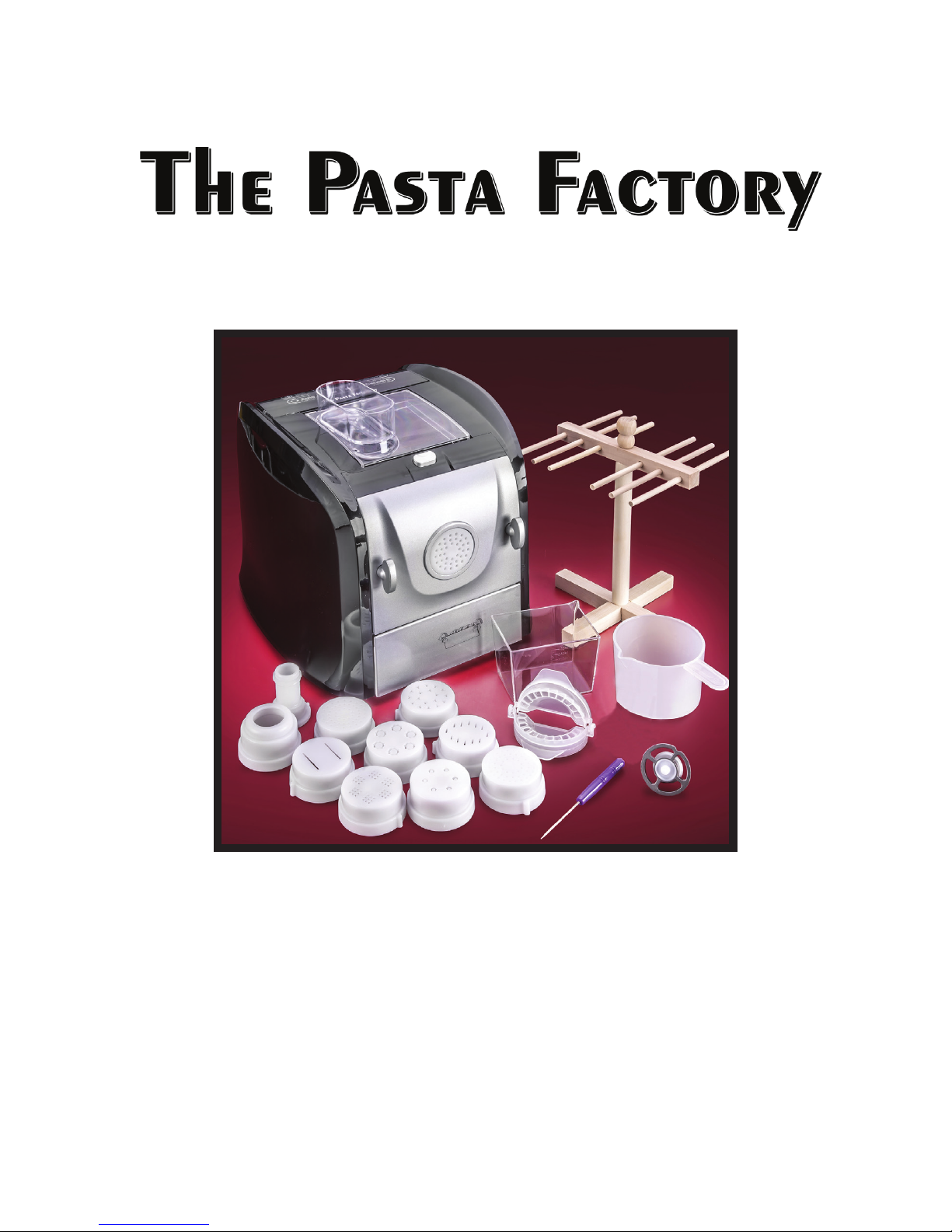

STX International STX-1400-TPF User manual

STX Pasta Factory

Instructions

- 3 -

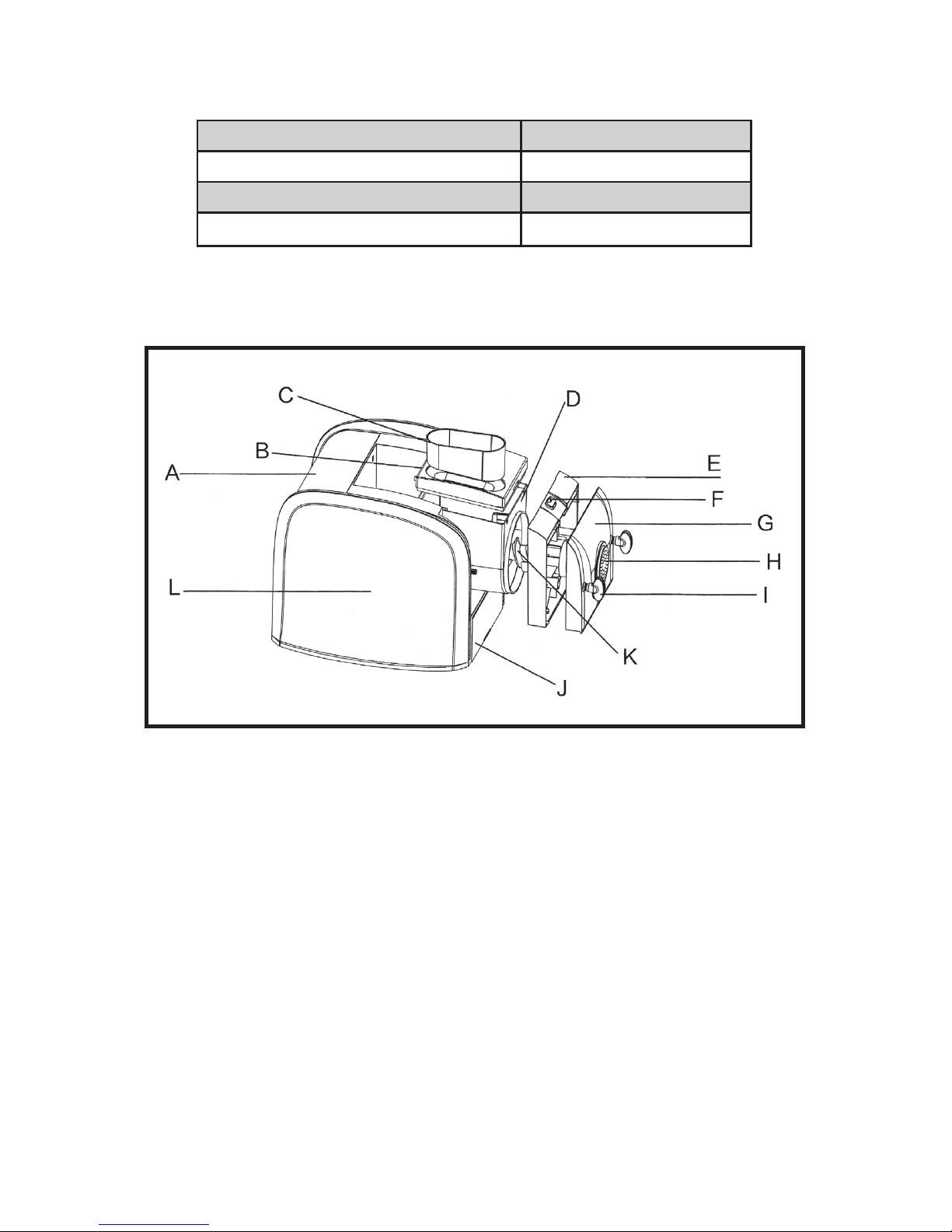

PARTS LIST AND PLACEMENT

A. Control Panel

B. Top Cover

C. Water Injection Dish

D. Mixing Bowl

E. White Inside Front Panel

(with black top edge & release button)

F. Release Button (on top side of white inside front panel)

G. Cast Aluminum Front Panel

H. Pasta Disc

I. Cast Aluminum Locking Nut

J. Pasta Disc Drawer

K. Auger

L. Main Unit

SPECIFICATIONS

Model STX-1400-TPF

Power Supply 110/120 V, 60 Hz

Net/Gross Weight 18.5 lbs../ 23.0 lbs.

Overall Dimensions (L x W x H) 12” X 13” X 12”

- 4 -

PARTS CONT.

Angel Hair Lasagna Linguine Macaroni Penne

Rotini

Adaptor Sausage

Core

Spaghetti Square Vermicelli

Dumpling/

Ravioli Core

Dumpling/

Ravioil Press

PASTA DISCS

Adaptor Dumpling/

Ravioi Core

Adaptor Sausage

Core

+=

+=

Dumpling/

Ravioli Disc

Sausage

Disc

- 5 -

CONTROL PANEL

Water Injection

Dish

Flour Cup Liquid

Measuring Cup

OTHER ACCESSORIES

Cleaning

Pick

Drying RackPasta Cutter

- 6 -

ASSEMBLY

1. Insert the plastic mixing bowl into the groove of the base with the

large round opening facing out and the square opening on the

top.

2. Insert the auger through the front opening of the mixing bowl into

the opening in the back of the base. The auger should securely

attach to the small hole on the interior of the base.

3. Secure the white plastic panel to the front of the base by lining the

appropriate holes up with the screws that are attached to the base

and pushing it back on the base over the screws until it is against

the mixing bowl.

4. Choose the white pasta disc you want to use and insert it into the

back of the metallic front panel. Make sure the tab on the white

pasta disc is inserted into the groove on the front panel.

5. Attach the metallic panel to the screws on the front of the machine

and push the panel in so it is flush against the machine. Secure

the panel by fastening the locking nuts tightly. Leave the locking

nuts in a vertical postion when tightened, this will allow room for

the pasta cutter to easily be used during operation.

6. Place the square plastic cover on top of the machine and push

down to lock it in place.

- 7 -

INGREDIENTS & MEASUREMENTS

Use the following chart to determine the appropriate amount of liquid and

flour to make the perfect noodle consistency.

Batch Size Flour Water Water & Egg Vegetable

Juice

Single 1 cup* 112.5 ml 1 egg + water to

measure 112.5 ml

112.5 ml

Double 2 cups* 225 ml 2 eggs + water to

measure 225 ml

225 ml

*The flour cup included is not equivalent to 1 cup in american standard

units.

Notes:

• When measuring flour with the measuring cup, flatten the scoop with

the pasta cutter to get the precise amount of flour required for the

batch.

• As pasta begins to extrude, coat it with additional flour to prevent it

from sticking.

• Use a tray instead of a bowl to separate the pasta and allow it to dry.

• The first parts of the noodle may be stringy, they will get smoother as

the machine runs.

• Stop and extrude again if machine is extruding too fast.

Choose ONE of the grayed options for liquids

- 8 -

MAKING PASTA

Automatic Method

1. Assemble the machine as described in the Assembly Section of the

manual, making sure to choose the correct pasta disc for the type of

pasta you desire.

2. Open the top of the machine.

3. Measure the flour and add it to the mixing bowl. Do not pack the flour

into the measuring cup. Use the pasta cutter to even out the flour

across the measuring cup. Replace the top cover and lock it in place.

4. Place the water injection dish onto the designated area on the top

cover. Ensure it is placed correctly. The holes in the water injection

dish should be on the opposite side of the holes on the top cover and

when it is placed it will sit level.

5. Put a tray under the extruding holes in the front of the machine.

6. Plug the machine in and the display will turn on.

7. Measure out the liquid so it will be ready - do NOT pour it into the

water injection dish quite yet.

8. Press the Auto button. The auger will begin to turn and the timer will

start for the indicated amount of time.

9. As soon as the mixing process begins, add the water to the water

injection dish. The water is slowly added and mixed into the flour to

make the dough.

10. When mixing is complete, the machine will automatically begin to

extrude the pasta.

11. When the pasta initially starts to extrude from the machine it will be a

little dryer and the noodles will get wetter as it extrudes more of the

dough.

12. As the pasta extrudes from the machine, use the pasta cutter along

the front of the pasta disc to cut the pasta to the length that you want.

Ensure the beveled edge of the pasta cutter is facing out (towards

you) when using it to cut the pasta from the machine.

13. When the machine finishes extracting all of the dough, 4 beeps will

sound and the machine will stop.

14. Unplug the machine when finished.

Note: If at any time you need to stop the machine during the process and

intend to continue (i.e. you wnat to add a little flour and then plan to

continue extruding), just press the release button on the top cover

and the machine will stop. When the top cover is secured again, the

machine will start again where it left off.

- 9 -

Manual Method

1. Assemble the machine as described in the Assembly Section of the

manual, making sure to choose the correct pasta disc for the type of

pasta you desire.

2. Open the top of the machine.

3. Measure the flour and add it to the mixing bowl. Replace the top

cover and lock it in place.

4. Place the water injection dish onto the designated area on the top

cover. Ensure it is placed correctly, it will be a snug fit.

5. Put a tray under the extruding holes in the front of the machine.

6. Plug the machine in and the display will turn on.

7. Measure out the liquid so it will be ready - do NOT pour it into the

water injection dish quite yet.

8. Press the Mix button. The display flashes showing the default time of

4 minutes. You can increase or decrease the amount of mixing time

by pressing the + or - buttons while the time is flashing.

9. After a couple of seconds, the display will stop flashing and the

auger begins to turn - the timer will start.

10. As soon as the mixing process begins, add the water to the water

injection dish. The water is slowly added and mixed into the flour to

make the dough.

11. When the mixing is finished, the machine will beep 3 times.

12. Put a tray under the extruding holes in the front of the machine.

Press the Extrude button. The pasta will begin coming out of the front

of the machine onto the tray.

13. As the pasta extrudes from the machine, use the pasta cutter along

the front of the pasta disc to cut the pasta to the length that you want

it.

14. When the machine finishes extracting all of the dough, 4 beeps will

sound and the machine will stop.

15. Unplug the machine when finished.

Making Egg Noodles

To make egg noodles, follow either pasta making method above with

one exception: Remove the water injection dish from the top cover.

Beat the egg and water in the measuring cup and when it is time to add

water (Step 9 or 10 respectively) slowly pour the liquid directly through

the small holes in the plastic cover on the top of the machine (where

the water injection cup would sit).

- 10 -

Making Sausage

1. Assemble the machine as described in the Assembly Section of the

manual.

2. Select the Adaptor parts and the sausage core from the parts. Insert

the sausage core into the shell and secure the shell to the spiral rod

with the sausage core facing out.

3. Attach the metallic front panel.

4. Add the meat and other sausage ingredients to the bowl and secure

the lid to the top of the machine.

5. Plug the machine in and press Mix. While the time is still blinking,

press the - button to reduce the mixing time to 3 minutes.

6. When the mixing is finished, put the sausage casing over the

sausage core, leaving enough to be able to tie the casing closed

when finished.

7. Hold the sausage casing in place on the sausage core and press

Extrude. The sausage mixture begins filling up the sausage casing.

8. Once the sausage casing is filled, press Cancel to stop the extruding

process.

9. Remove the sausage casing and tie it closed.

10. Repeat with more casings.

11. When finished, unplug the machine.

CLEANING

1. Before cleaning always ensure the power is off and the machine is

unplugged.

2. The mixing bowl, auger, top cover, panels, pasta discs, and locking

nut should all be washed with warm water and a mild detergent (like

Dawn Dishwashing Liquid).

3. The pasta discs will be easiest to clean if you let the dough dry first.

Use the cleaning pick to push out the dried dough from the holes.

Then wash with warm soapy water.

4. The exterior of the machine should be wiped down with a soft, damp

cloth.

5. Dry all parts thoroughly before storing or using.

6. The main unit should not be submerged in water or any other liquid.

7. Store the pasta machine in a cool, dry place.

- 11 -

TROUBLESHOOTING

The machine does not turn on. Check to ensure the machine is

plugged in.

Check to ensure the top cover is

closed tightly.

Check that the locking nuts in the

front of the machine are securely

fastened.

The dough does not extrude. The consistency of the dough is

not right. It may be too dry or too

wet.

If it is too dry you will see mostly

crumbs when you look through

the top cover and none of it will

be sticking together. Add more

liquid.

If it is too wet the dough will be

sticking to the auger and the

machine will make a thumping

noise as the auger rotates the

dough. You can try to add more

flour. Once it gets to this point it

is usually easier to start over, as

the mixing bowl will not be able to

mix the flour in since the dough is

stuck to the auger.

Note: It is easier to add more

liquid if it is too dry than to add

more flour if it is too wet - so start

on the dryer side and add liquid

as needed

Check that the end of the auger

is clean - the pasta disc needs to

fit in tight when the unit is asse-

bled to allow the pasta to ex-

trude. The end of the auger can

be cleaned by using the cleaning

pick to get any dough out.

- 12 -

SAFETY INSTRUCTIONS

1. Please read all instructions prior to operating this appliance.

Please keep this manual for future reference. Failure to comply with

the safety instructions and/or operating instructions contained in this

manual will void any warranty. The manufacturer/seller accepts no

liability for damages caused by failure to comply with the owner’s

manual or negligent use of this product.

2. Check for damaged parts prior to use. check that all parts are

operating properly and perform their intended functions.

3. Always check the condition of the power cord prior to use. If there is

any evidence of damage or fraying of the power cord discontinue use

and contact STX International for OEM replacement. (see Contact

Information on the back of this manual) STX International will only

use original OEM parts when/if replacement is necessary.

4. Always disconnect the unit from the power source before servicing

or cleaning the unit. Unplug the unit when not in use. Do not plug the

unit into an already damaged outlet.

5. This product is designed for indoor household use only. It is NOT

a commercial use product. Do NOT use for commercial industrial

purposes.

6. Do NOT operate outdoors or near any flammable or combustible

materials. Do NOT use during eletrical storms.

7. Keep out of the reach of children. Never leave this device

unattended.

8. It is important to monitor this product while in use. Do not leave this

unit unattended when plugged into an outlet or powered ON.

9. To prevent electric shock and damage to the unit, do NOT immerse

the main unit in water.

10. Do not operate this unit on or near near an open flame or any hot

surface.

11. Do not unplug the unit by pulling on the electrical cord itself. Never

unplug the unit with wet hands.

12. Always use 110/120 Volt power sources. DO NOT USE POWER

CONVERTERS (210/220V). DO NOT USE PLUG CONVERTERS.

13. Do not plug another high wattage appliance into the same outlet as

this product.

14. Do NOT operate under the influence of alcohol or drugs.

15. Any alteration of this unit’s components, substitution of other

manufacturer’s components to this unit, or any repairs to this grinder

not completed or authorized by STX International will immediately

void all guarantees/warranties.

16. Electrical repair or any other type of service must be done by

the seller (The Mercantile Station 2 / STX International). Proof of

purchase must be provided by consumer prior to any repair/service

acceptance. The seller will use only OEM parts and accessories.

All STX International Products come with a 3-Year Guarantee, valid only

in the 48 Contiguous United States. If you purchase this product and ship

it to a destination outside of the 48 Contiguous United States this warranty

becomes null and void.

The first 30 Days are covered by a Money Back or Replacement

Guarantee from the date of the receipt of the product. If your product

becomes damaged in shipment or is found to be defective in any way

during this period, we will replace or issue a complete refund for your

product upon return. We will pay all shipping involved during this first 30-

day period.

The remainder of the 3 Years (after the first 30 days) is covered by a

FREE REPAIR Guarantee (parts and labor included). If anything becomes

defective during this period we will fix the issue and provide a full service

inspection to your product, shipping (to & from) will be paid by the buyer.

Returns of New/Unused Products

If you have Buyer's Remorse and decide that you do not want the product,

it must be returned NEW & UNUSED in the original box and you will pay

the return shipping. PLEASE NOTE: There will be a 10% Restocking Fee

and original Shipping Costs (if applicable) will not be refunded. Used

product cannot be returned.

3-YEAR

WARRANTY

STX International

2159 Magnum Circle, Lincoln, NE 68522

How To Register Your Warranty

Go to www.STXInternational.com. Click on "Register Your Warranty" tab

and fill out the form. This is a fully secure website. Your information will

never be sold or misused in any way. This registration site is strictly for

order verification that will be used to speed up the process should you

ever need to use your Warranty for service.

QUESTIONS, PROBLEMS

OR COMPLIMENTS?

Thank You for purchasing this

STX International Product!

We are grateful for your business!

All of our STX International Products are inspected then

sealed with our NEW Product Seal prior to shipment.

Our goal is to ensure Quality, Completeness, and

Satisfaction for your order.

For Any Questions, Problems, or

Compliments please call or email us.

If you would like to shop for other STX International Products

Please visit our website

www.STXInternational.com

Toll Free: 844-861-4762

Our Business Hours are:

Monday - Thursday: 8am - 4pm CST

Friday: 8am - Noon CST

STX International

2159 Magnum Circle, Lincoln, NE 68522

Table of contents

Popular Pasta Maker manuals by other brands

Hamilton Beach Professional

Hamilton Beach Professional 63246 manual

DeLonghi

DeLonghi PM1000 Series instruction manual

Cuisinart

Cuisinart PRS-50 Quick reference guide

Hamilton Beach

Hamilton Beach 86651 manual

Fimar

Fimar MPF/1,5 Operation and maintenance manual

KitchenAid

KitchenAid 5KPEXTA Operating instructions and recipes