Manual, Robotic Electric Tool Changer, QC‑18

Document #9620‑20‑B‑18 Electric Tool Changer‑06

Pinnacle Park • 1031 Goodworth Drive •Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-6

US Patent No.: 8,132,816 B2

2. Installation

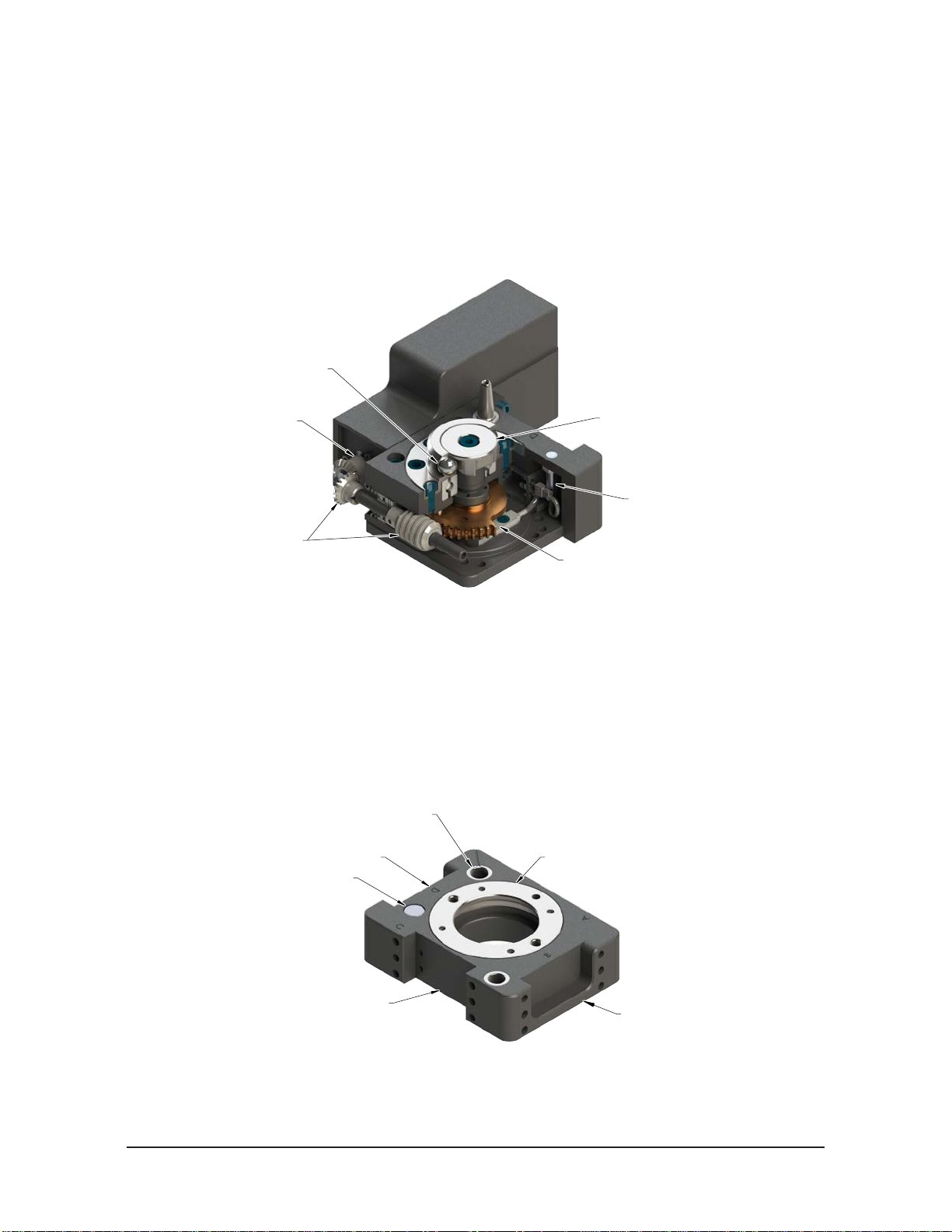

The Master plate assembly is attached to the robot arm and may require an interface plate to match mounting

patterns or create space to accommodate hollow wrist utilities. The Tool plate assembly is attached to the tooling

and may require an interface plate to match mounting patterns (refer to Section 8—Drawings for specific mounting

pattern details).

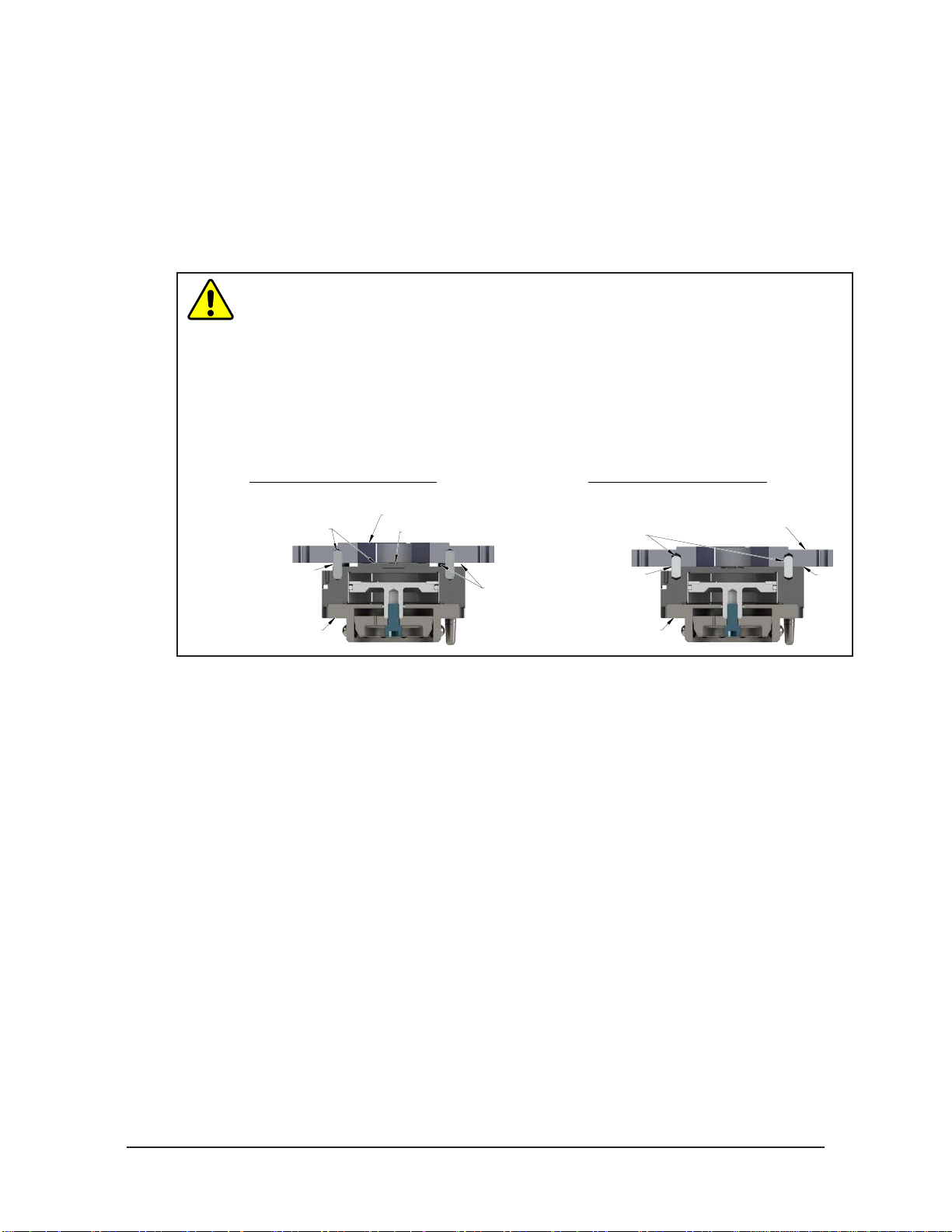

WARNING: Do not use lock washer under the head of the mounting fasteners or allow the

mounting fasteners to protrude above the mating surfaces of the Master and Tool plates.

Allowing fasteners to protrude above the mating surface will create a gap between the Master

and Tool plates and not allow the locking mechanism to fully engage, this can cause damage

to equipment or personal injury. Make sure the mounting fasteners are flush or below the

mating surfaces of the Master and Tool plates.

Head of Mounting Fastener Must Be Flush or

Below Mating Surface. (Do Not Use Lock

Washer under Head of Mounting Fastener).

Mating Surface

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (for example:

electrical, air, water, etc.) are turned off, pressurized connections are purged and power

is discharged from circuits in accordance with the customer specific safety practices and

policies. Injury or equipment damage can occur with the Tool not placed and energized

circuits on. Place the Tool in the tool stand, turn off and discharge all energized circuits,

purge all pressurized connections, and verify all circuits are de-energized before performing

maintenance or repair(s) on the Tool Changer or modules.

WARNING: Mounting fasteners must have a thread locker such as Loctite 242 or equivalent

applied to the threads unless they have a pre-applied thread locker. Fasteners may come

loose resulting in injury to personnel or damage to equipment. Use fasteners with pre-applied

thread locker or apply thread locker to all mounting fasteners.

CAUTION: Do not use fasteners that exceed the thread depth in the Tool Changer (refer to

Section 8—Drawings for details on mounting hole thread depth). Secure the Tool Changer

with the proper length fasteners. This is true for both robot and tool interfaces.

Table 2.1—Optional Module Fastener Size, Class, and Torque Specications

Mounting conditions Fastener Size &

Property Class Recommended

Torque Thread Locker

Optional Module or adapter plate to Master or

Tool plate, Supplied Fasteners

M3 x 0.5 Class 12.9

Pre-applied Adhesive or

Loctite 222

Socket head cap 10 in-lbs (1.13 Nm)

Socket at head cap 8 in-lbs (0.9 Nm)

M4 x 0.7 Class 12.9

Socket head cap 15 in-lbs (1.69 Nm)

Socket at head cap 10 in-lbs (1.13 Nm)