Stulz Tecnivel ClimaPac User manual

ClimaPac

Air Handling Unit

Installation, Operation and Maintenance Manual

Reference: IOM_ClimaPac

Version: V2 - EN/11.2020

Original instructions

2© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Contents

1. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1.1 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1.2 Components signs . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Duties of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Transport/Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Delivery of units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Type Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Air Handling Unit design. . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Operation limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. Assembly and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Requirements for the Installation site. . . . . . . . . . . . . . . . . . . . 11

4.1.1 Structure-borne sound insulation . . . . . . . . . . . . . . . . . 12

4.1.2 Space requirements for installation, maintenance and operation12

4.2 Positioning and assembly of the unit . . . . . . . . . . . . . . . . . . . 14

4.2.1 Positioning of the unit . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 Supplied parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.3 Assembly sequence: . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.1 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.2 Connection of drains. . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.3 Air connections. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.4 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.5 Cooling/heating Coils . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.6 Humidifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.7 Heat recovery systems . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.8 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.1 Previous checks and settings . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 First start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4 Plate heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5 Coils (water, direct expansion) . . . . . . . . . . . . . . . . . . . . . . . . 28

6.6 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.7 Unit housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7. Dismantling and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8. EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . 31

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 3

1. Safety

1.1 Marking

1.1.1 Safety signs

threatening danger, grievous bodily harm and death.

dangerous situation, grievous bodily injury.

CAUTION

dangerous situation, light bodily injury.

important information and application notice.

ESD NOTE risk of damaging electronical components.

1.1.2 Components signs

Following signs identify the different components of the unit.

They are used in this manual and on the proper unit in order every section can be quickly identified.

Fan

Empty section Plate heat

exchanger

Cooling coil Damper Run-around

coil

Heating coil Filter Rotary heat

exchanger

Cooling/ heating

coil Silencer Custom section

Humidifier Controller

1.2 Intended use

ClimaPac air handling unit must only be used for ventilation and air conditioning of building.

It includes:

• filtering normally polluted air.

• air cooling.

• air heating.

• air humidifying and/or dehumidifying.

4© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Proper use also includes observance of the operation manual and instructions from the manufac-

turer of the individual components, as well as the inspection and maintenance intervals stipulated by

STULZ Tecnivel.

Any use other than that described above is considered improper. If necessary, check if your units are

suitable for your intended purpose and application. The manufacturer/supplier is not liable for any

damages arising from improper use. The user alone bears the risk.

Misuse particularly includes:

• Conveying any other gases except air.

• Conveying steam or water.

• Coarse filtering and/or filtering any other media except air.

• Chopping up or reducing size of materials.

• Drying out clothing.

• The unit is not suitable for handling abrasive media.

Unless clearly specified by Stulz, the ClimaPac units shall not be used in following cases:

• in explosion-risk areas.

• in rooms with conductive dust.

• in rooms with strong electromagnetic fields.

• in rooms with aggressive atmosphere that may attack plastics or cause corrosion (especially in

atmosphere where zinc is particularly susceptible to corrosion).

ClimaPac units must not be installed in a place accessible to general public.

In case of doubt, please contact Stulz

1.3 Safety Instructions

These operating instructions contain basic information which is to be complied with for installation,

operation and maintenance. They must therefore be read and complied with by the fitter and the

responsible trained staff/operators before assembly and commissioning. They must be permanently

available at the place where the system is used.

• Works have to be carried out by competent staff only.

• Safety devices may not be bypassed.

1.4 Duties of the operator

The operator must ensure that all maintenance, inspection and assembly work is carried out

by authorized and qualified specialist staff who have made an in-depth study of the operating

instructions.

Independent conversion and manufacture of replacement parts.

The system may only be converted or modified after consultation with STULZ. Original replacement

parts and replacement parts/accessories authorized by STULZ are an aid to safety.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 5

2. Transport/Storage

2.1 Delivery of units

The ClimaPac unit is delivered packed with heat shrinkable plastic film in separated modules as

indicated in the unit drawing. Modules must be assembled together following the instructions of the

part 5. Assembly and installation. In case the unit is delivered completely assembled (to be consulted

with STULZ), the assembly is not required.

If you use a cutting tool (e.g. cutter) to remove the package, take care not to damage

the unit (scratching).

When delivery is accepted, check the unit against the consignment papers for

completeness and for external damage and record it on the consignment note in the

presence of the freight forwarder.

• You receive the consignment papers with the delivery of the A/C unit.

• The shipment is made ex works, in case of shipment damages, please assert your

claim towards the carrier.

2.2 Transport

Mortal danger by crushing.

A defective lifting device can lead to the uncontroler fall of the A/C unit.

Do not stay under suspended loads!

Service doors must always be closed during transport.

The ClimaPac unit can be moved by lifting devices with belts or ropes.

In order to ensure a safe craning of the units, instructions here below must be followed:

• Mount approriate shackles on the lifting lugs on the base frame.

• Use crossbeams with the appropriate width to prevent the sling to rub against the unit.

• With weatherproof units, make sure the protruding parts of the roof are not damaged by the lifting

gear.

• Do not lift any other loads together with the module/unit which is to be transported.

All the local standards and regulations about crane transport must be observed.

6© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Accessories required to transport the unit (crossbeams, shackles, slings/ropes) are

not supplied by STULZ.

Detail of the

attachment system

Transport of several modules fixed together

Transport of individual module

Crossbeams

Eye bolt dimensions:

W= 40 mm

Ø = 34 mm

Lifting gear

For transportation of modules or complete unit, lifting gear must be attached to all

eyebolts of the baseframe.

2.3 Storage

If you put the unit into intermediate storage before the installation, the following measures have to be

carried out to protect the unit from damage and corrosion:

• Make sure that the water connections are provided with protective hoods.

• The stotage point must be dry and not exposed to direct sunlight. Recommended storage condi-

tions are as following:

• Temperature [°C]: -10 - +50

• Humidity [% rel. h.]: 5 - 95, without condensation.

• Units equipped with a steam humidifier must be stored in a place protected from frost.

• The unit should be stored packaged to avoid the risk of corrosion especially of the heat exchanger

fins.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 7

Accessories required to transport the unit (crossbeams, shackles, slings/ropes) are

not supplied by STULZ.

Detail of the

attachment system

Transport of several modules fixed together

Transport of individual module

Crossbeams

Eye bolt dimensions:

W= 40 mm

Ø = 34 mm

Lifting gear

For transportation of modules or complete unit, lifting gear must be attached to all

eyebolts of the baseframe.

2.3 Storage

If you put the unit into intermediate storage before the installation, the following measures have to be

carried out to protect the unit from damage and corrosion:

• Make sure that the water connections are provided with protective hoods.

• The stotage point must be dry and not exposed to direct sunlight. Recommended storage condi-

tions are as following:

• Temperature [°C]: -10 - +50

• Humidity [% rel. h.]: 5 - 95, without condensation.

• Units equipped with a steam humidifier must be stored in a place protected from frost.

• The unit should be stored packaged to avoid the risk of corrosion especially of the heat exchanger

fins.

3. Description

3.1 Type Code

The type code represents the unit variant of your air handling unit and can be found on the type plate.

Type plate (example)

The type plate to be found on the unit may have a different design or additional information.

STULZ TECNIVEL SL

C/ Carabaña S/N - 28925 - Alcorcón Madrid - SPAIN

Tel: +34 915 571 130

E-mail: info@stulztecnivel.com

Producto

Product

Modelo

Model

N º de serie

Seria No.

Tensión de alimentación.

Supply voltage

Año de fabricación

Year of manufacture

Made in Spain

Unidad de tratamiento de Aire

Air Handling Unit

CLIMAPAC - 10.10

CL-000-

400 V ± 10 %

50 Hz ± 1 %

2020

20

Nomenclature

CLIMAPAC -10.10

Product range

ClimaPac

Size

from 10.10 to 75.50

8© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

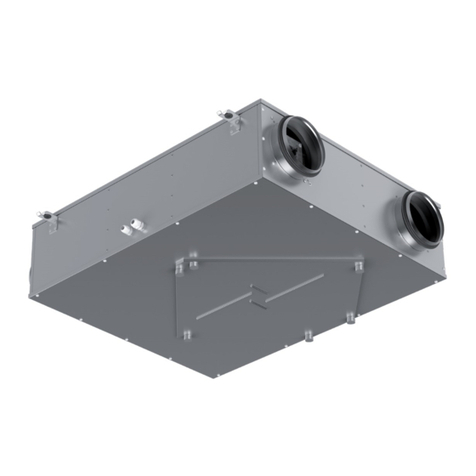

3.2 Air Handling Unit design

ClimaPac air handling units are configured with the TIP selection program and technical sheets pro-

vide technical details of the unit, such as:

• Unit dimensions,

• Description of each component,

• Power consumption,

• Sound levels at unit inlet/outlet,

• Energy efficiency class of the unit,

Particular technical documents (drawings, wiring diagram) of each unit is available on

demand.

Available configurations

In line

In this configuration, there is one single airflow

passing through the AHU.

Inlet air can be 100% fresh air or a mix of

outdoor air and recirculated air.

Front view

Double deck

In this configuration, two separate airflows pass

through the unit, one above the other.

The lower part supplies treated air to the

room (100% fresh air or a mix of fresh air and

recirculated air) and the upper part extracts air

from the room.

A unit in double deck configuration can be

equipped with heat recovery system.

Front view

Side by side

In this configuration, two separate airflows pass

through the unit, one next to the other.

The lower part supplies treated air to the

room (100% fresh air or a mix of fresh air and

recirculated air) and the upper part extracts air

from the room.

A unit in double deck configuration can be

equipped with heat recovery system.

Top view

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 9

Available sections

Example: double deck ClimaPac with rotary heat exchanger.

1. Regulation damper

Controls teh airflow passing through the AHU.

2. Filters section

In this section, air passing through the unit is filtered.

Different types of filters are available (pre-filters, bag filters, compact filters) with different

filtration levels. Slide in/out mounting for maintenance from the side of the unit is available

(up to size 20.10)

3. Heat recovery section

In this section, energy is taken from the return air and transferred to the supply air.

Heat recovery systems available are plate heat exchanger, rotary heat exchanger and

run-around coils.

4. Fan section

In this section air is driven through the AHU by the fan.

Fans are Plug-fan type with AC or EC motor.

5. Coil section

In this section the air is heated up or cooled down by a heating/cooling coil.

Coils can be water type or direct expansion (DX).

6. Humidifier section

In this section air is humidified by a humidifier.

Two types of humidifiers are available (evaporative pads and steam humidifiers)..

7. Sound attenuation section

In this section, sound level is reduced by a silencer.

Silencers are available with length from 600 mm up to 1800 mm according to the needs.

8. Sound attenuation section

Each unit can be equipped with a controller and electrical cabinet, mounted inside or

outside the AHU.

Technical sheet of the control (sensors, control sequences) is supplied with the technical

documentation of each unit.

Controller’s manual is provided in a separate document.

10 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

3.3 Operation limits

Outdoor air:

Lower limit Upper limit

Temperature -15ºC 70ºC

Return air:

Lower limit Upper limit

Temperature 0ºC 70ºC

Water supply

Lower limit Upper limit Max. Water pressure

Cooling/ heating coil 5ºC 90ºC 10 bar

Steam humidifier -40ºC 10 bar

Evaporative pad -25ºC 6 bar

Standar supply voltage*

Voltage 380 - 415V / 3ph / 50Hz; PE

Voltage tolerance ± 10%

Frequency Tolerance ± 1%

*Other supply voltages are available on demand.

Further information on the operation and storage conditions limits is available in the specific manual of

each component (available on demand).

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 11

4. Assembly and Installation

4.1 Requirements for the Installation site

The ClimaPac units is designed to be installed on a level foundation (concrete base or steel beam).

Uneven or insufficient foundation or a bad positioning of the unit on the foundation

can lead the unit to overturn.

See foundations requirements for a correct installation.

Risk of explosion.

The unit may be not operated in an explosive atmosphere!

• The base on which the unit is to be installed must be level, flat and of adequate load-bearing

capacity.

• The whole baseframe of the unit must rest on the base and make full surface contact with it.

• The minimum height of the base must correspond to the siphon height (for siphon calculation see

4.3.2 Connection of drains).

• In case of using strip foundations, additional cross supports are required at the beginning and end

of the unit, as well as at the joints between unit sections.

• The whole baseframe of the unit must rest on the base and make full surface contact with it.

• In case of using strip foundations, additional cross supports are required at the beginning and end

of the unit, as well as at the joints between unit sections.

• Pad or point contact is not permissible.

• Children, unauthorized persons and animals may not have access to the installation site of the AHU

• Take into account the necessary clearances for the maintenance and the air flow (see 4.1.2 Space

requirements for installation, maintenance and operation).

12 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

4.1.1 Structure-borne sound insulation

In order to insulate the supporting structure from the vibrations produced by the unit, it is

recommended to use suitable anti-vibration mounts, such as rubber strip.

Installation on concrete base. Installation on steel beam.

Unit’s baseframe

Vibration

absorber

Steel beam

Concrete base

Vibration absorber must be installed according to the instructions of the manufacturer.

4.1. 2 Space requirements for installation, maintenance and operation

The minimum space necessary for installation, operation and maintenance is one unit width on the

operator side, as indicated on the sketch below:

Space requirements.

If the unit is to be installed against a wall or back-to-back with another unit (see sketches below),

modules must be assembled together before positionning the unit in its final location.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 13

Installation against the wall.

Installation back-to-back.

If no ductwork is connected to the air intake/exhaust, a sufficient clearance must be left in the air

intake area in order to ensure a good air circulation, as indicated on the sketches below.

OUTDOOR AIR

≥W

Clearance in the air intake area.

14 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Duct work must be installed by qualified staff.

Weatherproof units must not be used for structural functions or as part of the roof

for the building.

4.2 Positioning and assembly of the unit

4. 2.1 Positioning of the unit

Transport each module with a lifting gear according to the chapter 2.2 Transport and place it in its

final position according to the drawing.

Before assembled the modules together, check the following points:

- Every module is provided with rubber strip, in order to ensure a correct tightness between 2

modules (installed in factory).

- All fixing elements, drilled holes are perfectly placed in order all the modules can be fixed together.

Risk of crushing limbs.

A defective lifting device can lead to the uncontrolled fall of the A/C unit.

Do not stay under suspended loads! Wear safety boots.

4.2.2 Supplied parts

The following parts, necessary for assembly, are supplied with the unit:

• Fixing elements assembly: DIN 912 Hex Socket Cap Screws, M8 30mm + hex nuts, M8.

• Base assembly: Hex Screws, M8 20mm + Hex nuts, M8.

• Upper/lower module assembly: DIN 7976 Hex set screws, 6,6 19 mm.

• Roof assembly (outdoor units):

• Rivets.

4.2.3 Assembly sequence:

Aluminium profiles assembly

• Insert first the M8 nuts in the joining element and then insert the M8 30 mm Hex socket cap

screw in the other part of the fixing element.

• Tighten the screw with the Allen key.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 15

Fixing element

Module 1

Module 2

Assembly of modules.

Lower baseframe assembly

• Insert first the M8 20 mm Hex screws in the fixing element of the baseframe and secure it with

the M8 nuts.

Screws/nuts

Module 1 Module 2

Assembly of baseframe.

Intermediate baseframe assembly

• The intermediate baseframe (if existing) of the double deck units must be fixed to the aluminium

profiles of the lower modules with the DIN 7976 Hex set screws.

Lower module

DIN 7976 Hex set screw

Upper module

Intermediate

baseframe

Assembly of intermediate baseframe.

16 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Roof assembly (units for outdoor installation)

• Make sure all modules are correctly assembled and drilled holes in the roof of module 1 are

perfectly facing drilled holes of module 2.

• Insert the rivets in the drilled holes and secure them with a rivet gun.

Rivet

Module 1 Module 2

Assembly of roof on two adjacent modules.

Units with a width ≤ 1500 mm are equipped with a single-pitch roof and units with a width

> 1500 mm are equipped with dual-pitch roof.

4.3 Installation

This chapter gives general guidelines for the connection of the different components of the unit.

Detailed installation and maintenance instructions can be found in the specific manual of each

component.

4. 3.1 Electrical connection

Before working with electrical wires, make sure they are de-energized.

Electric cables are only to be connected by authorized specialist.

Before connecting electrical wires, check the following points:

• The unit must be equipped with an earth connection.

• Power supply specifications (voltage, frequency) match the indication on type plate and/or indica-

tions on wiring diagrams supplied with the unit.

• Components and cables are in good conditions.

Electrical components such as air heaters, electric motors, actuators, etc. must be connected accord-

ing to manufacturer’s specifications, local standards and regulations.

General recommendations regarding electromagnetic interferences (earthing, cable length, shielded

cables, etc.) must be observed.

Cables used for wiring work (cross section, length, layout) must be chosen according to electric speci-

fications of the unit (available on the electrical data sheet on demand) and must be in accordance with

local requirements.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 17

Units with electrical cabinet:

Only the main switch, located in the electrical cabinet is to be connected to the power supply accord-

ing to the wiring diagram of the unit.

The electric cable must be introduced into the electrical cabinet from below, passing it through the

hole drilled on the lower part of the cabinet.

Modules must be electrically connected using the special connectors, as shown below

Connector for electrical connection of modules

Units without electrical cabinet:

Each electric component of the AHU must be connected to the power supply separately.

Electrical wiring must be performed according to the wiring diagram supplied with the unit and spe-

cific documentation of each component.

If a connection box is provided on the outside of the unit for wiring, cables must be connected inside

it, passing them through the hole on the side of the box.

If no connection box is provided on the outside of the unit for wiring, cables must be connected

directly to the connection box of the component, passing them through the cable gland on the unit’s

panel.

Each electrical component must be provided with appropriate safety device to protect it and the per-

sons in contact with it against events such as: electrical contacts, overloads, short circuits, moving

elements and burns.

The electrical installation must comply with directives and regulations in force in the country where it

is made.

Although installation and safety devices are under the responsibility of the installation’s owner, follow-

ing recommendations must be taken into account:

Regarding the motors, we recommend to use adjustable protection devices against overcurrent (short

circuits) and overvoltage (circuit breakers or magnetic starters), which must be set to the maximum

current of the motor to avoid damages.

If the motor is equipped with thermal protection, they must be appropriately connected.

For other electric components, we recommend to use protection devices against overcurrent (short

circuits) and overvoltage (magneto-thermal switches or fuse).

18 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Further information about electrical wiring can be found in the installation and

maintenance manual of the electrical components (available in separate documents).

4.3.2 Connection of drains

Components using water (evaporative pads humidifiers, water coils) are provided with a drain for emp-

tying it (e.g. condensate pan).

To avoid any trouble due to the pressure (positive or negative) in the sections where there is a drain,

every water outlet must be provided with a siphon of sufficient height to overcome the static pressure

of the unit, as explained below:

The minimum height of the siphon must be equal to 2H, calculating H according to the following

formula:

H (mm)= P(Pa)

10

P: total pressure (positive or negative) of the unit fan:

Siphon for positive pressure. Siphon for negative pressure.

In order the siphon works properly, do not connect several water outlets to the same

siphon.

© STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications 19

4.3.3 Air connections

Ductwork must have independent supporting devices.

ClimaPac unit cannot be used for supporting the Ductwork.

In order to avoid the transmission of noise to the structure, the connection between the ClimaPac and

duct-work must be free of tensions, using flexible duct connectors.

The length of the flexible duct connection once mounted must always be smaller than its maximum

length.

Dimensions of the duct connection frames are indicated in the technical sheet of the unit.

4.3.4 Fans

Plug fans with AC motors are mounted on anti-vibration springs. To avoid the fan to move during

transport and installation, 4 transport brackets are used to fix the fan structure to the steel support.

These brackets (in red in the following picture) must be removed before the first start-up of fans.

Transport bracket

4.3.5 Cooling/heating Coils

Water coils

To close the water circuit you must connect the unit to a chilled water ring mains, which contains

either a chiller or a dry cooler or cooling tower for the generation of cold water. Details of the water

coils connection are given in the table below.

Inlet/Outlet Draining

Diameter Connection Diameter Connection

Up to 2,0” External thread

1 1/2’’ External thread

Greater than 2,0” Grooved for mounting

Victaulic type flange*

*Flange is not supplied by Stulz

20 © STULZ Tecnivel – all rights reserved

EN/11.2020 Technical data subject to modifications

Air Handlers Units

ClimaPac Series

Connecting the unit to the external system

Water remaining from the test run may escape when the protective caps are removed.

• Rinse thoroughly water lines of the external system to ensure water entering the water coil is clean

and free of particles.

• Remove the protective caps of the pipes inlet and outlet.

• Fix the lines of the external system to the lines of the unit. Water inlet/outlet and connection type

are indicated in the table above.

• Insulate the water pipes with the diffucion tight insulating material, to prevent the introduction of

ambient air heat and the formation of condensate at the pipes.

Make sure the external system lines don’t put mechanical stress on the ClimaPac

connection pipes.

Condensate drain

The condensate water drains must be provided with a siphon (see siphon calculation in 4.3.2

Connection of drains and connected to local waste water system.

If the coil is designed to work with water, the use of an anti-freezing agent might

have an impact on the coil efficiency.

Direct expansion coil (DX)

DX coils are filled with dry nitrogen in factory. When removing the protective caps, the gas shall

escape emitting a hissing noise.

If not, it might indicate there is a leakage in the circuit and measured shall be taken.

DX coil is to be connected to the refrigerant circuit by welding (on the outside of the coil section).

The diameters of the connections must be observed in the installation, in order to avoid possible

pressure loss that would decrease the performance.

4.3.6 Humidifiers

Evaporative humidifier

Water supply and draining (located outside of the unit) are to be connected according to the following

table:

Water supply Water type Draining

Diameter Connection Diameter Connection

½’’ External thread Tap water or threated water 25 mm PVC female/glue

Table of contents

Popular Air Handler manuals by other brands

Powr-Flite

Powr-Flite PDS1 Operators manual & parts lists

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren KOMFORT EC LW Series Operation manual

Webasto

Webasto BlueCool A-Series operating instructions

Dettson

Dettson Atmos MHD-18 owner's manual

Rheem

Rheem RH1T2417STANAA installation instructions

Panasonic

Panasonic PAW-160MAH3M installation instructions

Exhausto

Exhausto VEX150CF Horizontal HCW instructions

Trane

Trane TAMXB0A24V21DB Installation, operation and maintenance

Vent-Axia

Vent-Axia Lo-Carbon PureAir Home 479090 Installation and wiring instructions

Armstrong Air

Armstrong Air BCE3M 18 installation instructions

Salda

Salda RIRS 400HW 3.0 Technical data

American Standard

American Standard TAM9A0A24V21DA Service facts