Sub-Zero 600 Series BI-30U User manual

Other Sub-Zero Refrigerator manuals

Sub-Zero

Sub-Zero IC-30FI User manual

Sub-Zero

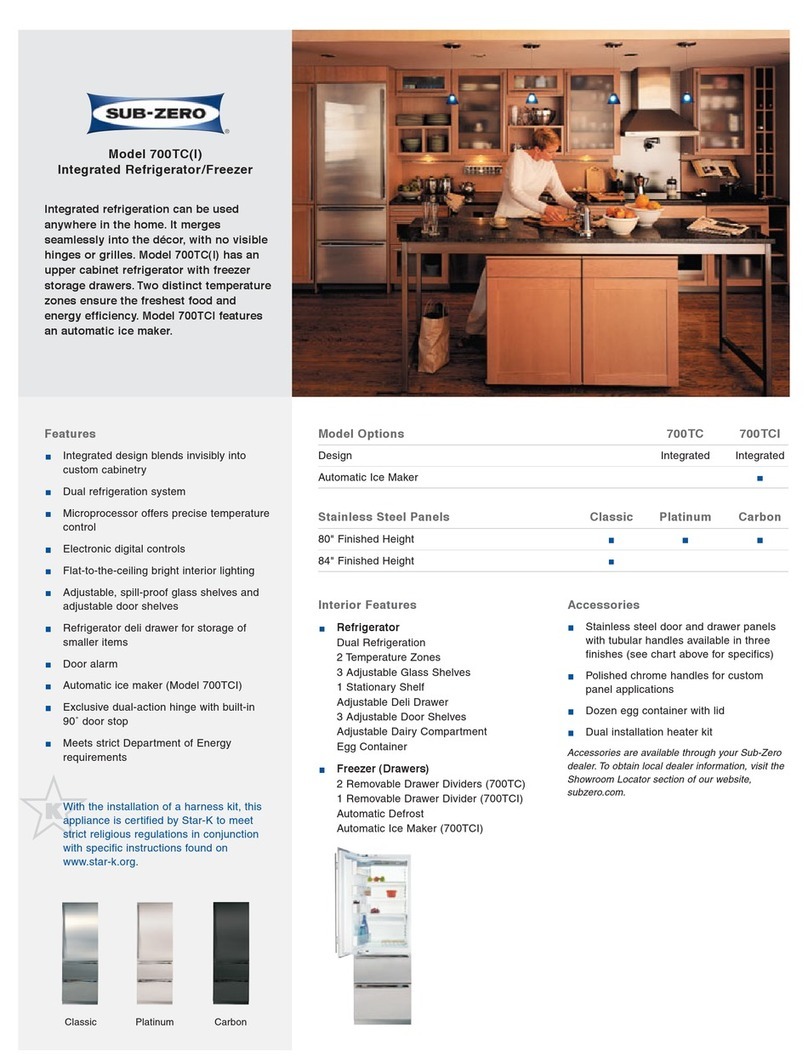

Sub-Zero 700TC User manual

Sub-Zero

Sub-Zero CBBI-36R Guide

Sub-Zero

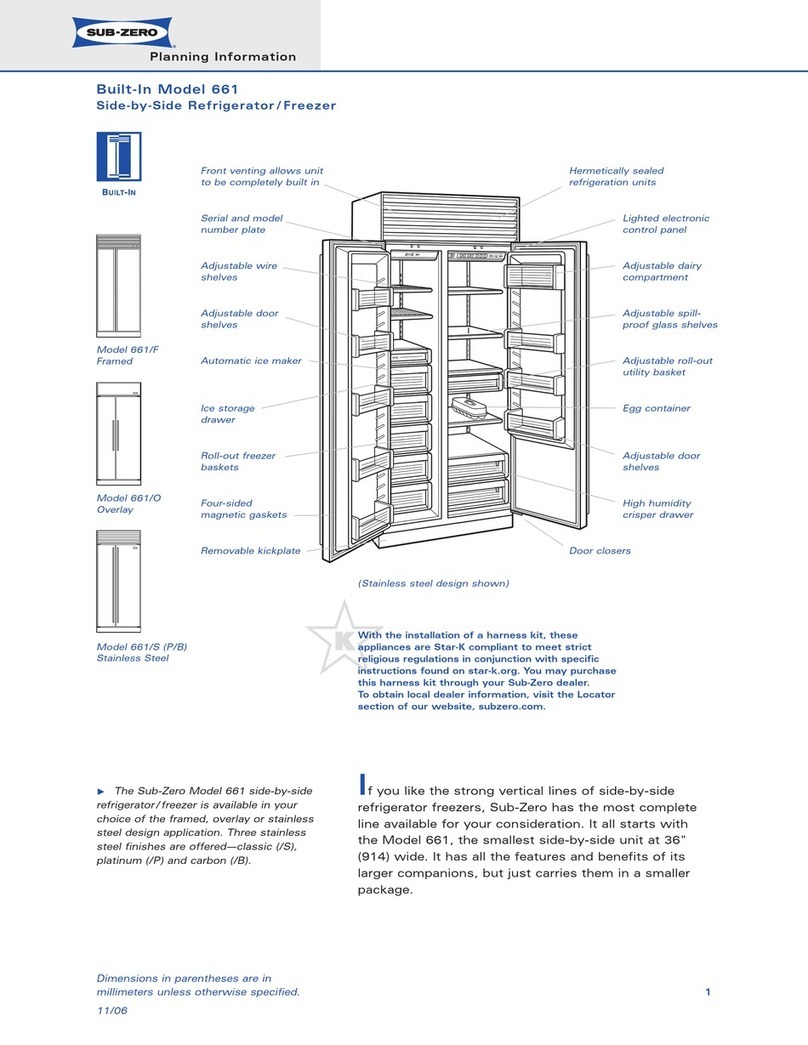

Sub-Zero 661 Instructions for use

Sub-Zero

Sub-Zero 601F User manual

Sub-Zero

Sub-Zero IC-24FI User manual

Sub-Zero

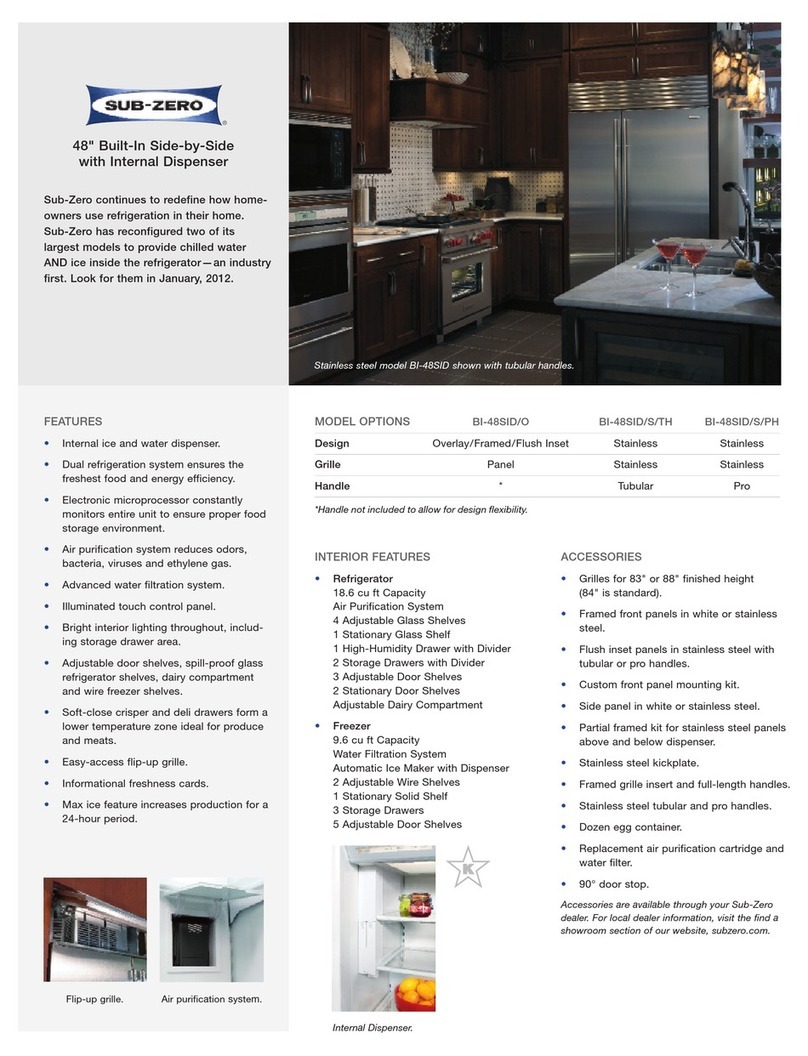

Sub-Zero PRO 48 User manual

Sub-Zero

Sub-Zero 648PRO User manual

Sub-Zero

Sub-Zero 736TCI User manual

Sub-Zero

Sub-Zero 642 Instructions for use

Sub-Zero

Sub-Zero ICBPRO3650RH User manual

Sub-Zero

Sub-Zero IC-27R User manual

Sub-Zero

Sub-Zero 700BCI Assembly instructions

Sub-Zero

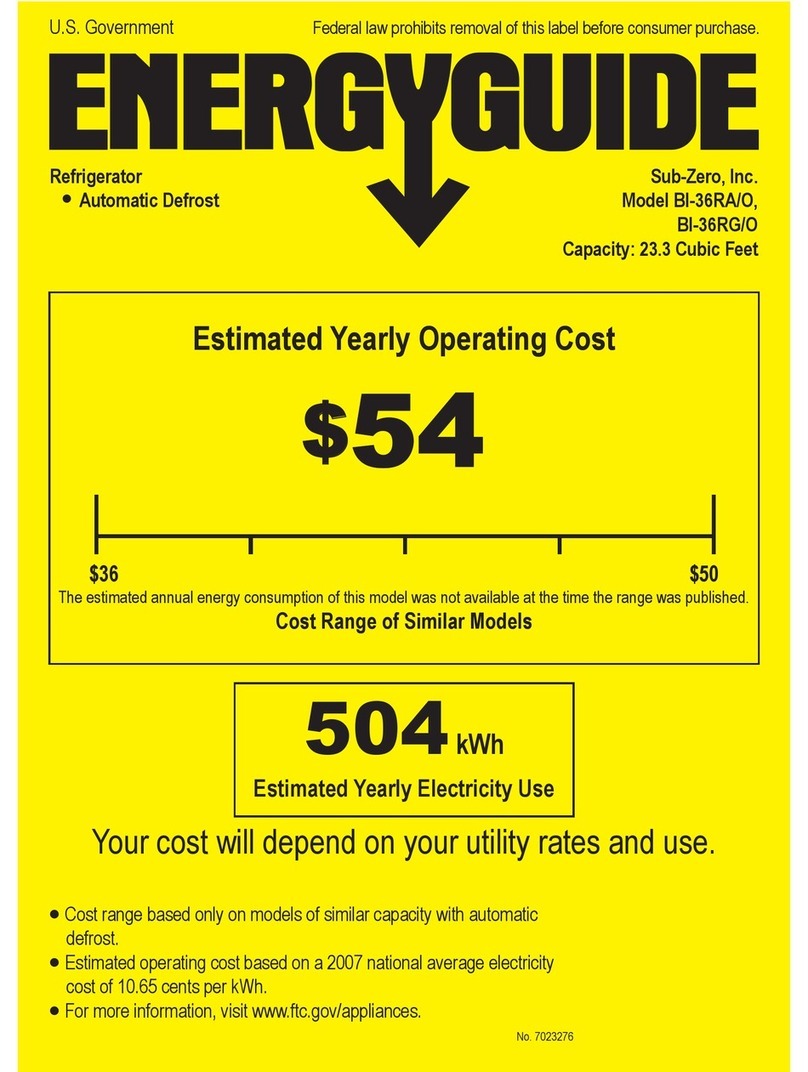

Sub-Zero BI-36R Guide

Sub-Zero

Sub-Zero ICBDEC2450FI/R User manual

Sub-Zero

Sub-Zero UC-24R User manual

Sub-Zero

Sub-Zero DEC3650RL User manual

Sub-Zero

Sub-Zero Wolf 500 Series User manual

Sub-Zero

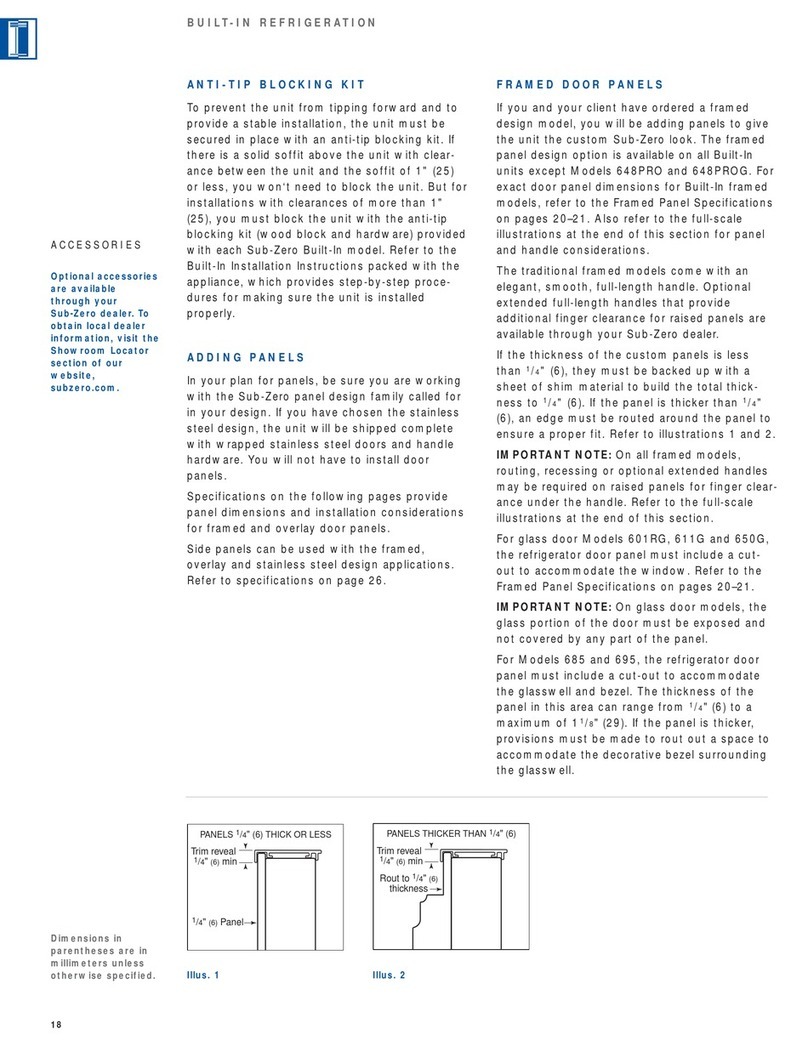

Sub-Zero Built-In Refrigeration User manual

Sub-Zero

Sub-Zero 611 User manual