INSTALLATIONREQUIREMENTS

WARNlNGl lnstallatlon ofthlsappllance mustbemadeInaccordance wlth

thewrltten InstructlonsprovldedInthls manual. Noagent, representatlve

or employee of Suburban or other person has the authority to change,

modlfy or walve any provlslon of the Instructlons contalned In thls

manual.

CAUTION: Ifposslble, donotInstallthe water heater to where the vent can

be covered orobstructed when any door on the traller lo opened. If thls lo

not posslble, then the travel of the door must be restrlcted In order to

providea6" mlnlmumclearance betweenthewaterheaterventandanydoor

whenever the door lo opened.

CAUTION: Dueto the dlfferences In vlnyl sldlng, this appllance should not

beInstalledon

vlnylsldlng without flrst consulting withthe manufacturer of

the sldlng or cuttlng the siding away from the area around the appllance

vent.

CAUTION: In any lnstallatlon In whlch the vent of thls appliance can be

covered duetothe constructlon ofthe RV orsome special feature ofthe RV

such as sllde out, pop-up etc., always Insure that the appllance cannot be

operated by settlng the thermostat to the posltlve "OFF" posltlon and

shuttlng off all

electrical

and gas supply to the appllance.

CAUTION: Donotlnstallthls appllance to where the vent terminates below

a slide-out. Thls appllance Isnotto beInstalled underanyoverhang. Itmust

befree and clear of any type overhang.

This installation must conform with the requirements of the authority having

jurisdiction or in the absence of such requirements with the latest edition of the

National Fuel Gas Code ANSl 2223.1; and the latest edition of the American

National Standard for Recreational Vehicles-50lC. In Canada the installation

should conform with the following standards.

A. For installation in Recreational Vehicle

1. Gas

-

CSA standard CSA 2240.4.2 Installation Requirements for Propane

Appliances and Equipment in Recreations Vehicles.

2. Electrical

-

CSA standard C22.2 No. 14812240.6.2 Electrical Requirements

for Recreational Vehicles.

3.

Plumbing

-

CSA standard CSA 2240.3.2 Plumbing Requirements for

Recreational Vehicles.

B. For installation in Moblle Housing

1. Gas

-

CSA standard CSA 2240.4.1 Installation Requirements for Gas

Burning Appliances and Equipment in Mobile Homes.

2. Electrical

-

CSA standard CSA C22.1 Canadian Electrical Code Part 1.

3.

Plumbing

-

CSA standard CSA 2240.3.1 Plumbing Requirements for Mobile

Homes.

Theapplianceshallbedisconnectedfrom the gassupply pipingsystem duringany

pressure testing of the system.

The appliance and its gas connections shall be leak tested before placing the

appliance in operation.

All air for combustion must be supplied from outside the structure. Air for

combustion must not be supplied from occupied spaces.

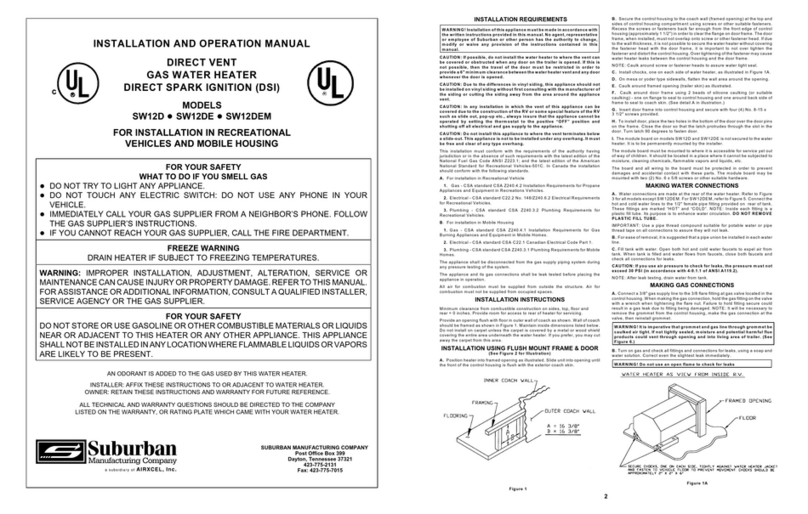

INSTALLATION INSTRUCTIONS

Minimum clearance from combustible construction on sides, top, floor and

rear

=

0 inches. Provide room for access to rear of heater for servicing.

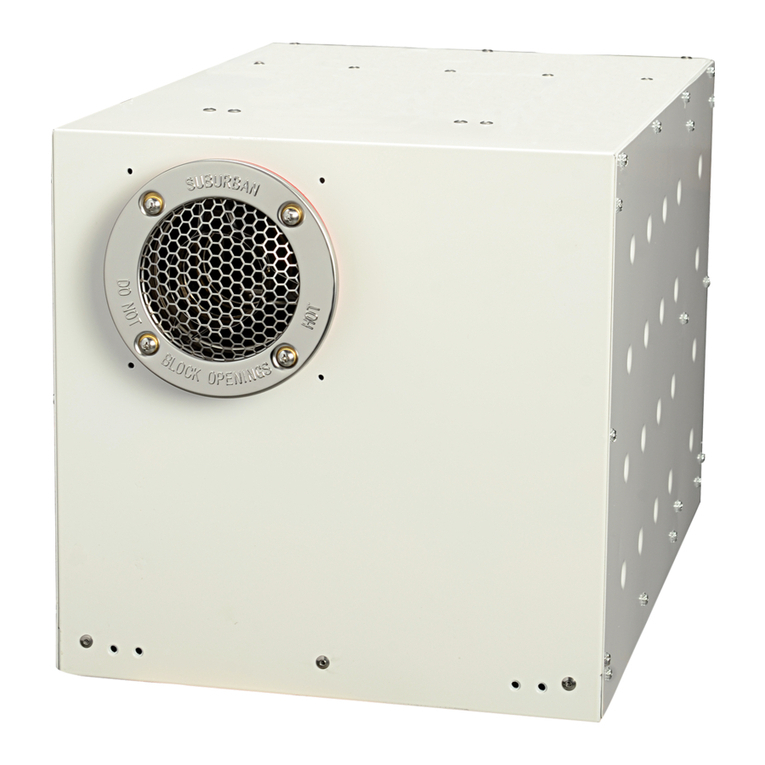

Provide an opening flush with floor in outerwall ofcoach as shown. Wall of coach

should beframed as shown in Figure 1. Maintain inside dimensions listed below.

Do not install on carpet unless the carpet is covered by a metal or wood shield

covering the entire area underneath the water heater. If you prefer, you may cut

away the carpet from this area.

INSTALLATIONUSINGFLUSH MOUNT FRAME

&

DOOR

(See Flgure 2 for Illustration)

A. Position heater into framedopening as illustrated. Slide unit into opening until

the front of the control housing is flush with the exterior coach skin.

B. Secure the control housing to the coach wall (framed opening) at the top and

INNER COACH WALL7

WALL

sides of control housing compartment using screws or other suitable fasteners.

Recess the screws or fasteners back far enough from the front edge of control

housing

(approximately

1 112")in order to clear the flange on door frame. The door

frame, when installed, must not overlap onto screw or other fastener head. If due

to the wall thickness, it is notpossible to secure the water heaterwithout covering

the fastener head with the door frame, it is important to not over tighten the

fastener and distort the control housing. Over tighteningof thefastener may cause

water heater leaks between the control housing and the door frame.

NOTE: Caulk around screw or fastener heads to assure water tight seal

C. Installchocks, one on each side of water heater, as illustrated in Figure 1A.

D.

On mesa or yoder type sidewalls, flatten the wall area around the opening

E. Caulk around framed opening (trailer skin) as illustrated.

F. Caulk around door frame using 2 beads of silicone caulking (or suitable

caulking)

-

one on flange to seal to control housing and one around back side of

frame to seal to coach skin. (See detail A in illustration.)

G. Insert door frame into control housing and secure with four (4) No. 8-15 x

3 112" screws provided.

H.

To installdoor, place the two holesin the bottom ofthe door over thedoor plns

on Ihe frame. Close the door so that the latch protrudes through the slot in the

door. Turn latch 90 degrees to fasten door.

I.

The module board on models SW 12D, SW I6Dand SW 12DE, SW 16DE is not

secured to the water heater. It is to be permanently mounted by the ~nstaller.

The module board must be mounted to where it is accessible for service yet out

ofway of children. It should be located in a place where it cannot be subjected to

moisture, cleaning chemicals, flammable vapors and liquids, etc.

The board and all wiring to the board must be protected in order to prevent

damages and accidental contact with these parts. The module board may be

mounted with two (2) No. 6 x 518 screws or other suitable hardware.

MAKINGWATER CONNECTIONS

A. Water connections are made at the rear of the water heater. Refer to Figure

3forallmodelsexceptSWI2DEM.SW

16DEM.ForSW12DEM.SW16DEM.refer

to Figure 5. Connect the hot and cold water lines to the 112' female pipe fitting

provided on rear of tank. These fittings are marked 'HOT'and 'COLD'. NOTE:

Inside each fitting is a plastic fill tube. Its purpose is to enhance water circulation.

DO NOT REMOVE PLASTIC FILL TUBE.

IMPORTANT: Use a pipe thread compound suitable for potable water or pipe

thread tape on all connections to assure they will not leak.

B. Forease ofremoval, it is suggested that a pipe union beinstalledin eachwater

line.

C. Fill tank with water. Open both hot and cold water faucets to expel air from

tank. When tank is filled and water flows from faucets, close both faucets and

check all connections for leaks.

CAUTION: Ifyou usealr pressure to check for leaks, the pressure mustnot

exceed

30

PSI (In accordancewlth 4-9.1.1 of ANSl A119.2).

NOTE: After leak testing, drain water from tank

MAKING GAS CONNECTIONS

A. Connect a 318" gas supply line to the 318 flare fitting at gas valve located in the

control housing. When making the gas connection, hold the gas fitting on the

valve w~tha wrench when tightening the flare nut. Failure to hold fitting secure

could result in a gas leak due to fitting being damaged. NOTE: Itwill be necessary

to removethe grommet from the control housing, make the gas

connection

atthe

valve, then reinstall grommet.

WARNlNGl ItIslmperatlve thatgrommet and gas llnethrough grommet be

caulked alr tlght. If not

tlghtly sealed, molsture and potentlal harmfulflue

products could vent through opening and Into llvlng area of trailer. (See

I

Flgure 6.)

I

B. Turn on gas and check allfittings and connections for leaks, using a soap and

water solution. Correct even the slightest leak

immediately.

WARNlNGl Donotuse an open flame to check for leaks

WATER HEATER AS VIEW FROM INSIDE R.V.

FRAMED OPENING

FLOOR

USECURE

CHOCKS.

ONE

ON

EACH

SIDE,

TIGHTLY AGAINST

WATER

HEATER

XKET

*ND FASTEN TO VEHICLE FLOOR TO PREVENT MOVEMENT. CHOCKS SHOULD BE

APPROXIMATELY

2.

X

2'

X

6'

Figure 1A

Flgure 1