Studer MBC 12-08 User manual

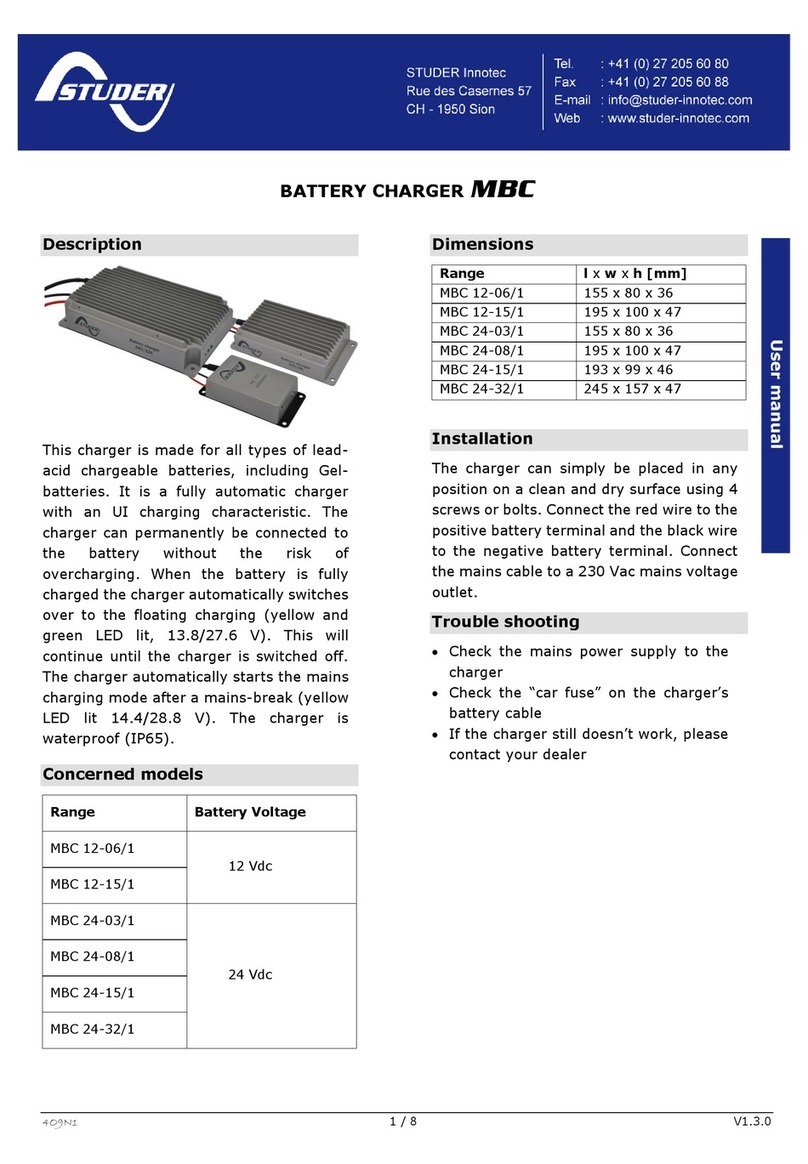

MBC Battery chargers, switch-mode, 3-STEP, IP65

Type MBC 12-06/1 MBC 12-15/1 MBC 24-03/1 MBC 24-08/1

Battery voltage (Vdc) 12 12 24 24

Input voltage (Vac) 100-260 100-260 100-260 100-260

Charge voltage (boost) 14.4 14.4 28.8 28.8

Charge voltage (float) 13.8 13.8 27.6 27.6

Output (Amp.) 6 15 3 8

Cooling Heat sink Heat sink Heat sink Heat sink

Outputs 1 1 1 1

Frequency 40-60 Hz 40-60 Hz 40-60 Hz 40-60 Hz

Efficiency > 85 % > 85 % > 85 % > 85 %

Ambient temp. range -25 to 50°C -25 to 50°C -25 to 50°C -25 to 50°C

Dimensions lxwxh (mm) 155x80x36 195x100x47 155x80x36 195x100x46

Weight (kg) 0.9 1.8 0.9 1.8

Recommanded battery capacity 18-60 Ah 45-150 Ah 9-30 Ah 24-80 Ah

Switch over current (A) 0.17-0.23 0.68-0.92 0.17-0.23 0.34-0.46

Secondary fuse (A) 7.5 20 7.5 15

Input wired (Vac) ✔✔✔✔

Output wired (Vdc) ✔✔✔✔

Warranty 2 years

MBC 12-15/1

MBC Battery chargers, switch-mode, 3-STEP

Type MBC 12-08/2 MBC 12-12/2 MBC 12-25/3 MBC 12-30/3 MBC 12-40/3 MBC 12-60/3

Battery voltage (Vdc) 12 12 12 12 12 12

Input voltage (Vac) 115-230 115-230 115-230 83-280 83-280 83-280

Charge absorption volt. (Vdc) 14.1 (14.4*) 14.1 (14.4*) 14.1 (14.4*) 14.1 (14.4*) 14.1 (14.4*) 14.1 (14.4*)

Charge float voltage (Vdc) 13.5 (13.8*) 13.5 (13.8*) 13.5 (13.8*) 13.5 (13.8*) 13.5 (13.8*) 13.5 (13.8*)

Output (Amp.) 8 12 25 30 40 60

Cooling Natural Fan Fan Fan Fan Fan

Outputs 2 2 3 3 3 3

Frequency 45-66 Hz 45-66 Hz 45-66 Hz 45-66 Hz 45-66 Hz 45-66 Hz

PFC

✔✔✔

Ambient temp. range -20 to +70°C -20 to +70°C -20 to +70°C -20 to +70°C -20 to +70°C -20 to +70°C

Dimensions lxwxh (mm) 155x205x75 155x205x75 155x268x75 272x334x127 272x334x127 272x412x127

Weight (kg) 1.3 1.4 2.3 4.2 4.2 5.4

EMC class EN 55022/B

Warranty 2 years

* GEL batteries MBC12-25/3

Type MBC 12-80/3 MBC 24-12/2 MBC 24-30/3 MBC 24-60/3 MBC 24-80/3

Battery voltage (Vdc) 12 24 24 24 24

Input voltage (Vac) 83-280 115-230 83-280 150-280 150-280

Charge voltage (boost) (Vdc) * 14.1 (14.4*) 28.2 (28.8*) 28.2 (28.8*) 28.2 (28.8*) 28.2 (28.8*)

Charge voltage (float) (Vdc) * 13.5 (13.8*) 27.0 (27.6*) 27.0 (27.6*) 27.0 (27.6*) 27.0 (27.6*)

Output (Amp.) 80 12 30 60 80

Cooling Fan Fan Fan Fan Fan

Outputs 3 2 3 3 3

Frequency 45-66 Hz 45-66 Hz 45-66 Hz 45-66 Hz 45-66 Hz

PFC ✔✔✔✔

Ambient temp. range -20 to +70°C -20 to +70°C -20 to +70°C -20 to +70°C -20 to +70°C

Dimensions lxwxh (mm) 272x495x127 155x268x75 272x412x127 272x495x127 272x495x127

Weight (kg) 7.1 2.3 5.4 7.1 7.1

EMC class EN 55022/B

Warranty 2 years

* GEL batteries

MBC 12-60/3

548/mbc

STUDER Innotec

Rue des Casernes 57

Tel. : + 41 (0) 27 205 60 80 info@studer-innotec.com

CH – 1950 Sion Fax : + 41 (0) 27 205 60 88 www.studer-innotec.com

Pag. 1 MBC 12-08/2, 12-12/2, 12-25/3, 24-12/2

INDEX

Pag. 13 MBC 12-30/3, 12-40/3, 12-60/3, 24-30/3

Pag. 29 MBC 12-80/3, 24-60/3, 24-80/3

REV 000

User’s Manual

MBC BATTERY CHARGER

MBC BATTERY CHARGER

MBC 12-08/2

MBC 12-12/2

MBC 12-25/3

MBC 24-12/2

GB

1

2

Pag. 3-4 Characteristics and Installation

Pag. 5Installation: voltage supply, batteries

Pag. 6Installation: Selecting the charging

method

Pag. 7Operation: Control signal,

Pag. 8Ope characteristicsration: Charging

Pag. 9Operation: Control panel - Maintenance

Pag. 10Technical data

INDEX

GB

CHARACTERISTICS AND INSTALLATION

GB

3

MBC BATTERY CHARGER SERIES BATTERY CHARGER

The long experience we have in the nautical field has given us the ability to evolve the range of MBC

battery chargers, now called MBC BATTERY CHARGER, with superior performance to those currently on the

market. The high level of performance of the MBC BATTERY CHARGER gives a charge to the batteries which

is both fast and safe.

Other important advantages which the MBC BATTERY CHARGER battery chargers offer, are:

• Three stage IUoU battery charging.

• Multiple outputs in order to charge more groups of batteries (internal battery isolator diodes).

• Charge selector for liquid/gel electrolyte batteries.

• Low residual fluctuation on output (ripple lower than 30 mV RMS).

• Compatible with every kind of generator.

• Short circuit, overloading, output overvoltage and overheating protection.

• Can work in a wide range of ambient temperatures.

INSTALLATION

BEFORE USING THE BATTERY CHARGER CAREFULLY READ THIS USER’S MANUAL. IN CASE OF

DOUBT CONTACT THE “STUDER INNOTEC” SUPPLIER OR AFTER SALES SERVICE DEPARTMENT.

THE BATTERY CHARGERS HAS BEEN DESIGNED FOR FIXED INSTALLATIONS (FOR INDOOR USE

ONLY).

“Studer Innotec” battery chargers have been designed and made for the reasons described in this

user’s manual. The “Studer Innotec” Company does not accept any responsibility for direct or

indirect damage caused by improper use of the equipment, bad installation or by possible errors

occurring in this manual.

THE OPENING OF THE BATTERY CHARGER BY UNAUTHORISED PERSONNEL MAKES THE

WARRANTY VOID.

THE PACKAGE CONTAINS: battery charger - warranty card - user’s manual - cable terminals (to be

used for connection to the output terminals).

CHARACTERISTICS AND INSTALLATION

GB

4

INSTALLATION SITE

Install the battery charger in a dry and ventilated place and as near to the batteries as possible. The

battery charger, although having high efficiency, develops a certain amount of heat during function-

ing, therefore, it is imperative that the installation area has sufficient ventilation, enough to allow use

of the equipment at maximum power.

The battery charger can be installed in a horizontal or vertical position with cables coming out in the

downward position. The vertical position is recommended because the natural convection of heat

helps to cool the equipment. The perimeter of the battery charger (except the base) must be kept at

a distance from walls or objects by a minimum of 5 cm.

FIG.1

The cables connected to the output terminals have a maximum length of 4 metres.

WARNING: the battery charger must be used only with a re-chargeable lead/liquid

electrolytic batteries or lead/gel (sealed or non-sealed).

WARNING: the outer surface of the battery charger is used as a heat sink, therefore it may

reach very high temperatures (risk of burns). Leave the equipment to cool down before

handling it.

MODEL

Battery voltage

Battery capacity

Minimum output cable size

MBC 12-08/2 MBC 12-12/2 MBC 12-25/3 MBC 24-12/2

12 V 24 V

35 ÷ 80 Ah 55 ÷ 120 Ah 110 ÷ 250 Ah 55 ÷ 120 Ah

4 mm

2

6 mm

2

10 mm

2

6 mm

2

EQUIPMENT REQUIRED FOR INSTALLATION

On the basis of the type of model, use the batteries and cables on the output terminals as specified

in the following table:

5

INSTALLATION

GB

BATTERY

WARNING: during charge, batteries can generate explosive gases, therefore avoid sparks or

naked flames. Provide adequate ventilation to the battery area whilst charging.

WARNING: before connecting the batteries check the terminals of the cables from the bat-

tery. Reversing the terminals could seriously damage the battery charger even if protected by

fuses.

The positive terminal of the battery or of the group of batteries must be connected to one of the posi-

tive terminals of the battery charger. The negative terminal of the battery or of the group of batteries

must be connected to the negative terminal of the battery charger. To make the connections use the

cable terminals supplied with the equipment.

EQUIPMENT SUPPLY

The equipment already includes a power cable for AC supply. For connections to an AC supply see

fig.2. Before powering up the battery charger check that the power supply voltage, described on the

rating label, corresponds to that supplied by the AC supply source.

In the electrical circuit a two-pole switch must be installed for the sole use of switching the equip-

ment ON & OFF.

The insulation between the contact points of the connections of the AC supply must be at least 3 mm.

The connections to the AC supply must be carried out according to local electrical codes.

WARNING: before connecting or disconnecting the cables from the electrical terminals of the bat-

tery charger, make sure that the equipment is disconnected from the AC mains and the batteries.

WARNING: in cases where the power cable could be damaged, have this changed by a “Studer

Innotec” service centre. In order to avoid accidents, the equipment must only be opened by au-

thorised personnel.

5 cm

5 cm

5 cm 5 cm

FIG.2

battery

n° 2

battery

n° 1

Battery

switches

Blue

Yellow

Green

Brown

Neutral

Earth

Live

SLAVE A MASTER

6

INSTALLATION

GB

SELECTION OF THE CHARGING MODE

The battery charger can be set to optimize the charge according to the type of battery used, either

liquid or gel electrolytic. The selection of the type of charge is made via the switch placed in the ter-

minal board area, as indicated in Fig.3a.

When charging liquid electrolytic, re-arrange the switch to position EL, for batteries with gel elec-

trolytic to the position GEL.

A

V

V

V

2

1

8

9

3

4

5

6

7

5

4

9

-

Vbat

1

27

38

6

MASTER

Slave A

Slave B

FIG.3 b

WARNING: check the charge mode. Incorrect selection

could cause shorter battery life or lengthen the char-

ging time.

FIG.3 a

If the installation has only one or two groups of batteries, always connect the output marked “MAS-

TER”. This is the main outlet of the battery charger.

If the “MASTER” is not connected, the battery charger may supply an output voltage lower than rated.

It is advisable to connect the group of batteries which are used more often (typically the service

group) to the MASTER output terminal.

The positive output terminals which are not used must be kept free (do not bridge the terminals).

WARNING: the use of inadequate size cables and incorrect connection of the terminals or

electrical joints may result in dangerous overheating of the connecting terminals or cables.

BATTERIES

WITH GEL

ELECTROLYTE

BATTERIES

WITH

LIQUID

ELECTROLYTE

TOTAL CURRENT

BASIC STATE

FIG.3.1 FIG.3.2

7

OPERATING

GB

CONTROL SIGNALS (ONLY MBC 12-25/3)

The battery charger has a 9-pin female connector (connector DB9, see fig..4) on which the analog si-

gnals can be seen and used to monitor and control the equipment.

The position and description of the signals on the connector are listed below:

BASIC STATE OF BATTERY CHARGER

Description

Positive MASTER output (650mA max). By drawing 100mA the error is less than 0.7%.

Positive SLAVE A output (650mA max). By drawing 100mA the error is less than 0.7%.

Not connected or if it present, positive SLAVE B output (650mA max). By drawing 100mA the error is less

than 0.7%.

Basic state of battery charger (20 mA max).

Battery charger total current positive shunt (10 mA max). The transduction ratio is 100mV/100A.

GND signal 1 (V master).

GND signal 2 (V slave A).

GND signal 3 (V slave B, if it present).

Battery charger total current negative shunt.

Connection PIN 4

HIGH IMPEDENCE

+ V CHARGE

State

OFF or PROBLEMS

ON WITHOUT PROBLEMS

For a wiring example of control signals look at figure 3b.

Number

1

2

3

4

5

6

7

8

9

The position and description of the signals on the connector are listed below.

CHARGE

POWER

FLOAT

CHARGE

POWER

FLOAT

12345

6789

CONTROL PANEL LED SIGNAL CONTROL

CONNECTOR

FIG. 4

SLAVE A MASTER

8

OPERATING

GB

BULK phase (constant current) - The batteries need more current than the battery charger can sup-

ply. Current is limited to the maximum rated output. The battery charger can enter this phase during

start-up, when the batteries are low or when a high load is connected.

ABSORPTION phase (constant voltage) - The battery charger charges the batteries at a constant

ABSORPTION voltage and at the current they need.

The current needed by the batteries will tend to diminish over time. When the required current is less

than 20% of the maximum output value, the charger will change to the FLOAT phase.

FLOAT phase (maintenance) - The battery charger charges the batteries at the constant FLOAT volt-

age. In this phase, as the batteries reach maximum capacity, they will tend to absorb current close to

zero Ampere. This FLOAT phase will allow the batteries to be on charge without the risk of overload-

ing. The next step to the ABSORPTION phase occurs when the demand for current goes over 20% of

the maximum output value.

CHARGING CHARACTERISTICS

Charging occurs in 3 phases:

OPERATION

When the battery charger is switched on, it automatically selects the optimum charge mode to

best suit the batteries or load connected. The battery charger has a loading characteristic of the

IUoU type.

(V)

14.1 (28.2) [Gel 14.4 (28.8)]

(I)

Imax

20% Imax

BULK ABSORPTION FLOAT NEW CYCLE

TIME

TIME

13.5 (27.0) [Gel 13.8 (27.6)]

9

OPERATING - MAINTENANCE

GB

MAINTENANCE

The battery charger does not need any maintenance. To ensure optimum performance from the

equipment, once a year check the cables and the electrical connections.

CONTROL PANEL

The control panel is made-up of three LEDS:

POWER LED, FLOAT LED and CHARGE LED (BULK, ABSORPTION, see fig.4)

The information supplied by the LEDS are listed below:

POWER LED

FLOAT LED

LED Color

No indication

FLOAT phase - FLOAT charge

Short circuit or overload in output.

Check output cables, the group of batteries and the points of use connected to the battery charger.

LED Status

Description

LED Color

Off No mains power or overheating.

In case of overheating check if the installation of the battery charger is correct.

Switch off and allow the equipment to cool down for at least 10 minutes.

Power ON

Green

Description

Off

Green

Green

Off

Fixed

Flashing

CHARGE LED (BULK, ABSORPTION)

LED Color

No indication

ABSORPTION phase or BULK phase

Short circuit or overload in output.

Check output cables, the group of batteries and the points of use connected to the battery charger.

LED Status

Description

Off

Yellow

Yellow

Off

Fixed

Flashing

10

TECHNICAL DATA

GB

STUDER RESERVES THE RIGHT TO MODIFY THE TECHNICAL CHARACTERISTICS OF THE EQUIPMENT AND THE CONTENTS OF THIS MANUAL WITHOUT PRIOR NOTICE.

MODEL MBC12-08/2 MBC12-12/2 MBC12-25/3 MBC24-12/2

MBC12-08/2 DR MBC12-12/2 DR MBC12-25/3 DR MBC24-12/2 DR

OUTPUT CHARACTERISTICS

Maximum output current(1)

Charge absorption voltage

Charge float voltage

Residual ripple (2)

Charging characteristics

Number of outputs (3)

8 A 12 A 25 A 12 A

14,1 Vdc (14,4 Vdc GEL) 28,2 Vdc (28,8 Vdc GEL)

13,5 Vdc (13,8 Vdc GEL) 27,0 Vdc (27,6 Vdc GEL)

30mV RMS max

Automatic in three stages IUoU

232

Yes, through fuse

Yes

Yes

Yes

207÷260 Vac (207÷260 Vac or 103÷130Vac

(5) (

*

)

)

45÷66 Hz

1,2 A 1,8 A 3,2 A 3,0 A

2,4 A 3,6 A 6,4 A 6,0 A

-20 to +70 °C, with power reduction over +50 °C

Natural Forced, with controlled fan (2 speed)

Max.95% RV without condensation

No Yes No

EN 60335-2-29

EN 55022/B

Aluminium - Cycoloy ®

Anodized - OR5066

155 x 205 x 75 mm 155 x 268 x 75 mm

1,3 Kg 1,4 Kg 2,3 Kg

INPUT CHARACTERISTICS

PROTECTION

Supply voltage (4)

Frequency

Maximum absorption (230 Vac) (6)

Maximum absorption (115 Vac) (6) (*)

CASE

Material

Colour

Dimensions (WxHxD)

Weight

Reverse polarity (7)

Overload

Output short circuit

Overheating

AMBIENT CHARACTERISTICS

Operating temperature

Cooling

Humidity

GENERAL

Connector for remote panel

Safety classification

EMC class

(*)

available early 2005

(1)

Maximum value at normal use or in short circuit.

(2)

At maximum output current on resistive load.

(3)

Each output can supply the maximum value of nominal current. The sum of the currents supplied from each output can not exceed

the maximum nominal value of the equipment.

(4)

Without power derating.

(5)

The battery charger measure the input AC voltage and choose the correct working input range.

(6)

With supply voltage specified as and output current equal to the maximum nominal value.

(7)

The protection could be inefficient in some operative conditions.

Cycoloy ® is a registered trade mark of GE Plastics.

TECHNICAL DATA

205

181

90

135

155

75

MBC BATTERY CHARGER -

DIMENSIONS (mm)

12-08/2

12-12/2

11

12

268

244

90

135

155

75

MBC BATTERY CHARGER -

DIMENSIONS (mm)

12-25/3

24-12/2

REV 001

MBC BATTERY CHARGER

MBC 12-30/3

MBC 12-40/3

MBC 12-60/3

MBC 24-30/3

User’s Manual

MBC BATTERY CHARGER

GB

13

14

Pag. 15Characteristics and Installation

Pag. 17Installation: voltage supply, batteries

Pag. 18Installation: Selecting the charging

method

Pag. 19 Operation: Control signal,

Pag. 20Operation: Charging characteristics

Pag. 21Operation: Control panel

Pag. 22-23Notification signs

Pag. 24-25Programming the battery charger

Pag. 26Maintenance - Technical data

INDEX

GB

CHARACTERISTICS AND INSTALLATION

GB

MBC BATTERY CHARGER SERIES BATTERY CHARGER

The long experience we have in the nautical field has given us the ability to evolve the range of

MBC battery chargers, now called MBC BATTERY CHARGER, with superior performance to

those currently on the market. The high level of performance of the MBC BATTERY CHARGER

gives a charge to the batteries which is both fast and safe.

Other important advantages which the MBC BATTERY CHARGER battery chargers offer, are:

• Three stage IUoU battery charging.

• Multiple outputs in order to charge more groups of batteries (internal battery isolator diodes).

• Differentiated charging for liquid electrolite or gel batteries.

• Integrated fuses inside the battery chargers (one for each output).

• Thermal battery protection (with optional sensors).

• Ability of providing full output power with low supply voltage.

• The possibility of using the battery charger as a power supply without batteries.

• Low residual fluctuation on output (ripple lower than 30 mV RMS).

• Universal AC supply input (280 ÷ 83 Vac, 45 ÷ 66 Hz).

• Power factor (cos ϕ) equal to 1.

• Compatible with every kind of generator.

• Short circuit, overloading, output overvoltage and overheating protection.

• Can work in a wide range of ambient temperatures.

• Variable speed for the cooling fan.

• High-technology control panel.

• Automatic and manual half power mode.

• CAN BUS interface for data transfer.

• Case constructed in stainless steel, Cycoloy®.

INSTALLATION

BEFORE USING THE BATTERY CHARGER CAREFULLY READ THIS USER’S MANUAL.

IN CASE OF DOUBT CONTACT THE “STUDER INNOTEC” SUPPLIER OR AFTER SALES

SERVICE DEPARTMENT.

THE BATTERY CHARGERS HAS BEEN DESIGNED FOR FIXED INSTALLATIONS (FOR INDOOR

USE ONLY).

“Studer Innotec” battery chargers have been designed and made for the reasons described in

this user’s manual. The “Studer Innotec” Company does not accept any responsibility for direct

or indirect damage caused by improper use of the equipment, bad installation or by possible

errors occurring in this manual.

THE OPENING OF THE BATTERY CHARGER BY UNAUTHORISED PERSONNEL MAKES THE

WARRANTY VOID.

THE PACKAGE CONTAINS: battery charger - warranty card - user’s manual - cable terminals

(to be used for connection to the output terminals).

15

INSTALLATION SITE

Install the battery charger in a dry and ventilated place and as near to the batteries as possi-

ble. The battery charger, although having high efficiency, develops a certain amount of heat

during functioning, therefore, it is imperative that the installation area has sufficient ventila-

tion, enough to allow use of the equipment at maximum power.

The battery charger can be installed in a horizontal or vertical position with cables coming

out in the downward position. The vertical position is recommended because the natural

convection of heat helps to cool the equipment. The perimeter of the battery charger (except

the base) must be kept at a distance from walls or objects by a minimum of 5 cm.

CHARACTERISTICS AND INSTALLATION

GB

The cables connected to the output terminals have a maximum length of 4 metres.

WARNING: the battery charger must be used only with a re-chargeable lead/liquid

electrolytic batteries or lead/gel (sealed or non-sealed).

16

FIG.1

PART. A

PART. B

EQUIPMENT NECESSARY FOR INSTALLATION

On the basis of the type of model, use the batteries and cables on the output terminals as

specified in the following table:

MODEL

Battery voltage

Battery capacity

Minimum output cable size

MBC 12-30/3 MBC 12-40/3 MBC 12-60/3 MBC 24-30/3

12 V 24 V

140 ÷ 300 Ah 180 ÷ 400 Ah 270 ÷ 600 Ah 140 ÷ 300 Ah

10 mm

2

16 mm

2

25 mm

2

10 mm

2

17

BATTERIES

To access the output terminals it is necessary to remove the cover by loosening the two screws

which hold it on top (see fig. 1 Part A). Before making the connections to the cables from the bat-

tery, loosen or remove the cable clamps by loosening the screws which fix it to the base (Fig.1

Part B).

WARNING: during charge, batteries can generate explosive gases, therefore avoid

sparks or naked flames. Provide adequate ventilation to the battery area whilst charg-

ing.

WARNING: before connecting the batteries check the terminals of the cables from the

battery. Reversing the terminals, could seriously damage the battery charger even if pro-

tected by fuses.

INSTALLATION

GB

EQUIPMENT SUPPLY

The equipment already includes a power cable for AC supply. For connections to an AC supply

see fig.2. Before powering up the battery charger check that the power supply voltage, de-

scribed on the rating label, corresponds to that supplied by the AC supply source.

In the electrical circuit a two-pole switch must be installed for the sole use of switching the

equipment ON & OFF. The insulation between the contact points of the connections of the AC

supply must be at least 3 mm. The connections to the AC supply must be carried out according

to local electrical codes.

WARNING: before connecting or disconnecting the cables from the electrical terminals of

the battery charger, make sure that the equipment is disconnected from the AC mains and

the batteries.

WARNING: in cases where the power supply cable could be damaged, have this

changed by a “Studer Innotec” service centre. In order to avoid accidents, the equip-

ment must only be opened by authorised personnel.

5 cm

5 cm

5 cm

5 cm

FIG.2

battery

n° 3

battery

n° 2

battery

n° 1

Battery switches

Blue

Yellow

Green

Brown

Neutral

Earth

Live

SLAVE B SLAVE A MASTER

18

INSTALLATION

GB

The positive terminal of the battery or of the group of batteries must be connected to one of the

positive terminals of the battery charger. The negative terminal of the battery or of the group of

batteries must be connected to the negative terminal of the battery charger. To make the con-

nections use the cable terminals supplied with the equipment.

If the installation has only one or two groups of batteries, always connect the output marked

“MASTER”. This is the main outlet of the battery charger.

If the “MASTER” is not connected, the battery charger may supply an output lower voltage than

rated and therefore less power.

It is advisable to connect the group of batteries which are used more often (typically the ser-

vice group) to the MASTER output terminal.

The positive output terminals that are not used must be kept free (do not bridge the terminals).

WARNING: the use of inadequate size cables and the incorrect connection of terminals

or electrical joints may result in dangerous overheating of the connecting terminals or

cables.

83

1

6

7

8

9

2

3

4

5

BASIC STATE

C

A

N

1

C

A

N

1

CONTROL SIGNALS

The battery charger is provided with a 9-pin female D-shell connector (DB9 connector, see

Fig. 3a) which indicates the signals which can be used for monitoring and controlling the

equipment.

FIG.3 a FIG.3 b

This manual suits for next models

15

Table of contents

Other Studer Batteries Charger manuals

Studer

Studer Xtender XTH 5000-24 User manual

Studer

Studer XPC 1400-12 Operating manual

Studer

Studer C2324 COMPACT Operating manual

Studer

Studer COMPACT C 1600-12 Use and care manual

Studer

Studer XP-COMPACT XPC 1112 Operating manual

Studer

Studer HP-COMPACT HPC 2512 Operating manual

Studer

Studer Cable Cover CFC-01 Use and care manual

Studer

Studer COMPACT C 1600-12 Operating manual

Studer

Studer HP-COMPACT HPC 2800-12 Use and care manual

Studer

Studer MBC User manual