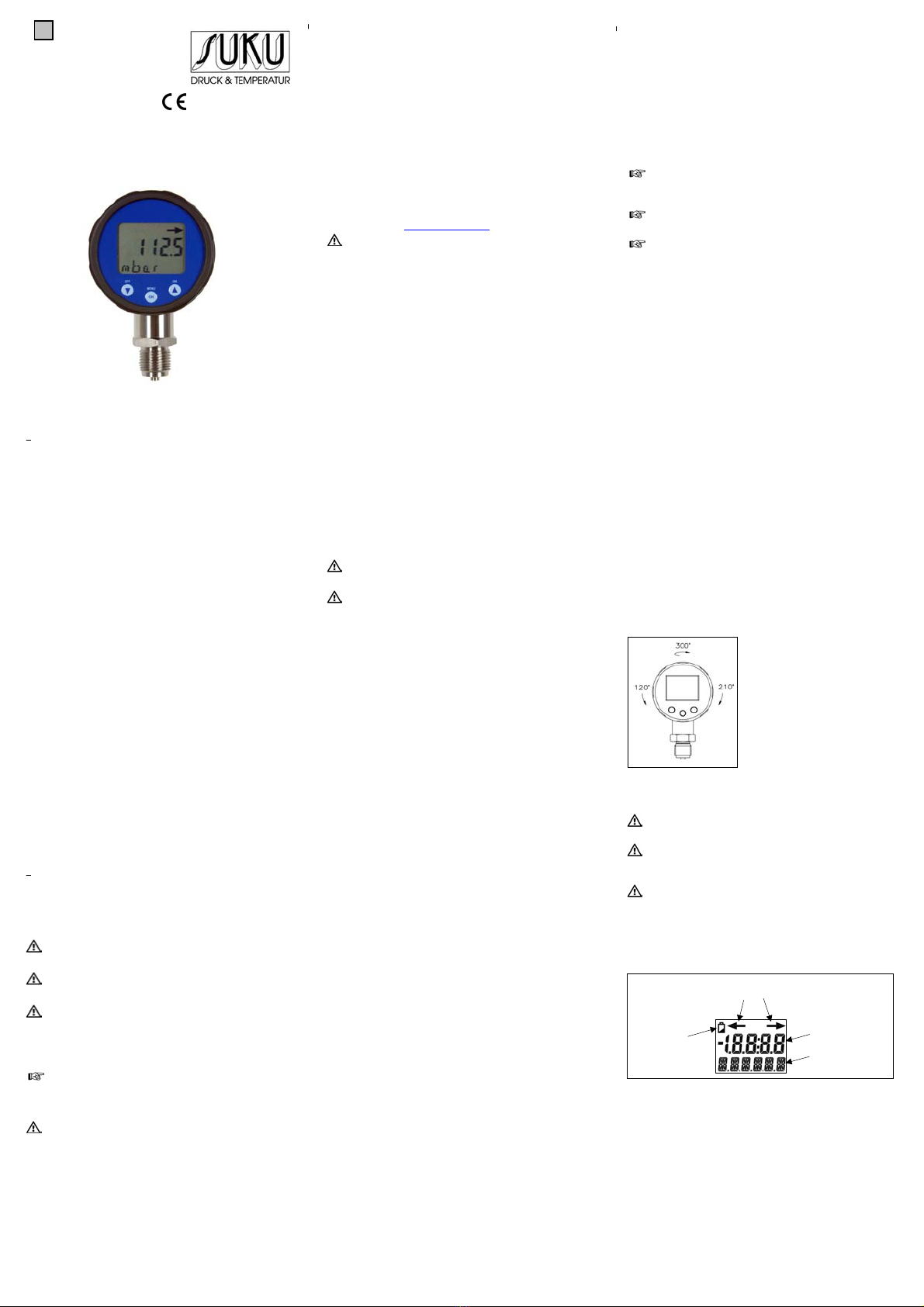

5.2 Structure of the menu system

5.3 Menu list

6. Supply / changing the batteries

The digital pressure gauge is supplied by two 3.6 V-lithium-

batteries (Type 1/2 AA). Stored values/parameters are also

kept after changing the batteries.

If the symbol for low batteries is indicated in the display, it is

necessary to replace them as soon as possible with two

new ones of the same type in order to ensure a good

readability of the values. This has only to be done in

switched-off condition.

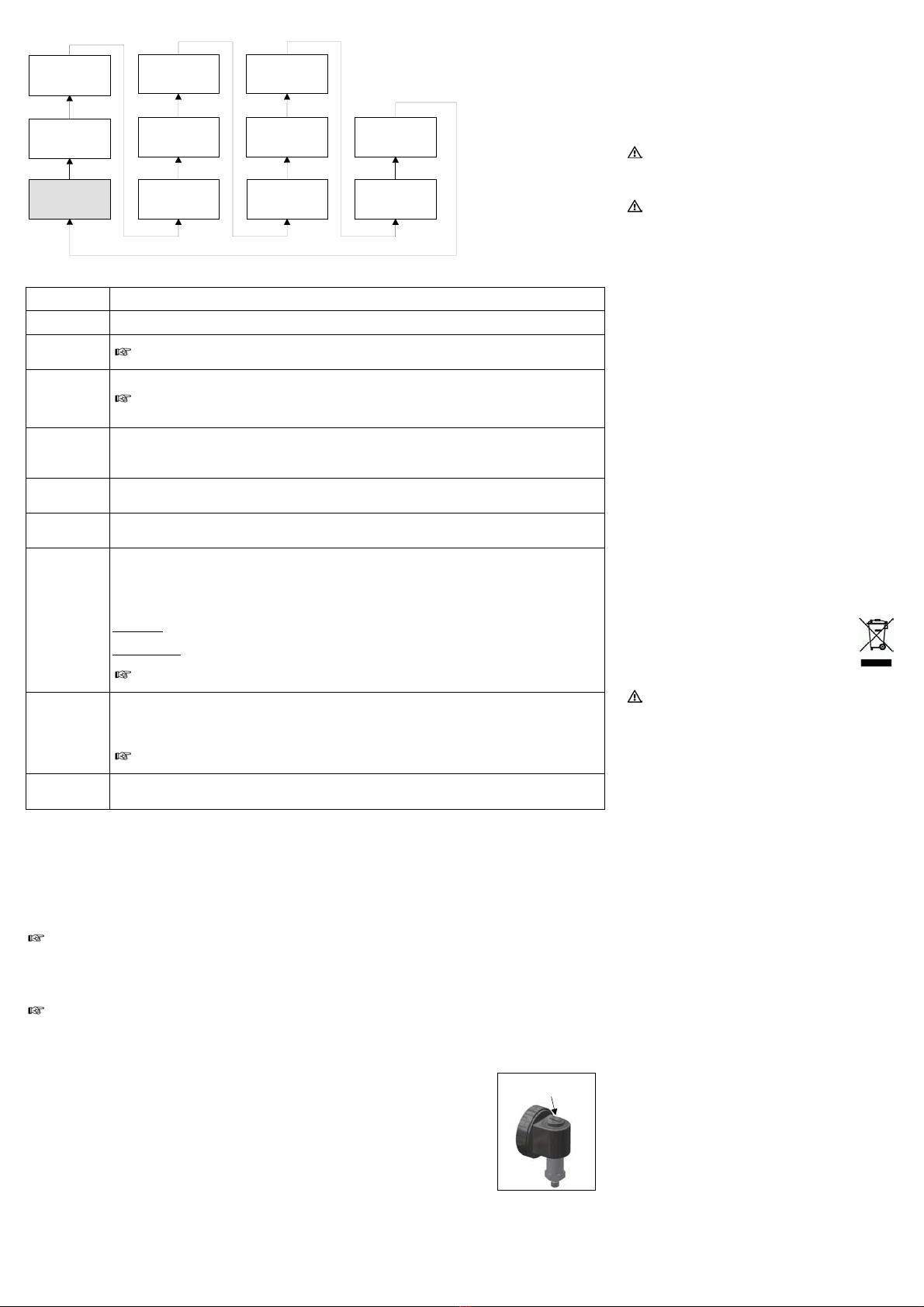

The battery case is located under the black, circular plastic

cap on the top of the housing. To change the batteries go

ahead as follows:

- turn the plastic cap 45° anti

clockwise by a coin (e.g. 2 €

coin) as far as possible

- hold the count tight and lever

the plastic cap out of the

housing with help of the

count

- take the cap off and change

the batteries

- lock the device after that

properly.

!An incorrect usage may cause a leak out of batteries

and so a damage the device!

!Never combine batteries of different types or old with

new ones.

!Make sure that the batteries are connected correctly

with the corresponding contacts in the battery tray.

!Never try to charge batteries, demount them, or short-

circuit them.

!Keep the batteries away from heat and unshielded

flame.

7. Placing out of service

WARNING! When dismantling the device, it must

always be done in the depressurized and currentless

condition! Check also if the medium has to be drained

off before dismantling!

WARNING! Depending on the medium, it may cause

danger for the user. Comply therefore with adequate

precautions for purification.

8. Maintenance

In principle, this device is maintenance-free. If desired, the

housing of the device can be cleaned when switched of

using a damp cloth and non-aggressive cleaning solutions.

Depending on the measuring medium, however, the

diaphragm may be polluted or coated with deposit. If the

medium is known for such tendencies, the user has to set

appropriate cleaning intervals. After placing the device out

of service correctly, the diaphragm can usually be cleaned

carefully with a non-aggressive cleaning solution and a soft

brush or sponge. If the diaphragm is calcified, it is

recommended to send the device to SUKUfor

decalcification. Please read therefore the chapter “Repair”

below.

!An incorrect cleaning can cause irreparable damages

on diaphragm. Never use spiky objects or pressured air

for cleaning the diaphragm.

9. Service / Repair

Before every return of your device, whether for recalibration,

decalcification, modifications or repair, it is necessary to

contact us to ensure a fast handling of your request. Please

Include the number of devices sent and request a RMA.

Then clean the device and pack it shatterproof before send

it to SUKUindicating the RMA.

10. Disposal

The device must be disposed according to the

European Directives 2002/96/EG and

2003/108/EG (on waste electrical and electronic

equipment) Waste of electrical and electronic

equipment may not be disposed by domestic

refuse!

WARNING! Depending on the measuring medium,

deposit on the device may cause danger for the user

and the environment. Comply with adequate

precautions for purification and dispose of it properly.

11. Warranty conditions

The warranty conditions are subject to the legal warranty

period of 24 months from the date of delivery. In case of

improper use, modifications of or damages to the device, we

do not accept warranty claims. Damaged diaphragms will

also not be accepted. Furthermore, defects due to normal

wear are not subject to warranty services.

12. Declaration of conformity / CE

The delivered device fulfils all legal requirements. The

applied directives, harmonised standards and documents

are listed in the EC declaration of conformity, which is

available online at: http://www.bdsensors.com/products/

download/certificates.

Additionally, the operational safety is confirmed by the CE

sign on the manufacturing label.

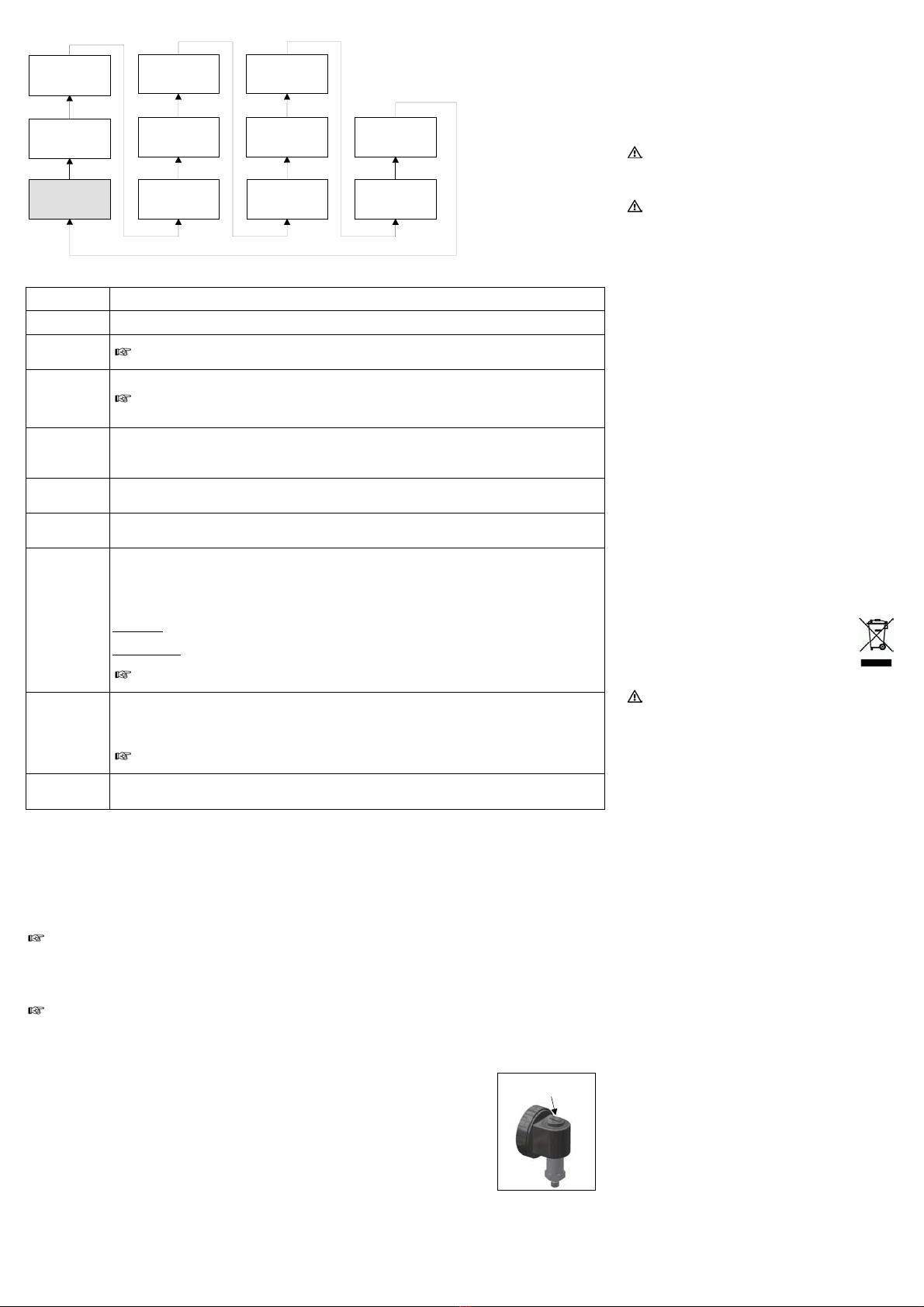

1 LOWER Displaying of the lower range

This value was determined on the order and cannot be changed.

2 UPPER Displaying of the upper range

This value was determined on the order and cannot be changed.

3 DECIMA Setting of the decimal point position

Depending on the nominal pressure range and on the set unit, only a limited number of positions after

the decimal point can be displayed.

4 UNIT Setting of the pressure unit

Permissible units: bar, mbar, psi, InHg, cmHg, mmHg, hPa, kPa, MPa, mH2O.

Along with the unit, the decimal point position has probably to be changed in order to get a correct

indication of the measured value. Besides, depending on the nominal pressure range, perhaps not all

available units can be used.

5 SW OFF Configuration of the switch-off automatic

Meaning of the permissible number:

"0": switch-off automatic is turned off

"1" – "5": automatic switch-off in 1 to 5 minutes

6 P MIN Minimum pressure display

▼–button: puts the current pressure as minimum value

▲–button: puts the value on zero

7 P MAX Maximum pressure display

▼–button: puts the current pressure as maximum value

▲–button: puts the value on zero

8 CAL ZP Calibration of initial point

If you detect a shifting of the measured value deviating from the offset, the display can be re-calibrated. For

this, a pressure reference is necessary if the offset differs from the ambient pressure. The used pressure

must be identical to the starting point of the pressure measuring range. For reading the new pressure into the

device, push the ▲button.

Please note the following diviation:

-1 … x bar: the offset is calibrated at -0.9 bar; during calibration we checked whether the device will be within

tolerance at -1 bar (in theory); for re-calibration a pressure reference of -0.9 bar is necessary

0 … x bar abs.: the offset is calibrated at 0.1 bar abs.; during calibration we checked whether the device will

be within tolerance at 0 bar abs.; for re-calibration a pressure reference of 0.1 bar is necessary

If the re-calibration leads to a worsening of the original calibration, e. g. as a result of a defect pressure

reference, the defaults can be re-set by the menu item "LD FAC" according to your order

9 CAL EP Calibration of end point

If you detect a shifting of the measured value deviating from the end point, the display can be re-calibrated.

For this, a pressure reference is necessary if the offset differs from the ambient pressure. The used pressure

must be identical to the end point of the pressure measuring range. For reading the new pressure into the

device, push the ▲button.

If the re-calibration leads to a worsening of the original calibration, e. g. as a result of a defect pressure

reference, the defaults can be re-set by the menu item "LD FAC" according to your order.

10 LD FAC Load defaults

To load the defaults you have to push the ▲–button. After the action "LOADED" and "OK" appears in the

display for a short time. The configuration mode will be left automatically.

- ▲/ on button: with this button you turn the device on; in the operating mode you move forward in the menu system or

increase the displayed value

- ▼/ off button: with this button you turn the device off; in the operating mode you move backwards in the menu system or

decrease the displayed value

- OK-button: with this button you enter the operating mode; besides, it is used to activate the different menu items and to

confirm the set values

To configure the different menu items, set the desired values by pushing the "▼" or "▲" buttons. Confirm the setting with the „OK“

button and the menu item will start blinking to indicate that you can start the configuration.

To save the configured values or to leave a menu item, you also have to push the “OK” button.

Changes of the adjustable parameters become only effective after pushing the OK button and leaving the menu item. After

leaving the menu system, all parameters will be checked against each other and in reference to the characteristics of the de-

vice. If the message "OK" appears in the display for some seconds, the configuration was successfully. If the message "ER-

ROR" appears, at least one of the set values is out of the permissible range. For example, an error will occur if a device with

a nominal pressure range of 400 bar should be set on 4 positions after the decimal point. If an error has been detected, the

lastly runnable parameters will be set again.

After configuring the unit, the conversion of the pressure range (in menus UPPER und LOWER) into the new unit will only

occur after leaving the complete menu system. Besides, depending on the number of displayed figures of the respective

nominal pressure range, probably not all available units (in menu UNIT) can be used.

Display mode

(measured value is

displayed)

Menu 7: P MAX

Maximal pressure

display

Menu 6: P MIN

Minimal pressure

display

Menu 5: SW OFF

Switch-off

automatic

Menu 4: UNIT

Unit

Menu 3: DECIMA

Decimal point

position

Menu 2: UPPER

Indication of

upper range

Menu 1: LOWER

Indication of

lower range

Menu 8: CAL ZP

Calibration of

starting point

Menu 9: CAL EP

Calibration of

end point

Menu 10: LD FAC

Load defaults

plastic cap above

battery case

Fig. 4 battery case