Sturtevant Richmont Exacta 1350-TD Series User manual

Sturtevant Richmont P/N 857424 Rev –07/15/2020 1

555 Kimberly Drive, Carol Stream, IL 60188

Phones: 847/455-8677 800/877-1347

Fax: 847/455-0347

E-mail: CustomerService@srtorque.com

Exacta 1350-TD Series Digital Torque and Angle Screwdriver

The Exacta 1350-TD Series Digital Torque and Angle Screwdrivers are designed to work with the Global 400 and Global

400mp process monitors. These wireless tools are designed for industrial assembly use. The tool is completely dependent

on the Global 400/400mp for directions and torque results reporting. Once connected to the Global 400/400mp, the tool

keypad is disabled. This prevents inadvertent operator changes to parameters.

The Exacta 1350-TD Series has four modes of measurement:

•Torque to Angle (T2A)

•Torque With Angle Monitoring (TAM)

•Peak

•Residual Torque

These tools are designed for ease of use. Operators simply apply torque to green, there are no buttons to push. The light

band turns yellow when approaching minimum torque. The display, audible beep, and vibration signal to the operator the

status for each fastening. Exceeding maximum torque causes the light bands to turn red and the audible beep changes to

one long tone. The tool provides the operator with visual, auditory, and kinesthetic guidance.

Details on programming the tool through the Global 400/400mp process monitors are found in the process monitor

manual. There are "how to" programming videos at www.srtorque.com. The Exacta 1350-TD Series does not communicate

with the Global 8.

SAFETY

•ALWAYS wear safety glasses and all other required safety equipment when operating this tool.

•Do NOT exceed the rated capacity of the tool.

•Do NOT use this tool for any purpose other than that for which it was designed and manufactured.

•Never immerse the tool in liquids

Tool features include:

•Backlit LCD graphic display:

Press to increase the displayed value or scroll up

Press to decrease the displayed value or scroll down

Press to go to next screen in sequence or select the highlighted line

⊚

Showing target torque and angle, as opposed to actual

Clockwise target or current torque direction

Counterclockwise target or current torque direction

Either target direction

🔒

Keypad locked

Battery charge level

•Status indicators –LEDs, buzzer, handle vibration

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 2

BATTERY AND BATTERY CHARGER

Use of any batteries not meeting SR NiMH rechargeable battery requirements could electrically or physically damage the

tool and immediately voids the warranty.

Battery Requirements

Use one AA NiMH rechargeable battery, 1400 to 2700 mAh. Using a battery with a higher mAh rating will result in longer

life in the tool.

Battery Installation

Unscrew the battery holder counterclockwise. Insert a fully charged battery in the holder. Screw in the battery holder

clockwise until snug. Do not overtighten.

OPERATING INSTRUCTIONS

Getting Started

When powered on, the tool will begin a startup routine and display:

oZeroing angle.

(For best results, set the tool on a hard surface to allow the angle sensor to zero.)

oSturtevant Richmont logo.

oIdentification screen displaying the model and firmware version.

oRadio ID.

oAt this point, if the tool has not been learned into a controller or a parameter has not been selected for it,

the following screen will be displayed.

Otherwise, the sequence will continue as follows.

oAn idle screen similar to the following will be displayed. The information displayed is different for each

mode of operation.

ZEROING ANGLE

DO NOT MOVE TOOL

TD1350-100

V1.00

TOOL DISABLED

🔒

🔋

TAM

12.50

IN

OZ

⊚

RADIO ID:

1234

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 3

General Operation

Three phases of operation are repeated for each joint:

1. Idle: showing the measurement mode and target; waiting for torque.

2. Torque Applied: showing the Measurement Screen.

3. Torque Released: showing the Measurement Screen and waiting to clear.

Idle Screen

As shown below, the Idle Screen is somewhat different for each mode. Residual mode doesn’t show target values. The

target angle, not torque, is shown for T2A mode. Angle values are shown white-on-black.

Measurement Screen

•When torque is applied, the Measurement Screen replaces the Idle Screen.

•The large digits show the current peak torque or angle depending on the mode.

•The current angle of rotation is shown white-on-black.

•Status is shown for torque and for angle –OK, HI, or LO. (The target icon disappears.)

•Direction of measured torque is shown (clockwise or counterclockwise arrow).

•When torque is released, the digits show the final torque and angle measured. At the auto-clear timeout, the Idle

Screen is shown again or “TOOL DISABLED” will be displayed if the batch is complete and lock on batch is active.

MODES

Settings Per Mode

The meaning of some settings may change depending on mode.

Peak Mode

Peak mode shows the current peak torque on the tool until torque is released. Torque display begins at 4% of full scale

torque capacity. Yellow LEDs light up in sequence as minimum torque is approached.

•Target Torque –Apply torque to this value to get a green LED.

•Minimum Torque –This is the minimum acceptable torque for the joint. The light band will be yellow and status

OK when this value is met. If torque is between the minimum and maximum settings, it will turn green when

torque is released and the dwell timer has expired.

•Maximum Torque –The light band will turn red and status HI if the peak value exceeds this setting.

Residual Mode

Residual mode shows zero torque on the tool until residual torque is detected, then it shows the residual torque until

torque is released, with an OK status.

•Target Angle –The default is 3°. To look for the torque dip only, set the target angle to 0°.

Two methods may be applied to detect residual torque.

•On a soft joint, apply torque through a small prescribed angle that denotes residual torque has been reached. The

value at that exact angle represents the residual torque that was in the joint. A minimum of 3° is recommended

but may be adjusted to reflect joint behavior.

•On a hard joint, a dip in torque may be detected when the applied torque breaks the joint loose momentarily. The

value at the bottom of the dip represents the residual torque that was in the joint.

Torque To Angle (T2A) Mode

In T2A mode, a joint is tightened to a prescribed target torque. Then the fastener is turned through an additional angle,

intended to stretch the fastener and thus apply clamp load by an amount proportional to the angle.

🔒

🔋

PEAK

12.50

IN

OZ

⊚

🔒

🔋

TAM

12.50

IN

OZ

⊚

🔒

🔋

RESIDUAL

0.0

IN

OZ

🔒

🔋

T2A

123°

⊚

🔒

🔋

TAM

12.50

IN

OZ

⊚

12° OK

12.63

IN

OZ

OK

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 4

The tool will display the target angle in the Idle state. As torque is applied, the measured torque is displayed in large digits,

with an angle of 0°. One yellow LED lights when the Target Torque is reached. The display changes to angle in large digits,

starting at 0°. The other yellow LEDs light up as the angle approaches its target.

•Target Torque –Apply torque to this value to get a yellow LED and start counting angle. This is typically set to the

snug point on the joint (the point at which the head of the fastener has bottomed out).

•Minimum Torque –This is the minimum acceptable torque for the joint.

•Target Angle –This is the minimum acceptable angle. The light band will turn green and status OK when minimum

torque and target angle are met.

•Maximum Angle –This is the maximum acceptable angle. The light band will turn red and status HI if angle exceeds

this setting.

•Maximum Torque –This is the maximum acceptable torque for the joint. While final angle is of primary interest, a

check on final torque may be warranted as well (e.g., to detect a fastener that is too hard to stretch). The light

band will turn red and status HI if the peak value exceeds this setting. Final torque must fall the minimum and

maximum torque settings to be acceptable.

Torque With Angle Monitoring (TAM) Mode

TAM mode is an extension of Peak mode, adding the ability to detect cross-threaded fasteners, double hits on a joint, and

the like. Primarily, it adds the constraint that a fastener must turn through a minimum angle before minimum torque is

reached. TAM mode uses the same settings as Peak mode, plus:

•Snug Torque –This is the torque value at which angle measurement starts. This is typically set to the snug point on

the joint (the point at which the head of the fastener has bottomed out).

•Target Angle –This is the minimum angle needed before minimum torque is reached. The light band will turn red

and status DH (Double Hit) if minimum torque is reached before minimum angle.

•Maximum Angle –This is the maximum acceptable angle. The light band will turn red and status HI if angle exceeds

this setting.

RADIO COMMUNICATIONS - 2.4 GHZ COMMUNICATION OVERVIEW

These tools use the 2.4GHz band for communication with the controller. As with all radio communications, there are limits

on the distance at which reliable bi-directional communication may be obtained. Physical barriers such as steel framing,

sheet metal and other objects that impede radio waves can significantly reduce the reliable communication distance.

Another factor affecting the reliability and distance combination is the radio environment in which the unit will be used.

The controller and torque tool may operate on any of the 12 channels these products use. It is generally best to think about

this even before the unit is installed.

The radio modules in the controllers and torque tooles used with them comply with the IEEE 802.15.4 standard. The

channel numbers loosely match the channels used by the IEEE 802.11b/g WLAN standard. It may be beneficial to use

channels that do not match the channels used by a nearby wireless network. Refer to the controller user manual for the

specific frequencies being used.

Notice that the channels we use have a much smaller footprint than WLAN. Also notice that one WLAN channel radiates

energy onto several of the adjacent WLAN and controller channels. For the most reliable communication between the SR

controller and the tool in an 802.11b/g LAN environment, it is usually best to choose a channel for the controller and tool

that is separated from the channel of the LAN.

ESTABLISHING RF COMMUNICATION WITH SR CONTROLLERS

The transceiver in the controller and the one in the torque tool each have identification numbers. When communication

between the two is first established, the numbers are exchanged and stored in memory. The controller and tool will

thereafter ignore communications from other radios until the number stored in memory is replaced with a different

identification number.

Under all conditions, the controller and the tool to be used with it must be on the same channel. If the channel on the

controller is changed and the channel on the tool is not, they will not communicate or will cease communicating if they

have previously been associated with each other. To establish communication with the controller, it is necessary to follow

the instructions included with the specific controller to be used. Refer to the Global 400 or Global 400mp user manual for

details.

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 5

CALIBRATION

The calibration process for the Exacta 1350-TD Series tools has three sub-processes. The first is testing the tool to

determine the “as found” condition. If the tool is out of calibration, then two subsequent processes are performed;

calibration adjustment to bring the tool into calibration, and subsequent repetition of tool testing to assure that the

adjustments were effective and the results are valid.

We strongly recommend that when performing the calibration process a torque tester of not less than 0.25% Indicated

Value Accuracy be used, and that it be used in conjunction with a mechanical loader to obtain proper loading of the tool.

We recommend that the tool be temperature stabilized before testing and that a fully charged battery be used during the

procedure to assure that the tool does not suffer a loss of power during the process.

To begin any part of the calibration process, the tool must be placed in calibration mode. There are two ways that this can

be accomplished:

1. Press the “CALIBRATE” soft key from the Edit tool screen on the controller. Note: The tool must remain powered

on once the calibration mode is initiated.

2. Establish a direct radio connection with the tool and the SR Connect software application. Before this can be done,

the tool must be unlearned from the controller using the Replace or Forget options. Refer to the controller manual

for details on these processes.

SR CONNECT SETUP

The SR Connect application has the ability to connect to a tool via direct radio communication. The following are basic

instructions to establish the connection. Refer to the SR Connect manual for more details.

Direct Radio Communication

1. Connect the radio dongle to a PC.

2. Open the SR Connect application.

3. Use the “COM Port:” dropdown menu to set the COM port that the radio is connected to.

4. Click “Connect to Dongle”. The button will change to “Connecting to Dongle”. When the dongle is connected, the button

will change to “Disconnect from Dongle”.

5. Type the serial number marked on the tool into the “Tool S/N” field.

6. Click “Learn tool”. The button will change to “Learning tool…”

7. Insert the AA battery into the holder and screw that into the tool.

8. When the learn process is complete, the button will change to “Forget Tool” and the “Tool Model” field is populated.

Verify the “Tool model” is correct.

9. Click “Terminal”.

10. Set the date on the tool by typing “AFmm/dd/yy” into the text boxes (mm is the 2-digit month, dd is the 2 digit day,

and yy is the 2-digit year). Click “Send”.

11. Enter calibration mode by typing “CM” into the text box. Click “Send”.

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 6

CALIBRATION ADJUSTMENT PROCEDURE

1. The tool should display “CALIBRATE WRENCH”, “NO “, “YES ”.

2. Press to enter calibration mode.

3. Enter the CAL PASSWORD using or to change the value of the digit. Pressto move to the next digit. The

default password is “3112”. After all four digits have been entered, press to submit the password.

4. The “CAL HEAD LENGTH” screen is displayed. This is not used with the 1350-TD family. Pressto bypass this screen

and enter torque calibration mode.

5. Tool Display Note

•At this point the tool LCD should display “CAL 0%”, “”, and “0.0 IN LB”.

oNOTE: If there is an offset on the tool that simulates a torque, the target value may not be displayed.

Refer to the Accuracy Tables for the appropriate calibration target values.

•The green LED will flash when the calibration point is captured.

6. Install drive square on torque tester. Place tool with proper bit onto torque tester. Apply three 100% clockwise (CW)

Full Scale (FS) loads to tool.

7. Remove the torque load from tool. Remove tool from tester and hold in vertical position. Press ZERO on tester, then

press on tool to save the zero setting. Replace tool on tester.

8. Press so “CAL 100%”, “”, and the target torque value appear on the display. Apply 100% CW FS load to the unit.

When the tester shows exactly 100% CW FS torque is applied, press on tool to save the value. Unload the tool.

9. Press so “CAL 60%”, “”, and the target torque value appear on the display. Apply 60% CW FS load to the unit.

When the tester shows exactly 60% CW FS torque is applied, press on tool to save the value. Unload the tool.

10. Press so “CAL 20%”, “”, and the target torque value appear on the display. Apply 20% CW FS load to the unit.

When the tester shows exactly 20% CW FS torque is applied, press on tool to save the value. Unload the tool.

11. Press so “CAL -0%”, “”, and “0.0 IN LB” appear on the display. Apply 3 full-scale loads to the tool in the

counterclockwise (CCW) direction.

12. Remove the torque load from tool. Remove tool from tester and hold in vertical position. Press ZERO on tester, then

on tool to save the zero setting. Replace tool on tester.

13. Press so “CAL -100%” “”, and the target torque value appear on the display. Apply 100% CCW FS load to the unit.

When the tester shows exactly 100% CCW FS torque is applied, press on tool to save the value. Unload the tool.

14. Press so “CAL -60%” “”, and the target torque value appear on the display. Apply 60% CCW FS load to the unit.

When the tester shows exactly 60% CCW FS torque is applied, press on tool to save the value. Unload the tool.

15. Press so “CAL -20%” “”, and the target torque value appear on the display. Apply 20% CCW FS load to the unit.

When the tester shows exactly 20% CCW FS torque is applied, press on tool to save the value. Unload the tool.

16. Press so ““, ““, and “SET CAL DATES ”appear on the display. Press to set the calibration date.

17. “NEXT CAL ” and the date “mm/dd/yyyy“ appear on the display. Press to set the date. (The tool is now in Angle

Calibration mode.)

18. Remove the tool from the tester.

19. At this point the tool should display “CAL ANGLE SET 0° “, “DONE “, and “CCW 180° ” with the angle value in

the black background of the display. Place tool on angle calibration fixture with the display to the right.

20. Press to save the 0° value.

21. Rotate the tool CCW 180°, press to save the 180° value.

22. Rotate the tool CW 180°. The angle reading should show 0°. If not, press to save the 0° value again.

23. The sequence of CCW 180° and CW 180° may be repeated to dial in to the recorded values.

24. Pressto exit angle calibration. (The tool is now in Torque Check mode.)

25. Remove the tool from the fixture.

26. Calibration adjustment is complete.

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 7

CALIBRATION VERIFICATION

Calibration Verification Notes

1. The following procedure assumes the tool is still wirelessly connected to the radio dongle. Refer to the SR Connect

Setup section to reconnect if needed.

2. The accuracy tables for each model are located at the end of this document.

3. Perform the procedure in the clockwise direction first, then in the counter clockwise direction.

Calibration Verification Procedure

1. If the tester has not been zeroed in the CW direction, zero the tester and load the tool in the clockwise (CW) direction

to 100% capacity and then unload to 0% 3 times, remove the tool, and zero the tester.

2. Click “Terminal”.

3. If the tool is in Torque Check mode, proceed to Step 8. Otherwise, type “CM” into the text box. Click “Send”.

4. The tool should display “CALIBRATE WRENCH”, “NO “, “YES ”.

5. Press to enter calibration mode.

6. Enter the CAL PASSWORD using or to change the value of the digit. Pressto move to the next digit. The default

password is “3112”. After all four digits have been entered, press to submit the password.

7. Pressuntil the torque check screen appears.

8. The tool is in torque track mode to allow readings to be verified.

9. Pressto advance to the angle check screen.

10. The tool is in angle track mode. The tool displays the number of degrees the tool has been rotated. Press to zero the

angle value on the tool at any time.

11. Pressto exit angle check mode.

CALIBRATION COMPLETION

1. The following procedure assumes the tool is still wirelessly connected to the radio dongle. Refer to the SR Connect

Setup section to reconnect if needed.

2. Disable calibration mode by typing “CF” into the text box. Click “Send’. Click “Done”.

3. Click “Forget tool”.

4. Unscrew the battery holder and remove the battery.

5. Screw the battery holder back onto the tool.

CLEANING

This tool should be cleaned with a soft cloth dampened with water. Do not immerse this tool in liquid or use any solvent

other than water to clean the tool.

CALIBRATION AND REPAIR

Factory calibration from our ISO 17025 Accredited Calibration Laboratory is available. Calibration and verification are

performed using the SR Connect PC application. Contact your SR distributor for details. Parts and factory repair are also

available.

ADDITIONAL INFORMATION

Additional information is available at www.srtorque.com. You can also call customer service at 1-847-455-8677 or send

e-mail to customerservice@srtorque.com.

EXACTA 1350-TD SERIES Operating Instructions

Sturtevant Richmont P/N 857424 Rev –07/15/2020 8

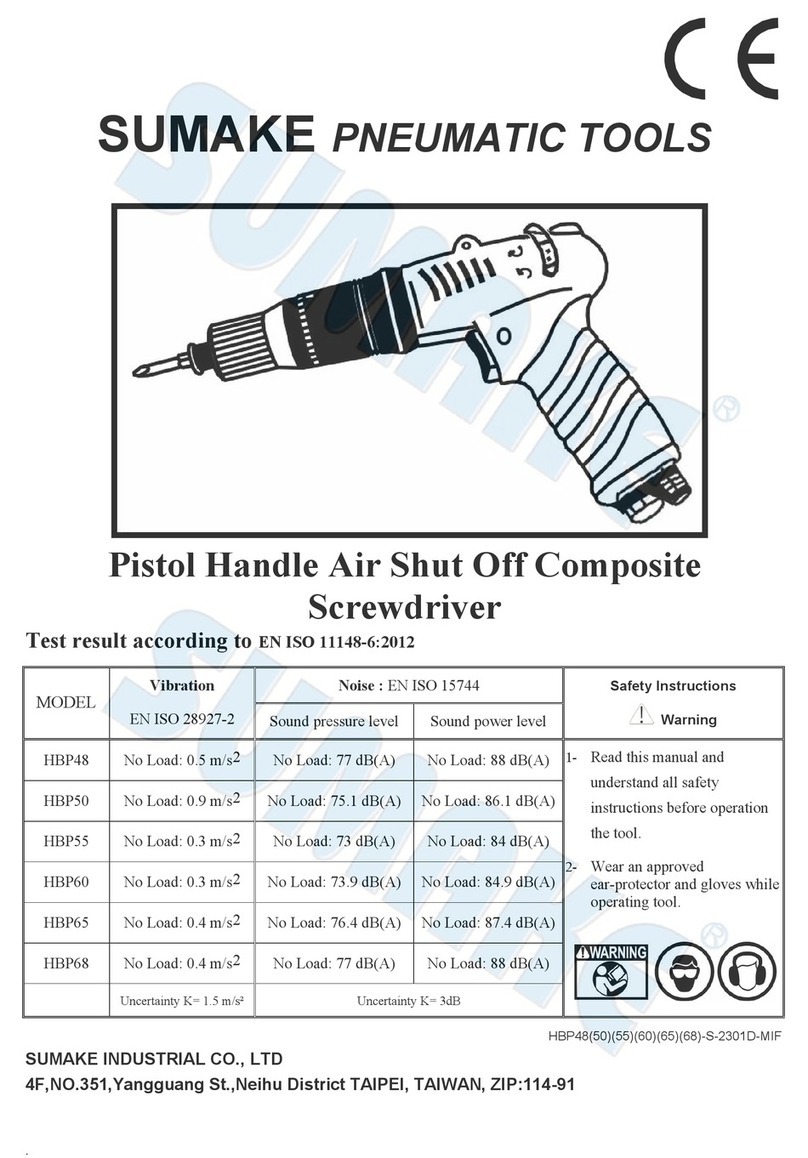

ACCURACY TABLES

Accuracy tables are based on +/-2% tolerance.

Capacity

In.Oz.

% Full

Scale

Torque

In.Oz

+ Tol. -Tol.

10 10 10.2 9.8

20 20 20.4 19.6

30 30 30.6 29.4

40 40 40.8 39.2

50 50 51.0 49.0

60 60 61.2 58.8

70 70 71.4 68.6

80 80 81.6 78.4

90 90 91.8 88.2

100 100 102.0 98.0

100

Exacta 1350-TD100 – 100 Inch-Ounce Capacity

Capacity

In.Lb

% Full

Scale

Torque

In.Oz

+ Tol. -Tol.

10 128 130.6 125.4

20 256 261.1 250.9

30 384 391.7 376.3

40 512 522.2 501.8

50 640 652.8 627.2

60 768 783.4 752.6

70 896 913.9 878.1

80 1024 1044.5 1003.5

90 1152 1175.0 1129.0

100 1280 1305.6 1254.4

80

Exacta 1350-TD80 – 80 Inch-Pound Capacity

Capacity

In.Lb

% Full

Scale

Torque

In.Oz

+ Tol. -Tol.

10 128 130.6 125.4

20 256 261.1 250.9

30 384 391.7 376.3

40 512 522.2 501.8

50 640 652.8 627.2

60 768 783.4 752.6

70 896 913.9 878.1

80 1024 1044.5 1003.5

90 1152 1175.0 1129.0

100 1280 1305.6 1254.4

80

Exacta 1350-TD80M – 80 Inch-Pound Capacity

This manual suits for next models

3

Table of contents

Other Sturtevant Richmont Power Screwdriver manuals

Sturtevant Richmont

Sturtevant Richmont CAL 36/4 User manual

Sturtevant Richmont

Sturtevant Richmont P Series User manual

Sturtevant Richmont

Sturtevant Richmont ExacTorq 100 User manual

Sturtevant Richmont

Sturtevant Richmont PM-36 Use and care manual

Sturtevant Richmont

Sturtevant Richmont PM-5 User manual

Sturtevant Richmont

Sturtevant Richmont ExacTorq 100 User manual

Sturtevant Richmont

Sturtevant Richmont EMTSK 36/4 User manual