S/RP/N:857123C

Issue/Rev.Date:111122

Use of Extensions and Adapters

Onlyin-lineextensionsandadaptersshouldbeusedwiththescrewdriver.Therecommendedmaximum

overallextensionlengthissixinches(6”).

Operation

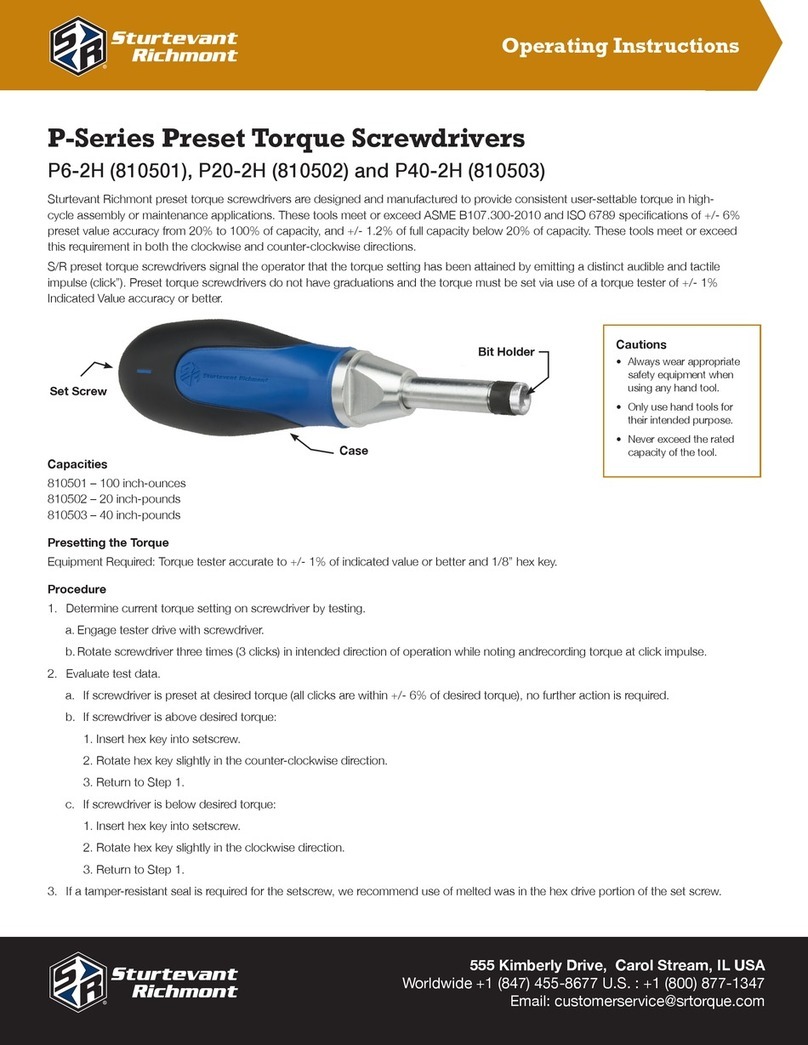

1. Insertappropriatefastenerengagementdevice(bit/adapter/socket)into1/4”femalehexbitholder.

2. Engagefastenerandrotatescrewdriveruntilaudible/tactileimpulse(click)isgenerated.

3. Stoprotatingscrewdriver.Thesettorquehasbeenreachedandfurtherrotationwillnotincrease

appliedtorque.

Care & Cleaning

Whenthetoolisnottobeusedforanextendedperiod,werecommendthatitbesettoitslowestsetting

(20%ofcapacity)priortostorage.Alwaysstorescrewdriverinaclean,dryenvironment.Donotimmerse

screwdriverincleaninguids.Cleanexteriorofscrewdriverwithdampcloth.

Calibration Instructions

RequiredEquipment

• Hexkey(0.50”)forThimblesetscrew

• HexKey(5/64”forKnobsetscrews

• Torquetesterof+/-1%orbetterI.V.accuracyfrom20%to100%oftoolcapacity.

Procedure

1. Screwdrivertestpointsshouldbeat20%,60%and100%oftoolcapacity.Theaccuracyateachtest

pointshouldbe+/-6%ofthesetpoint.Testingsequenceisfromlowesttohighesttestpoint.

2. Adjustscrewdrivertotestpoint.Alignscrewdriverwithtorquetransducerontester.

3. Testtorque.Ifallchecksatalltestpointsarewithintolerance,noadjustmentisneededandthetool

maybereturnedtoservice.Ifnot,gotonextstep.

4. Adjusttoolto20%ofcapacity.Test.Ifreadingsareoutoftolerance,disregardmakingsonshaftof

screwdriverandturnKnobuntilreadingsareintoleranceat20%ofcapacity.Iffineradjustmentthan1

incrementisneeded,removeKnob(nextstep)andadjust.

5. LoosentheThimblesetscrewwiththehex

key.LoosentheKnobsetscrewswiththe

hexkeyandremoveKnob,makingsurenot

tolosethedetentball,lockpinorsprings.

Setpartsaside.Makeanyfineadjustments

requiredbyrotatingKnobstemCWorCCW

toobtainrequiredreadingsat20%ofcapac-

ity.RotatetheThimbleuntiltheedgeofthe

Thimbleisevenwiththelowestsettingline

ontheShaft.RetightenThimblesetscrew.

Placedetentball,lockpinandspringsbackintheiroriginalinstalledpositions.ReinstallKnobwiththe

“0”markontheKnobalignedwiththeArrowontheHandlesopartsnextinadetentrecess.Hold

KnobonhandlewithsufficientforcetokeeppartsinpositionandtightentheKnobsetscrews.Repeat

steps2&3.

Service and Calibration

RepairPartscanbeorderedthroughyourlocalS/Rdistributor.ForthenameofalocalS/Rdistributor,

pleasecontactususingtheinformationonthefrontofthisdocument.Factoryrepairandcalibrationin

ourISO/IEC17025AccreditedCalibrationLaboratorycanbeobtainedby

sendingthescrewdriverandyourinstructionstousatthefactory.