogen pressure. If the pressure is not approxi ately 10PSI,

adjust the regulator. If the pressure doesn't change, check the

cylinder is at 1Bar and check the internal piping for gas leaks. If

the issue still is there, replace the regulator.

Heaters

Via View Stats in the Maintenance enu, set to phase 1. Record

the Concentrator te perature. It should stabilise around

240degC. If it doesn't, return instru ent to anufacturer. To

check the Per eation heater, run a calibration cycle with a

te perature probe in the per eation oven. This probe should

stabilise around 80degC. If it doesn't return instru ent to

anufacture.

9

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

Flow Measure ent

Via View Stats in the Maintenance enu, in phase 6, record the

internal flow easure ent and co pare it with an external flow

easure ent on the vent line. If these differ by ore than 20%

return instru ent to anufacture.

Te perature, Pressure and CH4

sensors

Via View Stats in the Maintenance enu, in phase 1, record the

te peratures, pressures and CH4 values.

Solenoids

Via View Stats in the Maintenance enu. In Phase 0, if Solenoid

2 is operational the pu p pressure should be approxi ately

zero. In phase 3, if solenoid 4 is operational the pu p pressure

should be greater than 1PSI but less than 14PSI. To test Solenoid

1 and 3, run calibration cycle with a D5 sa ple and if the correct

ass is present the solenoid is operational.

Calibration

Via Maintenance Menu, run a calibration cycle. Leave the first

cycle blank, then use 20ul of 1 g/ l D5. Attach Calibration

Report. Adjust the Calibration coefficient to achieve a reading of

20ug. Replace per eation oven seal once finished.

10

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

5.0 MAINTENANCE -WEEKLY

5.1 FITTINGS & CABLES

Visually check fittings and cables for any sign of wear or for loose connections.

5.2 A TOMATED WATER TRAP

Check the automated trap is empty and the float is in its lower position, check the end of the drain

line is clear and unblocked.

5.3 COALESCING FILTER

This trap does not drain and should not have any visible water inside. If there is water present, the

filter element should be changed immediately and the auto drain trap should also be checked to

ensure its correct function.

5.4 INSTR MENT AIR INTAKE FAN

Check that fan is running, check the external vent for any blockages and clear if required, check

the pipe is secured to the vent plate and instrument securely.

5.5 INSTR MENT EXHA ST FAN

Check that fan is running, check the external vent for any blockages and clear if required, check

the pipe is secured to the vent plate and instrument securely.

5.6 KIOSK EXHA ST FAN

Check that fan is running, check the external vent for any blockages and clear if required.

6.0 MAINTENANCE –ANN ALLY

6.1 COALESCING FILTER

Change the filter in the coalescing trap once a year. After isolating the gas supply unscrew the

bowl of the trap by hand in a anticlockwise direction. Remove the bowl and exchange the filter for

a new one, the filter just pulls off the stem. Replace the bowl, tighten and turn the supply back on

– leak check.

6.2 FLAME ARRESTOR

Disconnect and remove the flame arrestor, blow through with nitrogen at 1 bar observing

any particulate matter that is discharged. Check the filter for obvious signs of clogging,

should there be any which is not removed by the nitrogen the arrestor should be replaced

and the unit returned to STS for overhaul.

6.3 BIOGAS REG LATOR PRESS RE SET

11

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

The gas stream into the instrument is regulated in the kiosk to a maximum of 35mbar.

Annually the regulators should be checked to ensure the pressure is correctly set using a

gauge.

Be careful to not over pressurise the regulators, or to back pressurise them as

this will cause damage to the components.

6.4 HEATED LINE

Check temperature set point of the heated line is correct using a temperature gauge, check the

line for damage, and check the length for any failings in the insulation of fixings.

7.0 MAINTENANCE MEN

7.1 ACCESS TO MEN

The maintenance menu can be accessed from the main menu screen:

Select: OPTIONS

Hold CLEAR on the number pad for approximately 4 secs.

12

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

The Maintenance menu screen is displayed

Enter the password “SILOX” and press ENTER, START to confirm.

Hold 5 to see the View Stats screen

13

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

Within this readout, pressing 1 to 8 on the keypad will change the instrument phase.

Phases:

1. Cleaning

2. Cooldown

3. Sample

4. Purge

5. Background preheat

6. Background

7. Measurement preheat

8. Measurement

The internal variables will be displayed on the readout and will change every second.

14

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

8.0 FA LT IDENTIFICATION

8.1 INSTR MENT ERROR CODES

All Faults will cause instrument to enter a Safe Mode Configuration. In Safe Mode the instrument

disables the heaters and the biogas input into the system but leaves the fans running in order to

exhaust the case of any potential leak.

•Fault# 1: Communications Error. Board Faulty.

•Fault# 2: Low Nitrogen Error. Check supply pressure, if empty -Replace Supply. If

there is still an error, internal Plumbing is Faulty.

•Fault# 4: High Nitrogen Error. Internal Plumbing is Faulty.

•Fault# 8: Sample Volume Low. Internal Pump Faulty.

•Fault# 10: Sample Volume High. Internal Pump Faulty, or Biogas Pressure too high.

•Fault# 20: Concentrator Oven Low Error. Oven Heater is Faulty or Board.

•Fault# 40: Concentrator Oven High Error. Oven Heater is Faulty or Board.

•Fault# 80: Calibration Oven Low Error. Oven Heater is Faulty or Board.

•Fault# 100: Calibration Oven High Error. Oven Heater is Faulty or Board.

•Fault# 200: Internal Temperature High Error. Internal temperature is >60degreesC.

Installation error or Oven Heater error.

•Fault# 400: CH4 High Error. Instrument CH4 threshold has been exceeded.

Installation error, or internal plumbing.

•Fault# Optical Signal: Instrument analytical system or board faulty.

•Fault# Fans Faulty: Instrument purging system or board faulty.

•

Instrument will need resetting via the mains power upon a fault however an Internal

Temperature error will automatically reset once the internal temperature has dropped

below the threshold.

8.2 4-20MA REMOTE DATA ERROR CODES

Error line 4-20mA reading:

0: Standby

25: Communications Fault

50: Fan Fault

75: CH4 High Fault

100: N2 Fault

125: Internal Temp Fault

150: Biogas Volume Fault

175: Concentrator Temp Fault

200: Logging Normally

15

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

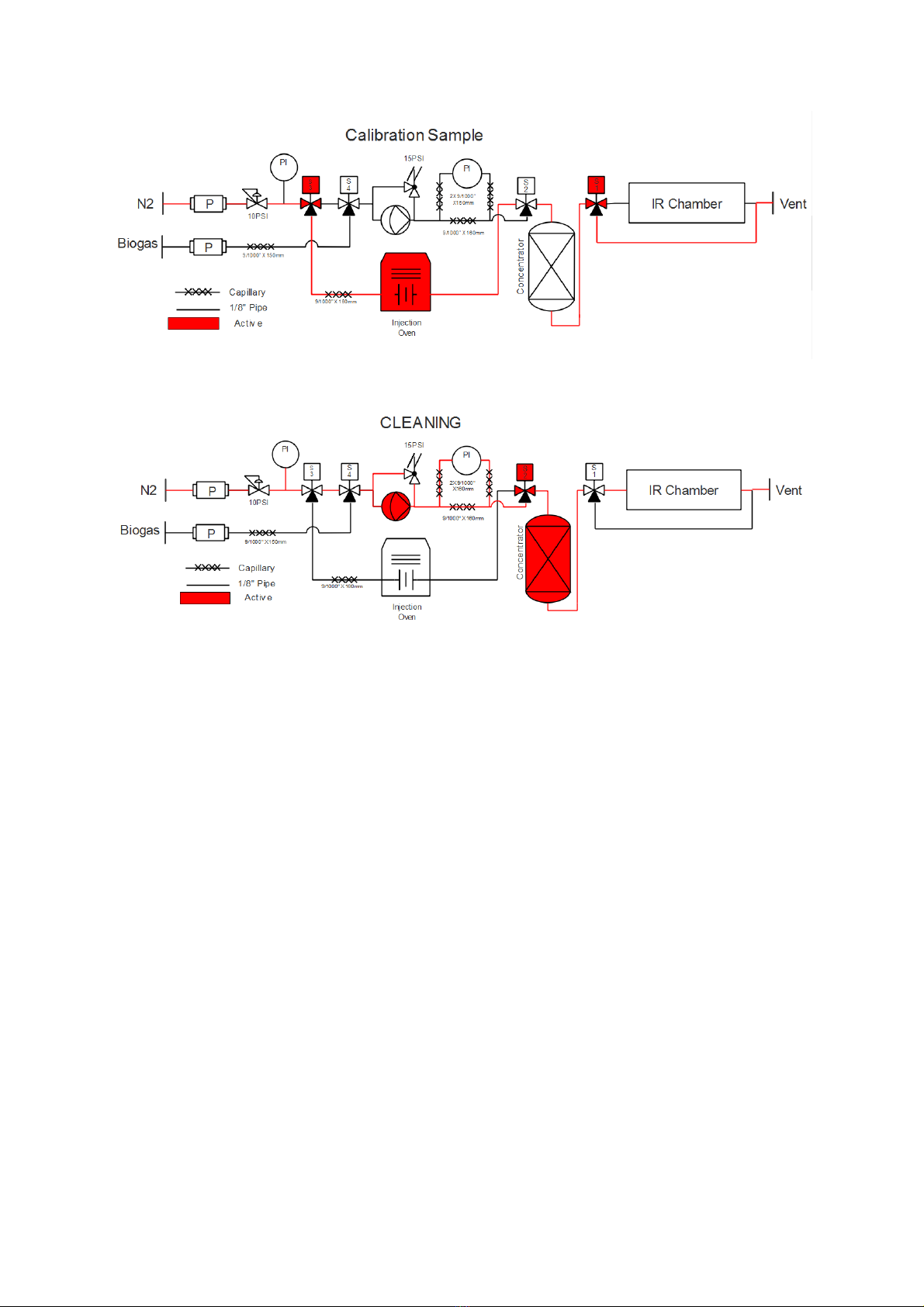

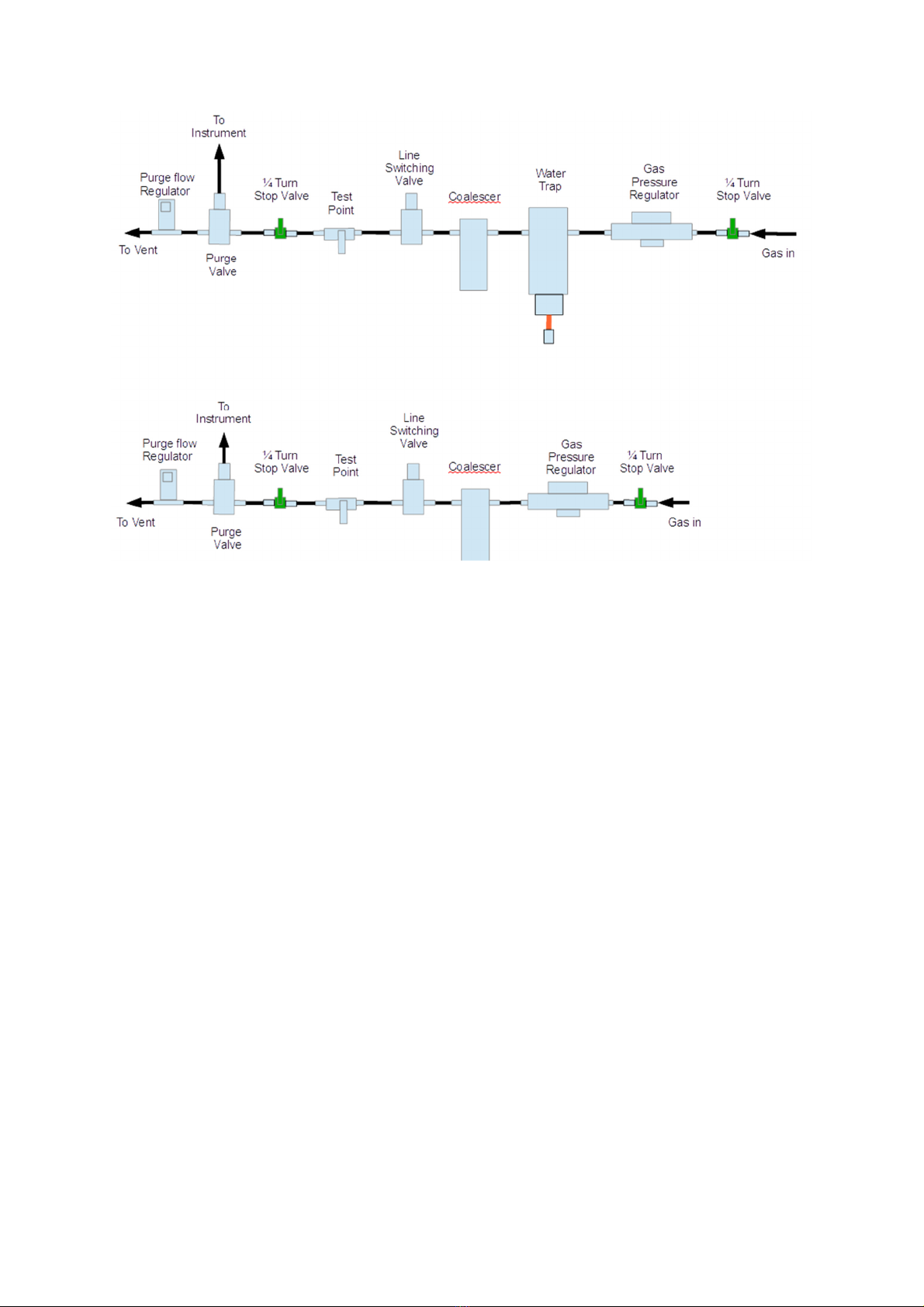

9.0 FLOW DIAGRAMS

16

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

17

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

18

16/08/2017, STS Instruments Ltd, Service & Maintenance Manual

Other manuals for Siloxane

4

Table of contents